Anti-freeze nanometer titanium dioxide composite material and application thereof

A nano-titanium dioxide and composite material technology is applied in the field of anti-icing nano-titanium dioxide composite material and its preparation, and the field of titanium dioxide composite material and its preparation, and achieves the effects of simple preparation method, good anti-icing resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

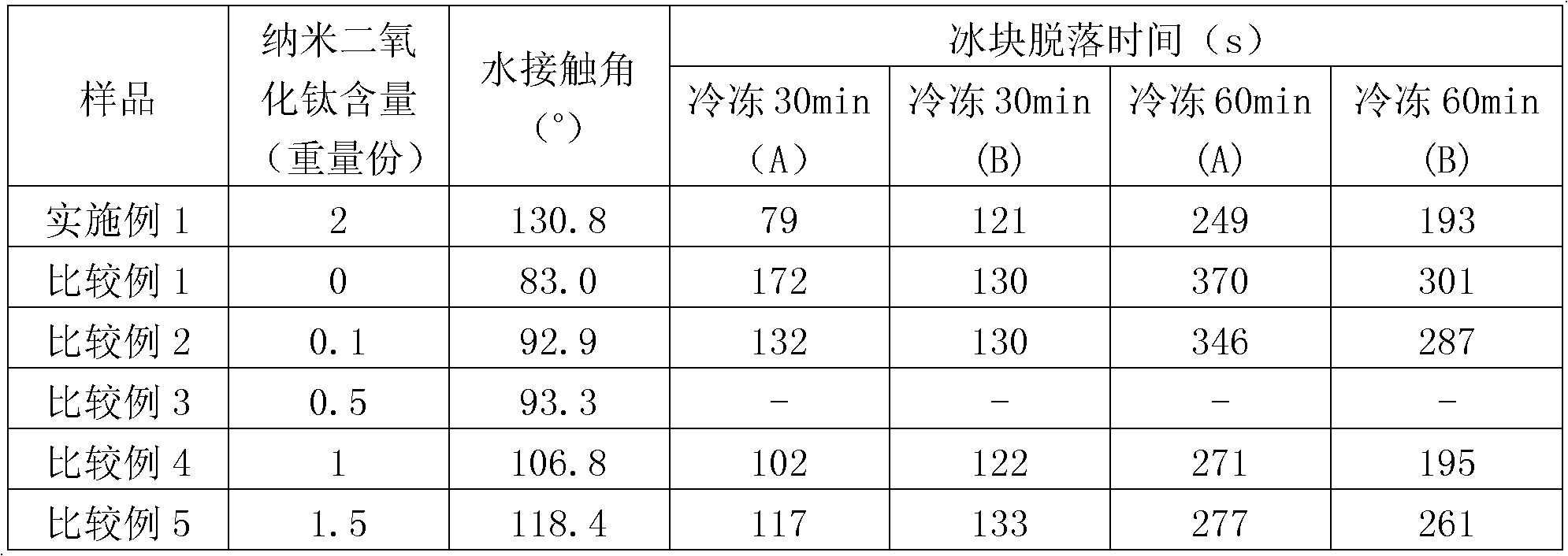

Image

Examples

Embodiment 1

[0020] (1) Preparation of copolymer

[0021] A 100mL three-necked bottle equipped with a thermometer and a constant pressure dropping funnel, in parts by weight (unit: gram), sequentially add 3 parts of styrene, 4 parts of glycidyl methacrylate, and 15 parts of methacrylic acid Butyl ester and 35mL toluene, under the protection of nitrogen flow, magnetic stirring, constant temperature heating to 85 ° C, 0.2 parts of azobisisobutyronitrile (AIBN) dissolved in 5mL toluene, slowly drop into the three-necked flask through the constant pressure dropping funnel , After the dropwise addition, continue heating and stirring at constant temperature for 2.5h. Add the reactants dropwise to petroleum ether (b.p. 60-90°C), and the formed white flocculent precipitate is the copolymer. The copolymer is vacuum-dried at room temperature to obtain a colorless transparent crystalline solid, which is the pure copolymer.

[0022] (2) Preparation of polymer binder

[0023] In parts by weight (unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com