Light foaming wall material based on granite and preparation method thereof

A light-weight wall and granite technology, applied in the field of building wall materials, can solve the problems of falling off of the outer wall decorative surface, high cost and complicated construction, etc., and achieve the effects of improving construction efficiency, saving cost and reducing construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

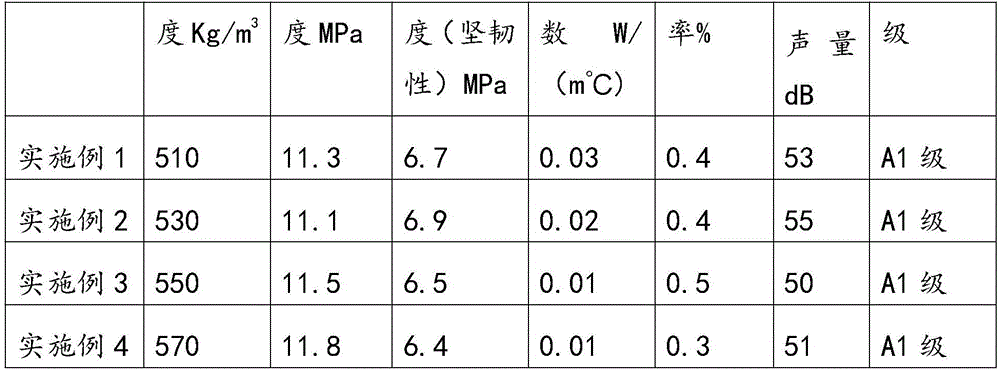

Examples

Embodiment 1

[0026] A lightweight wall material based on granite foam, comprising the following components:

[0027] Granite 80%, clay 5%, foaming agent 5%, stabilizer 5%, debonding agent 5%.

[0028] Described clay is yellow mud;

[0029] The flux is calcined talc;

[0030] The blowing agent is silicon carbide;

[0031] The stabilizers are yttrium oxide and cerium oxide.

[0032] The preparation method comprises the following steps:

[0033] S1. Mixing of raw materials: weighing according to the percentage by weight of each raw material in the formula, and mixing with a ball mill for 5 hours;

[0034] S2. spray drying granulation;

[0035] S3. Fabric: fabricate the material dried in the spray drying tower, put it into a shuttle kiln or a tunnel kiln, and take it out of the kiln after firing at 900-1300°C for 120 minutes to obtain a coarse granite foam wall material. product;

[0036] S4. The rough product is cut to obtain a lightweight wall material based on granite foam.

Embodiment 2

[0038] A lightweight wall material based on granite foam, comprising the following components:

[0039] Granite 75%, clay 10%, flux 5%, foaming agent 2%, stabilizer 5%, debonding agent 3%.

[0040] The clay is red mud.

[0041] The flux is raw talc.

[0042] The blowing agent is silicon carbide.

[0043] The stabilizers are yttrium oxide and cerium oxide.

[0044] The preparation method refers to Example 1.

Embodiment 3

[0046] A lightweight wall material based on granite foam, comprising the following components:

[0047] Granite 85%, clay 5%, flux 3%, foaming agent 3%, stabilizer 2%, debonding agent 2%.

[0048] The clay is manganese mud.

[0049] The flux is fluorite.

[0050] The foaming agent is expanded perlite.

[0051] The preparation method refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com