Patents

Literature

37 results about "Cobalt(II) oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt(II) oxalate is the inorganic compound with the formula of CoC₂O₄. Like other simple inorganic oxalates, it is a coordination polymer. The oxalate ligands bridge of Co(OH₂)₂ centres. Each cobalt adopts octahedral coordination geometry.

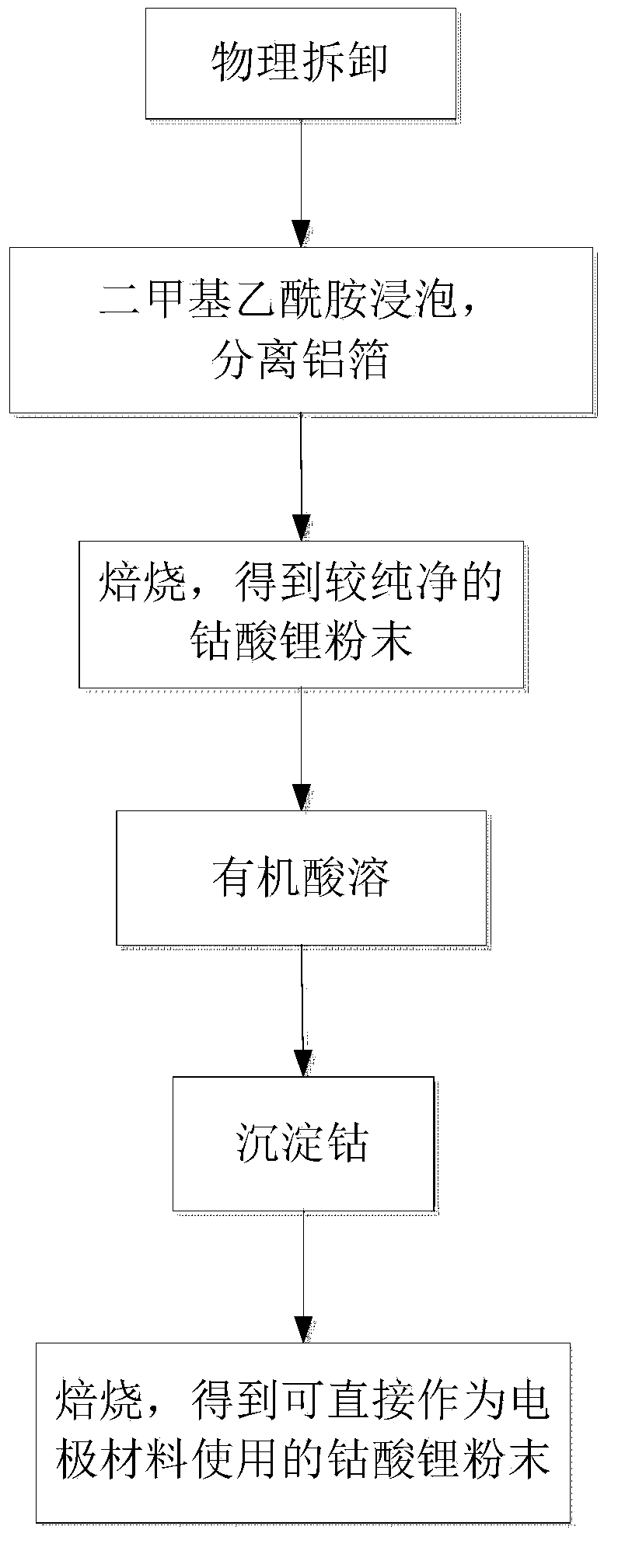

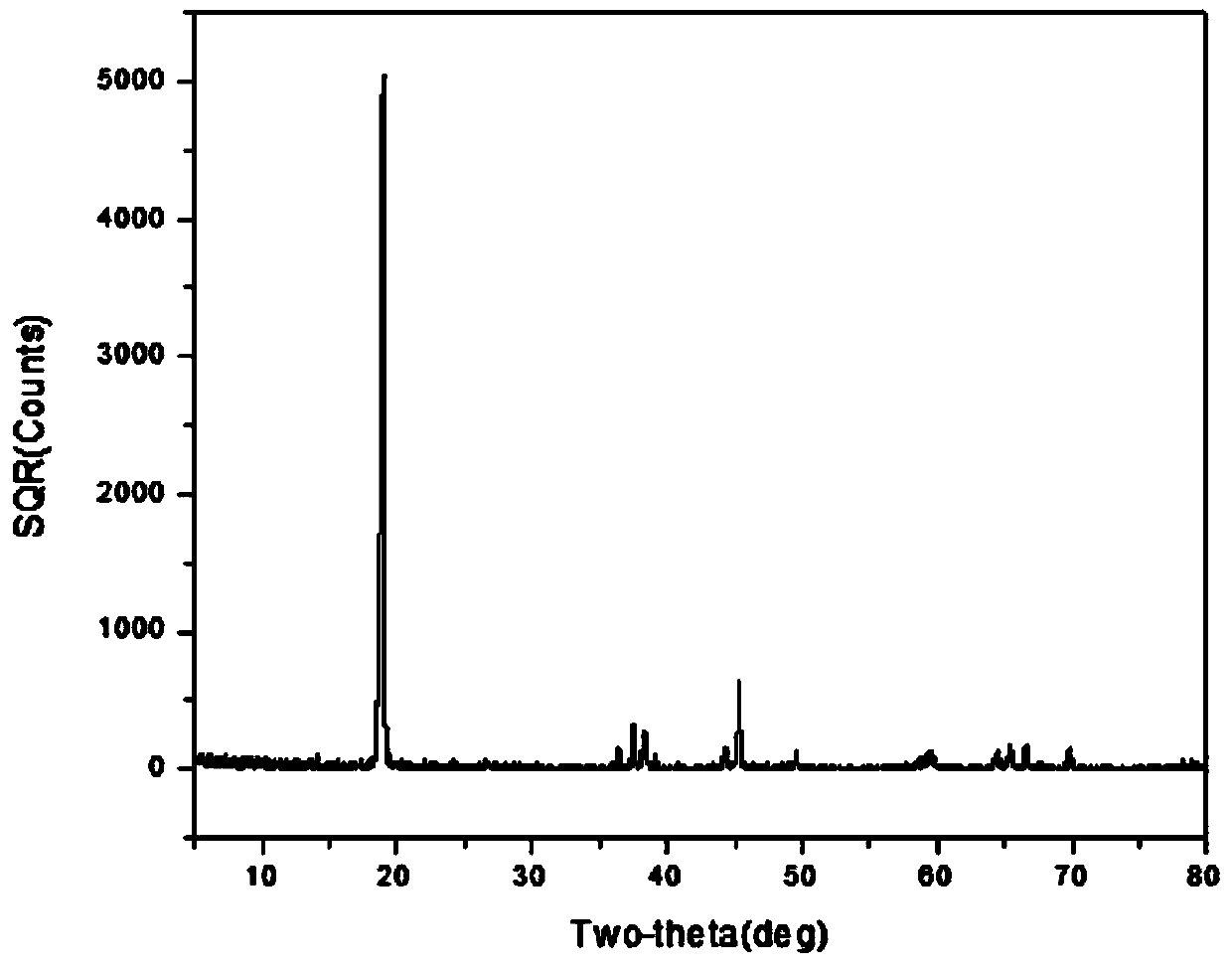

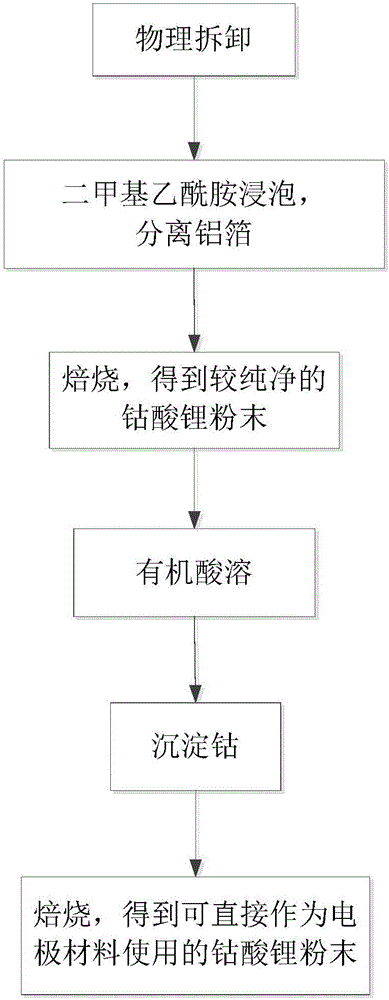

Method for recovering cobalt from lithium battery anode material

ActiveCN103474718AHigh recovery rateLow powder impurity contentWaste accumulators reclaimingBattery recyclingSolid matterAmmonium oxalate

The invention discloses a method for recovering cobalt from a lithium battery anode material. The method is characterized by comprising the following steps of: (1) removing aluminum foil from the anode material, obtaining a black solid matter containing lithium cobalt oxide, roasting the black solid matter to form lithium cobalt oxide powder, (2) weighing and adding the lithium cobalt oxide powder into 119-240g / L of citric acid according to a solid-to-liquid ratio of (20-30):1g / L, adding hydrogen peroxide at a mass fraction of 30% according to a mole ratio of 2:(1-1.05), performing stirring leaching for 5-7h at 80-90 DEG C, filtering to form filtrate containing the cobalt, (3) adding an ammonium oxalate solution into the filtrate to form a cobalt oxalate precipitate, and (4) after drying the cobalt oxalate precipitate, adding lithium carbonate powder according to a mole ratio (1:(1-1.05)) of the cobalt to lithium, grinding uniformly, roasting for 6-8h at 800-850 DEG C, and obtaining lithium cobalt oxide powder capable of directly serving as the electrode material. The method is easy to operate and high in recovery rate, equipment is simple, waste liquid is easy to treat, and the pollution of waste lithium batteries to an environment can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH WUCHANG BRANCH

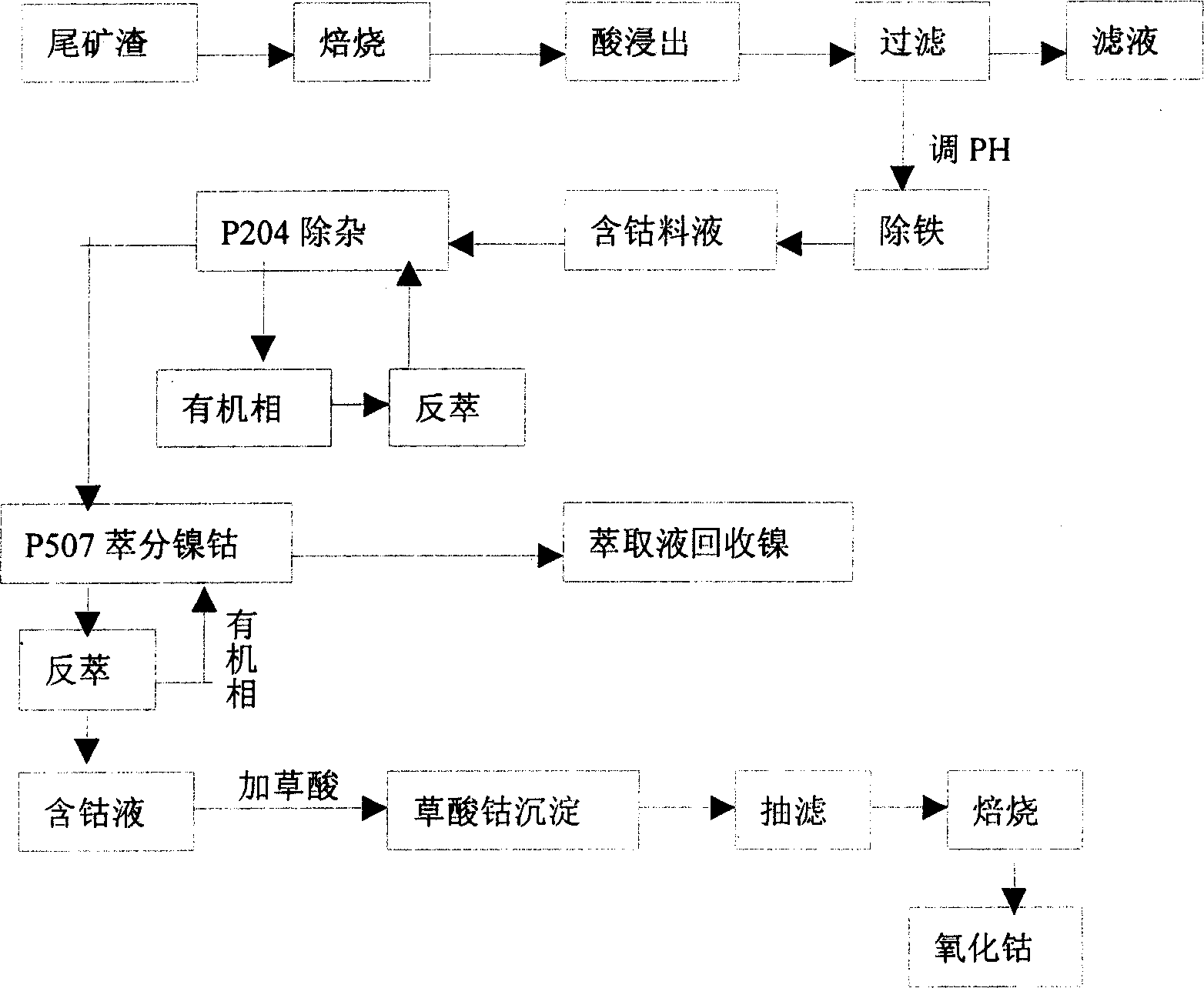

Tech. of extracting metallic cobait from magnetic-iron ore tailing slag

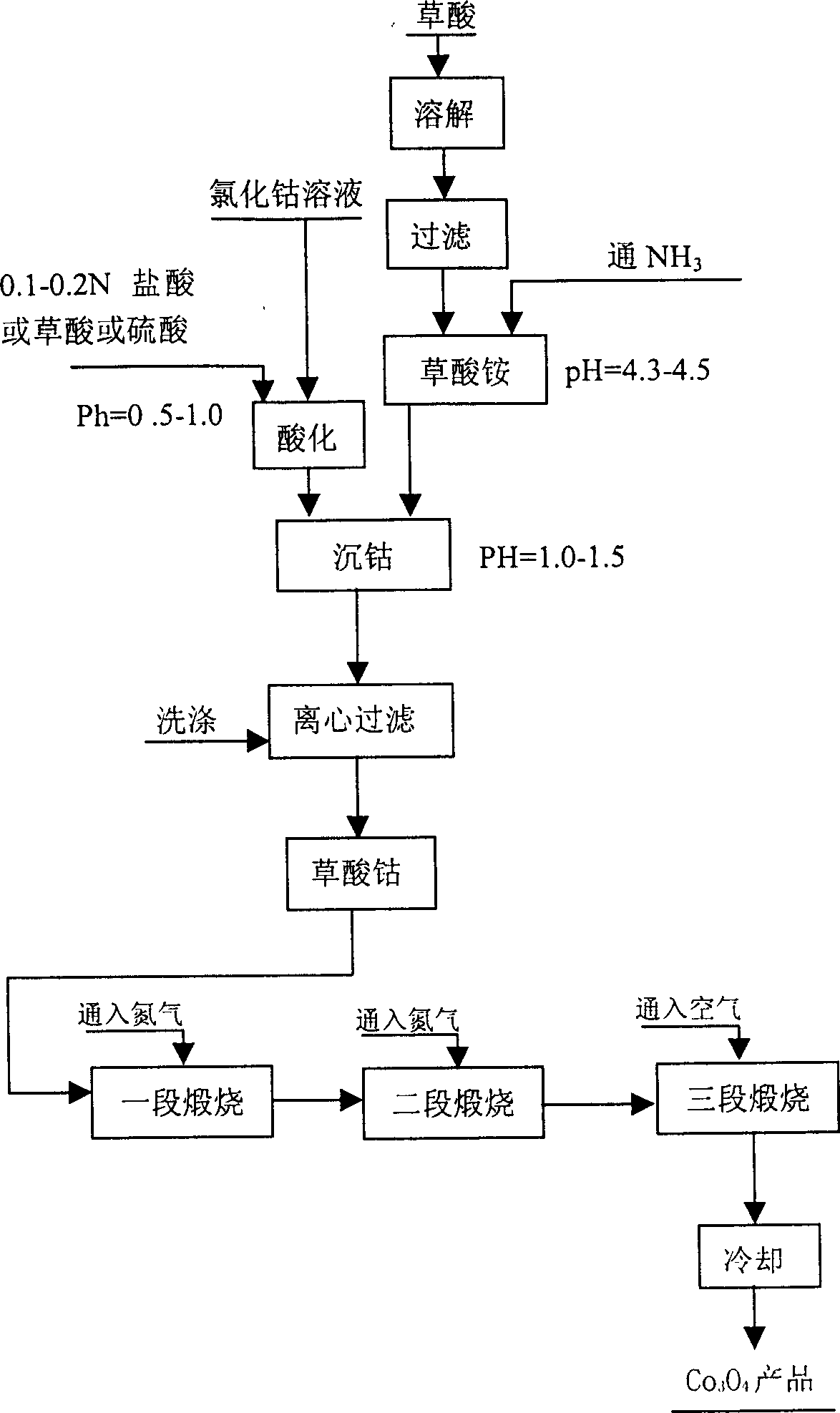

This invention discloses a technology to extract the cobalt from the tailing of magnetic iron ore. Its characteristics are as follows: (1) calcining the pretreatment magnetic iron ore at high temperature, (2) prophyrizing the magnetic iron ore which is handed as (1), (3) extracting the ore by sulfuric acid, (4) eliminating the rare-earth, iron, calcium and magnesium by chemical neutralization, (5) eliminating the copper, manganese, zinc and other substance with extraction reagent P204, then we can get cobalt solution by separating nickel and cobalt with extraction P507, (6)back-extracting, (7)depositing the cobalt with ammonium oxalate, (8) calcining the ammonium oxalate to high lever cobalt dioxide. The quality of cobalt dioxide recovered by this way can achieve to the lever of international Y0, the recovery ratio of cobalt can be above 85%.

