C/N-NiCoFeMn LDH composite electrode material and preparation method thereof

A composite electrode, 2·6H2O technology, applied in the field of materials, can solve the problems of further improvement of specific capacitance, cycle stability and rate performance to be improved, etc., to improve electrochemical reaction activity, facilitate contact, and improve charge storage. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

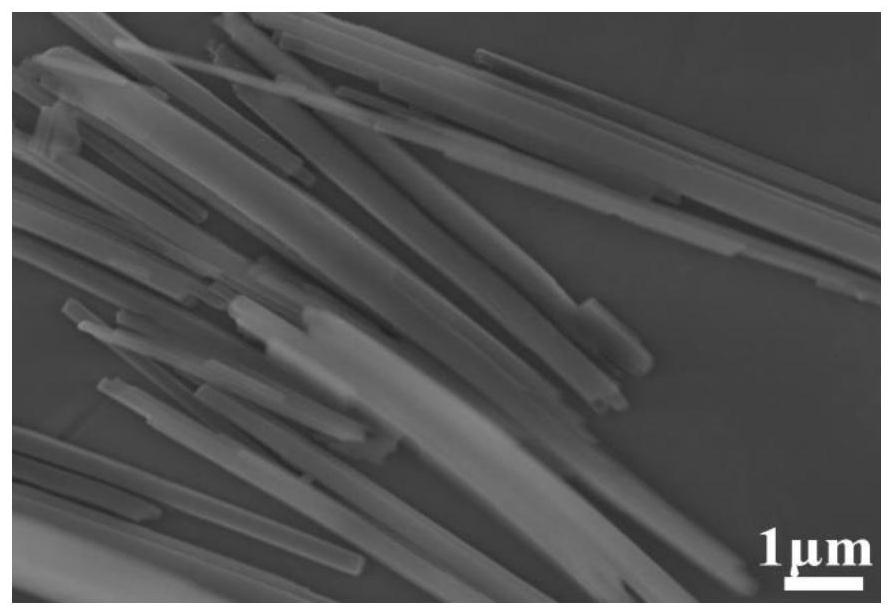

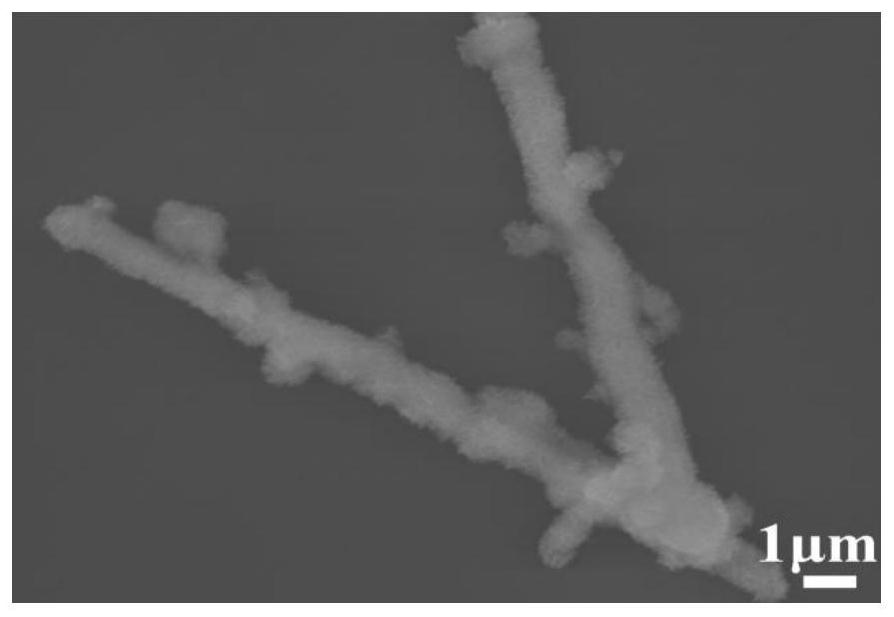

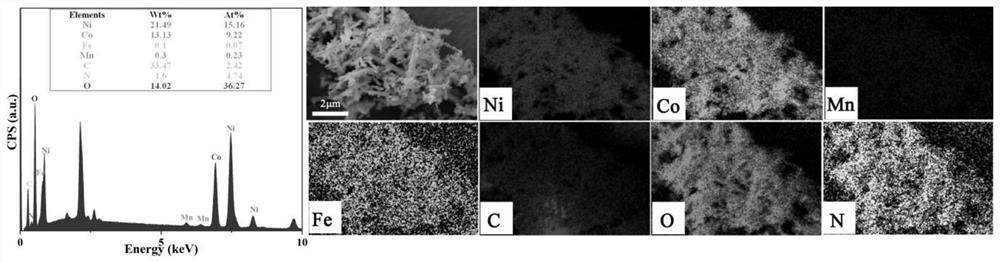

[0033] Embodiment 1, this embodiment is a preparation method of C / N-NiCoFeMn LDH composite electrode material, including CoC 2 O 4·2H 2 Preparation of O precursor and preparation of C / N-NiCoFeMn LDH composite electrode material, the specific steps are as follows:

[0034] 1) CoC 2 O 4 ·2H 2 Preparation of O precursor

[0035] (1) Weigh 1 mmol of cobalt nitrate (Co(NO) 3 ) 2 ·6H 2 O) Dissolve in 30mL ultrapure water, stir for 0.5h under 50 ℃ water bath condition, obtain cobalt nitrate aqueous solution; Described ultrapure water (Ultrapure water) is familiar in the art, also known as UP water, refers to that the resistivity reaches 18MΩ·cm (25℃) water;

[0036] (2) Weigh 8mmol of oxalic acid (H 2 C 2 O 4 ·2H 2 O) Dissolve in 30 mL of ultrapure water, under the condition of magnetic stirring at 50 °C, to obtain an oxalic acid solution, add the oxalic acid solution dropwise to the cobalt nitrate aqueous solution at a rate of 0.2 drops / s, and then keep at 50 °C for 0.5...

Embodiment 2

[0049] Embodiment 2, this embodiment is a preparation method of C / N-NiCoFeMn LDH composite electrode material, including CoC 2 O 4 ·2H 2 Preparation of O precursor and preparation of C / N-NiCoFeMn LDH composite electrode material, the specific steps are as follows:

