Fire-proof aluminum composite board

An aluminum composite board and mixture technology, applied in the field of building materials, can solve the problems of reduced machinability, high brittleness of the core material, poor flexibility, etc., and achieve the effects of improved processing performance, high cost performance, and small harmful smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

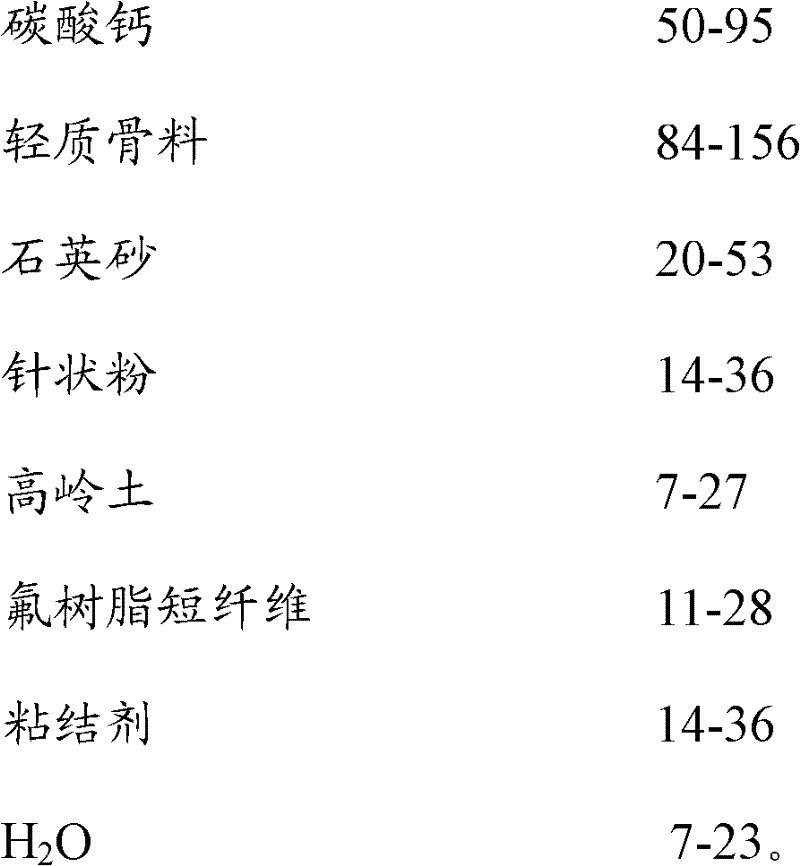

[0041] A fireproof aluminum composite board, the A2 grade fireproof aluminum composite board is prepared by proportioning the following components according to the weight parts:

[0042]

[0043]

Embodiment 2

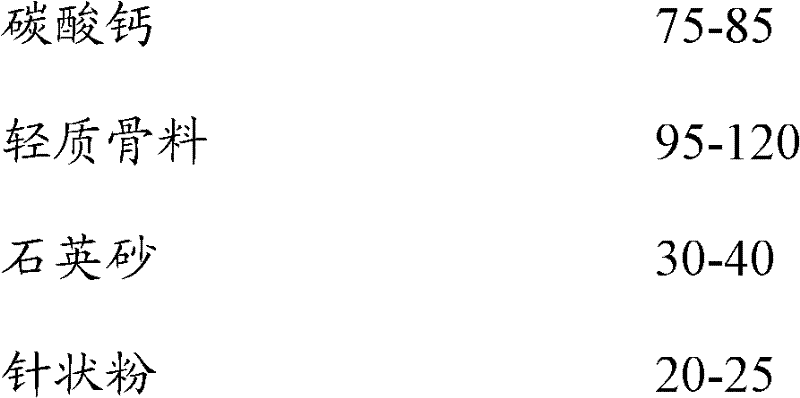

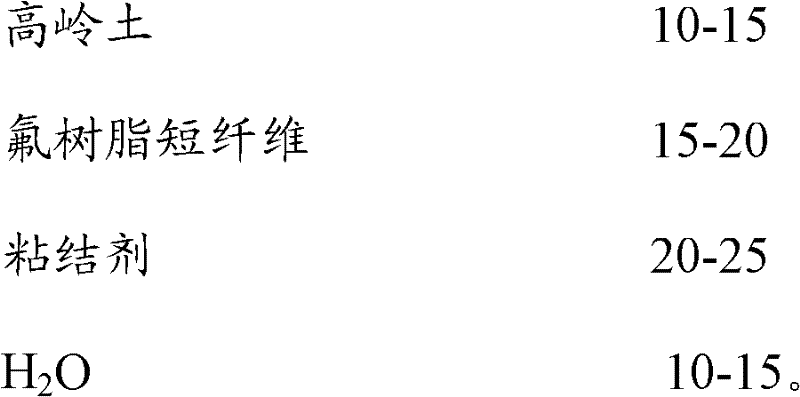

[0045] A fireproof aluminum composite board, the A2 grade fireproof aluminum composite board is prepared by proportioning the following components according to the weight parts:

[0046]

Embodiment 3

[0048] A fireproof aluminum composite board, the A2 grade fireproof aluminum composite board is prepared by proportioning the following components according to the weight parts:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com