Production method and device of waterproof rolled material

A technology for waterproofing membranes and manufacturing equipment, which is applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., to achieve the effects of simple structure, good structural performance and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

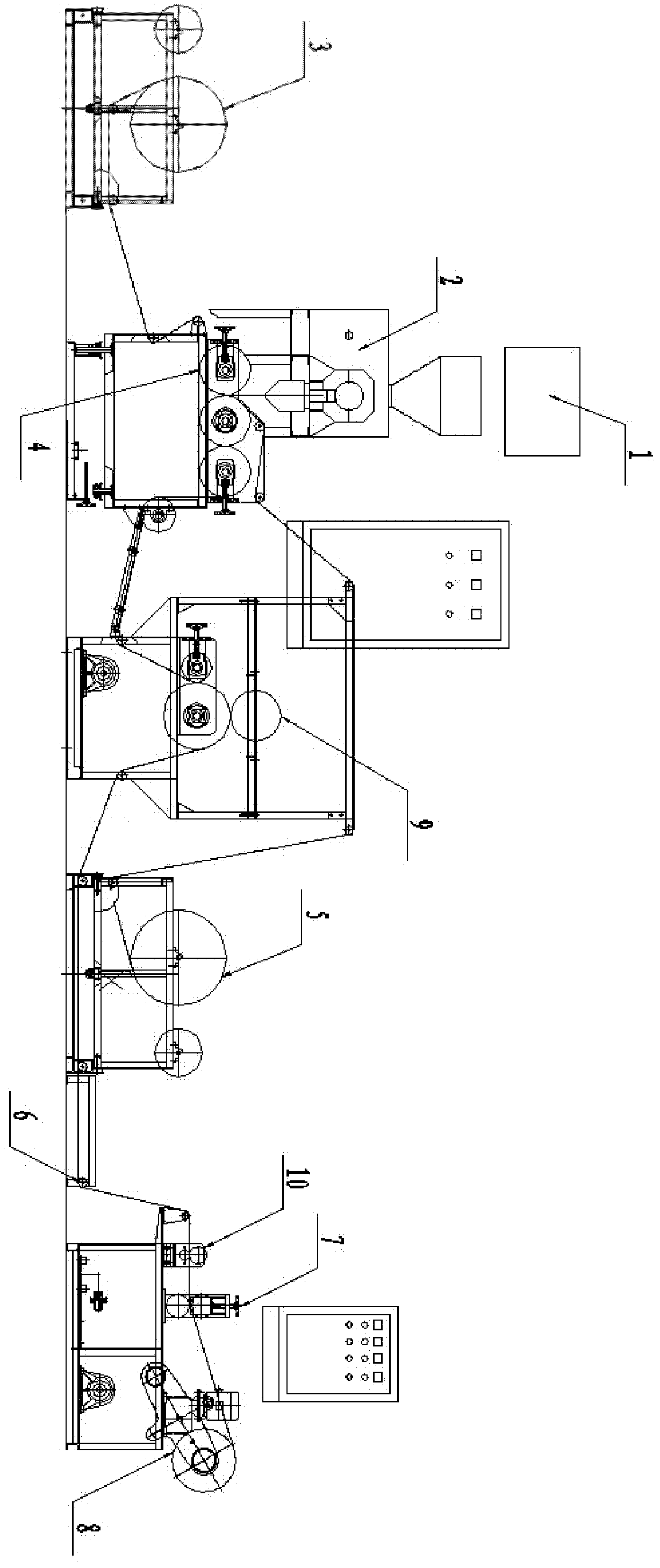

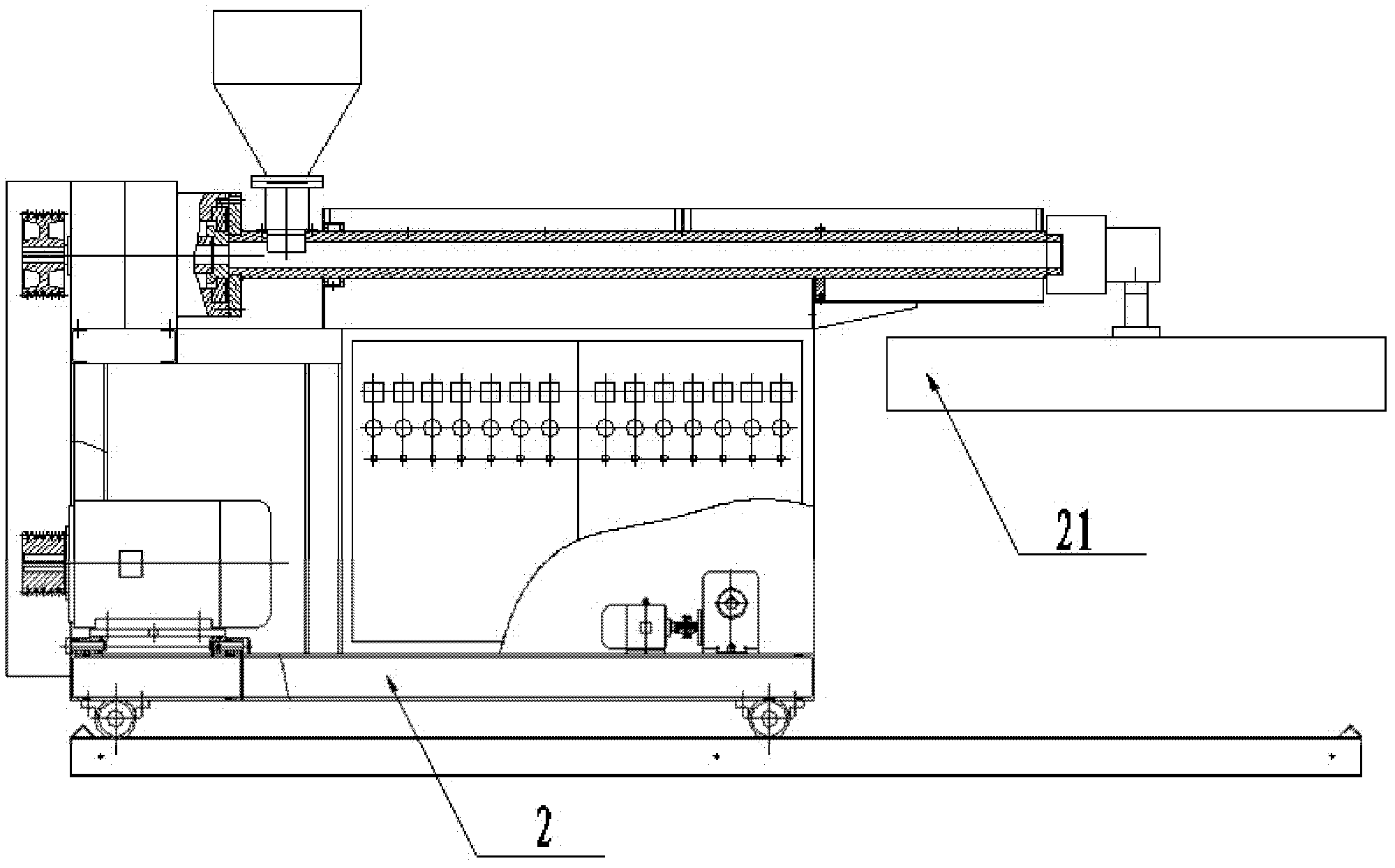

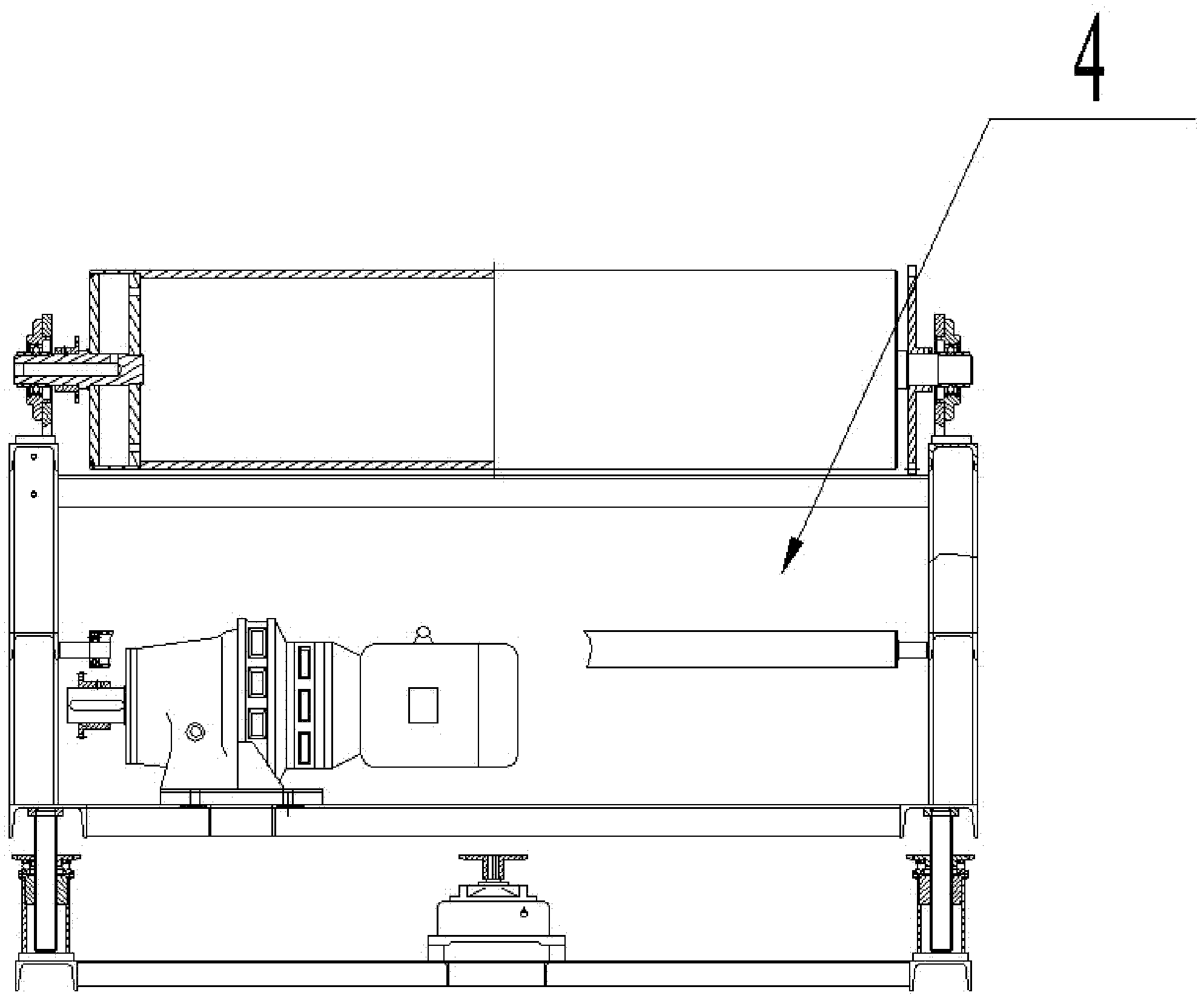

[0022] A kind of manufacturing method of waterproof coiled material adopts such as Figure 1~2 The equipment shown is manufactured. First, 15% calcium carbonate, 1% plastic defoamer, and the remaining amount of polyethylene are stirred and mixed for 4 minutes through the raw material compounding device 1; then the mixed polyethylene mixture is extruded The outlet device 2 is melted