Cf/SiC dot matrix composite flat plate with rectangular pyramid structure and preparation method for flat plate

A composite material and quadrangular pyramid technology, which is applied in the field of lattice composite materials and its preparation, can solve the problems that ceramic-based lattice composite materials, metal-based and resin-based lattice materials cannot meet the needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

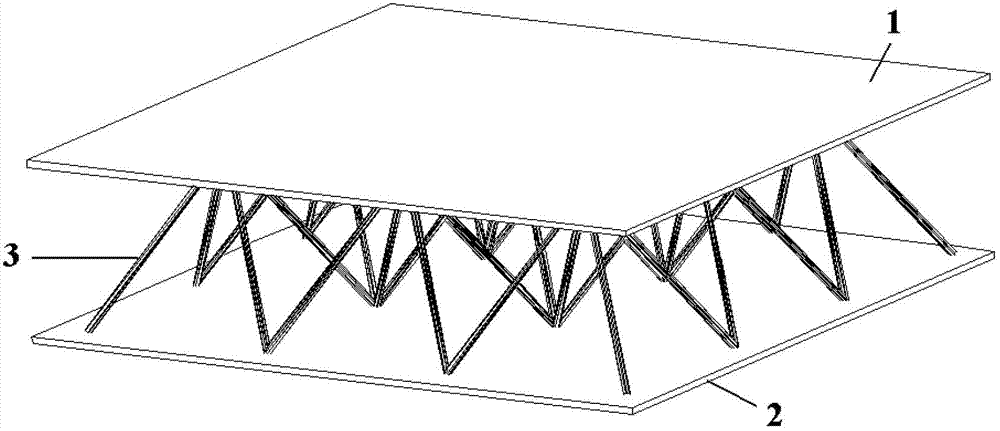

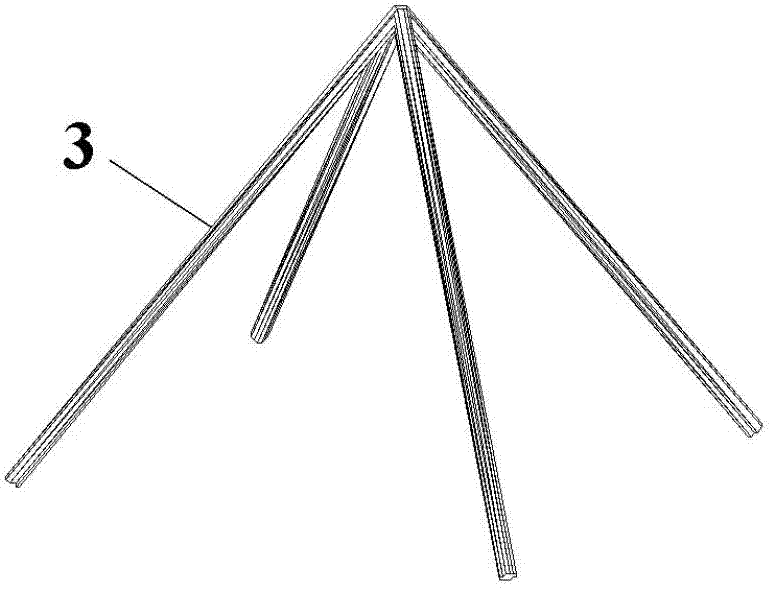

[0023] Specific embodiment 1: This embodiment is quadrangular pyramid configuration C f / SiC lattice composite material plate, composed of upper panel 1, lower panel 2, and quadrangular pyramid cells periodically arranged between the upper and lower panels with lattice core 3, characterized in that the upper panel 1 And the lower panel 2 is composed of C f / SiC composite material, the lattice core 3 is made of C f / SiC composite rods.

[0024] The quadrangular pyramid configuration C provided by this embodiment f / SiC lattice composite material plate preparation method to prepare quadrangular pyramid configuration C f / SiC lattice composite material flat plate, which not only has the excellent characteristics of lattice structure of lattice material, but also has the characteristics of high temperature resistance, oxidation resistance, corrosion resistance and friction resistance of SiC ceramics. At the same time, because carbon fiber is used as a framework material, it also reduce...

specific Embodiment approach 2

[0025] Specific embodiment 2: This embodiment is a quadrangular pyramid configuration C f The preparation method of / SiC lattice composite material plate is specifically completed according to the following steps:

[0026] 1. Mix polycarbosilane, divinylbenzene, xylene and tetrahydrofuran to obtain an impregnation solution; wherein the mass ratio of divinylbenzene to polycarbosilane is (0.3~0.5):1, and the mass of xylene and polycarbosilane The ratio is (0.05~0.1):1, and the mass ratio of tetrahydrofuran to polycarbosilane is (1~3):1;

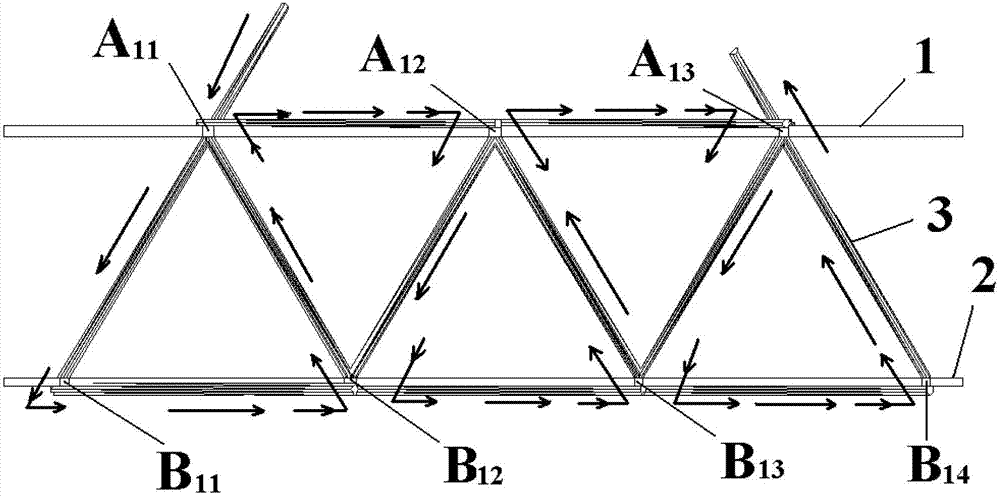

[0027] 2. Punch m rows×n columns of array through holes on the carbon fiber cloth I to obtain a perforated carbon fiber cloth I; punch (m+1) rows×(n+1) columns of array through holes on the carbon fiber cloth II, Obtain the through-hole carbon fiber cloth II; the through holes in the first row and the first column of the array of through holes on the through-hole carbon fiber cloth I are A 11 , The through holes in the first row and the second colum...

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is different from the specific embodiment two in that: the molecular weight of the polycarbosilane described in step one is 1000-1500. Others are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com