[0050] 1) CoC 2 O 4 ·2H 2 Preparation of O precursor

[0051] (1) 2 mmol of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) was dissolved in 50 mL of ultrapure water, and stirred for 0.5 h under a water bath condition of 50 °C to obtain an aqueous solution of cobalt nitrate;

[0052] (2) 12 mmol of oxalic acid (H 2 C 2 O 4 ·2H 2 O) Dissolved in 50 mL of ultrapure water, under the condition of magnetic stirring at 50 °C, to obtain an oxalic acid solution, the oxalic acid solution was added dropwise to the cobalt nitrate aqueous solution at a rate of 0.5 drops / s, and then kept at 80 °C for 1 h;

[0053] (3) the product obtained in (2) of step 1) is washed three times with ultrapure water;

[0054] (4) washing the ...

Embodiment 3

[0065] Embodiment 3, this embodiment is a preparation method of C / N-NiCoFeMn LDH composite electrode material, including CoC 2 O 4 ·2H 2 Preparation of O precursor and preparation of C / N-NiCoFeMn LDH composite electrode material, the specific steps are as follows:

[0066] 1) CoC 2 O 4 ·2H 2 Preparation of O precursor

[0067] (1) 3 mmol of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) was dissolved in 60 mL of ultrapure water, and stirred for 0.5 h under the condition of a water bath at 50 °C to obtain an aqueous solution of cobalt nitrate;

[0068] (2) 12 mmol of oxalic acid (H 2 C 2 O 4 ·2H 2 O) Dissolved in 60 mL of ultrapure water, under the condition of magnetic stirring at 50 °C, to obtain an oxalic acid solution, the oxalic acid solution was added dropwise to the cobalt nitrate aqueous solution at a rate of 2 drops / s, and then kept at 100 °C for 2h;

[0069] (3) the product obtained in (2) of step 1) is washed three times with ultrapure water;

[0070] (4) washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com