Owner:HENAN UNIV OF SCI & TECH

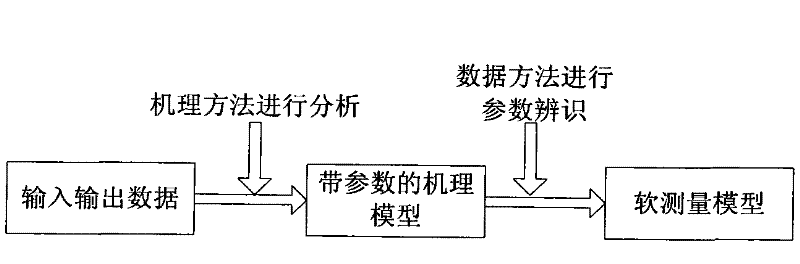

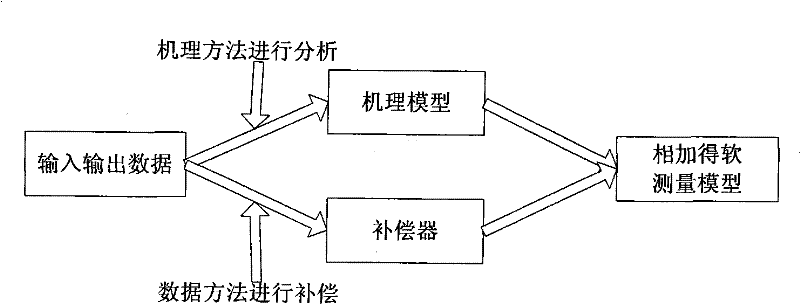

Cobalt oxalate coarseness prediction technique in hydrometallurgy synthesis course

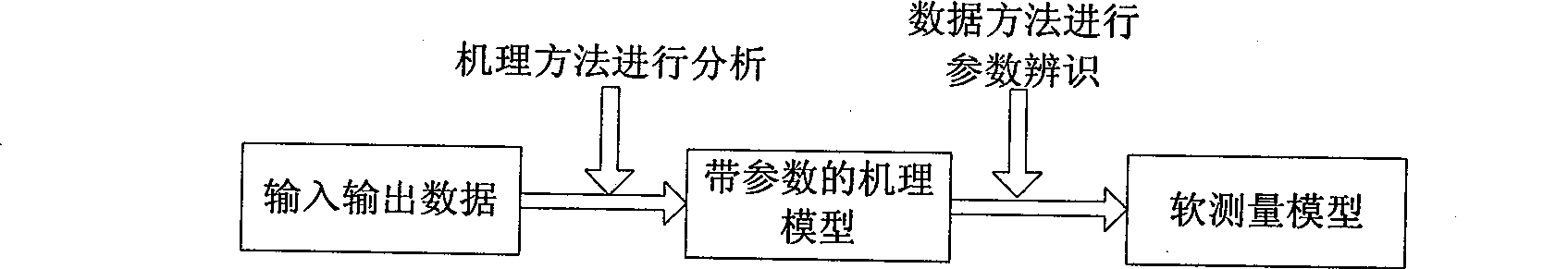

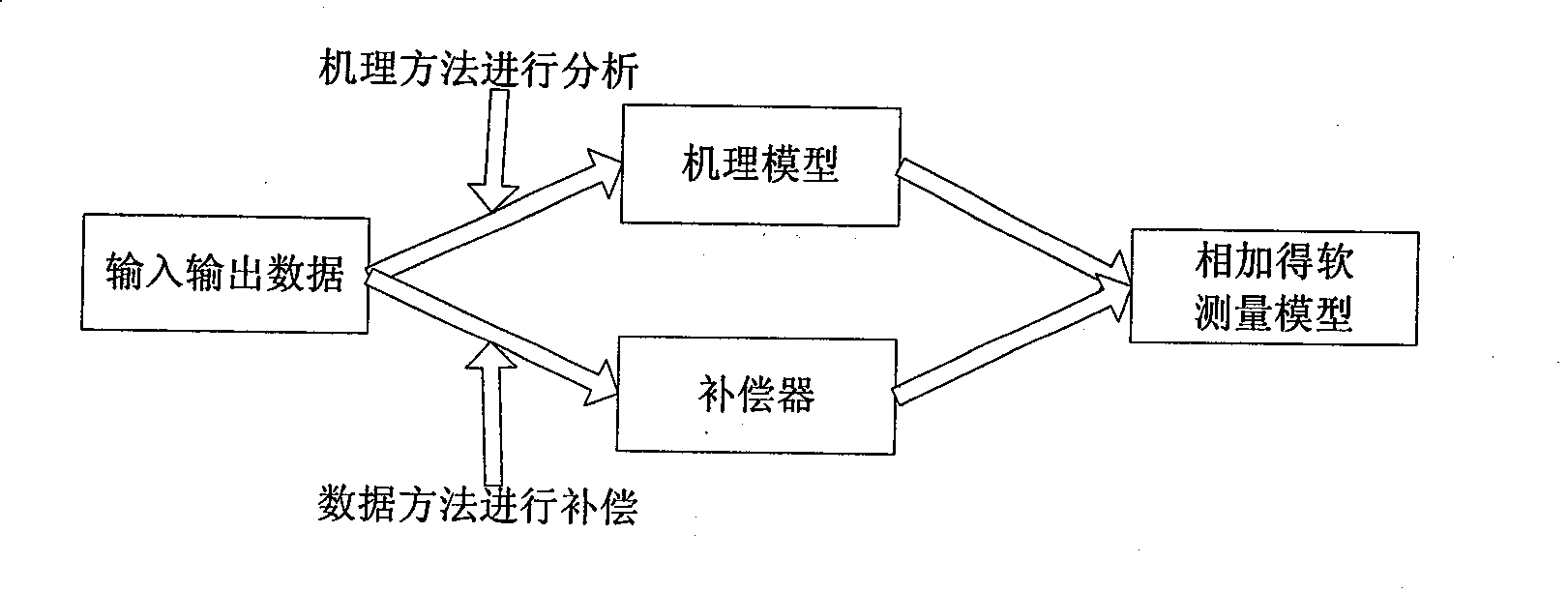

InactiveCN101482750AComplex process monitoringImplement inputOrganic chemistryTotal factory controlSoftware systemPredictive methods

The present invention provides a cobalt oxalate granularity real-time prediction method in hydrometallurgy synthesis process. The method comprises the steps of data collecting, auxiliary variable selecting, standardized processing, hybrid model establishing, etc. The invention is characterized in that a parallel-connected structure hybrid model composed based on mechanism model and based on data driving model is established. A genetic algorithm is adopted for confirming the related model parameter in the mechanism model. A model based on data driving is used as an error compensating model of mechanism model. The invention also provides a software system which actualizes the cobalt oxalate granularity prediction. The software system comprises a main program, a database and a human-machine interaction interface. The system software uses a microcomputer of hydrometallurgy synthesis process control system as a hardware platform. When the cobalt oxalate granularity real-time prediction method is used for the cobalt oxalate synthesis process of a certain hydrometallurgy factory for predicting the granularity of cobalt oxalate, the prediction result is in the preset error range. The cobalt oxalate granularity real-time prediction method according to the invention has the advantages of simple model, strong interpretability, good extrapolation property and higher prediction precision.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

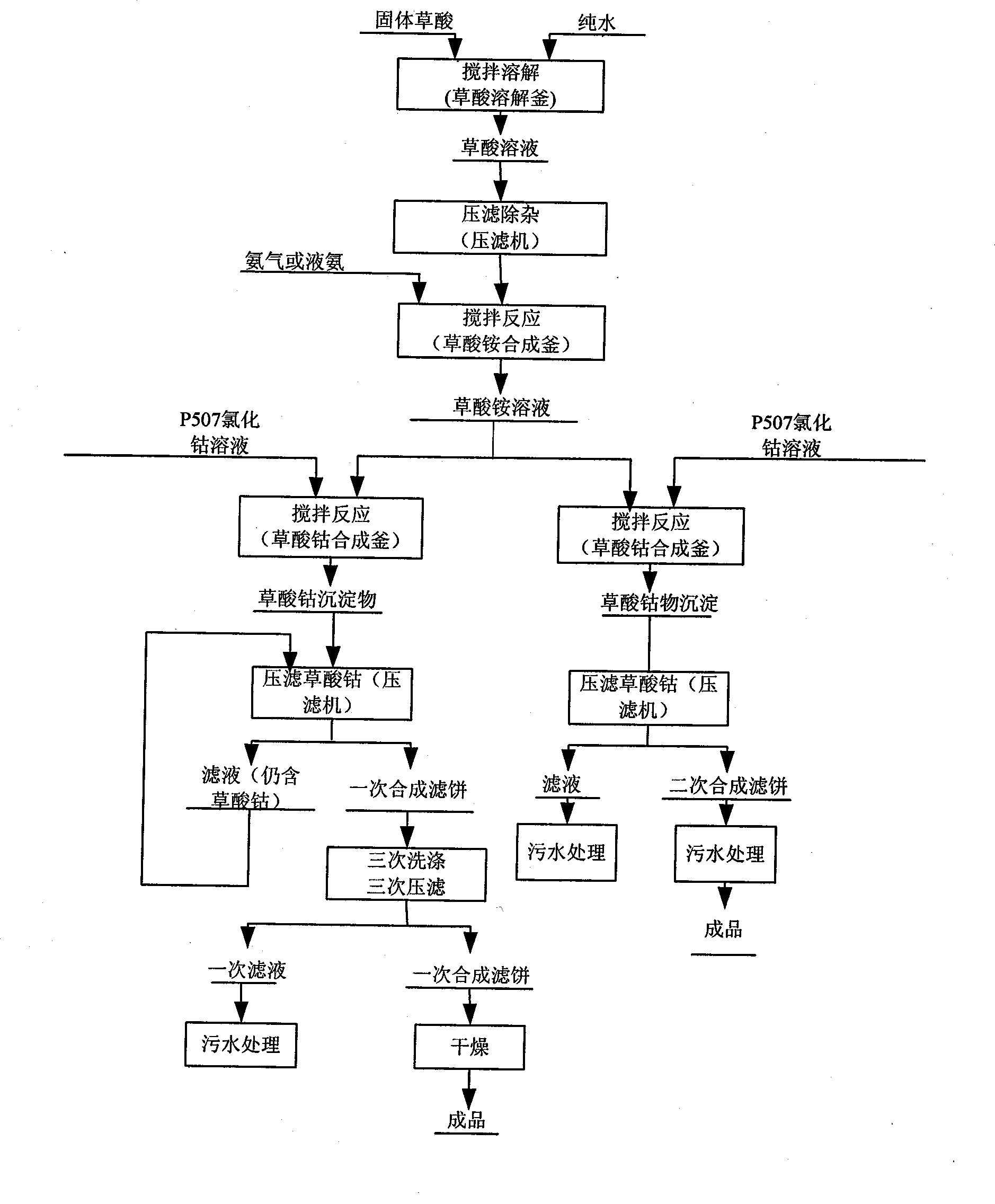

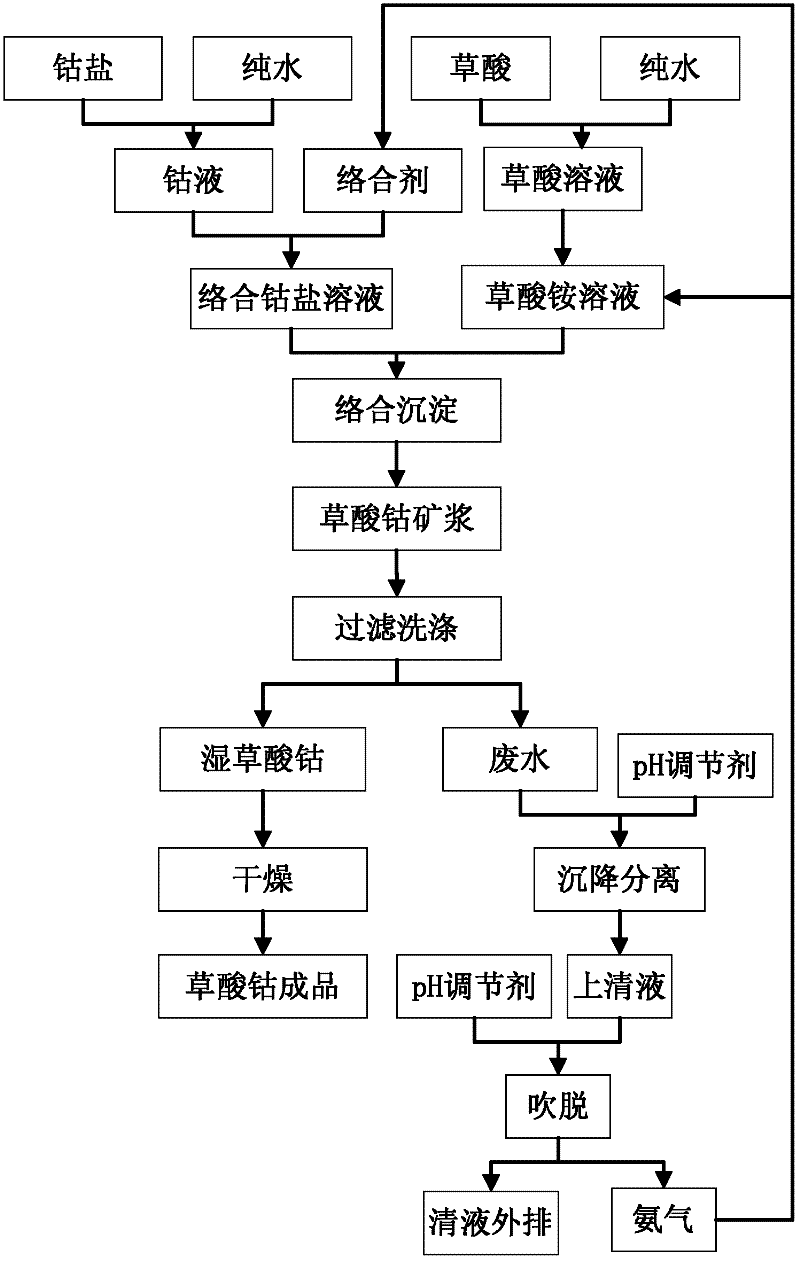

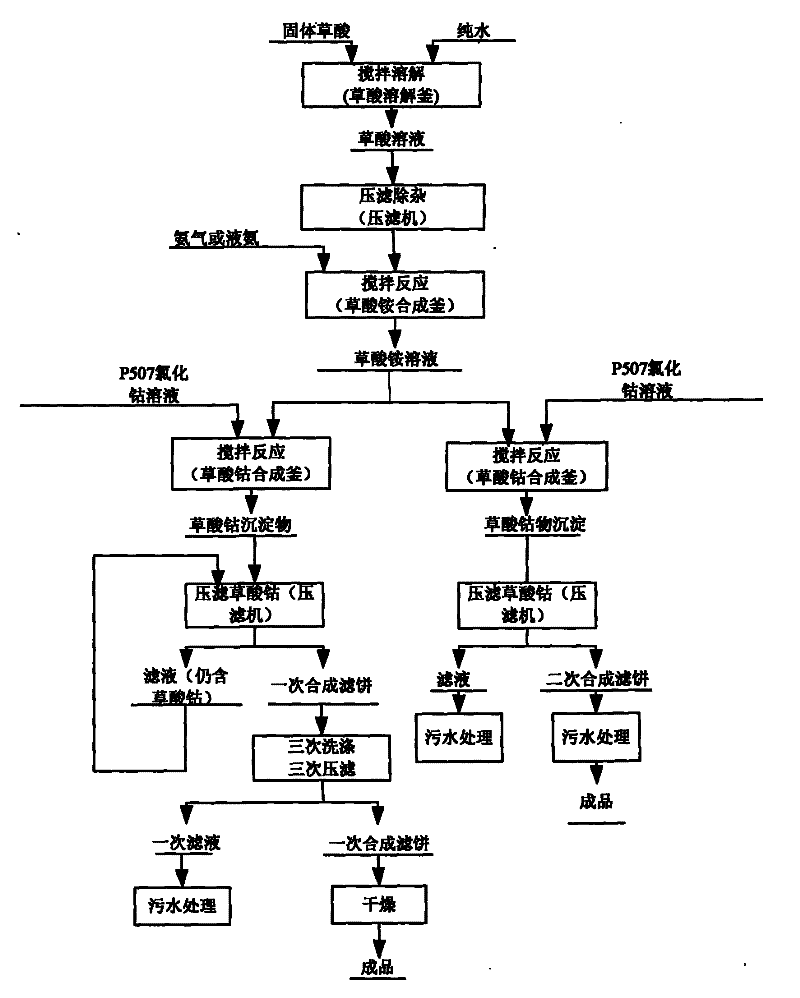

Ammonia circulative preparation method for cobaltous oxalate

InactiveCN102381958AShape is easy to controlGranularity controllableCarboxylic acid salt preparationOXALIC ACID DIHYDRATEAmmoniacal nitrogen

The invention relates to an ammonia circulative preparation method for cobaltous oxalate. In the current commonest liquid phase precipitation method, because ammonium salt is introduced in the reaction process and the amount of oxalic acid is excessive during the reaction, impurities like ammonia nitrogen and oxalic acid root in synthesized waste water are required for processing. According to the invention, cobalt liquid is taken as a raw material, an oxalic acid solution is used for absorbing ammonia gas to prepare an ammonium oxalate solution which can be taken as an auxiliary material, cobalt liquid and the ammonium oxalate solution are added in a reaction vessel for synthesizing to obtain cobaltous oxalate pulp, the cobaltous oxalate pulp is filtered and washed, and dried to obtain the cobaltous oxalate product; simultaneously, waste water after filtering and washing is carried out pH regulation, ammonia molecule is separated from waste water by using an air stripping method, the oxalic acid solution is absorbed to be the ammonium oxalate solution for realizing the ammonia circulative utilization. The preparation method of the invention has the advantages that ammonia circulative utilization is realized, the waste water treatment avoids the introduction of ammonium salt and ammonia nitrogen, the production cost is reduced and the circular economy is realized.

