Heat preservation wallboard and manufacturing method thereof

A technology for thermal insulation wall panels and manufacturing methods, which is applied in the field of building wall materials, can solve problems such as unfavorable overall thermal insulation of wall panels, and achieve the effects of resource utilization, low thermal conductivity, and improved durability and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

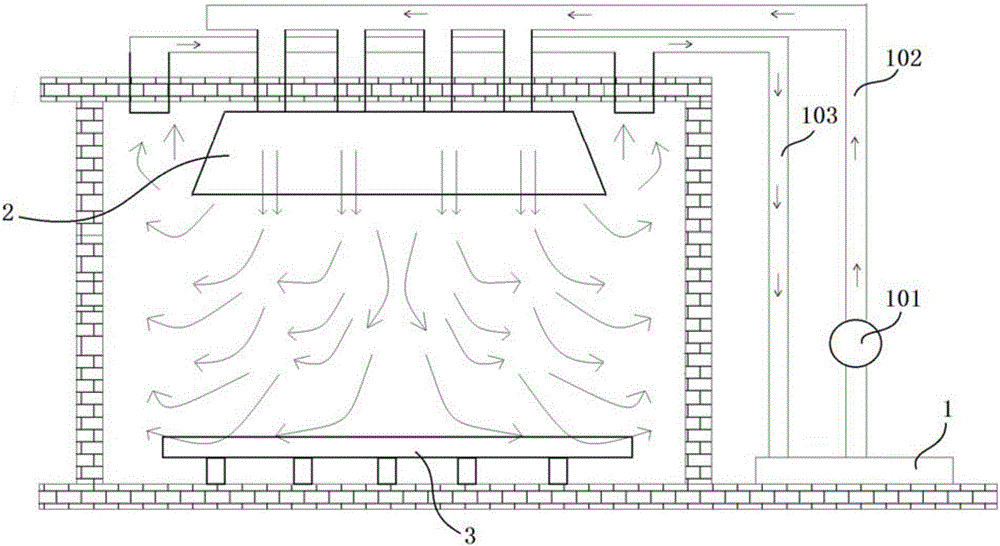

[0066] combine figure 1 , the clean room of the present embodiment includes an air-conditioning unit 1 and a sealed space surrounded by thermal insulation wall panels, the bottom of the sealed space is provided with a horizontal support platform 3, and the top of the sealed space is provided with an air inlet hood 2, the air inlet The cover 2 communicates with the air conditioning unit 1 through the air inlet pipe 102 ; the surrounding area of the air inlet cover 2 communicates with the air conditioning unit 1 through the exhaust pipe 103 .

[0067] During the use of the clean room, the indoor temperature needs to be strictly controlled by the air conditioning unit. One of the important technical indicators is the temperature uniformity in the clean room, that is, the temperature is detected at different positions in the clean room, and the indoor temperature is compared. Whether the temperature values at different positions are relatively consistent, so as to meet the req...

Embodiment 2

[0069] The structure of the clean room of this embodiment is basically the same as that of Embodiment 1. More specifically, the air inlet hood 2 is a channel with a gradually expanding aperture from top to bottom, and the height from the lower opening to the upper opening of the air inlet hood 2 is: sealed space The height=1:6.2~8.4 (in this embodiment, get 1:6.2 specifically), the aperture of the opening under the air intake hood 2: the width of the sealed space=1:1.4~2.7 (the width of the sealed space here refers to the sealing The narrower side of the space is long, specifically 1:1.4 in this embodiment), the top of the sealed space is provided with at least eight air outlets, and the above-mentioned at least eight air outlets are distributed equidistantly around the circumference of the air inlet hood 2, each The air outlets are all communicated with the air conditioning unit 1 through the exhaust pipe 103 .

[0070]In this embodiment, the air inlet hood 2 is set as a chan...

