Waterproof single-component glass printing ink and preparation method thereof

A glass ink, one-component technology, applied in the field of ink, can solve the problems of poor adhesion, poor water resistance and alcohol resistance, poor water resistance, etc., and achieve excellent bond strength and water resistance, good wear resistance. And the effect of excellent weather resistance and interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

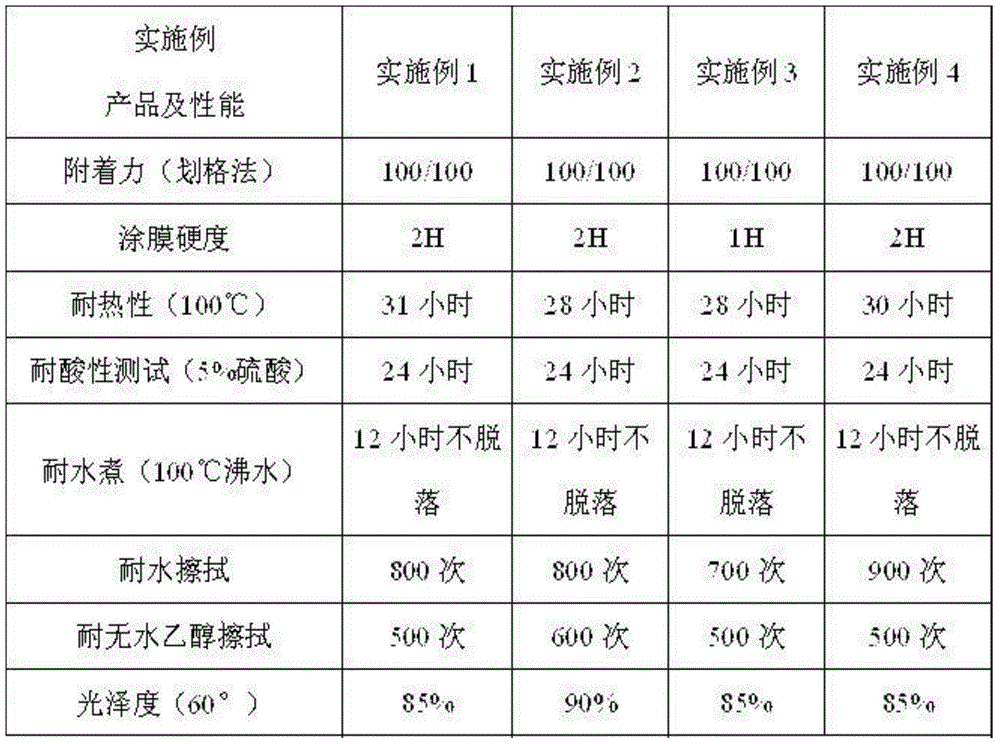

Embodiment 1

[0028] By weight percentage, 40% modified polyester (purchased from Kunshan Ruitai Chemical Co., Ltd., A-473), 5% heat-resistant bisphenol A liquid epoxy resin (purchased from Japan Mitsubishi Chemical Company), 5% solid content 45% methyl etherified amino resin, 40% titanium dioxide with a particle size of 100 nanometers, 1.4% fumed silica, 1% polyacrylate, 0.5% polymethylphenylsiloxane leveling agent, 1.5 Add % polydimethylsiloxane and 5.6% isophorone into the mixing container, mix well, and then disperse in a disperser with a rotation speed of 3000r / min for 30 minutes; pass the above dispersed samples through a three-roll machine Grinding, grinding 3 times until the fineness is below 5um.

Embodiment 2

[0030] By weight percentage, 42% modified polyester (purchased from Kunshan Ruitai Chemical Co., Ltd., A-473), 3% heat-resistant bisphenol A liquid epoxy resin (purchased from Japan Mitsubishi Chemical Company), 10% solid content 45% methyl etherified amino resin, 32% titanium dioxide with a particle size of 90 nanometers, 2% fumed silica, 0.9% modified polyacrylate, 0.1% tributyl phosphate and 10% isoflurane Add the ketone into the mixing container, mix evenly, and then disperse for 60 minutes in a disperser with a rotating speed of 2500r / min; grind the above-dispersed samples through a three-roller machine for 3 times until the fineness is below 5um.

Embodiment 3

[0032] By weight percentage, 50% modified polyester (purchased from Kunshan Ruitai Chemical Co., Ltd., A-473), 10% heat-resistant bisphenol A liquid epoxy resin (purchased from Japan Mitsubishi Chemical Company), 2% solid content 45% methyl etherified amino resin, 35% titanium dioxide with a particle size of 60 nanometers, 0.5% fumed silica, 0.7% polyacrylate leveling agent, 0.6% modified polyacrylate leveling agent, 0.1 % modified silicone defoamer, 0.1% tributyl phosphate defoamer and 1% isophorone are added to the mixing container, mixed evenly, and then dispersed in a disperser with a rotating speed of 2500r / min for 40 minutes; The above-mentioned dispersed samples are ground by a three-roll machine, and ground twice to a fineness of 5um or less.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com