Owner:ZHEJIANG HUAYOU COBALT

Recycling method of samarium cobalt magnetic waste material

InactiveCN103555950AEasy extractionSimple processRare earth metal compoundsProcess efficiency improvementOXALIC ACID DIHYDRATERare-earth element

The invention relates to a recycling method of a samarium cobalt magnetic waste material. The method is characterized by comprising the steps of: a, leaching a samarium cobalt waste material with dilute hydrochloric acid, and after the complete reaction, filtering to remove substances insoluble in acid; b, regulating pH of a leaching solution, precipitating rare earth elements in the solution with oxalic acid to generate a grey and white oxalate precipitate, filtering, drying and calcining the precipitate to obtain solid samarium oxide; c, precipitating samarium, oxidizing Fe<2+> into Fe<3+> in a filtrate by an oxidant, regulating the pH value to precipitate iron in the solution before cobalt, and filtering; and d, removing iron, adjusting the pH value of filtrate, adding oxalic acid to obtain a cobalt oxalate precipitate, and conducting filtration, drying and calcination to obtain cobalt oxide. The method has the following advantages: hydrochloric acid optimal solution, oxalic acid precipitation, iron removal by oxidation and calcination method are employed according to the chemical properties of the elements contained in the waste material, so as to successfully extract valuable elements in the samarium cobalt in waste material; the recycling process is simple in process and low in production cost and the does not produce secondary pollution of the environment; and the prepared samarium oxide and cobalt oxide products have high extraction rate.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

