Composite black plant fermentation composition with whitening effect as well as preparation method and application in facial mask product

A plant fermentation and composition technology, applied in the fields of biotechnology and cosmetics, can solve the problems of lack of efficacy and safety, not easy to obtain, and no industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

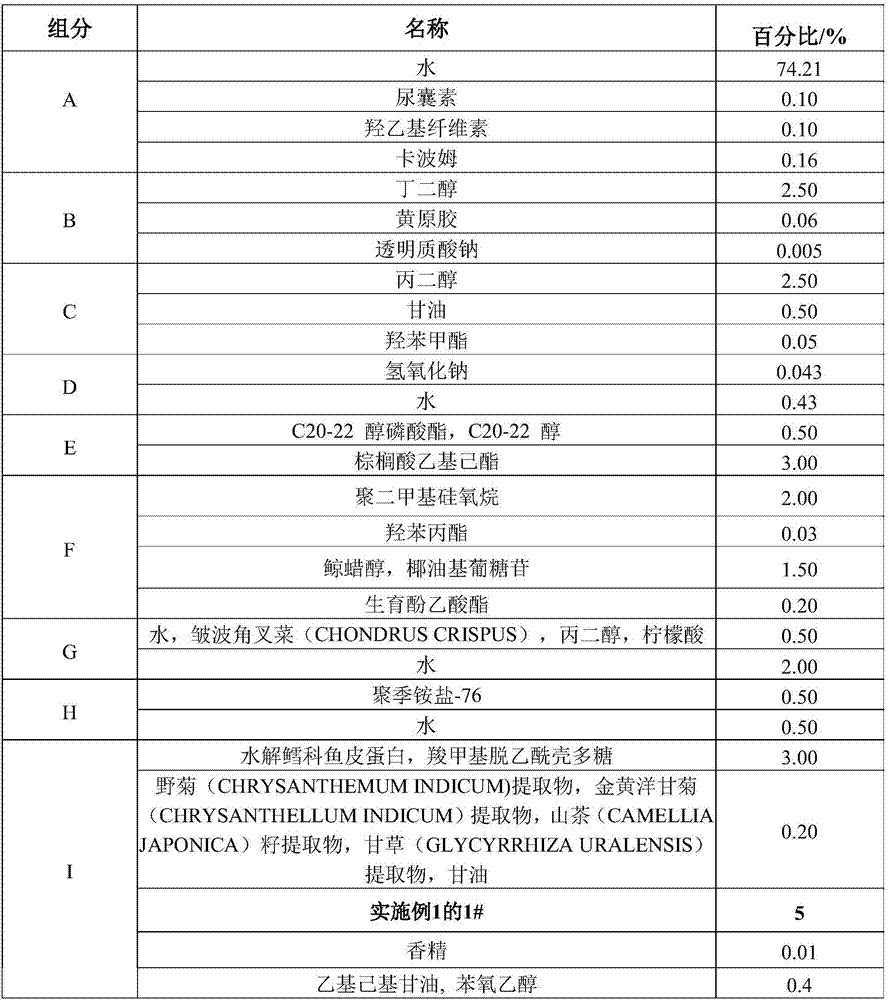

Examples

Embodiment 1

[0098] (1) The degreasing process of black currant and blackberry

[0099] 5 parts by mass of black currant and 5 parts by mass of blackberry (both with a moisture content of 0.7%) were crushed to 60 mesh, and degreased with 50 parts by mass of absolute ethanol at 20° C. for 24 hours, with a stirring speed of 50 rpm / min. After the degreasing is completed, the degreasing agent is separated, and the filter residue is freeze-dried at -1.5MPa for 10 hours to obtain about 8.5 parts by mass of degreasing dry powder, which is set aside;

[0100] (II) Enzymolysis

[0101] Add 8 parts by mass of degreasing dry powder and 80 parts by mass of water obtained in step (I) to an enzymolysis kettle, 80 Hz ultrasonic for 15 min, and adjust the pH to 7.0 with triethanolamine; add 0.0016 parts by mass of compound enzyme A (0.0008 parts by mass of pectinase Pectinex BE XXL and 0.0008 parts by mass of amylase Amylase AG XXL), reacted at 40°C for 4h; then added 0.0008 parts by mass of compound enz...

