Ag-Cu-Ti/Sn nano-particle soldering paste and preparation method thereof

A technology of ag-cu-ti and nanoparticles, applied in welding equipment, welding medium, manufacturing tools, etc., to achieve the effect of simple process, less agglomeration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

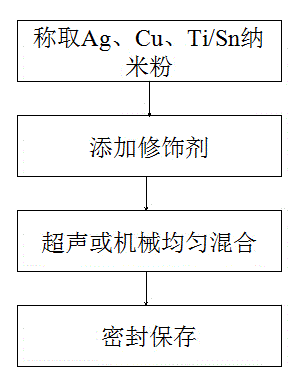

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: This embodiment provides a method for preparing 72Ag-28Cu eutectic nano-solder paste, which is specifically implemented according to the following steps:

[0020] Take Ag and Cu nano-powders of a certain quality, the mass percentages of the two are 72% and 28% respectively, and the Ag and Cu nano-powder particle sizes are selected to be 30±10nm and 50±10nm respectively, and the weighed Ag and Cu nano-powders are weighed Mix the two kinds of nano powders; add the dispersant polyacrylamide, the binder terpineol, the diluent alcohol and terpineol in sequence according to the mass ratio of 5:5:5:5 (alcohol and terpineol can be mixed according to 1: 1), flux rosin, so that the modifier system accounts for 20% of the overall mass percentage; the above system is uniformly mixed in acetone solvent by ultrasonic vibration method, and then the excess solvent is volatilized to make 72Ag- 28Cu nano-solder paste, the solid content of which is more than 80%; put the pre...

specific Embodiment approach 2

[0022] Specific embodiment two: This embodiment provides a method for preparing 68.4Ag-26.6Cu-5Ti nano-solder paste, which is specifically implemented according to the following steps:

[0023] Weigh a certain amount of Ag, Cu, and Ti nano-powders. The mass percentages of the three are 68.4%, 26.6%, and 5% respectively. ±10nm, mix the weighed Ag, Cu, Ti three kinds of nano-powders; according to the mass ratio of 3:4:5:6, add dispersant fish oil, binder terpineol, diluent alcohol and terpineol, Soldering flux rosin, so that the modifier system accounts for 18% of the overall mass percentage; the above system is uniformly mixed in acetone solvent by ultrasonic vibration, and then the excess solvent is volatilized to make 68.4Ag-26.6Cu-5Ti Nano-solder paste, wherein the solid content is above 82%; the prepared 68.4Ag-26.6Cu-5Ti nano-solder paste is put into a needle tube for sealed storage, and the storage temperature is 0-10°C.

[0024] The 68.4Ag-26.6Cu-5Ti nano-solder paste p...

specific Embodiment approach 3

[0025] Specific embodiment three: This embodiment provides a method for preparing 64Ag-34.5Cu-1.5Ti nano-solder paste, which is specifically implemented according to the following steps:

[0026] Weigh a certain mass of Ag, Cu, and Ti nano-powders. The mass percentages of the three are 64%, 34.5%, and 1.5% respectively. ±10nm, mix the weighed Ag, Cu, and Ti nano-powders; add dispersant fish oil, binder terpineol, diluent terpineol, and flux in sequence according to the mass ratio of 3:4:5:6 Rosin, so that the modifier system accounts for 18% of the overall mass percentage; the above-mentioned system is uniformly mixed in acetone solvent by means of ultrasonic vibration, and then the excess solvent is volatilized to make 64Ag-34.5Cu-1.5Ti nano-welding Paste, the solid content of which is above 82%; put the prepared 64Ag-34.5Cu-1.5Ti nano-solder paste into a needle tube for sealed storage, and the storage temperature is 0-10°C.

[0027] The 64Ag-34.5Cu-1.5Ti nano-solder paste pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com