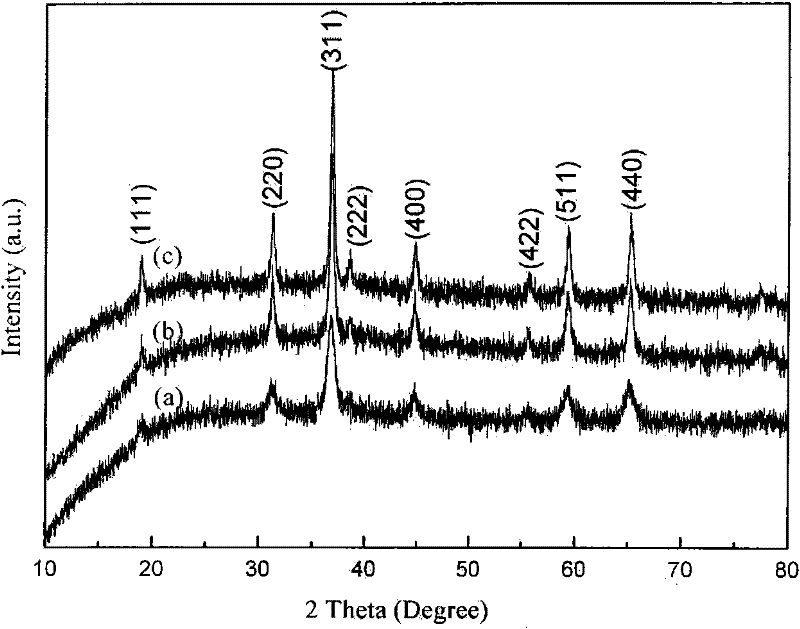

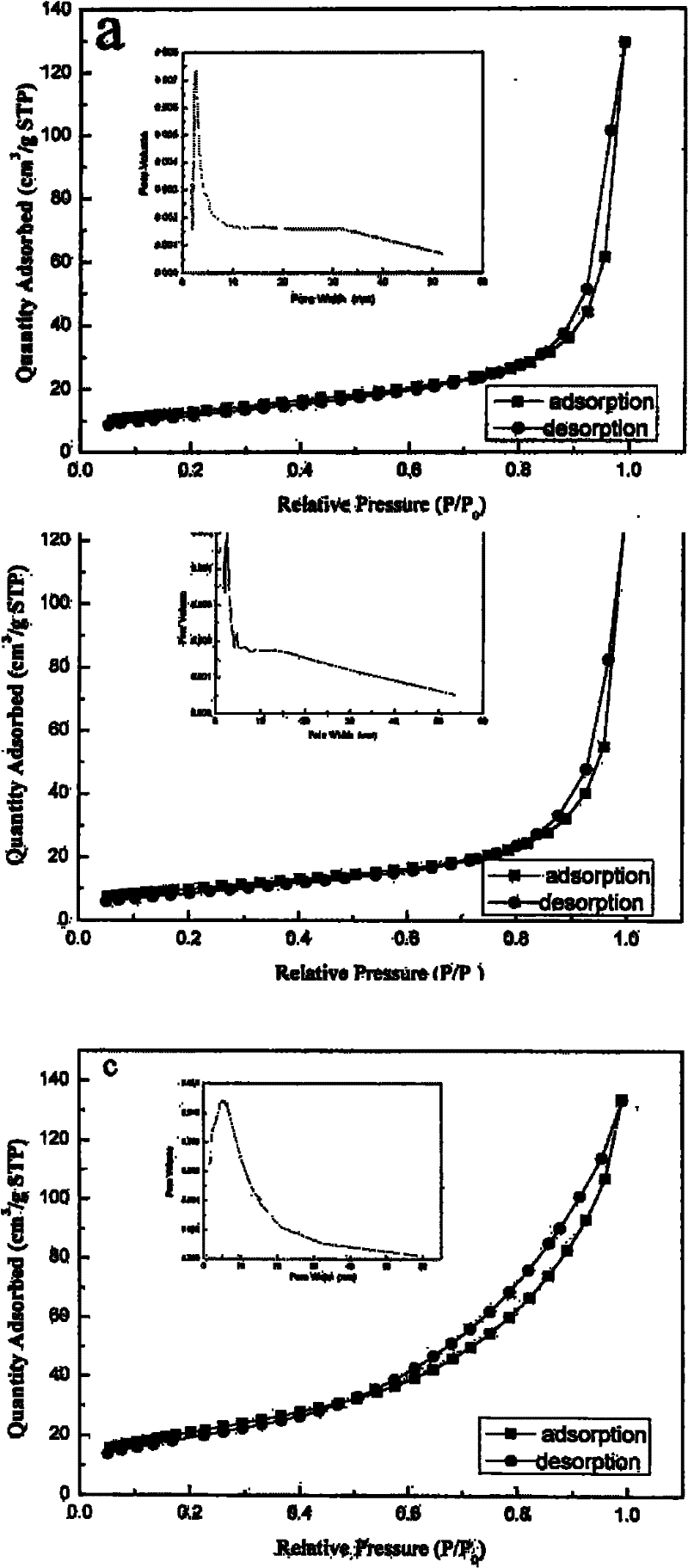

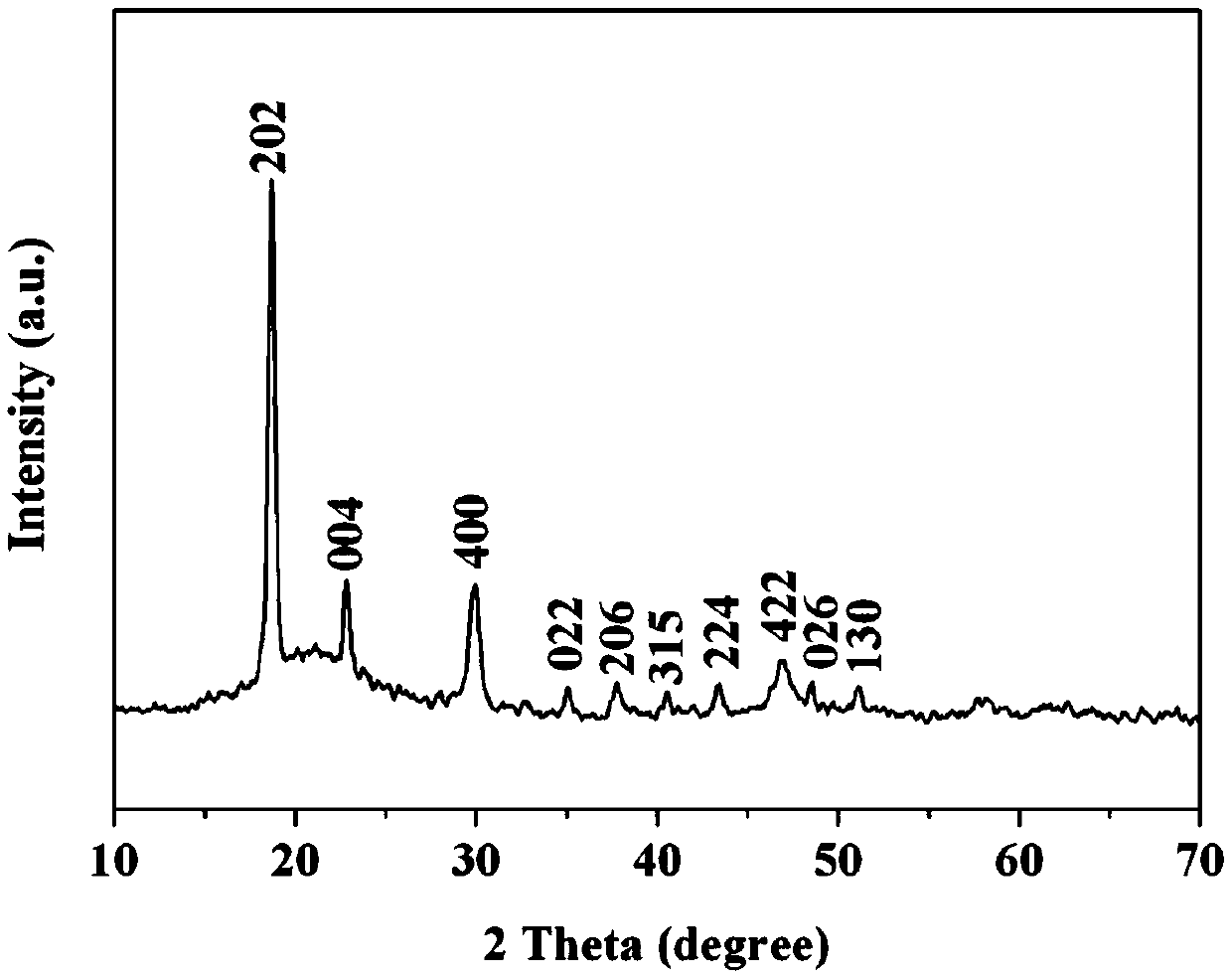

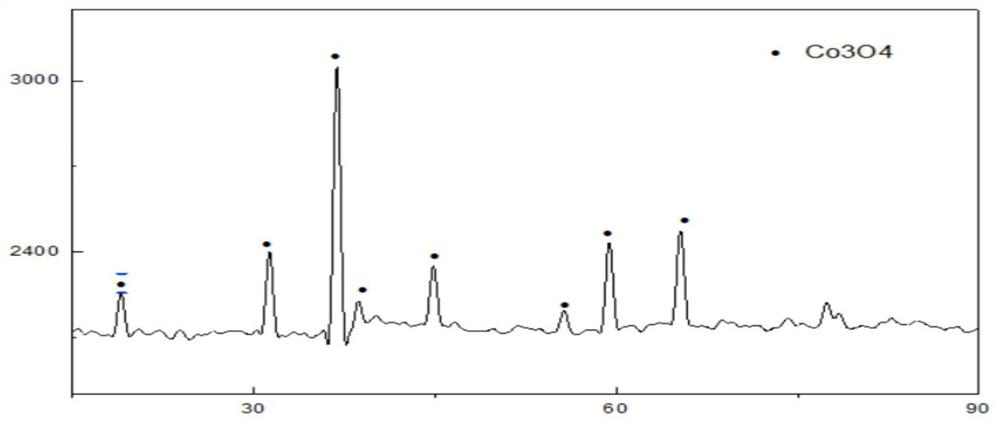

Cobaltosic oxide preparation method

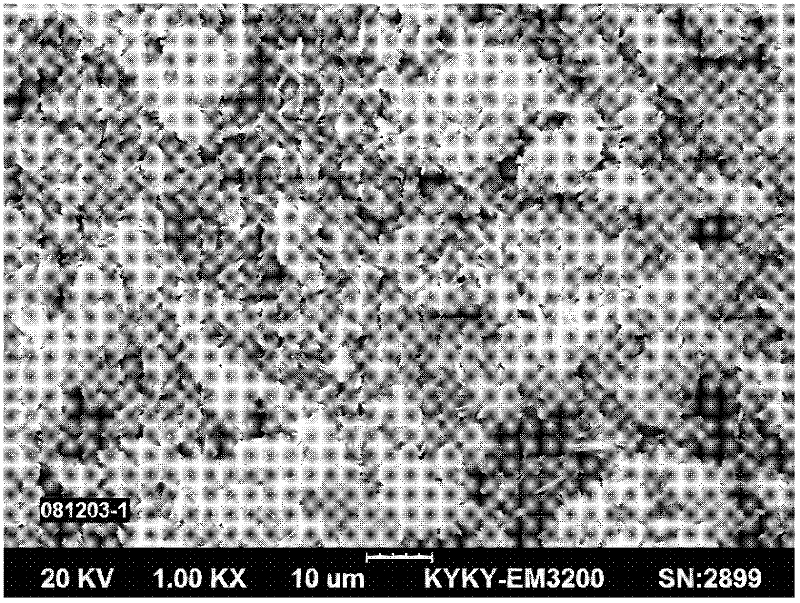

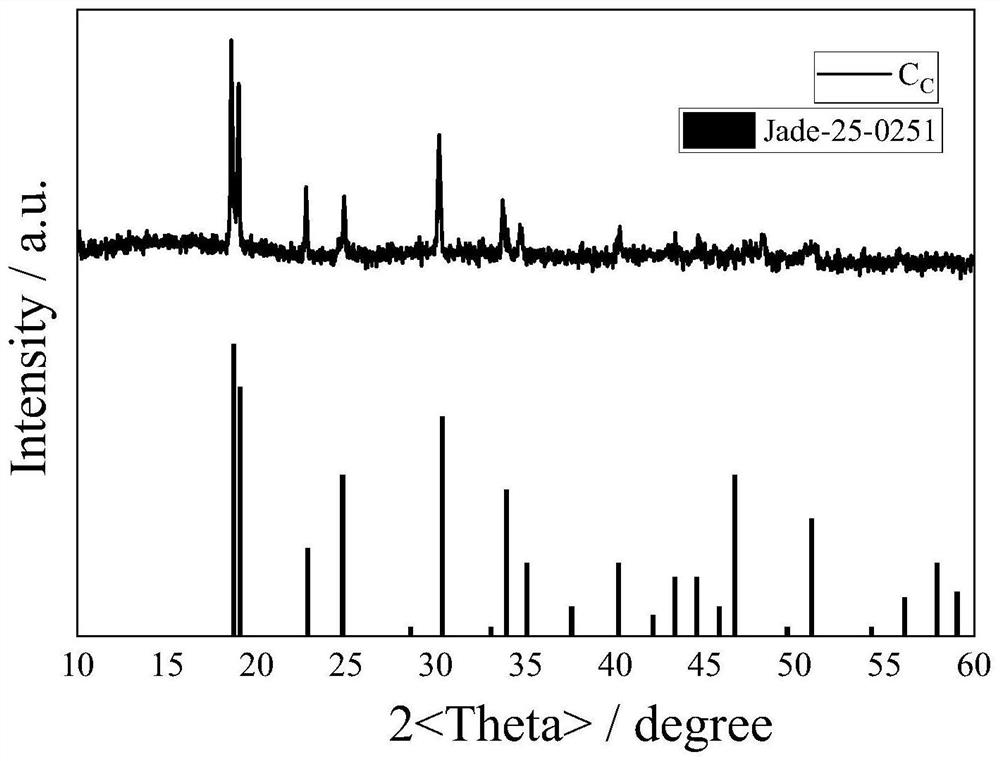

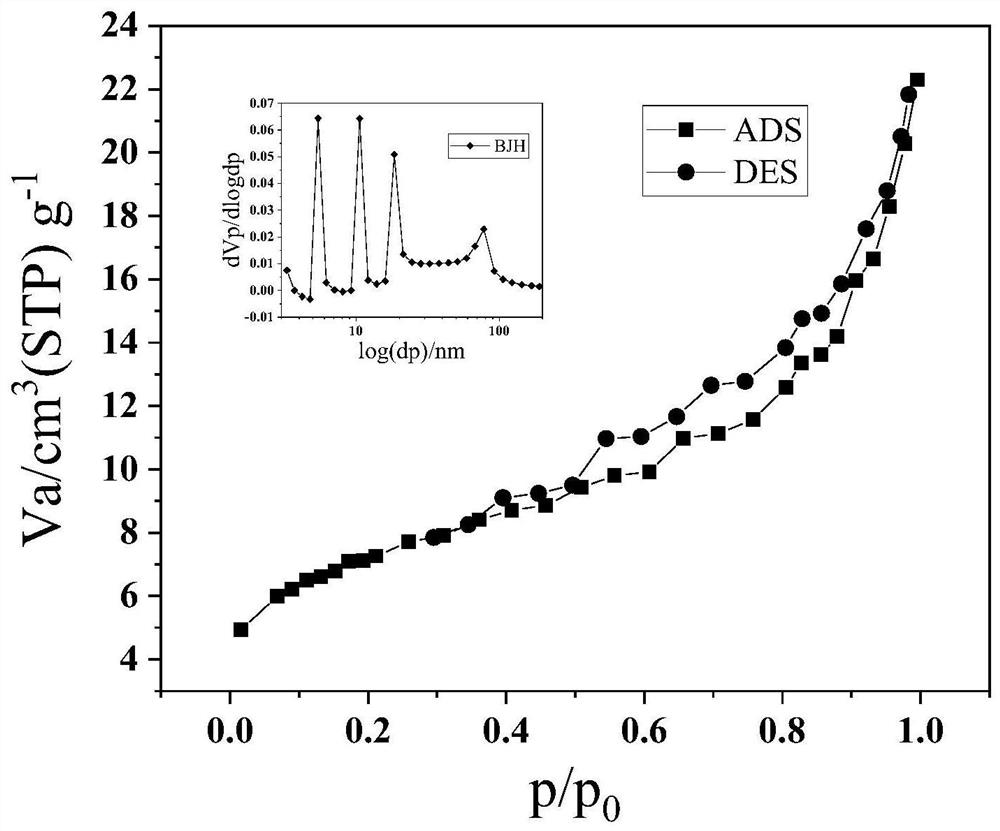

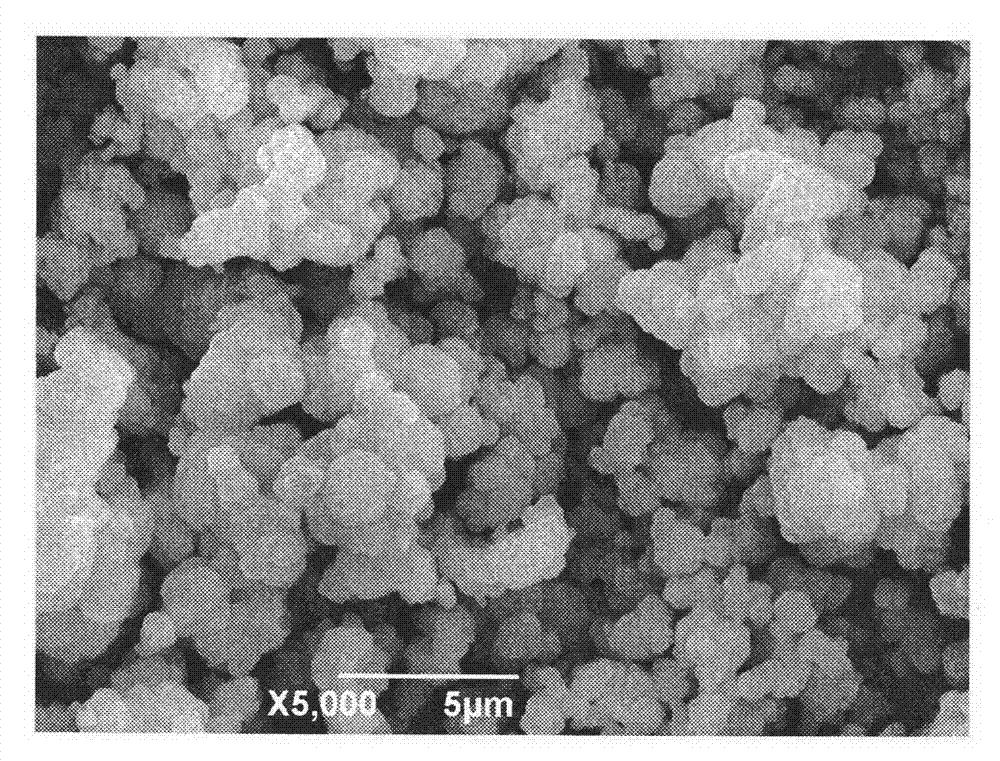

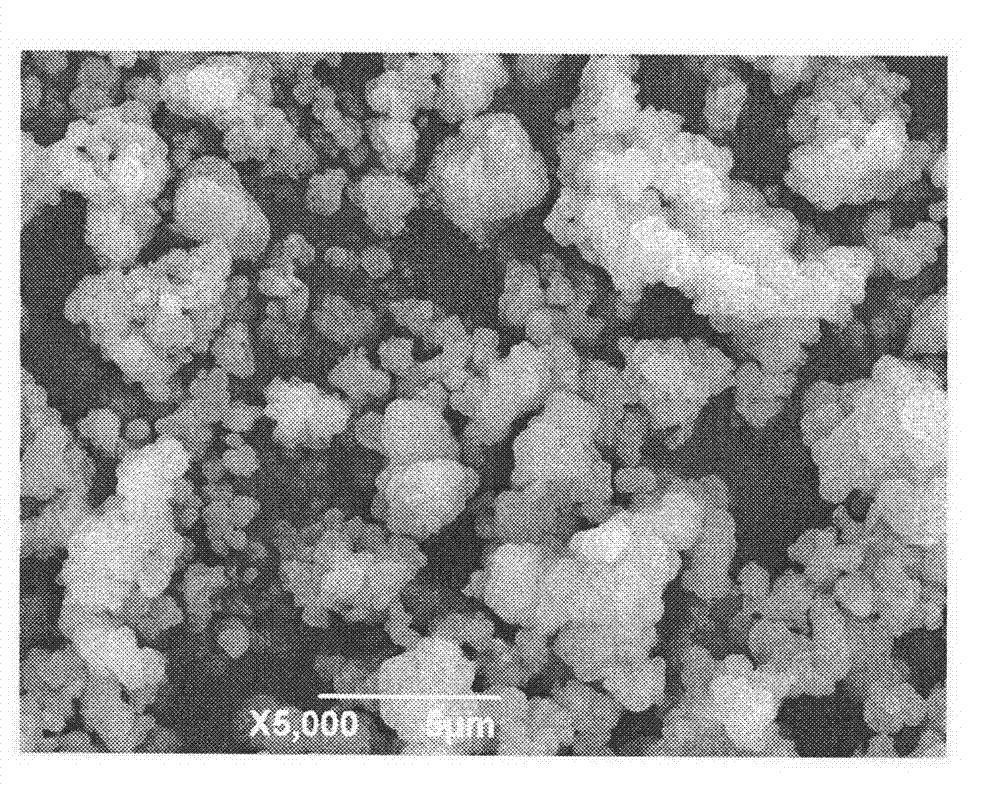

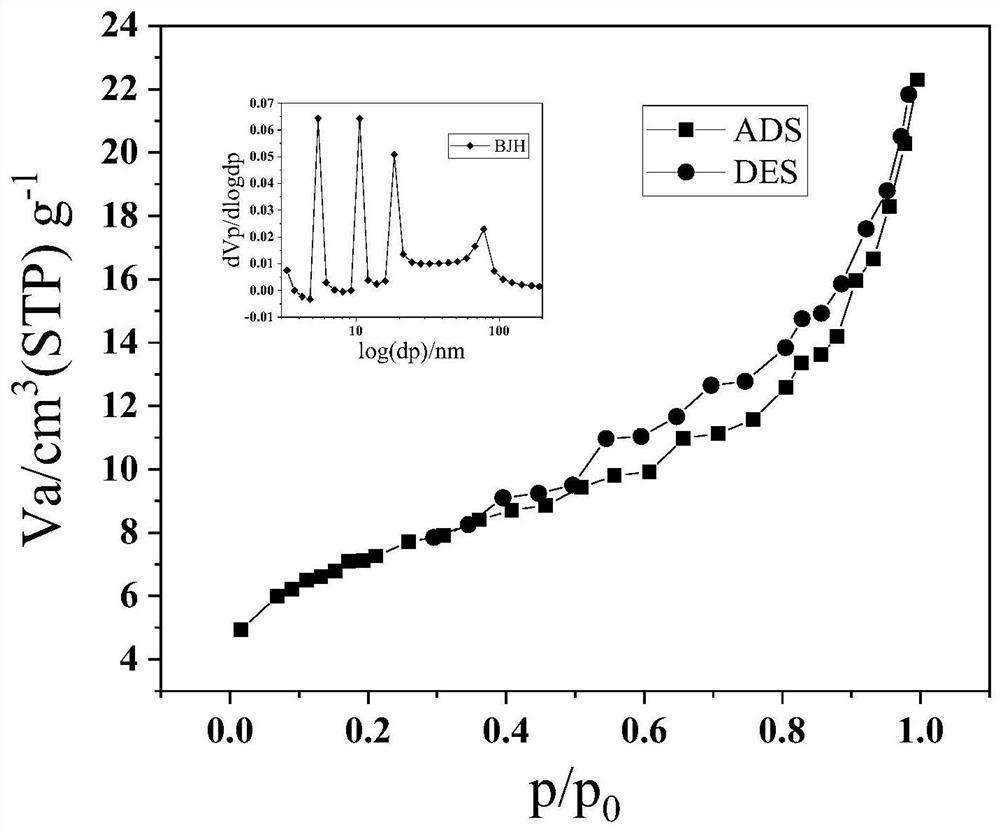

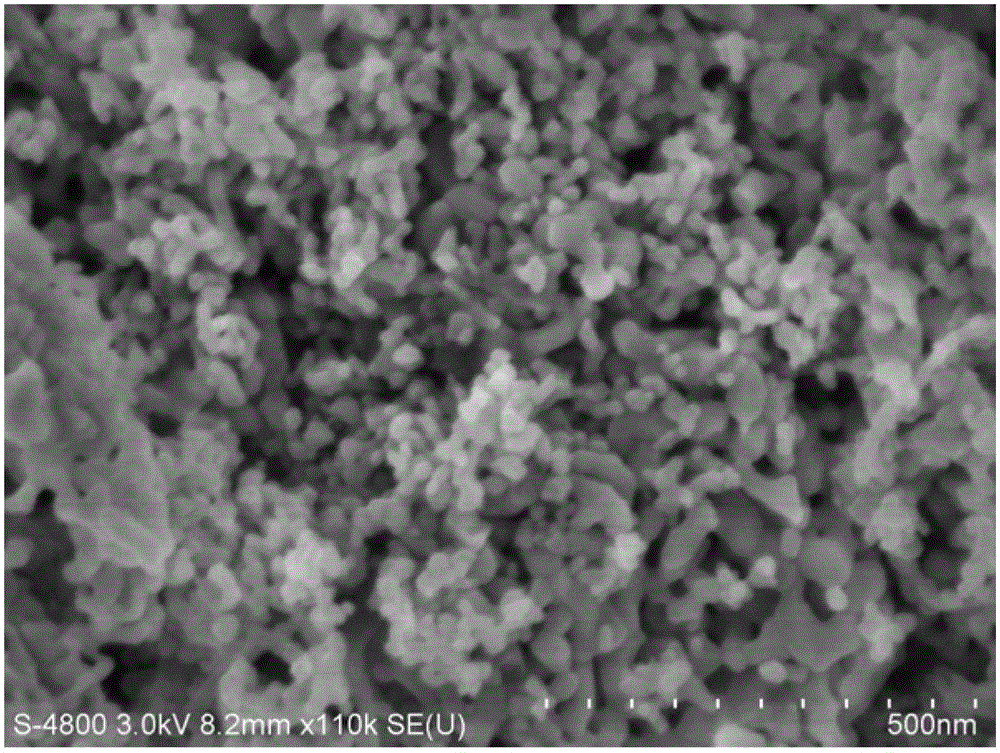

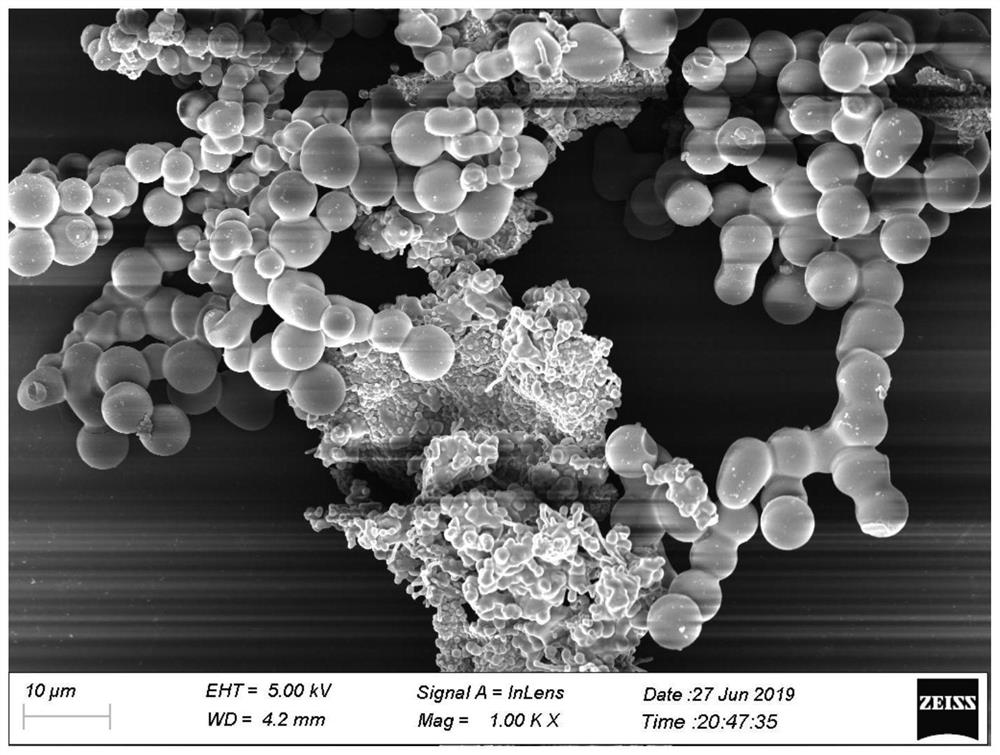

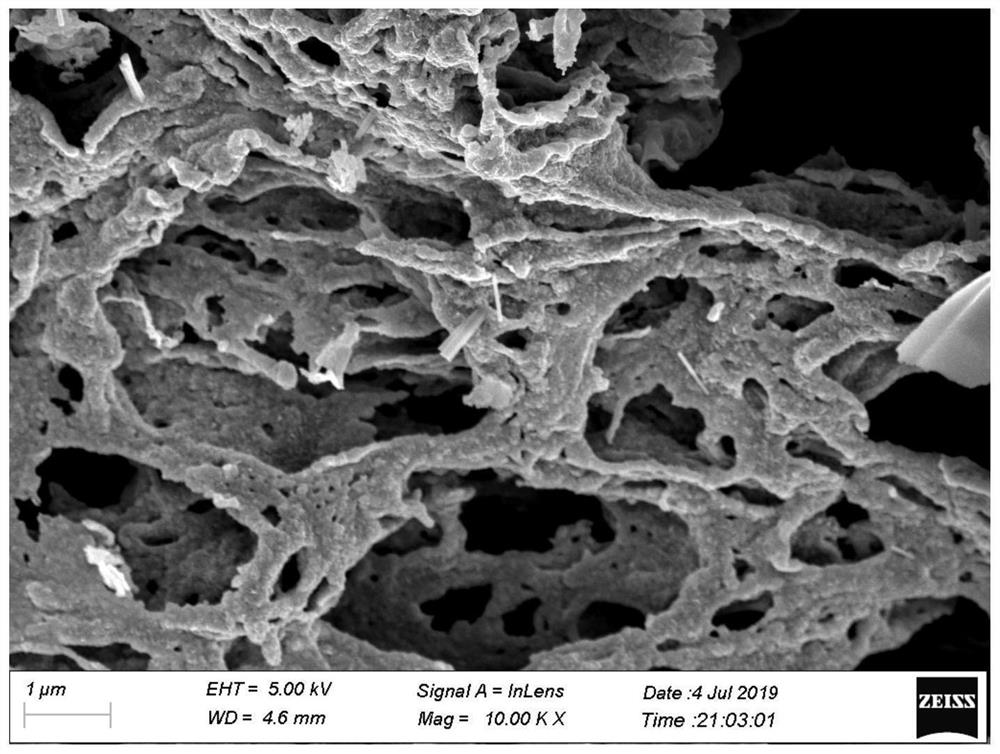

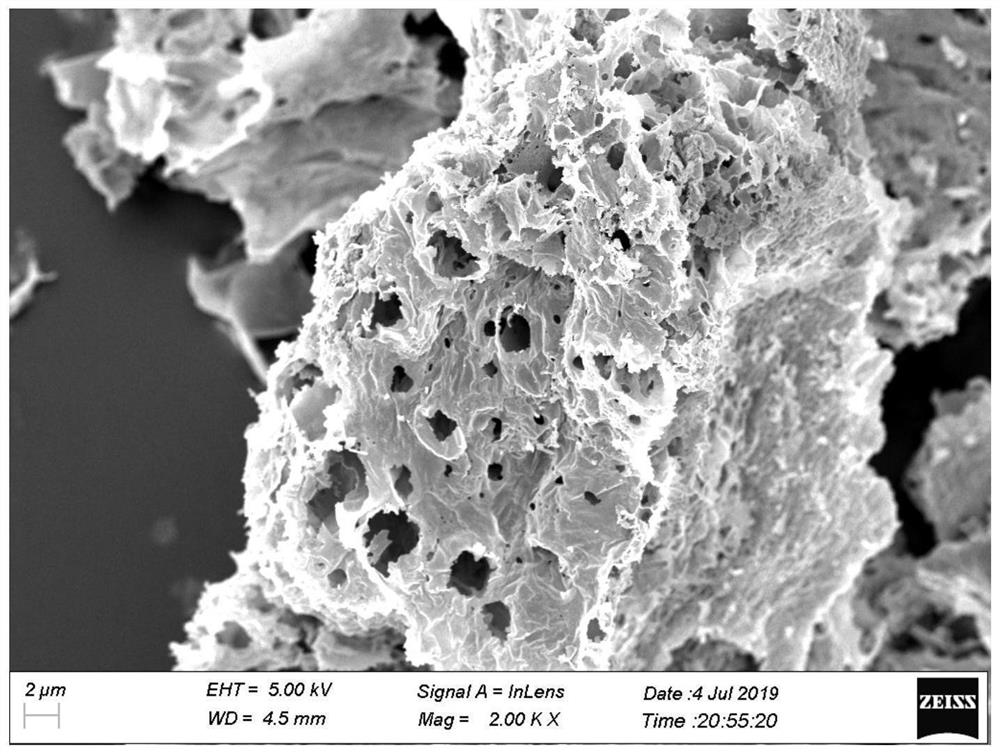

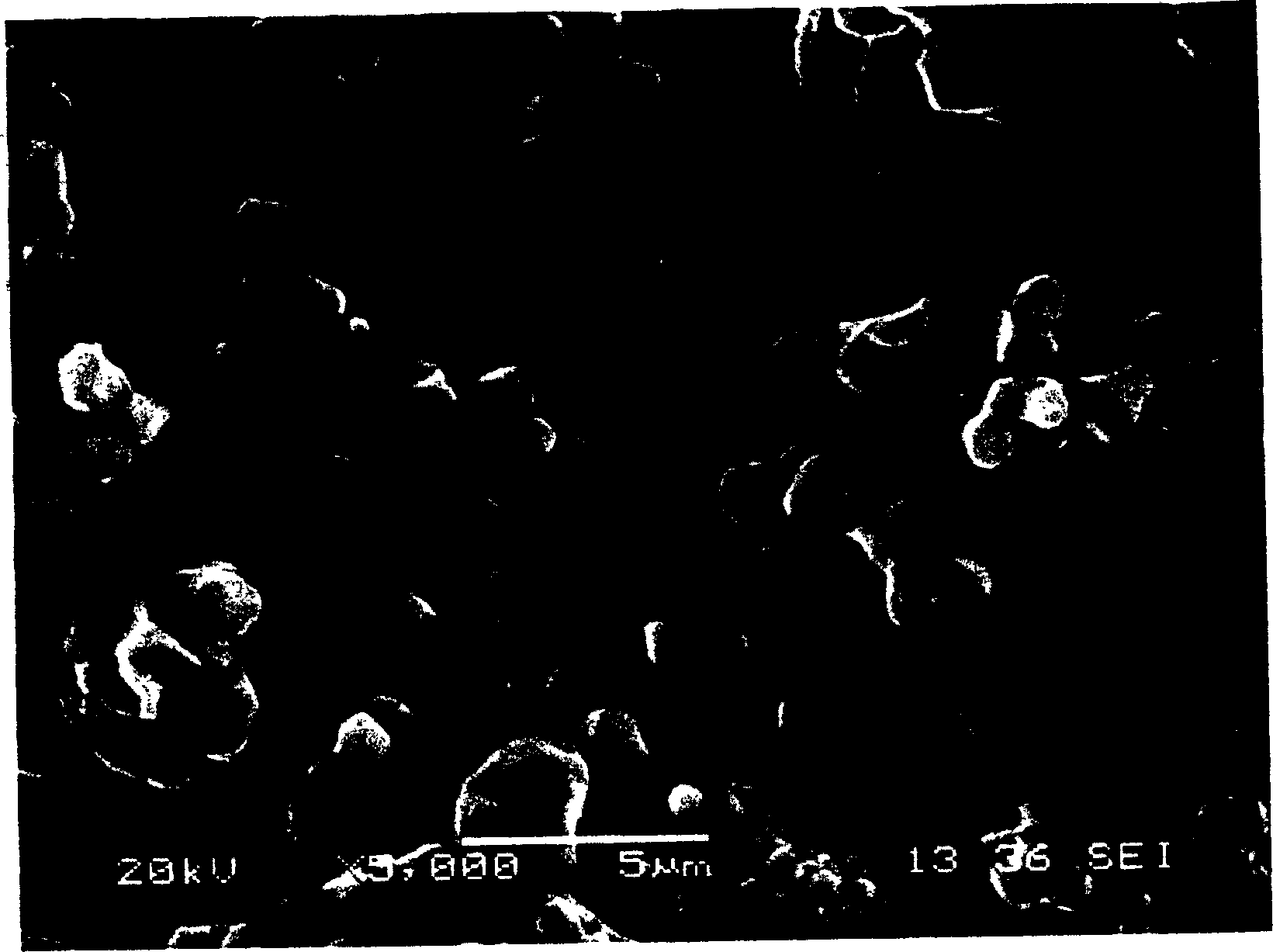

InactiveCN102476832ALarge specific surface areaShape is easy to controlCobalt oxides/hydroxidesNano structuringCobalt(II,III) oxide

