Heavy cable and zero float cable mixed type photoelectric composite tow

A photoelectric composite, zero buoyancy technology, applied in the direction of cables, circuits, electrical components, etc., can solve the problems of difficult retraction, complex structure, low reliability, etc. The effect of convenient cable retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

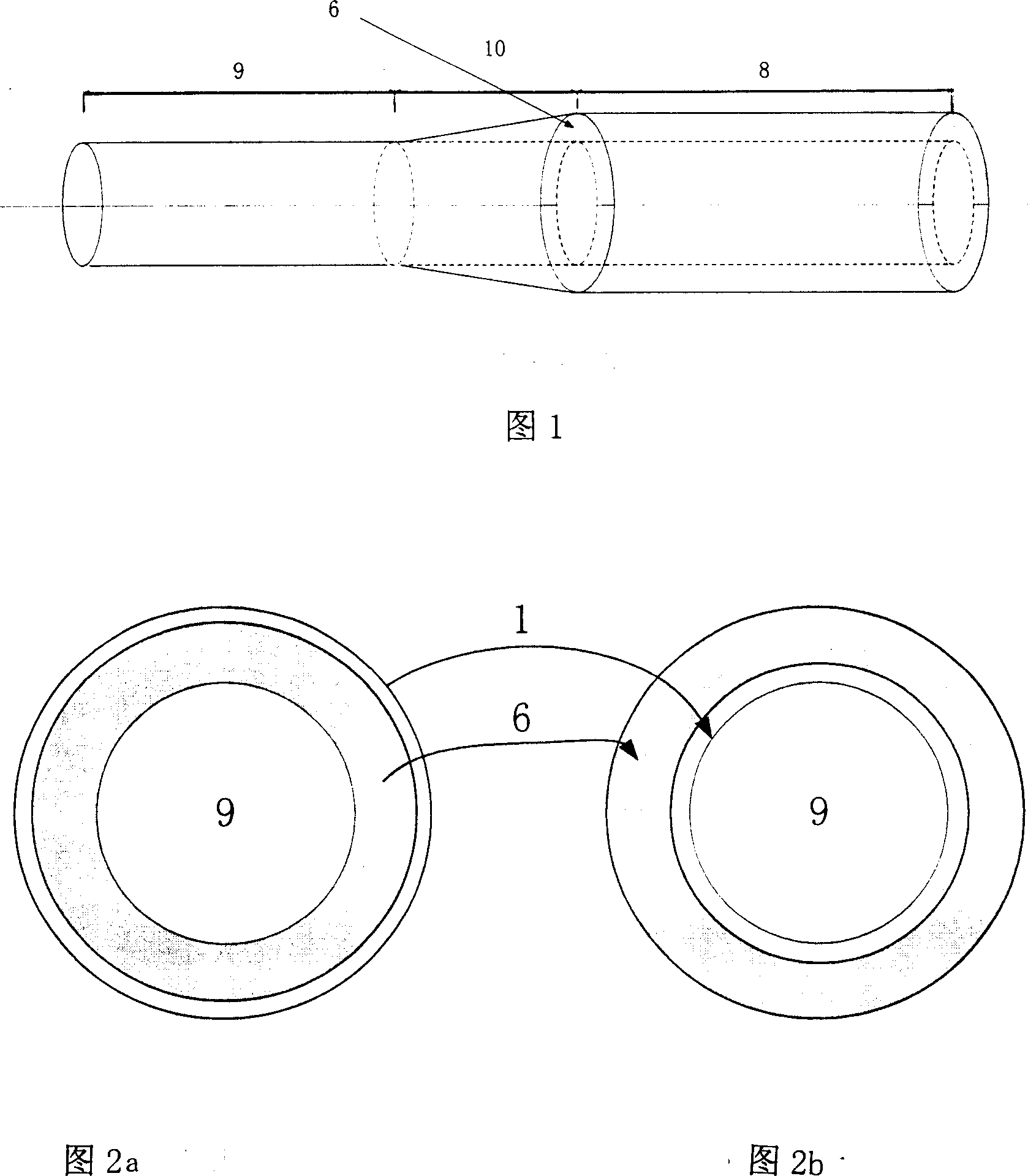

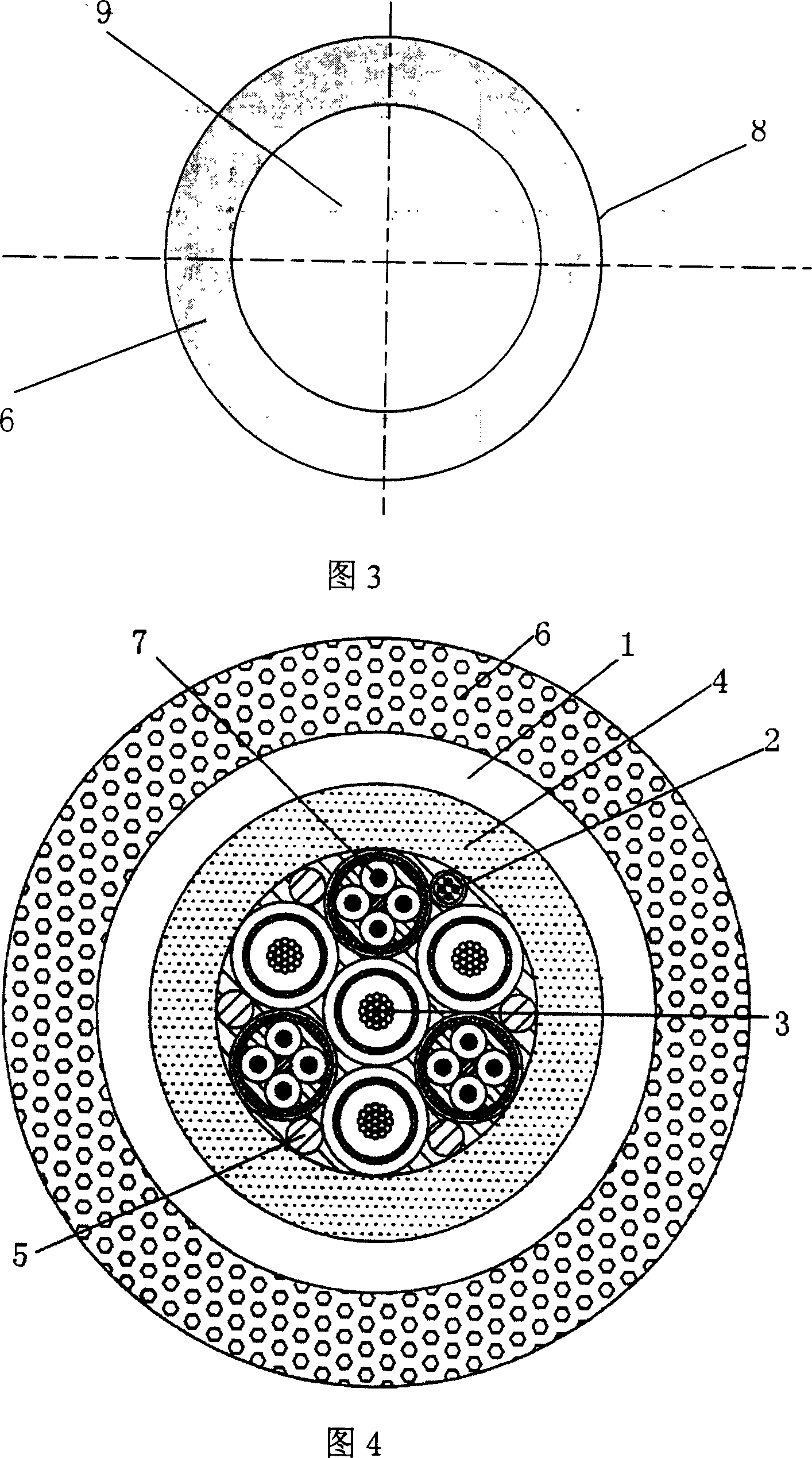

[0034] Referring to Figure 1, two sets of load-bearing cables with cable lengths of 700 meters and 800 meters were ordered from abroad. The bending radius of the cables is 0.4 meters and the breaking force is 15 tons. The load-bearing cable of the present embodiment is divided into 3 sections, heavy cable section 9, zero buoyancy section 8 and transition section 10 (as shown in Figure 1 and Figure 2), the length of heavy cable section 9 is 700 meters, and zero buoyancy section 8 The length is 800 meters. The Kevlar tensile layer 4 of the load-bearing cable has a multimode optical fiber 2, a shielded power cord 3, and a shielded twisted pair 7, and is filled with oil as a water-blocking material 5 to form a whole. One end of the load-bearing cable is used as the heavy cable section 9, and then the polyurethane sheath 1 is covered outside the other two sections, and then a layer of foam sheath 6 is placed on the polyurethane sheath 1 to form a zero-buoyancy cable 8 The zero-buo...

Embodiment 2

[0036] The structure of this embodiment is the same as that of Embodiment 1, except that on the basis of Embodiment 1, a layer of non-foamed polyethylene film is added outside the foam sheath 6, because the composition of this gravity and buoyancy hybrid cable The cable method has certain requirements on the friction resistance of the buoyancy material, because the surface of the buoyancy foam material is generally rough, and it will inevitably increase the resistance of the towline when it is dragged underwater. The thin-film method can make the towline more beautiful and can reduce the fluid resistance of the towline when it is towed obliquely. Since the zero-buoyancy towline is generally horizontal when working underwater, the buoyancy material may not be provided with a protective film, and the water flow resistance will not be increased much.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com