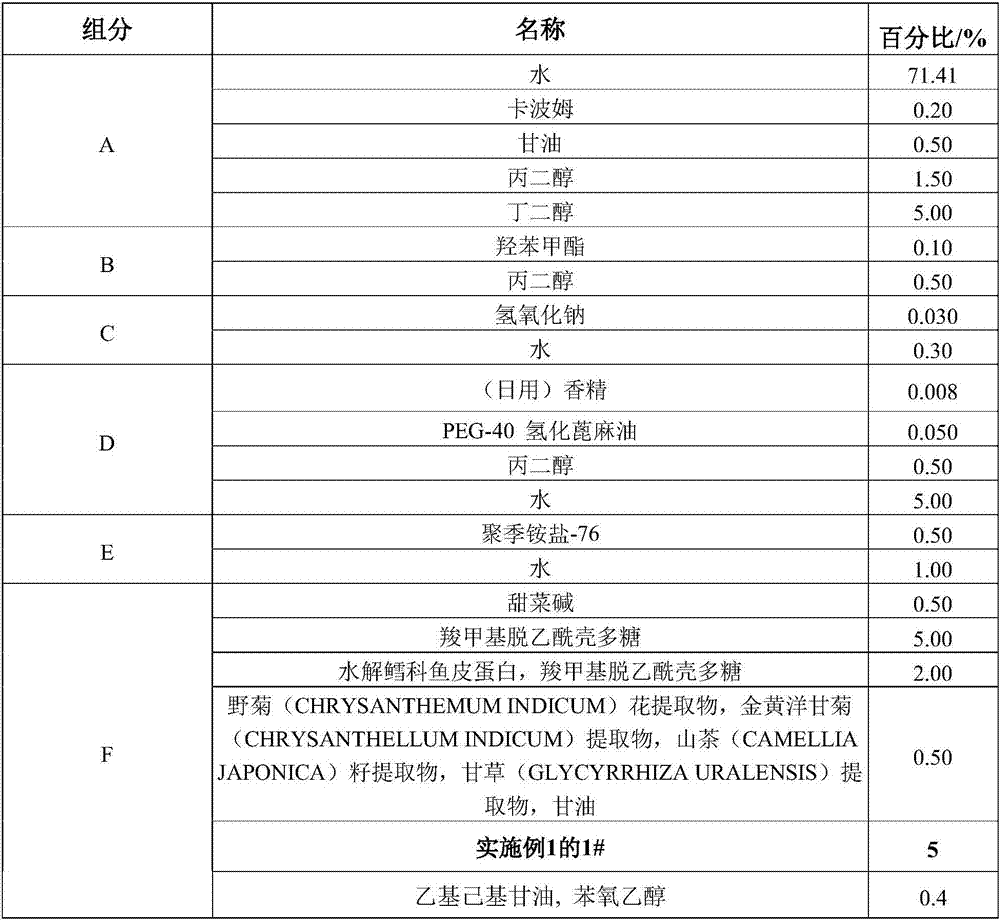

Embodiment 2

[0108] (1) The degreasing process of black currant and blackberry

[0109] 2.5 parts by mass of black currant and 7.5 parts by mass of blackberry (both with a moisture content of 0.6%) were crushed to 80 mesh, and degreased at 30° C. with 80 parts by mass of absolute ethanol for 48 hours, with a stirring speed of 150 rpm / min. After the degreasing is completed, the degreasing agent is separated, and the filter residue is freeze-dried at -0.5MPa for 15 hours to obtain about 9 parts by mass of degreasing dry powder, which is set aside;

[0110] (II) Enzymolysis

[0111] 9 parts by mass of degreasing dry powder and 135 parts by mass of water obtained in step (I) were added to the enzymolysis kettle, 120 Hz ultrasonic for 45 min, and the pH was adjusted to 7.5 with triethanolamine; 0.045 parts by mass of compound enzyme A (0.015 parts by mass of pectinase PectinexBE XXL and 0.03 parts by mass of amylase Amylase AG XXL), reacted at 55°C for 8h; then added 0.0225 parts by mass of co...

Embodiment 3

[0118] (1) The degreasing process of black currant and blackberry

[0119] 4 parts by mass of black currant and 6 parts by mass of blackberry (both with a moisture content of 0.5%) were crushed to 70 mesh, and degreased with 60 parts by mass of absolute ethanol at 25° C. for 30 h with a stirring speed of 100 rpm / min. After the degreasing is completed, the degreasing agent is separated, and the filter residue is freeze-dried at -1.0MPa for 12 hours to obtain about 8.8 parts by mass of degreasing dry powder, which is set aside;

[0120] (II) Enzymolysis

[0121] 8.8 parts by mass of degreasing dry powder and 105.6 parts by mass of water obtained in step (I) were added to the enzymolysis kettle, ultrasonicated at 100 Hz for 20 min, and the pH was adjusted to 7.2 with aminomethyl propanol; 0.0088 parts by mass of compound enzyme A (0.00352 parts by mass Pectinase Pectinex BE XXL and 0.00528 parts by mass of amylase Amylase AG XXL), reacted at 45°C for 6h; then added 0.0088 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation amount | aaaaa | aaaaa |

| Inoculation amount | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com