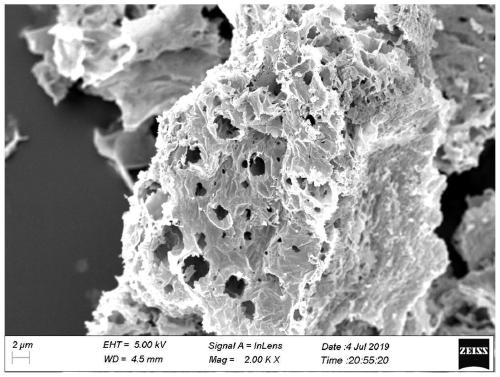

The invention discloses a cobaltosic oxide preparation method. Hydrate cobalt oxalate with an excellent crystal form is prepared at first and used as precursor, and small H2O and CO2 gas molecules are released by controlling a roasting process, so that a cobaltosic oxide nano structure with narrow pore size distribution, high specific surface area and controllable texture is obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

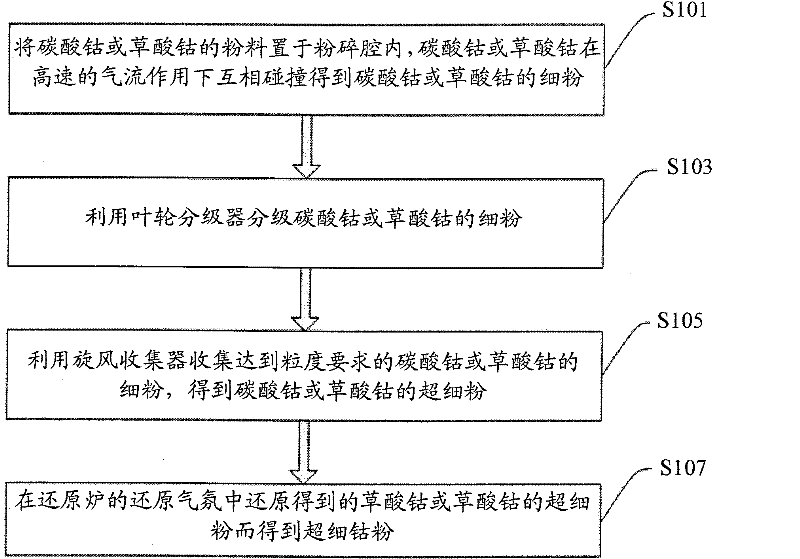

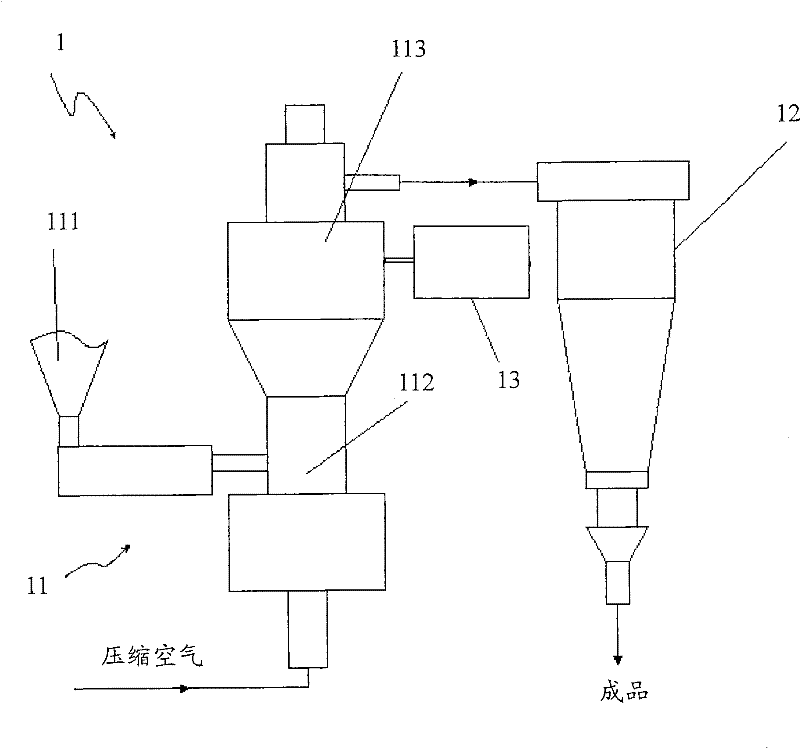

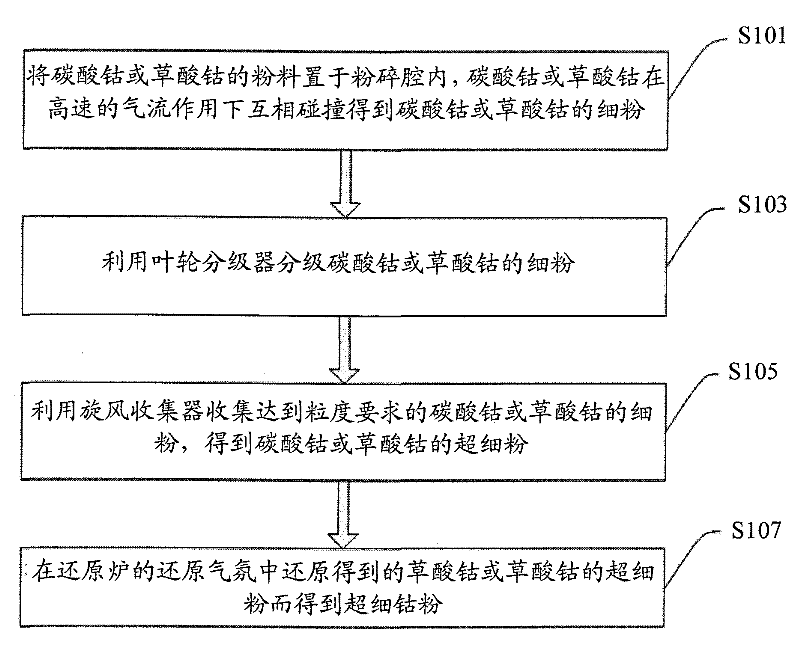

Method for preparing super-fine cobalt powder

The invention provides a method for preparing super-fine cobalt powder which comprises the steps as follows: A) powder of cobalt carbonate or cobalt oxalate is placed in a crushing chamber; the powderof cobalt carbonate or cobalt oxalate is crushed under the action of high-speed airflow, thereby obtaining fine powder of cobalt carbonate or cobalt oxalate; B) the fine powder of cobalt carbonate orcobalt oxalate is graded by a blade grader, so as to facilitate the fine powder of cobalt carbonate or cobalt oxalate with required granularity to go through and the fine powder of cobalt carbonate or cobalt oxalate without required granularity to be retained in an airflow crusher and further crushed; C) the fine powder of cobalt carbonate or cobalt oxalate with required granularity is collectedby a cyclone collector, thereby obtaining the super-fine powder of cobalt carbonate or cobalt oxalate; and D) the obtained super-fine powder of cobalt carbonate or cobalt oxalate is reduced under reducing atmosphere in a reducing furnace. The method for preparing super-fine cobalt powder by super-fine powder of cobalt carbonate or cobalt oxalate, which is obtained by the airflow crusher, has simple operation, profitably improved production efficiency and reduced production cost, so that the method satisfies economic benefit.

Owner:NANJING HANRUI COBALT

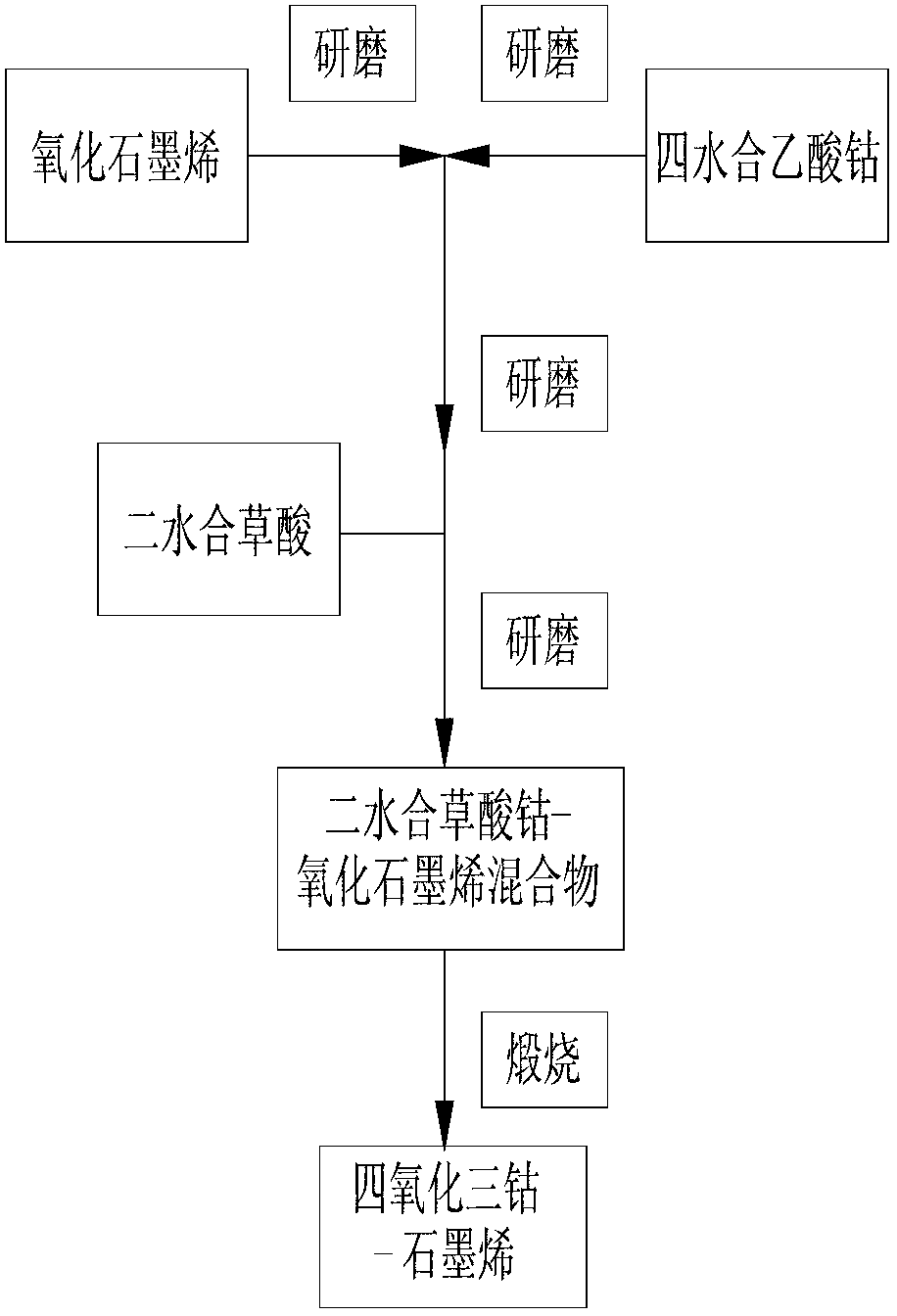

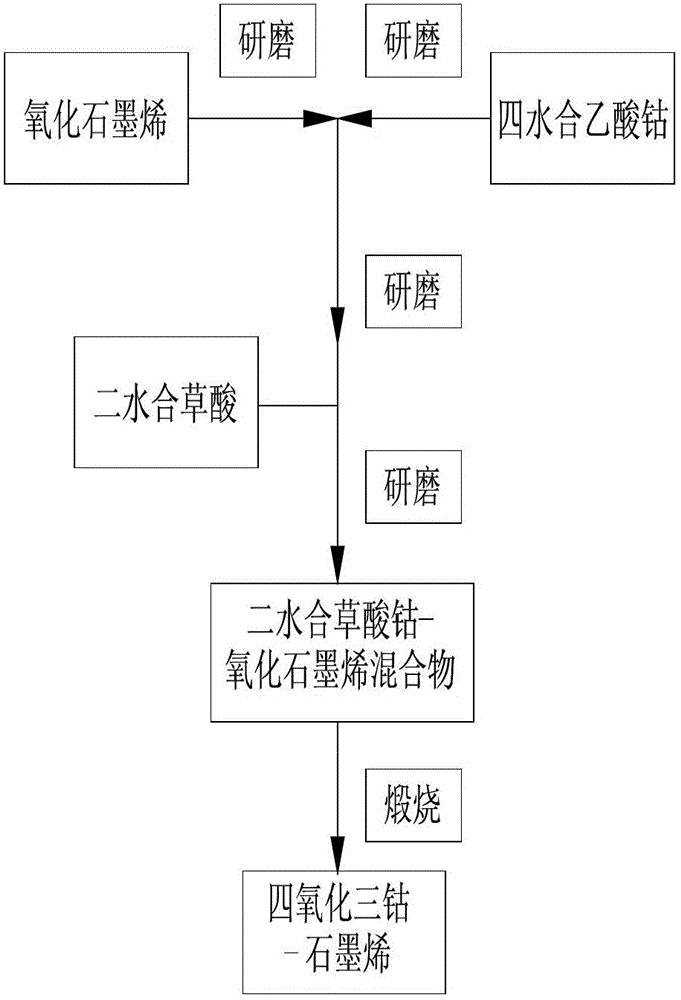

Preparation method based on solid-phase reaction for capacitor electrode material

ActiveCN103274481AInhibit side effectsHigh yieldHybrid capacitor electrodesCobalt oxides/hydroxidesCapacitanceHexamethylenetetramine

The invention discloses a preparation method based on a solid-phase reaction for a capacitor electrode material. The preparation method comprises the following steps of: 1) adequately mixing and grinding cobalt acetate, oxalic acid and oxidized graphene to obtain an cobalt oxalate-oxidized graphene mixture; and 2) calcining the cobalt oxalate-oxidized graphene mixture aforementioned to obtain a cobaltosic oxide-graphene electrode material, wherein the dosage ratio by mole of cobalt acetate to oxalic acid is 1: 1, and the dosage of oxidized graphene is 5-30% of the mass of the finally obtained cobaltosic oxide; additionally, the selected ligand can also be citric acid and hexamethylenetetramine except oxalic acid; a solvent is not used in the solid-phase reaction of the preparation method disclosed by the invention, so that the side reactions generated in a water-phase reaction are avoided, the yield and the purity are increased, the reaction conditions are easy to control, and the operation is simple and practicable; and moreover, via the introduction of the graphene material, a novel way is provided for an oxide material with bad electrical conductivity, good energy storage property, and high theoretical specific capacitance in the field of capacitors, and the graphene material has important theoretical and practical application significance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