Embodiment 3

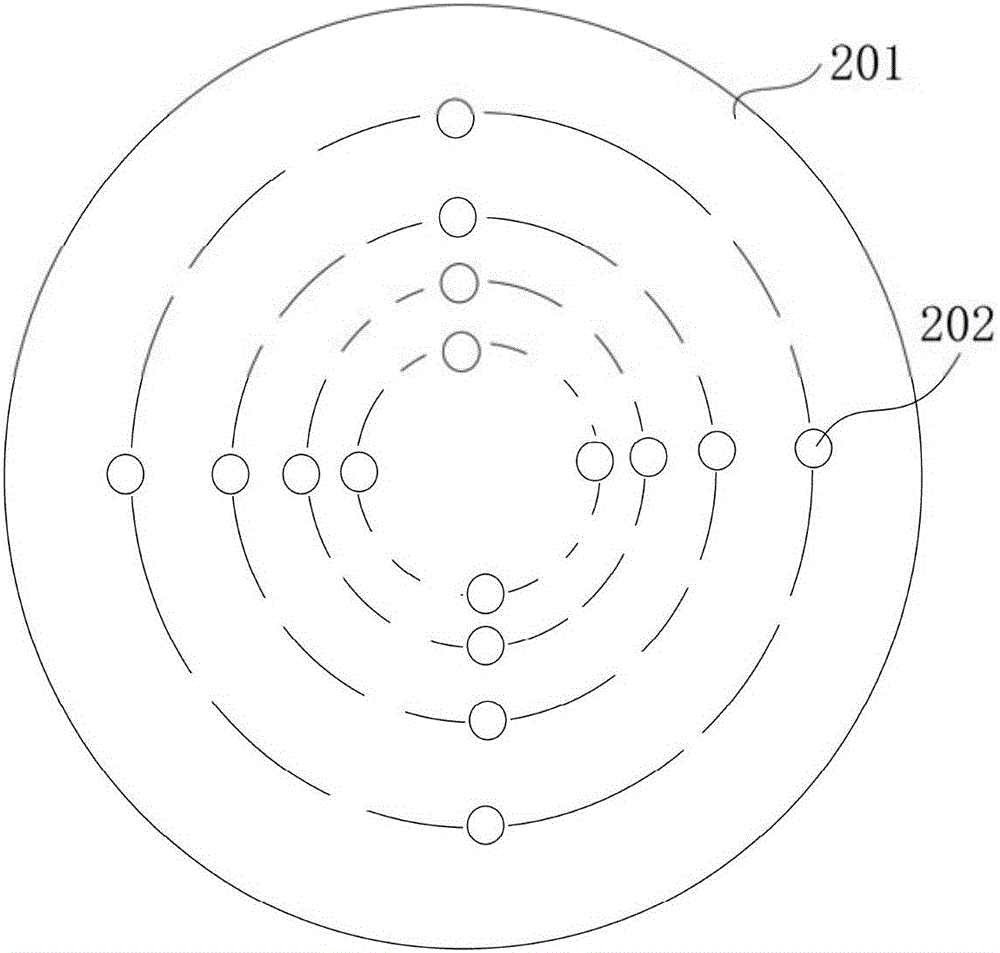

[0072] combine figure 2 , the structure of the clean room of this embodiment is basically the same as that of Embodiment 2. More specifically, the upper opening of the air inlet hood 2 is provided with a sealing plate 201, and the above sealing plate 201 is provided with at least four groups of air inlets 202, each The group of air inlets 202 includes a number of air inlets 202 that are equally spaced around the center of the sealing plate, and the above-mentioned at least four groups of air inlets 202 are arranged in concentric circles, and the closer to the center of the sealing plate, two groups of air inlets are adjacent to each other. The smaller the distance between the tuyere 202 circles (that is, the several air inlets 202 included in each group of air inlets 202 are arranged at equal intervals on a circle with the center point of the sealing plate as the center of the circle, and the closer to the sealing plate The smaller the distance between two adjacent circles of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com