Method for preparing no-yellowing polyurethane sponge capable of being foamed at normal temperature

A technology of polyurethane sponge at normal temperature, which is applied in the field of preparing non-yellowing polyurethane sponge, which can solve the problems of easy aging of aromatic polyurethane sponge, unstable product quality, poor light resistance, etc., achieve excellent environmental tolerance, and is not easy to yellow , Excellent anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

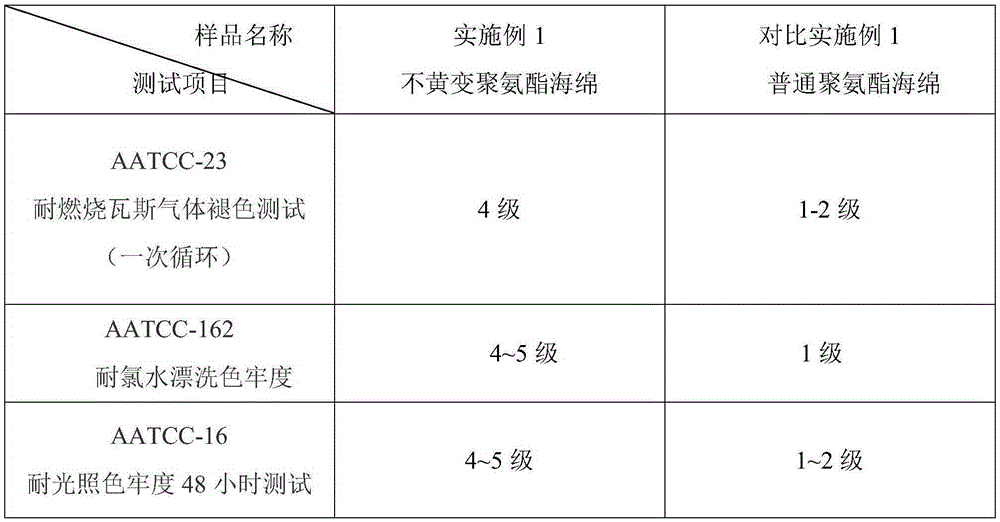

Examples

Embodiment 1

[0063] The non-yellowing polyurethane sponge that can be foamed at room temperature is prepared by one-step method, and consists of the following raw materials in parts by weight:

[0064] Polyether polyol GEP-560100 parts

[0065] 60 parts of 4,4′-dicyclohexylmethane diisocyanate (HMDI)

[0066] 4 parts water

[0067] Momentive L-580 (silicone oil) 1.5 parts

[0068] Triethylenediamine (basic catalyst) 0.8 part

[0069] Organic bismuth (metal catalyst) 0.3 parts

[0070] Dichloromethane MC (physical blowing agent) 6 parts

[0071] Triethanolamine (crosslinking agent) 1.3 parts.

[0072] According to the above formula, according to the size of the manual foam curing mold, first weigh 700g GEP-560 polyether polyol, 28g water, 10.5gL-580 silicone oil, 5.6g triethylenediamine, 2.1g organic bismuth, 42g dichloromethane and 9.1 Put 1 g of triethanolamine into the mixer for high-speed stirring, the rotating speed is 200r / min, the stirring time is 70s, and the mixture is evenly...

Embodiment 2

[0090] The non-yellowing polyurethane sponge that can be foamed at room temperature is prepared by prepolymer method, and consists of the following raw materials in parts by weight:

[0091] Polyether polyol ACCLAIM8220N100 parts

[0092] 70 parts of 4,4'-dicyclohexylmethane diisocyanate prepolymer

[0093] 3 parts water

[0094] Evonik B-8715 (silicone oil) 1 part

[0095] Triethylenediamine (basic catalyst) 0.6 part

[0096] Titanium acetylacetonate (metal catalyst) 0.7 parts

[0097] Liquid carbon dioxide (physical blowing agent) 7 parts

[0098] 1 part of 1,4-butanediol (crosslinking agent)

[0099] according to n (NCO) :n (OH) =1.3:1 molar ratio, pre-reacted to obtain 4,4'-dicyclohexylmethane diisocyanate prepolymer.

[0100] According to the formula of the above-mentioned non-yellowing sponge, according to the size of the manual foam curing mold, weigh 700g ACCLAIM8220N polyether polyol, 21g water, 7gB-8715 silicone oil, 4.2g triethylenediamine, 4.9g titanium ace...

Embodiment 3

[0103] The one-step method prepares the flame-retardant non-yellowing polyurethane sponge that can be foamed at room temperature, and consists of the following raw materials in parts by weight:

[0104] Polyether polyol NJ-330D100 parts

[0105] 70 parts of 4,4′-dicyclohexylmethane diisocyanate (HMDI)

[0106] 5 parts water

[0107] Air DC-6070 (silicone oil) 2 parts

[0108] Dimethylcyclohexylamine (basic catalyst) 1 part

[0109] Organic zinc (metal catalyst) 0.4 parts

[0110] Dichloroethane (physical blowing agent) 6 parts

[0111] Glycerol (crosslinking agent) 1.4 parts

[0112] If non-yellowing sponge products need to have certain flame retardancy, flame retardants can be added to the formula or flame-retardant polyether can be used to improve its flame-retardant effect.

[0113] According to the formula of the above non-yellowing sponge, according to the size of the manual foam curing mold, first weigh 700g NJ-330D flame-retardant polyether polyol, 35g water, 14gD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com