and plasticized, and the plasticizing temperature is 220°C. After melting and plasticizing, a film with a thickness of 1.0mm is extruded from the die head 21 of the extrusion device 2 and is in a molten state; then the above-mentioned film and the two-layer non-woven fabric The substrates are laminated, pressed and bonded and cooled by the metal cooling roller of the compound device 4 to form a composite material; finally, the above composite material is pulled by the guide roller 6 and the traction device 7, and then transported to the double-station center coil Take machine 8 and wind up into coil...

Embodiment 2

[0025] A kind of manufacturing method of waterproof coiled material adopts such as Figure 1~2 The equipment shown is manufactured. First, 20% calcium carbonate, 2% plastic defoamer, and the remaining amount of polyethylene are stirred and mixed for 5 minutes through the raw material compounding device 1; then the mixed polyethylene mixture is extruded The outlet device 2 is melted and plasticized, and the plasticizing temperature is 200°C. After melting and plasticizing, a film with a thickness of 1.3mm is extruded from the die head 21 of the extrusion device 2 and is in a molten state; then the above-mentioned film and the two-layer non-woven fabric The substrates are laminated, pressed and bonded and cooled by the metal cooling roller of the compound device 4 to form a composite material; finally, the above composite material is pulled by the guide roller 6 and the traction device 7, and then transported to the double-station center coil Take machine 8 and wind up into coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com