Aqueous road marking paint and preparation method thereof

A road marking, water-based technology, used in polyester coatings, coatings, etc., can solve the problems of adding glass beads, high energy consumption, and increased use costs, achieving fast drying speed, long service life, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

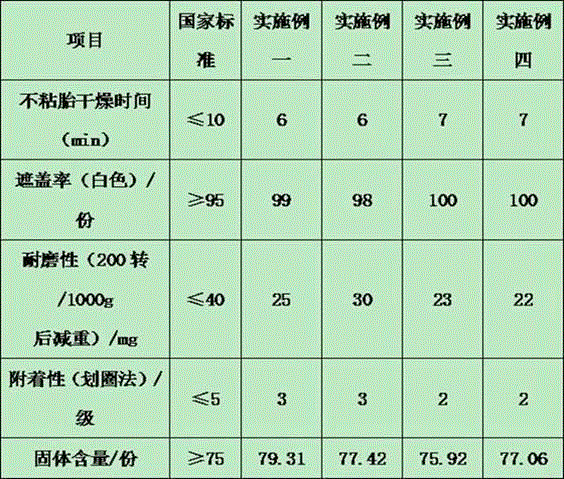

Examples

Embodiment 1

[0046] raw material

[0047] 152 parts of water-based high-performance NH resin curing agent

[0048] 6 parts of wetting agent

[0049] 3 parts defoamer

[0050] Dispersant 10 parts

[0051] 812 parts of deionized water

[0052] 7 parts of thickener

[0053] Polyether modified polyorganosiloxane leveling agent 8 parts

[0054] 350kg premixed powder

[0055] Rutile titanium dioxide 140 kg

[0056] Quartz powder 210 kg

[0057] 80 mesh glass beads 310 kg

[0058] Water-based high-performance NH resin 1000 parts

[0059] Glass fiber cloth 142 parts

[0060] Preparation of component A: Add 152 kg of water-based high-performance NH resin curing agent into a stirring container, add wetting agent, defoamer, and dispersant in sequence at a stirring speed of 350 rpm, and stir and mix evenly, then add deionized water, Thickener, polyether-modified polyorganosiloxane leveling agent, after stirring for 11 minutes, pass the test, filter and pack, it is component A. Preparation of...

Embodiment 2

[0062] raw material:

[0063] 138 parts of water-based high-performance NH resin curing agent

[0064] 3 parts wetting agent

[0065] Defoamer 5 parts

[0066] Dispersant 15 parts

[0067] 822 parts of deionized water

[0068] Thickener 6 parts

[0069] Silicone leveling agent 10 parts

[0070] 390 parts of premixed powder

[0071] 130 parts of rutile titanium dioxide

[0072] 220 parts of quartz powder

[0073] 120 mesh glass beads 260 parts

[0074] Water-based high-performance NH resin 1000 parts

[0075] Glass fiber cloth 130 parts

[0076] Preparation of component A: Add 138 kg of water-based high-performance NH resin curing agent into the stirring container, add wetting agent, defoamer, and dispersant in sequence at a stirring speed of 400 rpm, and after stirring and mixing evenly, add deionized water, Thickener, silicone leveling agent, after stirring for 8 minutes, pass the test, filter and pack, it is component A. Preparation of component C: add the premix...

Embodiment 3

[0078] raw material:

[0079] 178 parts of water-based high-performance NH resin curing agent

[0080] 6 parts of wetting agent

[0081] 6 parts of defoamer

[0082] 12 parts of dispersant

[0083] 782 parts of deionized water

[0084] Thickener 6 parts

[0085] 10 parts of mixed leveling agent of polyether modified polyorganosiloxane and silicone

[0086] 300 parts of premixed powder

[0087] 160 parts of rutile titanium dioxide

[0088] 270 parts of quartz powder

[0089] 270 parts of 100 mesh glass beads

[0090] Water-based high-performance NH resin 1300 parts

[0091] Glass fiber cloth 135 parts

[0092] Preparation of component A: Add 178 kg of water-based high-performance NH resin curing agent into the stirring container, add wetting agent, defoamer, and dispersant in sequence at a stirring speed of 420 rpm, and stir and mix evenly, then add deionized water, Thickener, polyether-modified polyorganosiloxane and silicone mixed leveling agent, after stirring for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com