A kind of green phase bright yellow inorganic nano pigment and preparation method thereof

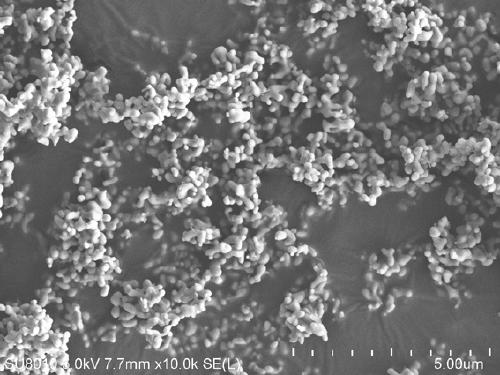

A technology of inorganic nano and inorganic pigments, applied in the field of inorganic pigments, can solve the problems of affecting the coloring effect of pigments and the decrease of yellow chroma value, and achieve the effect of uniform size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

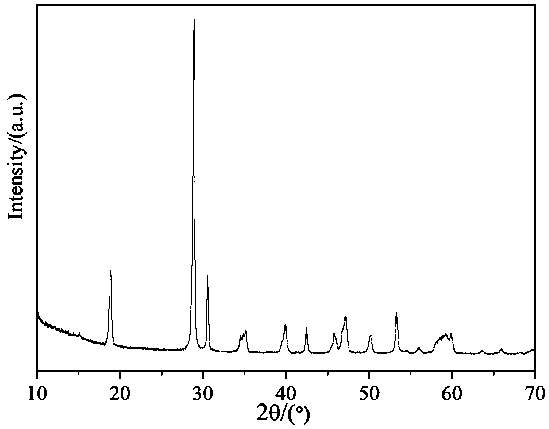

[0022] Example 1 Bi 0.88 Zn 0.08 Nd 0.04 V 0.9 al 0.1 o 4-δ Pigment preparation

[0023] According to theory, 0.25mol / L Bi can be synthesized 0.88 Zn 0.08 Nd 0.04 V 0.9 al 0.1 o 4-δ Prepare the solution.

[0024] First, according to the composition of the formula, bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), ammonium metavanadate (NH 4 VO 3 ), zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), neodymium nitrate (Nd(NO 3 ) 3 ) and aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) Add it into pure water, heat it to 80°C with constant stirring, then add diethylenetriaminepentaacetic acid as a complexing agent, and obtain a mixed solution after the components are fully dissolved. The molar ratio of the complexing agent to the total amount of metal ions For: complexing agent: metal ion = 2.5:2. Add sodium dodecylbenzenesulfonate as a dispersant while continuing to stir, and the dosage of the dispersant is 0.35% (relative to the mass percentage concentra...

Embodiment 2

[0025] Example 2 Bi 0.9 Zn 0.1 V 0.88 al 0.06 Mo 0.06 o 4-δ Pigment preparation

[0026] According to theory, 0.4mol / L Bi can be synthesized 0.9 Zn 0.1 V 0.88 al 0.06 Mo 0.06 o 4-δ Prepare the solution.

[0027] First, according to the composition of the formula, bismuth oxide (Bi 2 o 3 ), vanadium pentoxide (V 2 o 5 ), zinc oxide (ZnO), aluminum oxide (Al 2 o 3 ) and ammonium molybdate tetrahydrate were added to pure water, heated to 90°C with constant stirring, and then diethylenetriaminepentaacetic acid was added as a complexing agent. After the components were fully dissolved, a mixed solution was obtained. The complexing agent and metal The molar ratio of the total amount of ions is: complexing agent: metal ion = 4:2. Add sodium dodecylbenzenesulfonate as a dispersant while continuing to stir, and the dosage of the dispersant is 0.2% (relative to the mass percentage concentration of the added water). After the dispersant is fully dissolved, add ammonia ...

Embodiment 3

[0028] Example 3 Bi 0.92 La 0.08 V 0.9 Ta 0.1 o 4-δ Pigment preparation

[0029] According to theory, 0.5mol / L Bi can be synthesized 0.92 La 0.08 V 0.9 Ta 0.1 o 4-δ Prepare the solution.

[0030] First, according to the composition of the formula, bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), ammonium metavanadate (NH 4 VO 3 ), lanthanum nitrate hexahydrate (La(NO 3 ) 2 ·6H 2 O), tantalum oxalate was added to pure water, heated to 80°C with constant stirring, then ethylenediaminetetraacetic acid was added as a complexing agent, and each component was fully dissolved to obtain a mixed solution, in which the complexing agent and the total amount of metal ions The molar ratio is: complexing agent: metal ion = 3:2. While continuing to stir, add sodium lauryl sulfate as a dispersant, and the amount of the dispersant is 0.3% (relative to the mass percentage concentration of the added water). After the dispersant is fully dissolved, add ammonia water with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com