Preparation method and application of reduced graphene oxide

A graphene and allyl-based technology, applied in the field of preparation of reduced graphene oxide, can solve the problems of low preparation efficiency, use of toxic and corrosive solvents, etc., achieve high specific capacity, simple method, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 150mg graphene oxide to 20ml BMIMHSO 4 ionic liquid solution of graphene oxide was obtained by ultrasonic dispersion at 40°C for 4 h. The solution was poured into a polytetrafluoro reactor, and placed in an oven at 180° C. for 12 hours to obtain a reduced graphene oxide gel. After the gel was washed with water or ethanol, it was dried in a freeze dryer for 24 hours to obtain reduced graphene oxide.

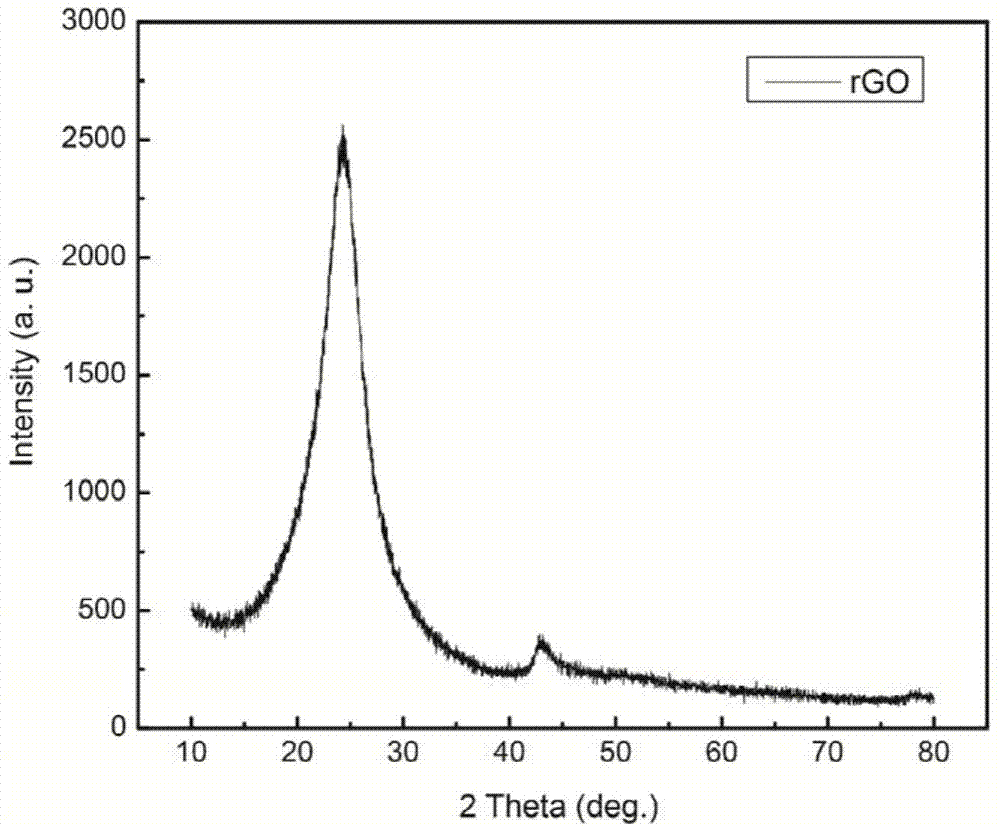

[0020] The structure was confirmed by X-ray powder diffractometer analysis, such as figure 1 The graphene oxide shown has been reduced with an interlayer spacing of 0.368 nm

