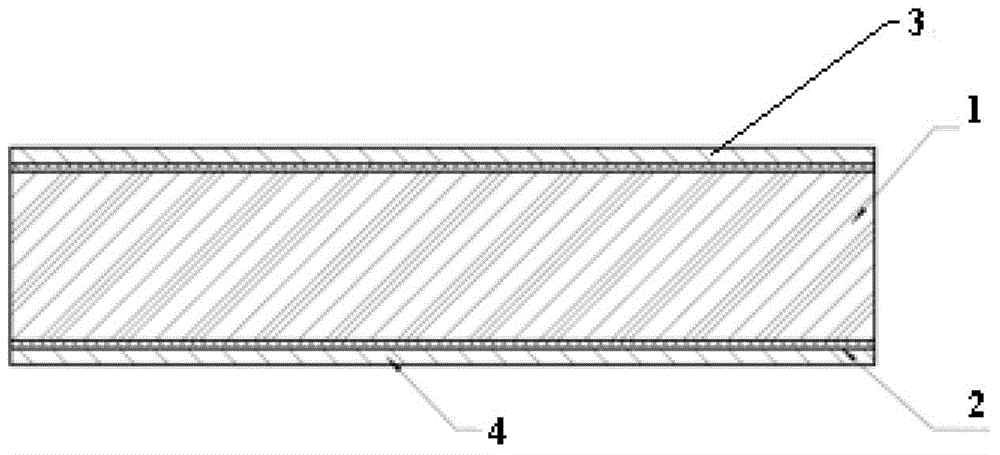

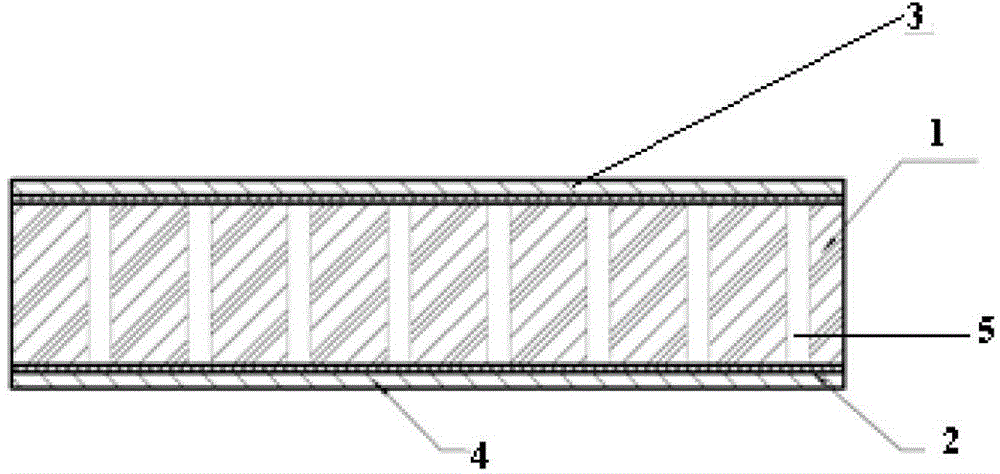

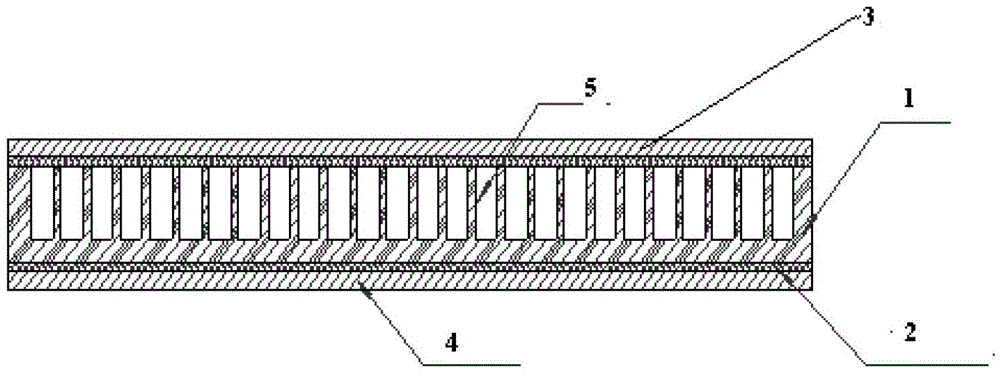

Composite plate and preparation method thereof

A composite board and composite metal technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of high cost and poor fireproof performance, and achieve low cost, better high temperature resistance, and better anti-aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention also discloses a method for preparing a composite board, comprising the following steps:

[0046] (A) After the fireproof hard material is ball-milled into powder, it is mixed with the binding substance to obtain a mixture;

[0047] The fireproof hard material is a discarded non-metallic material;

[0048] The adhesive substance includes: waste engine oil, polyvinyl alcohol, magnesium oxide and unsaturated resin adhesive; the mass ratio of waste engine oil, polyvinyl alcohol, magnesium oxide and unsaturated resin adhesive is (10-20): (10-20 ):(35~45):(25~35);

[0049] The mass ratio of fireproof hard material and adhesive substance is (70wt%~80wt%): (20wt%~30wt%);

[0050] (B) stirring and dissolving the mixture described in step (A), extruding and drying to obtain the substrate;

[0051] (C) Fireproofing the surface of the metal panel and the metal base plate, and pressing them with the polymer film after heating to obtain a composite metal base plate ...

Embodiment 1

[0063] Get 70 kilograms of fireproof hard materials that are made up of discarded glass, discarded ceramics, fruit shells and waste plastics and carry out ball milling. The particle size after ball milling is 300 meshes. It is mixed with an adhesive substance composed of an unsaturated resin adhesive to obtain a mixture. The ratio of discarded glass, discarded ceramics, fruit shells and waste plastics in the fireproof hard material is not limited, and the mass ratio of waste engine oil, polyvinyl alcohol, magnesium oxide and unsaturated resin adhesive is 15:15:40:30 .

[0064] The mixture was stirred and dissolved in an environment of 50° C., extruded by an extruder, and dried naturally in an oven at 120° C. to obtain a substrate.

[0065] The stainless steel is prepared into two 1mm stainless steel plates, which are heated to 120°C on a heat paste machine, and the EVA film is laminated. Pressing two stainless steel plates with the same EVA film bonded to the substrate, the ...

Embodiment 2

[0069] Get 75 kilograms of fireproof hard material that is made up of waste pottery, fruit shell, waste plastics, marble waste slag and coal cinder and carry out ball milling, the particle diameter after ball milling is 350 orders, the powder that will obtain is mixed with 25 kilograms of waste engine oil, polyvinyl alcohol, oxidation A binder mass consisting of magnesium and an unsaturated resin binder is mixed to obtain a mixture. The ratio of discarded glass, discarded ceramics, fruit shells and waste plastics in the fireproof hard material is not limited, and the mass ratio of waste engine oil, polyvinyl alcohol, magnesium oxide and unsaturated resin adhesive is 12:12:35:35 .

[0070] The mixture was stirred and dissolved at 80° C., extruded by an extruder, and dried naturally in an oven at 120° C. to obtain a substrate.

[0071] Prepare the aluminum foil into a 0.5mm stainless steel plate, heat it to 125°C on a heat paste machine, and press the EVA film.

[0072] A mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com