Manufacturing method of ecological fire preventing and heat insulating building material

A technology for fire prevention and heat preservation and building materials, applied in chemical instruments and methods, manufacturing tools, ceramic products, etc., can solve problems such as polluting the environment, easily causing fires, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Taking the production of 1 square meter of ecological fireproof and thermal insulation building materials as an example, the production method is as follows:

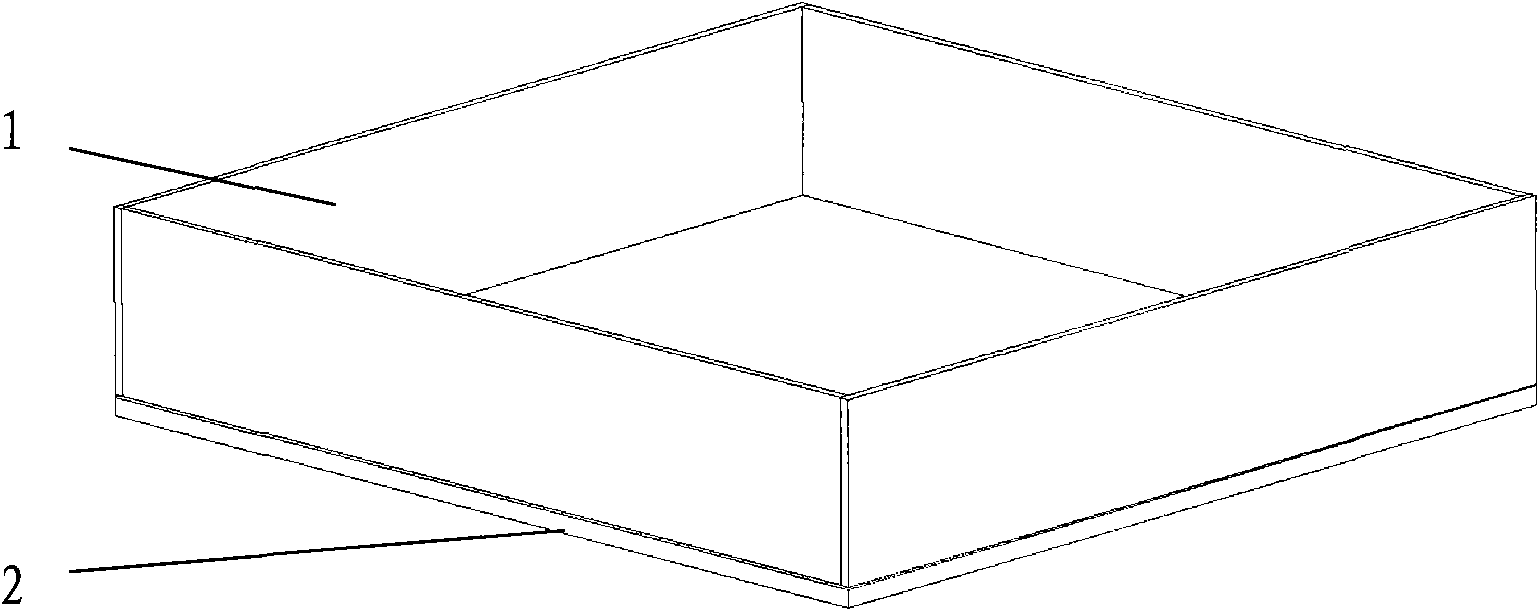

[0019] 1), making plate mold 1, the shape of the mold is a square frame with a certain height, and the side length of the frame is 1 meter;

[0020] 2) Place the liner 2 on the bottom of the plate mold;

[0021] 3), according to the following steps to prepare the raw material of fireproof and thermal insulation building materials

[0022] (1) Add 8kg of water to 10Kg of ordinary cement, and mix well to form cement slurry;

[0023] (2) Foaming agent is dropped into foaming equipment to make foam, then 5kg of foam produced by foaming agent is imported into cement slurry and fully stirred, finally forming foamed cement slurry;

[0024] (3) Add 30kg of perlite, 20kg of ceramsite, 5kg of glass beads, and 0.3kg of environmentally friendly fiber into the foam cement slurry, and then fully stir to form the original s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com