Light emitting diode (LED) packaging technology based on silver alloy wires

A technology of LED packaging and silver alloy, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of point B breakage, mechanical performance degradation, and coarse grains, etc., and achieve the effects of increased brightness, low price, and good reflective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

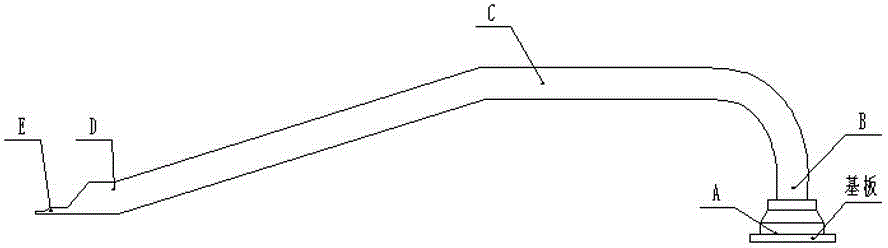

[0017] Such as figure 1 As shown, a kind of LED packaging process based on silver alloy wire is carried out according to the following steps:

[0018] 1) Raw material preparation: Ultrasonic cleaning of the LED bracket, drying, and then thawing the crystal-bonding glue;

[0019] 2) Die-bonding production: place the LED chip on the LED bracket coated with die-bonding glue;

[0020] 3) Die-bonding adhesive baking: Send the LED bracket into the baking station for the die-bonding adhesive to bake, so that the LED chip is fixed on the LED bracket, and the thrust test is performed after the die-bonding adhesive is baked;

[0021] 4) Welding wire: Use a silver alloy wire to electrically connect the positive and negative poles of the LED chip and the positive and negative poles of the LED bracket on the wire bonding machine. The gold content in the alloy wire is 8%, and the silver content is 89%. The diameter of the wire is 0.9mil, the bonding parameters of the LED chip and the allo...

example 2

[0027] A kind of LED encapsulation technology based on silver alloy wire, carries out according to the following steps:

[0028] 1) Raw material preparation: Ultrasonic cleaning of the LED bracket, drying, and then thawing the crystal-bonding glue;

[0029] 2) Die-bonding production: place the LED chip on the LED bracket coated with die-bonding glue;

[0030] 3) Die-bonding adhesive baking: Send the LED bracket into the baking station for the die-bonding adhesive to bake, so that the LED chip is fixed on the LED bracket, and the thrust test is performed after the die-bonding adhesive is baked;

[0031] 4) Welding wire: Use a silver alloy wire to electrically connect the positive and negative poles of the LED chip to the positive and negative poles of the LED bracket on the wire bonding machine. The gold content in the alloy wire is 7-9%, and the silver content is 88-90% %, the diameter of the silver alloy wire is 0.9mil, the bonding parameters of the LED chip and the alloy wi...

Embodiment 3

[0036] A kind of LED encapsulation technology based on silver alloy wire, carries out according to the following steps:

[0037] 1) Raw material preparation: Ultrasonic cleaning of the LED bracket, drying, and then thawing the crystal-bonding glue;

[0038] 2) Die-bonding production: place the LED chip on the LED bracket coated with die-bonding glue;

[0039] 3) Die-bonding adhesive baking: Send the LED bracket into the baking station for the die-bonding adhesive to bake, so that the LED chip is fixed on the LED bracket, and the thrust test is performed after the die-bonding adhesive is baked;

[0040] 4) Welding wire: Use a silver alloy wire to electrically connect the positive and negative poles of the LED chip to the positive and negative poles of the LED bracket on the wire bonding machine. The gold content in the alloy wire is 7-9%, and the silver content is 88-90% %, the diameter of the silver alloy wire is 0.9mil, the bonding parameters of the LED chip and the alloy wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com