Hot melting reflective type road reticule coating

A road marking and reflective technology, used in reflective/signal coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as cumbersome construction, and achieve the effects of short drying time, good reflectivity, and enhanced bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

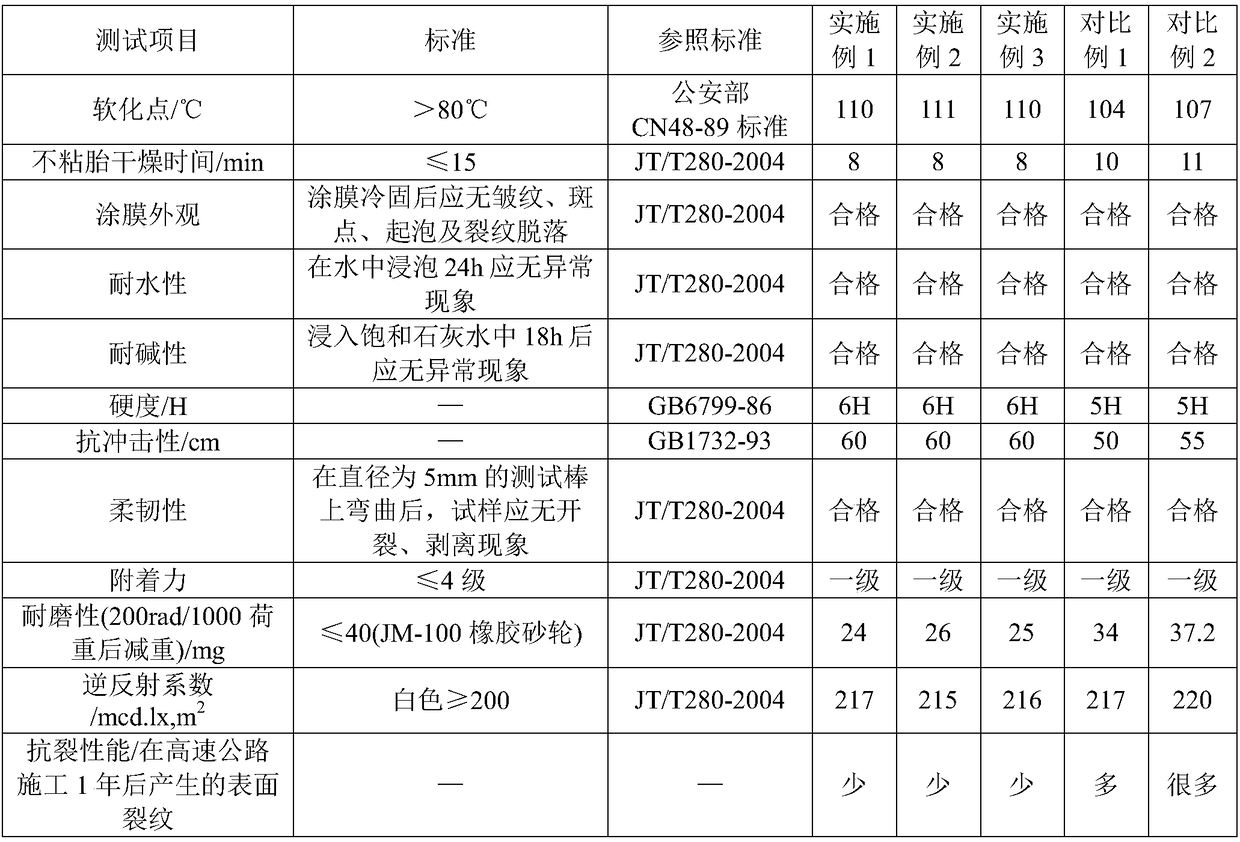

Examples

Embodiment 1

[0031] Preparation of modified rosin-alkyd resin: Add 10Kg of rosin to 1.5Kg of maleic anhydride under nitrogen atmosphere and temperature of 150°C, heat up to 200°C for 1.5 hours, add 1.9Kg of glycerin, and then heat up to 275°C ℃ heat preservation reaction for 7 hours, remove small molecular compounds, and obtain modified rosin resin; 22.5Kg of methyl diphenyl glycolate and 7Kg of glycerin are transesterified to obtain monoglyceride, monoglyceride and phthalic anhydride 43Kg in The temperature is 222°C and the polyesterification reaction occurs for 0.75 hours in the presence of lithium hydroxide to obtain alkyd resin oligomers; the modified rosin resin and alkyd resin oligomers with a weight ratio of 4:1.1-1.3 are obtained at temperature React at 200°C for 1.5 hours to obtain modified rosin-alkyd resin.

[0032] Preparation of hot-melt reflective road marking paint: modified rosin-alkyd resin 20Kg, EVA resin 10Kg, filler 110Kg (heavy calcium carbonate 55Kg, quartz sand 25Kg,...

Embodiment 2

[0034]Preparation of modified rosin-alkyd resin: 10Kg of rosin was added to 1.6Kg of maleic anhydride under the conditions of nitrogen atmosphere and temperature of 155°C, the temperature was raised to 203°C for 1.25 hours, and 2.0Kg of glycerin was added, and then the temperature was raised to 270°C ℃ heat preservation reaction for 8 hours, remove small molecular compounds, and obtain modified rosin resin; 23Kg of methyl diphenyl glycolate and 6Kg of glycerin are transesterified to obtain monoglyceride, monoglyceride and phthalic anhydride 42Kg at temperature Under the conditions of 220°C and the presence of lithium hydroxide, a polyesterification reaction takes place for 1 hour to obtain an alkyd resin oligomer; a modified rosin resin and an alkyd resin oligomer with a weight ratio of 4:1.1-1.3 can be obtained at a temperature of React at 205°C for 1.25 hours to obtain a modified rosin-alkyd resin.

[0035] Preparation of hot-melt reflective road marking paint: modified rosi...

Embodiment 3

[0037] Preparation of modified rosin-alkyd resin: Add 10Kg of rosin to 1.7Kg of maleic anhydride under nitrogen atmosphere and temperature of 153°C, heat up to 205°C for 1 hour, add 1.8Kg of glycerin, and then heat up to 272°C ℃ heat preservation reaction for 7.5 hours to remove small molecular compounds to obtain modified rosin resin; 22Kg of methyl diphenyl glycolate and 6.5Kg of glycerin were transesterified to obtain monoglyceride, monoglyceride and phthalic anhydride 44Kg in The temperature is 225°C and the polyesterification reaction occurs for 0.5 hours in the presence of lithium hydroxide to obtain an alkyd resin oligomer; the modified rosin resin and alkyd resin oligomer with a weight ratio of 4:1.1-1.3 React at 210°C for 1 hour to obtain modified rosin-alkyd resin.

[0038] Preparation of hot-melt reflective road marking paint: modified rosin-alkyd resin 25Kg, EVA resin 5Kg, filler 120Kg (heavy calcium carbonate 65Kg, quartz sand 30Kg, talcum powder 25Kg), titanium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com