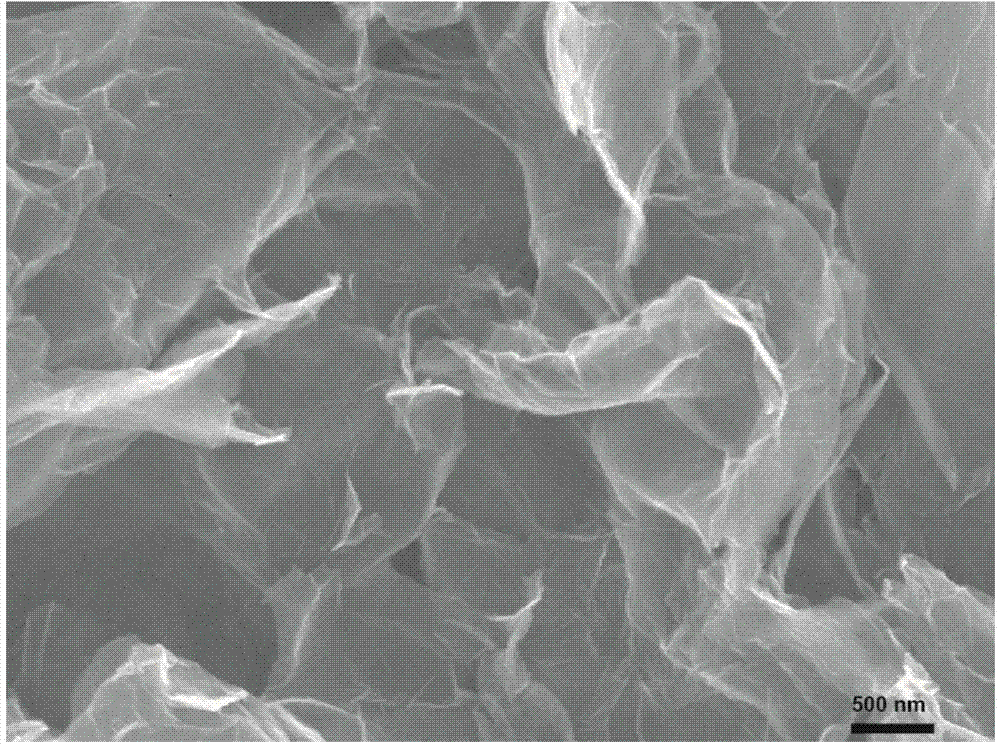

[0021] The morphology of the obtained reduced graphene oxide was characterized by scanning electron microscopy. Such as figure 2 As shown, the reduced graphene oxide was exfoliated after an ionothermal process, showing a sheet-like structure.

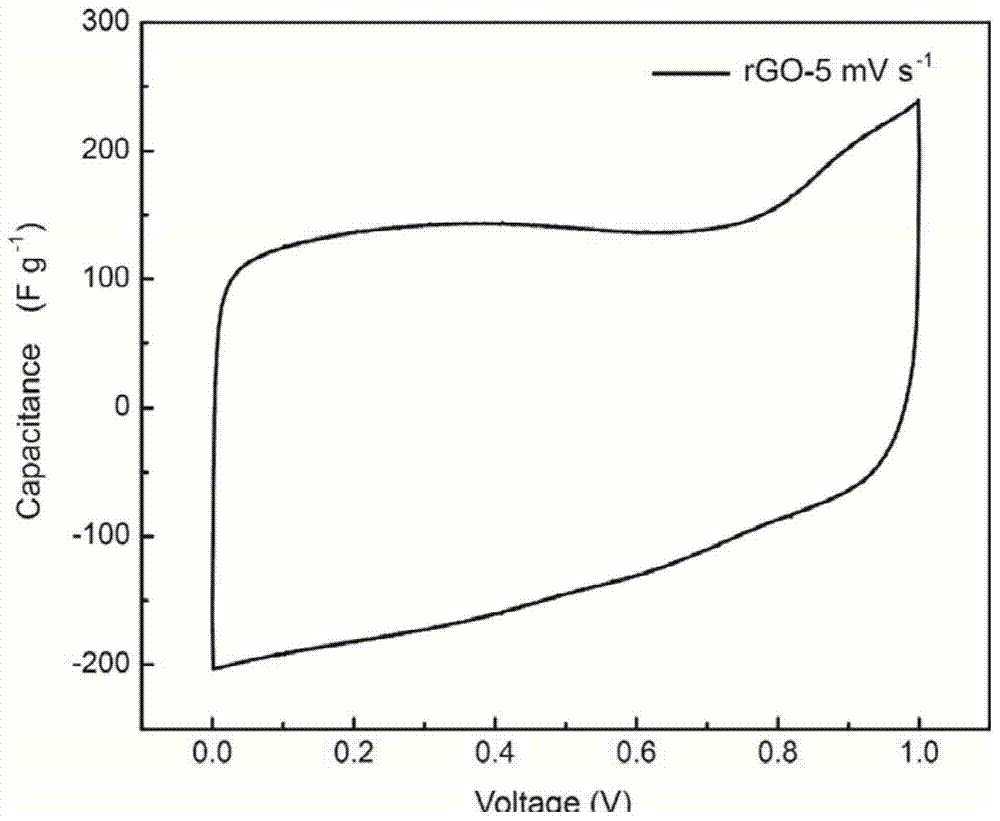

[0022] Electrochemical performance characterization of reduced graphene oxide:

[0023] The prepared reduced graphene oxide (rGO) was directly press...

Embodiment 2

[0026] Add 100mg graphene oxide to 10ml EMIMHSO 4 , ultrasonically dispersed at 30°C for 3 h to obtain an ionic liquid solution of graphene oxide. The solution was poured into a polytetrafluoro reactor, and placed in an oven at 180° C. for 12 hours to obtain a reduced graphene oxide gel. After the gel was washed with water or ethanol, it was dried in a freeze dryer for 24 hours to obtain reduced graphene oxide.

[0027] The structure, morphology and electrochemical properties of the reduced graphene oxide are the same as in Example 1. 5mV s -1 The results of the electrochemical performance tests are listed in Table 1.

Embodiment 3

[0029] Add 100mg graphene oxide to 15ml AMIMH 2 PO 4 In the process, the ionic liquid solution of graphene oxide was obtained by ultrasonic dispersion at 30°C for 2 h. The solution was poured into a polytetrafluoro reactor, and placed in an oven at 160° C. for 10 h to obtain a reduced graphene oxide gel. After the gel was washed with water or ethanol, it was dried in a freeze dryer for 24 hours to obtain reduced graphene oxide.

[0030] The structure, morphology and electrochemical properties of the reduced graphene oxide are the same as in Example 1. 5mV s -1 The results of the electrochemical performance tests are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com