Polyurethane fireproof building exterior wall coating and production method thereof

A technology of fire-resistant building and exterior wall coatings, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of low solid content of polyurethane coatings, poor gloss of latex films, and poor fire-proof effects, and achieve fire-proofing Good performance, high gloss, excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Add 5 parts of water, 10 parts of titanium dioxide, 7 parts of hollow glass microspheres, 9 parts of additives (including 1 part of chain extender, 2 parts of leveling agent, 3 parts of dispersant, and 1 part of thickener) in the mixer , 0.5 parts of defoaming agent, 1 part of dustproof agent), 12 parts of fireproof filler (antimony trioxide white powder, marble powder and mica, the mass fraction ratio is 0.3:1:1), stir well, and pass the obtained solution through the scrub Machine grinding until the particle size is within 40 microns, then put the solution back into the mixer, put 3 parts of silane adhesion promoter, 50 parts of water-curable polyurethane, 15 parts of water-based acrylic resin, and 3 parts of polytetrafluoroethylene into it, mix and stir uniform.

Embodiment 2

[0051] Add 8 parts of water, 6 parts of titanium dioxide, 9 parts of hollow glass microspheres, 13 parts of additives (including 3 parts of chain extender, 2 parts of leveling agent, 1 part of dispersant, 3 parts of thickener) in the mixer , 1.5 parts of defoamer, 2 parts of dustproof agent), 16 parts of filler (antimony trioxide white powder marble powder and mica, the mass fraction ratio is 0.3:1:1), stir evenly, and pass the obtained solution through a sander Grind until the particle size is within 40 microns, then put the solution back into the mixer, put 7 parts of silane adhesion promoter, 45 parts of water-curable polyurethane, 25 parts of water-based acrylic resin, 4 parts of polytetrafluoroethylene, mix and stir evenly .

Embodiment 3

[0053] Add 6 parts of water, 7 parts of titanium dioxide, 5 parts of hollow glass microspheres, 8 parts of additives (including 1 part of chain extender, 1 part of leveling agent, 2 parts of dispersant, and 1 part of thickener) in the mixer , 1 part of defoaming agent, 1 part of dustproof agent), 14 parts of filler (antimony trioxide white powder, marble powder and mica, the mass fraction ratio is 0.3:1:1), stir evenly, and pass the obtained solution through a sander Grind until the particle size is within 40 microns, then put the solution back into the mixer, put 5 parts of silane adhesion promoter, 40 parts of water-curable polyurethane, 20 parts of water-based acrylic resin, and 5 parts of polytetrafluoroethylene into it, mix and stir evenly .

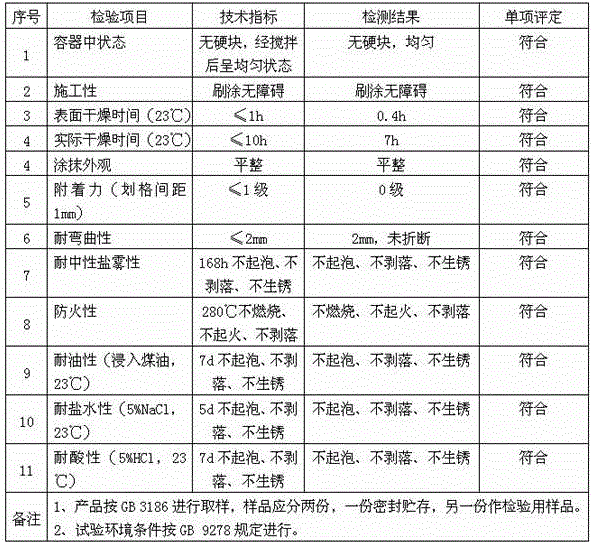

[0054] According to GB / T1723-93, GB / T 1724-89, GB / T 1731-93, GB / T 1732-93, GB / T1733-93, GB / T 1734-93 standards, the results are listed in the table below.

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com