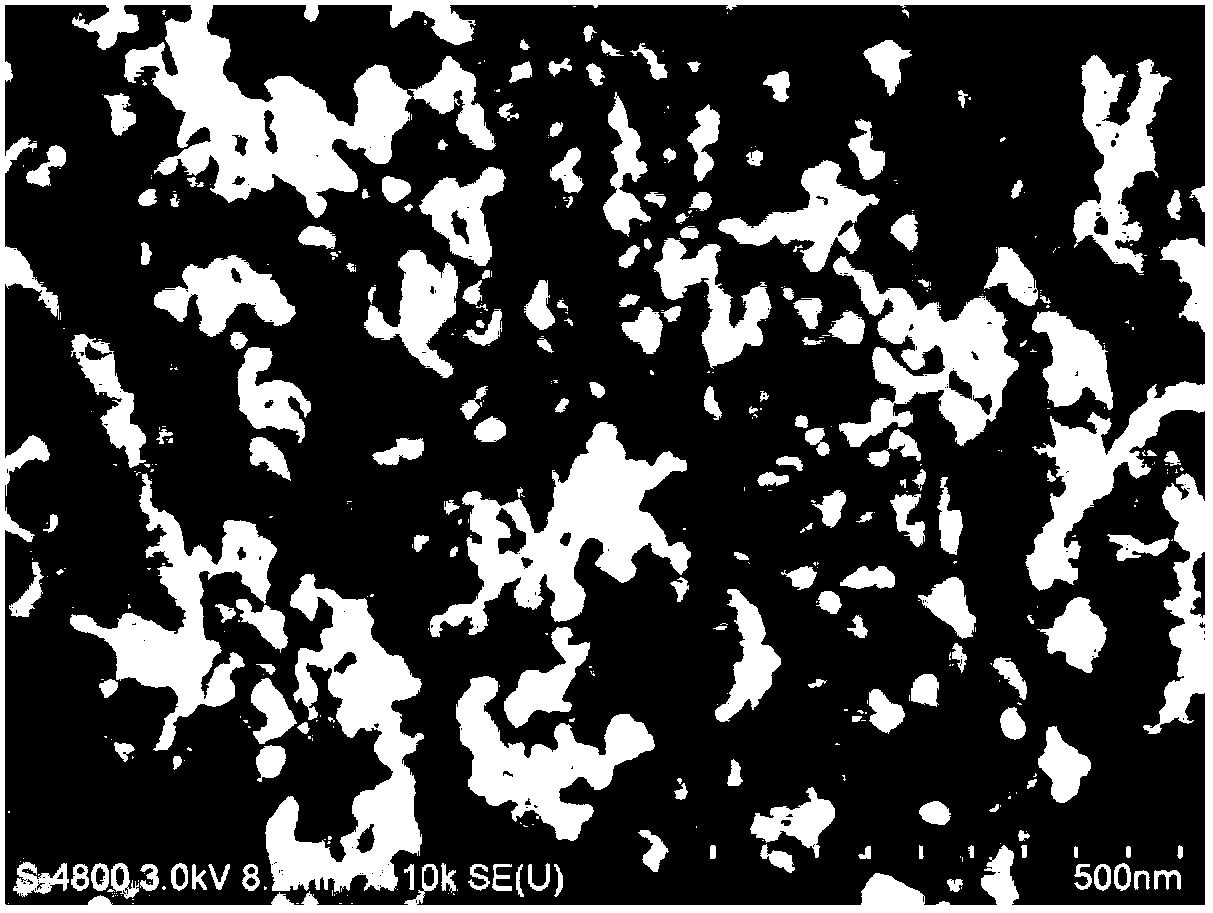

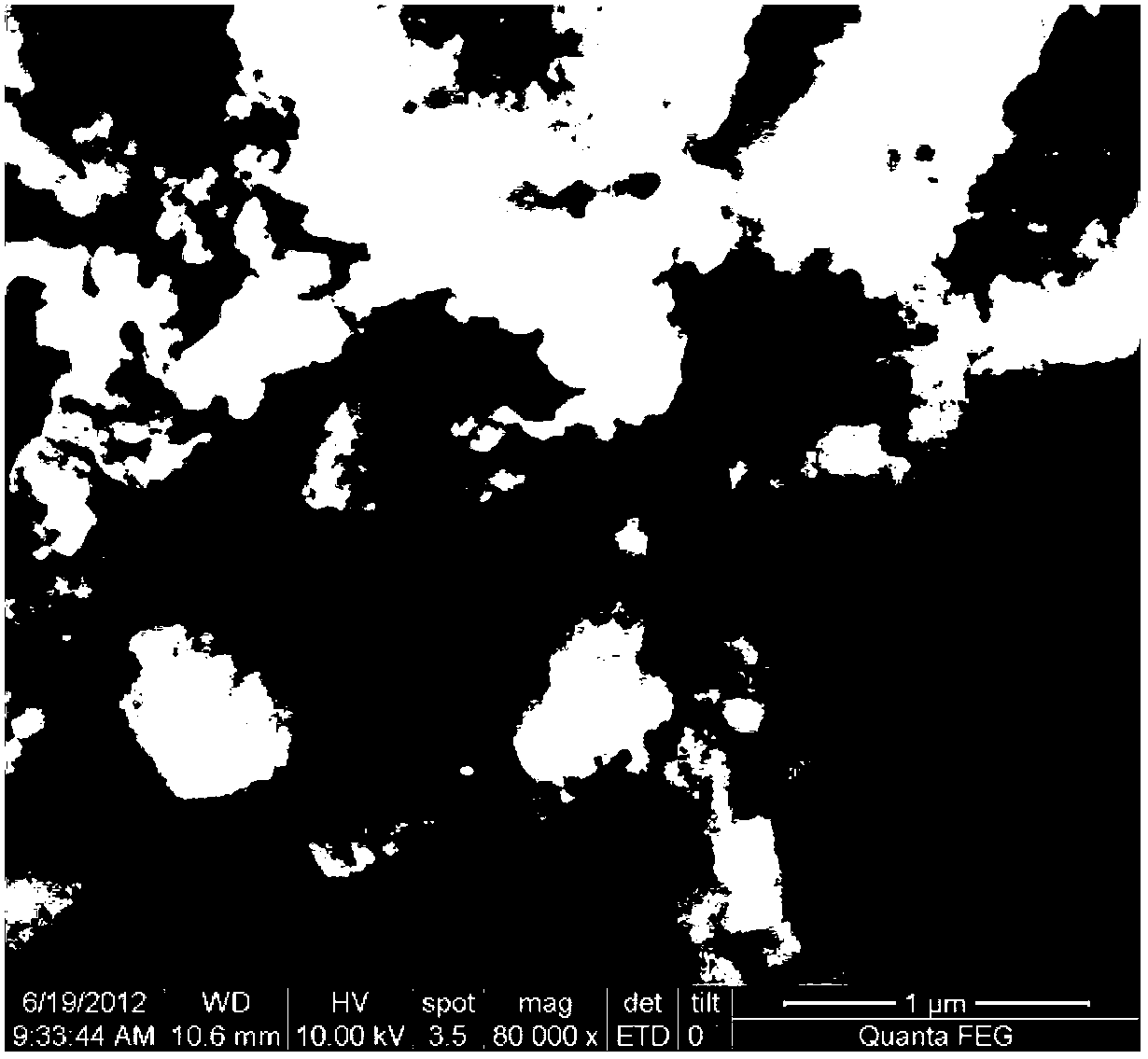

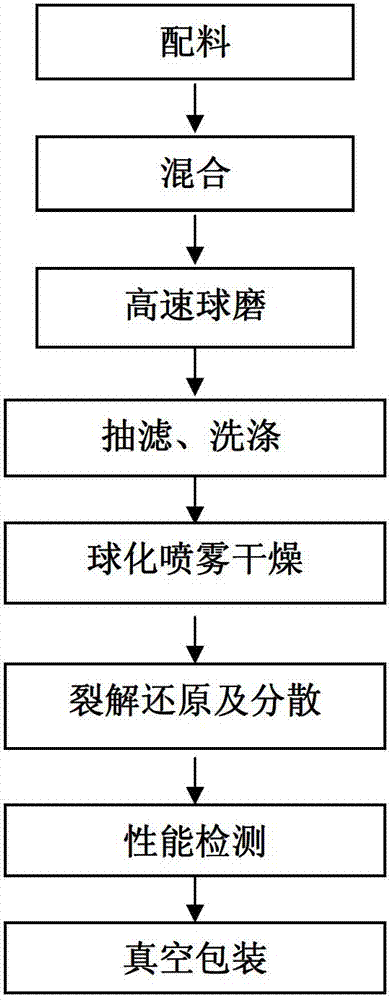

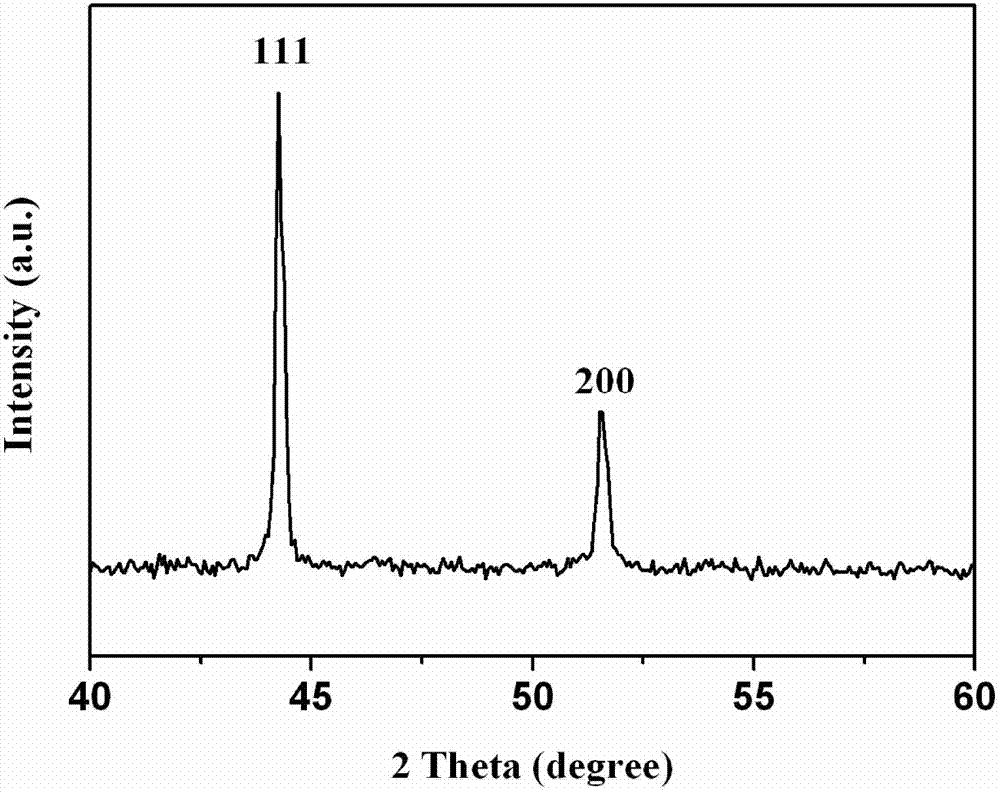

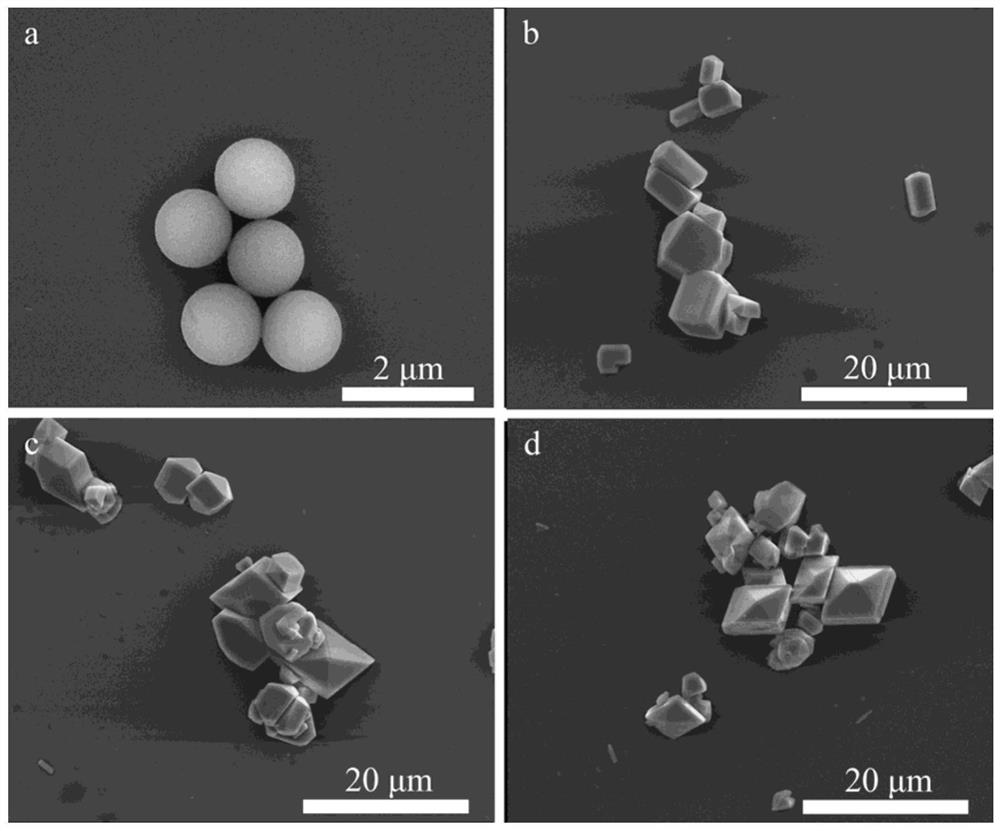

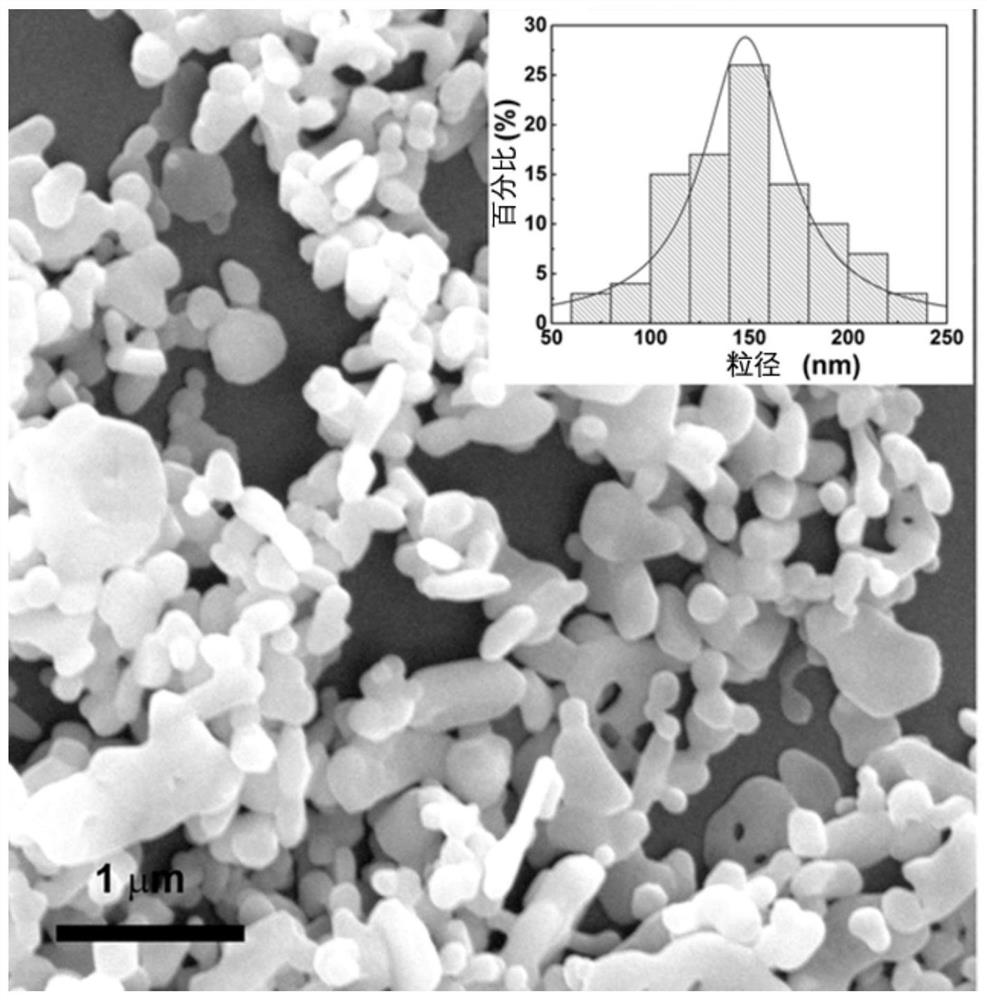

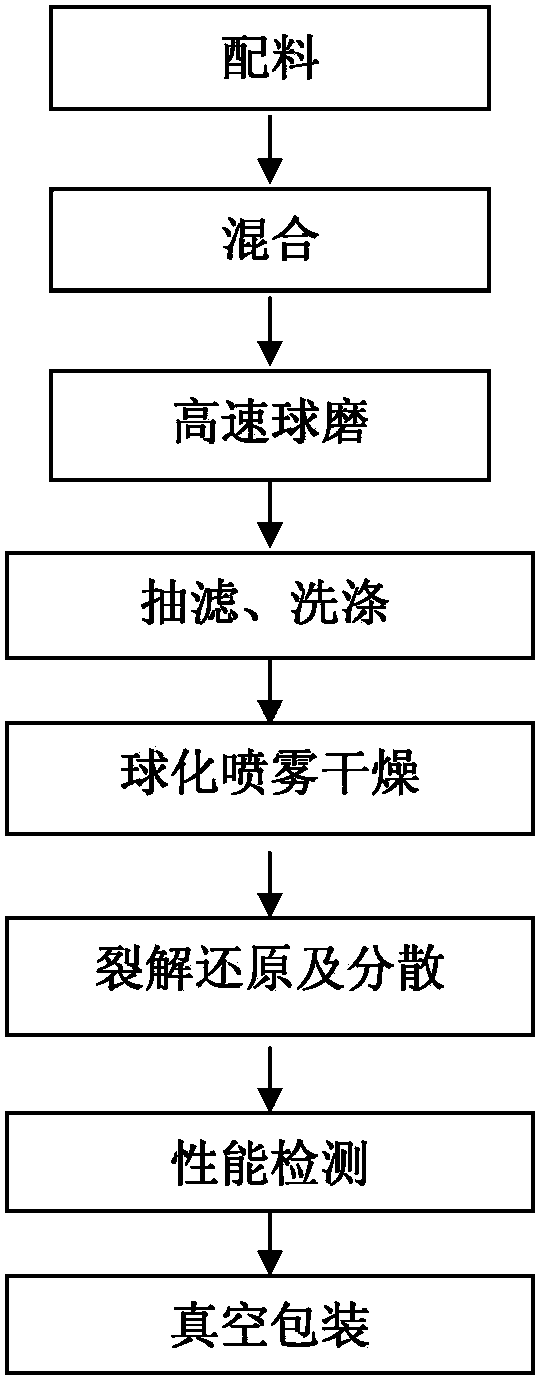

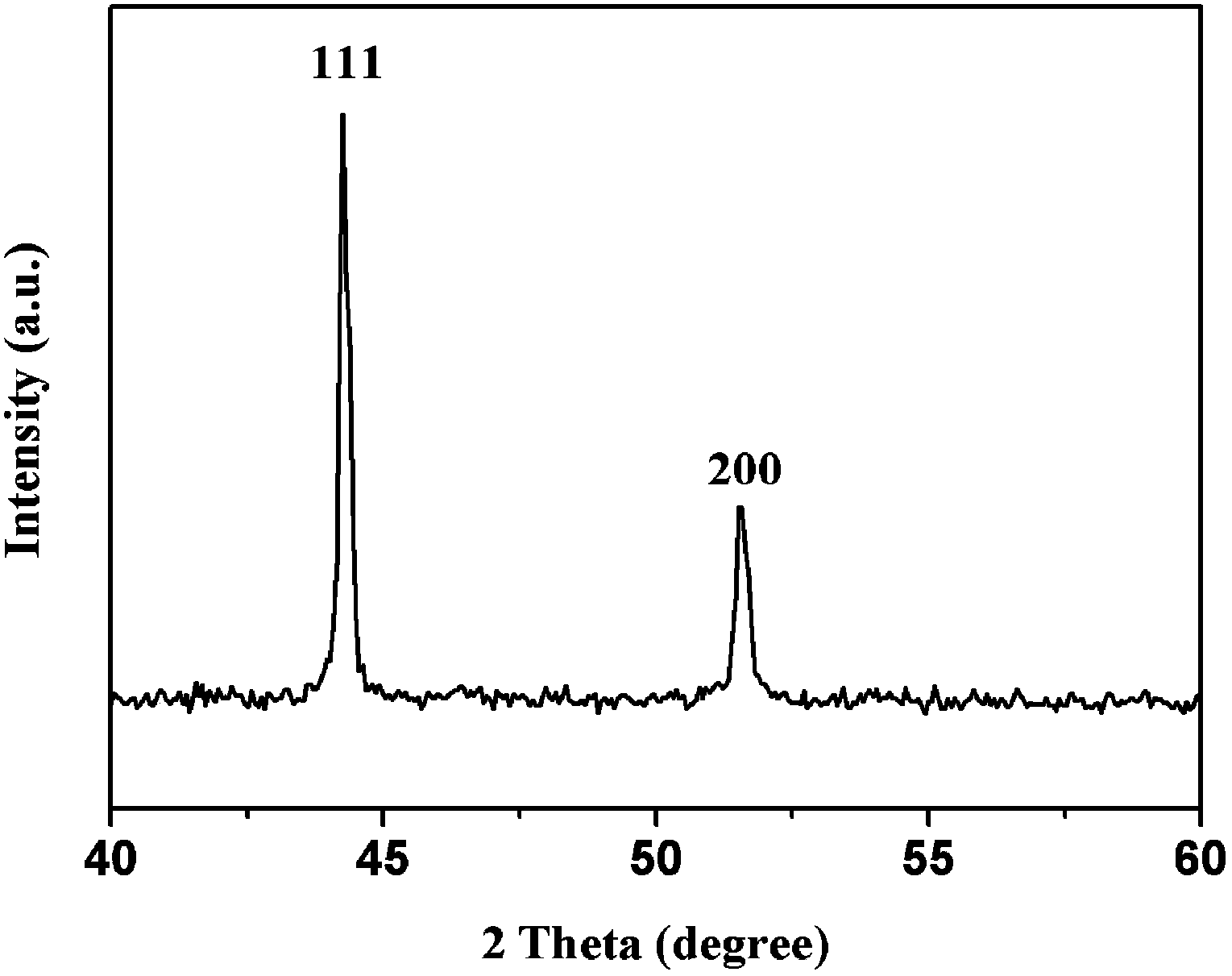

Method for preparing nanometer cobalt powders with spherical face-centered cubic structures by using mechano-chemical method

The invention provides a method for preparing nanometer cobalt powders with spherical face-centered cubic structures by using a mechano-chemical method, which belongs to the technical field of preparing metal powders from metal material. The method comprises the following steps of: weighting the corresponding oxalic acid, cobalt salt and surfactant according to the stoichiometric ratio of each element in a chemical formula, and then mixing; ball-milling, leaching and washing to obtain a precursor liquid; balling and atomizing to prepare the spherical precursors; splitting and reducing the precursors in a nitrogen-hydrogen atmosphere; and finally dispersing through sealed gas flow and performing vacuum packaging to obtain the target matters. The nanometer cobalt powders prepared by the method provided by the invention has the following characteristics: the average particle size is smaller than 200 nanometers, the structure is a 100% face-centered cubic structure, the purity is larger than 99.9% (excepting the oxygen content), the oxygen content is smaller than 1.0%, the appearances of the particles are in spherical shapes, and the size distribution is good. The method is widely applied to the ultrafine and nanometer-scale hard alloy, the ball-milling and mixing time can be reduced, cobalt pools can be reduced, and the performances of the hard alloy can be improved. The production process of the method is simple, so that the method is easy to operate.

Owner:重庆金锐新材料技术研究院有限公司

Treatment purification technology for cobalt oxalate defective products

ActiveCN109912405AReduce lossLow costCarboxylic acid salt preparationCarboxylic compound separation/purificationCobalt saltAmmonium carbonate

The invention discloses a treatment purification technology for cobalt oxalate defective products. The treatment purification technology comprises the following steps: step one, adding ammonium carbonate into waste cobalt oxalate to obtain filter residues containing cobalt carbonate and an ammonium oxalate solution; step two, adding hydrochloric acid into the filter residues in the first step, wherein filtrate is a cobalt chloride solution; step three, extracting and purifying the cobalt chloride solution in the second step; step four, concentrating the ammonium oxalate solution obtained in the first step to 50 to 100 g / L; step five, adding ammonia water into the high-quality cobalt chloride solution obtained in the third step according to 5 to 30 mass percent of cobalt to obtain a complexcobalt salt solution; then adding the ammonium oxalate solution obtained in the fourth step into the complex cobalt salt solution according to excessive 10 to 30 percent. According to the treatment purification technology disclosed by the invention, a defective product ammonium oxalate is purified and then high-quality ammonium oxalate is prepared; in addition, ammonium oxalate transformed from carbonate can be used as a material for preparing the ammonium oxalate; the loss of the ammonium oxalate is reduced and the cost is reduced through recycling; the treatment purification technology forthe cobalt oxalate defective products is worthy of vigorous promotion.

Owner:赣州逸豪优美科实业有限公司

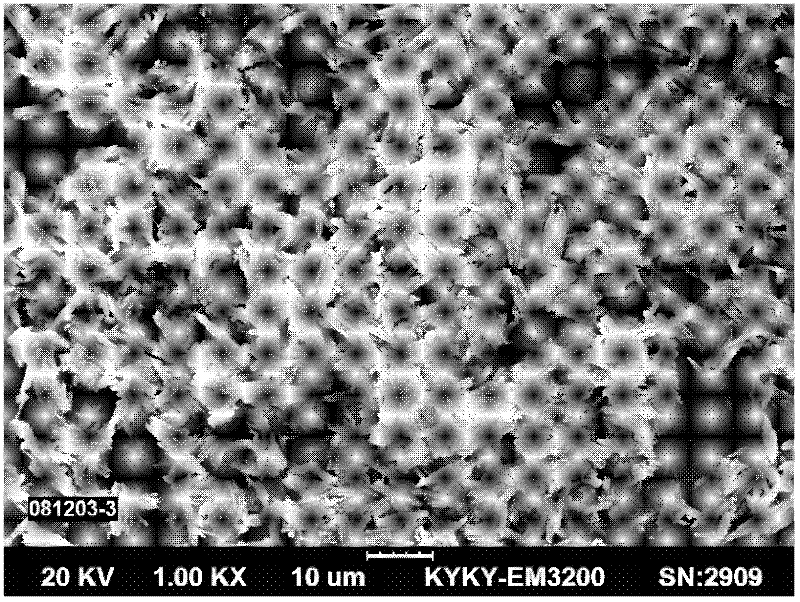

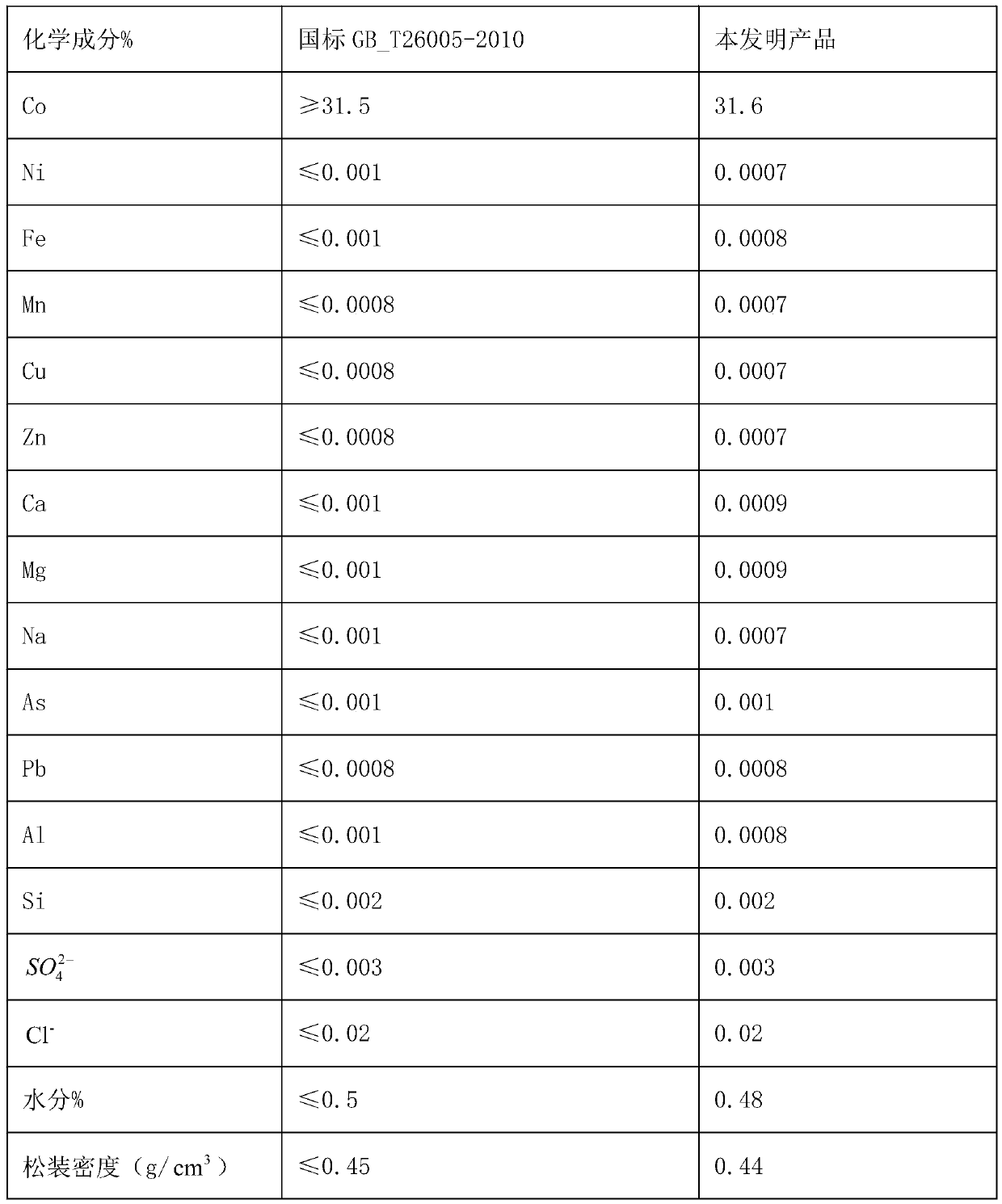

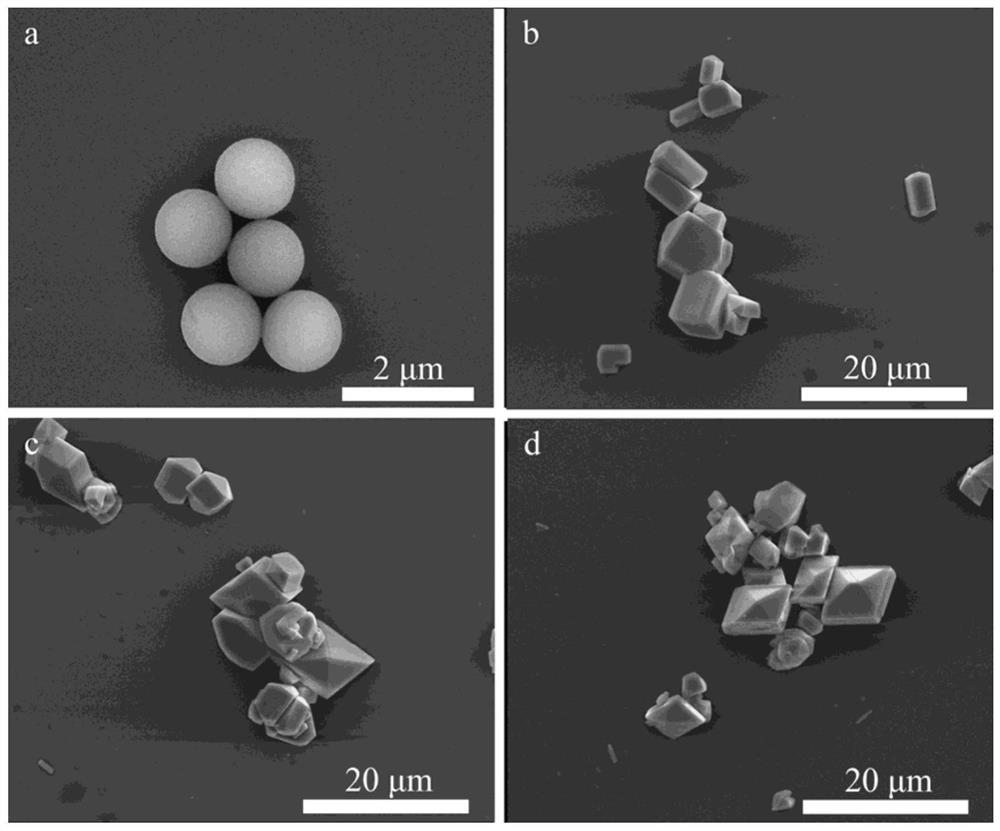

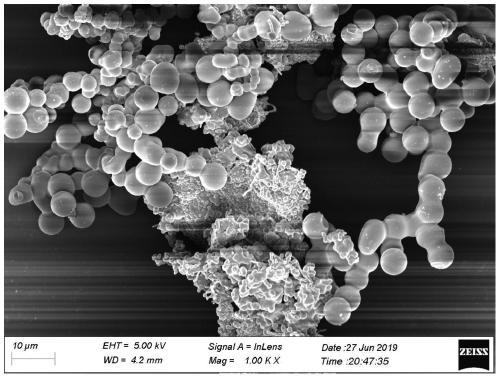

Preparation method and application of spherical cobalt oxalate

ActiveCN113416129ANarrow particle size distributionImprove lithium storage performanceOrganic compound preparationCell electrodesOXALIC ACID DIHYDRATEElectrical battery

The invention discloses a preparation method and application of spherical cobalt oxalate. The preparation method comprises the steps that an oxalic acid solution is dropwise added into a cobalt acetate solution containing cetyltrimethylammonium bromide, stirring is carried out while dropwise adding is carried out, then a precursor is subjected to hydrothermal treatment for a period of time, washing and drying are carried out, and uniform spherical cobalt oxalate with the regular morphology and the particle size being 1-1.2 micrometers can be obtained. The specific capacity of the lithium ion battery negative electrode material reaches up to 1029 mAh / g under the current density of 0.1 A / g, the specific capacity of the lithium ion battery negative electrode material is still 609 mAh / g after 350 cycles under the current density of 0.5 A / g, and the lithium ion battery negative electrode material has application potential. The method disclosed by the invention is simple, the morphology and the particle size of the spherical cobalt oxalate are easy to control, and the cobalt ions in the waste lithium battery are expected to be changed into things of value after being extracted by using an oxalic acid solution, so that the method has relatively great industrial application potential and economic value.

Owner:湖南金鑫新材料股份有限公司

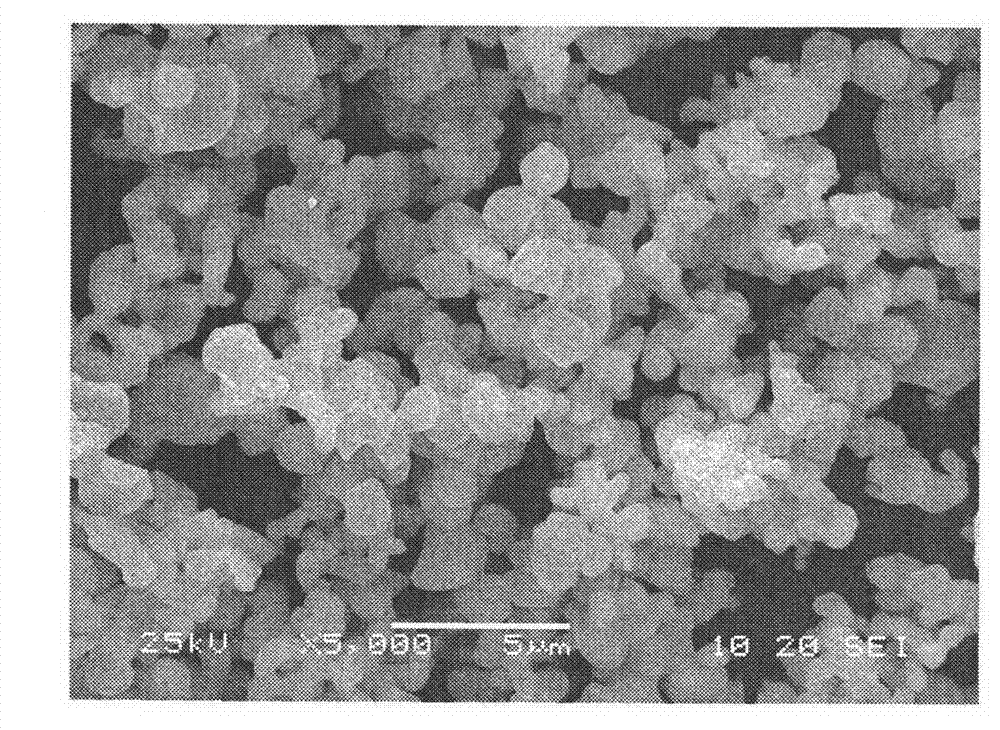

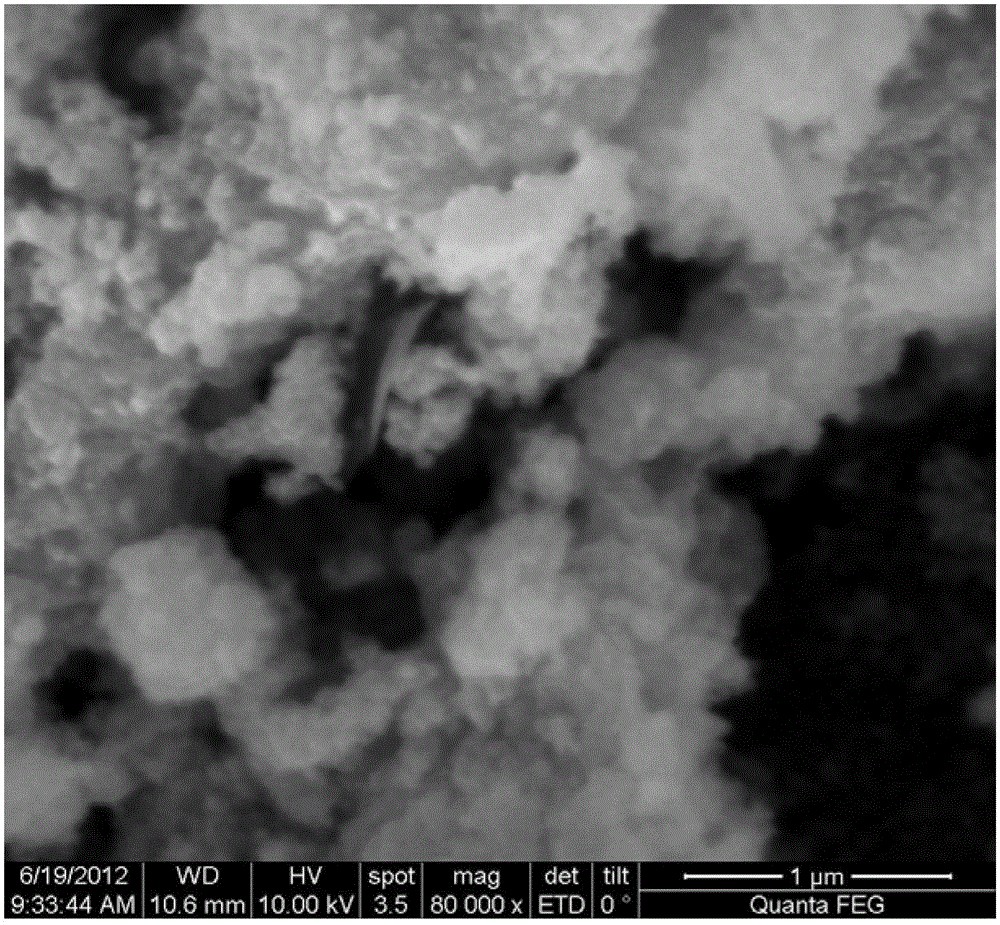

Low-oxygen content submicron cobalt powder and cobalt oxalate precursor and manufacturing method thereof

ActiveCN101780545BThe shape is stable and rarely fluctuatesImprove scrap rateProcess engineeringOxygen content

The invention relates to low-oxygen content submicron cobalt powder and a cobalt oxalate precursor and a manufacturing method thereof, wherein the low-oxygen content submicron cobalt powder is prepared by the steps of preparing the cobalt oxalate precursor through the solid-liquid reaction of cobalt carbonate powder and an oxalate solution and then reducing the cobalt oxalate precursor. The low-oxygen content submicron cobalt powder can keep low oxygen content in fine submicron-level products, is difficult to fire in the reduction procedure, is easy to stably run in all processes of the production process and has convenient preparation.

Owner:GEM CO LTD +1

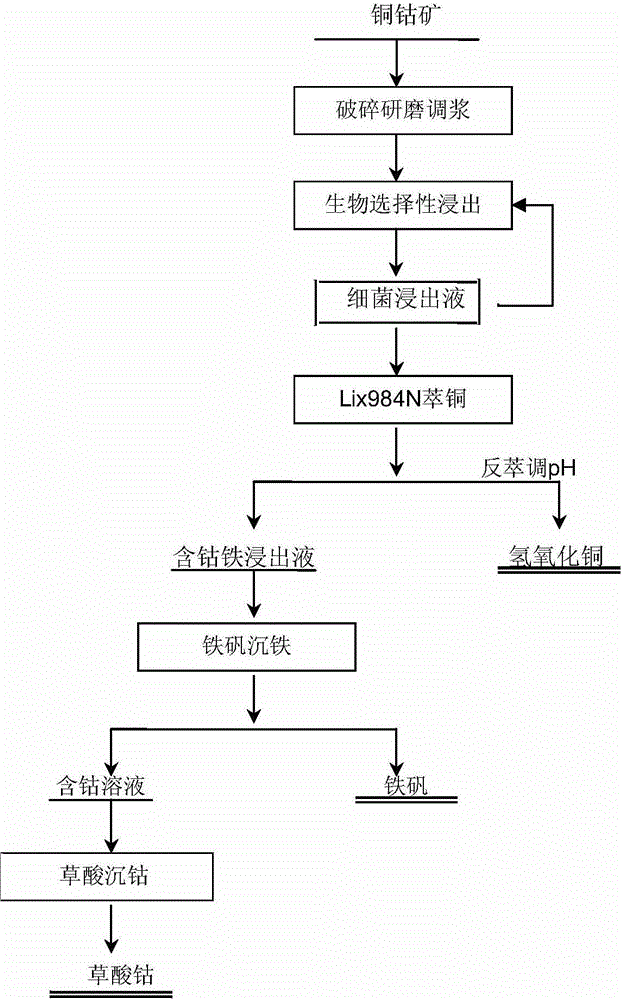

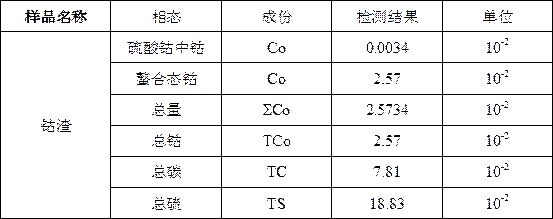

A kind of bioselective leaching method of low-grade copper-cobalt ore

ActiveCN103572050BAchieve separationEfficient recyclingProcess efficiency improvementThiobacillus ferrooxidansIron(II) oxide

A bioselective leaching method for low-grade copper-cobalt ores belongs to the field of microbial metallurgy. Follow the following steps: crush and grind the copper-cobalt ore, and inoculate the mixed bacterial solution containing Microspirillum ferrooxidans, Thiobacillus acidophilus Thiobacillus ferrooxidans and Thiobacillus acidophilus into the 9K culture medium for cultivation to obtain bacterial culture. liquid. Add copper-cobalt ore to the bacterial culture solution and perform bacterial leaching of the cobalt concentrate. When the leaching rate of cobalt in the bacterial leach solution is more than 97%, separate the leach solution containing cobalt, copper and other valuable metal ions from the leaching residue. , and then use Lix984N extraction agent to extract copper to obtain copper products; the raffinate after copper extraction is subjected to iron vitriol precipitation and iron removal to obtain iron products; the cobalt-containing liquid after iron removal is crystallized to obtain cobalt oxalate products. The invention has short process flow, simple operation, simple equipment, low energy consumption, does not require high-temperature smelting, does not emit polluting smoke and toxic gases, and can quickly realize the separation and efficient recovery of cobalt from other valuable metals.

Owner:NORTHEASTERN UNIV LIAONING

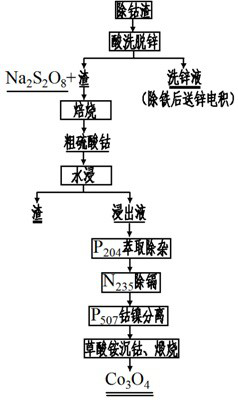

A kind of processing method of sodium formazan cobalt slag

ActiveCN110358917BHigh recovery rateLow investment costProcess efficiency improvementSlagSodium sulfate

The invention discloses a process method for treating cobalt slag of formazan, which comprises the following steps: (1), acid washing and zinc removal, (2), roasting, (3), water immersion, (4), extraction and purification, ( 5) Precipitation of ammonium oxalate, (6) Calcination of cobalt oxalate, the calcination includes adding 10-30wt% sodium persulfate to the pickling slag obtained by pickling and dezincification, after one stage of calcination, the temperature is raised for a second stage of calcination. The beneficial effect of the invention is that in the pickling process, most of the zinc can be recovered by pickling under normal pressure and low pressure, without using high-temperature pressure leaching and other strengthening means, which reduces equipment investment and production costs. Sodium sulfate is used as a roasting additive. It decomposes to generate oxygen to provide an enhanced oxidizing atmosphere for thermal decomposition. The generated sodium sulfate replaces the commonly used concentrated sulfuric acid, reduces the generation of acid mist, and can also destroy the dense oxide film formed on the surface of the ore particles, so that the oxidation of the inner layer Cobalt continues to contact with O2, SO2, SO3, so as to achieve complete sulfation and improve the recovery rate of cobalt.

Owner:铜陵有色金属集团股份有限公司 +1

Preparation method of superfine cobalt powder

PendingCN113909485AProne to spontaneous combustionPrevent spontaneous combustionCobalt saltMuffle furnace

The invention discloses a preparation method of superfine cobalt powder, and relates to the technical field of metal processing. The preparation method of the superfine cobalt powder comprises the following steps that (1) an oxalate solution and a cobalt salt solution are prepared; (2) cobalt oxalate is prepared in ultrasonic and microwave environments; (3) the cobalt oxalate is washed, filtered and dried; and (4) the cobalt oxalate is reduced into cobalt powder in a microwave muffle furnace. Compared with an existing method for preparing cobalt powder, the cobalt powder prepared through the method is finer in particle size and more uniform. The synthesis rate is high, so that the use of raw material reagents is effectively saved; and in the preparation process, energy needed in the preparation process of a precursor and the reduction process is greatly reduced, and the production cost is reduced.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

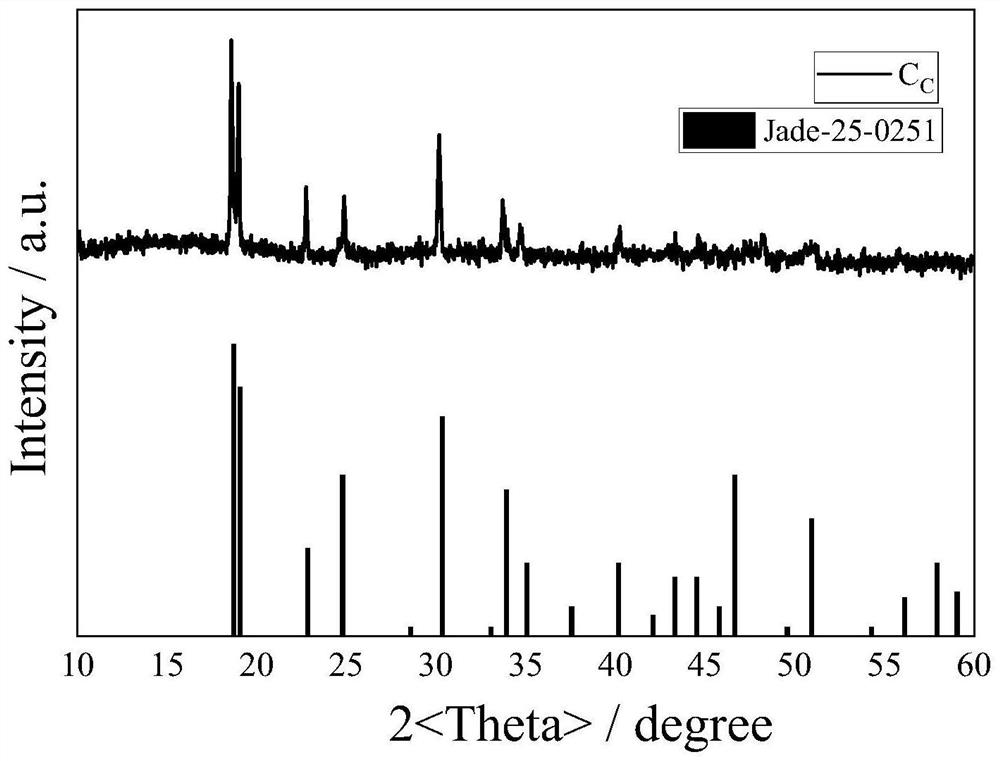

Cobaltous oxide photocatalytic material with high photoelectrocatalytic activity and preparation method thereof

ActiveCN113663672ALow costImprove photocatalytic reactivityHydrogen productionHydrogen/synthetic gas productionPhotocatalytic reactionAqueous sodium hydroxide

The invention relates to a cobaltous oxide photocatalytic material with high photoelectrocatalytic activity and a preparation method thereof. According to the method, a precursor is prepared from a cobalt oxalate aqueous solution and a sodium hydroxide aqueous solution, and the cobaltous oxide is prepared through microwave hydrothermal treatment, drying and high-temperature treatment. The invention provides a novel synthesis method of cobaltous oxide powder with a controllable grain size. The method can significantly improve the photocatalytic reaction activity of the material. The cobaltous oxide powder produced by the method is expected to be further applied in the field of photocatalysis. The production method is low in cost and simple and convenient in synthesis process, can be applied to mass production, and effectively saves the production cost. The cobaltous oxide powder prepared by the method has excellent photoelectrocatalytic activity and has a relatively large commercialization prospect.

Owner:香港城市大学深圳研究院

Method for preparing high-quality cobalt oxide from copper cobalt oxide ore copper extraction raffinate

PendingCN113846216ALow impurity contentReduce energy consumptionProcess efficiency improvementPhysical chemistryHydrometallurgy

The invention belongs to the field of nonferrous metallurgy and hydrometallurgy, and relates to a method for extracting cobalt from copper cobalt oxide ore copper extraction raffinate and preparing high-quality cobalt oxide. The method comprises the steps of removing iron and aluminum from calcium oxide; removing copper from magnesium oxide; removing calcium and magnesium from sodium fluoride; saponifying and preparing an extracting agent P2O4; conducting extracting and removing impurities; preparing a cobalt oxalate precursor; and preparing high-quality cobalt oxide. In order to solve the problems of high impurity content and large cobalt loss in the cobalt extraction and product preparation process of the copper cobalt oxide ore copper extraction raffinate, the deep impurity removal process step is additionally arranged in the method, and the cobalt oxalate precursor is prepared by using a precipitation method and is calcined into high-quality cobalt oxide. The method has the advantages of being thorough in impurity removal and high in cobalt recovery rate.

Owner:SHENYANG RES INST OF NONFERROUS METALS

A kind of preparation method and application of spherical cobalt oxalate

ActiveCN113416129BNarrow particle size distributionImprove lithium storage performanceOrganic compound preparationCell electrodesOXALIC ACID DIHYDRATECobalt acetate

The invention discloses a preparation method and application of spherical cobalt oxalate. First, an oxalic acid solution is dropped dropwise into a cobalt acetate solution containing cetyltrimethylammonium bromide, and the dropwise addition is performed while stirring, and then a precursor is added dropwise. The body water is heated for a period of time, and then washed and dried to obtain uniform spherical cobalt oxalate with regular morphology and particle size of 1-1.2 μm. After 350 cycles at A / g, it still has a specific capacity of 609mAh / g, which is a potential anode material for lithium-ion batteries. The disclosed method is simple, the shape and particle size of spherical cobalt oxalate are easy to control, and it is expected to turn waste into treasure after extracting cobalt ions in waste lithium batteries with oxalic acid solution, which has great industrial application potential and economic value.

Owner:湖南金鑫新材料股份有限公司

Method for preparing nanometer cobalt powders with spherical face-centered cubic structures by using mechano-chemical method

The invention provides a method for preparing nanometer cobalt powders with spherical face-centered cubic structures by using a mechano-chemical method, which belongs to the technical field of preparing metal powders from metal material. The method comprises the following steps of: weighting the corresponding oxalic acid, cobalt salt and surfactant according to the stoichiometric ratio of each element in a chemical formula, and then mixing; ball-milling, leaching and washing to obtain a precursor liquid; balling and atomizing to prepare the spherical precursors; splitting and reducing the precursors in a nitrogen-hydrogen atmosphere; and finally dispersing through sealed gas flow and performing vacuum packaging to obtain the target matters. The nanometer cobalt powders prepared by the method provided by the invention has the following characteristics: the average particle size is smaller than 200 nanometers, the structure is a 100% face-centered cubic structure, the purity is larger than 99.9% (excepting the oxygen content), the oxygen content is smaller than 1.0%, the appearances of the particles are in spherical shapes, and the size distribution is good. The method is widely applied to the ultrafine and nanometer-scale hard alloy, the ball-milling and mixing time can be reduced, cobalt pools can be reduced, and the performances of the hard alloy can be improved. The production process of the method is simple, so that the method is easy to operate.

Owner:重庆金锐新材料技术研究院有限公司

Preparation method based on solid-phase reaction for capacitor electrode material

ActiveCN103274481BInhibit side effectsHigh yieldHybrid capacitor electrodesCobalt oxides/hydroxidesCapacitanceHexamethylenetetramine

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Composite material loaded by taking starch as carbon base as well as preparation method and application of the composite material

ActiveCN111333051ALarge apertureImprove conductivityHybrid capacitor electrodesCarbon preparation/purificationPtru catalystCobalt chloride

The invention relates to a preparation method loaded by taking starch as a carbon base, and relates to the technical field of supercapacitors. The method comprises the following steps: S1, uniformly mixing a starch solution and a cobalt source solution to obtain a mixed solution, with the cobalt source solution being an aqueous solution of a cobalt-containing compound, and the cobalt-containing compound being selected from one or more of cobalt nitrate, cobalt chloride or cobalt oxalate; S2, carbonizing the mixed solution to obtain a carbon template; and S3, adding deionized water into the carbon template for hydrothermal reaction, and cooling and drying a reaction product to obtain the composite material. The invention also relates to the composite material prepared by the method and an application of the composite material in a supercapacitor. The composite material has excellent electrochemical performance, and has a great application prospect in the fields of energy storage, conversion, catalysts and other related applications.

Owner:厦门睿珩兴能源科技有限公司

A kind of treatment and purification process of cobalt oxalate defective product

ActiveCN109912405BReduce lossLow costCarboxylic acid salt preparationCarboxylic compound separation/purificationCarbonateAmmonium oxalate

Owner:赣州逸豪优美科实业有限公司

A kind of composite material with starch as carbon-based load, preparation method and application thereof

ActiveCN111333051BLarge apertureImprove conductivityHybrid capacitor electrodesCarbon preparation/purificationPtru catalystCarbonization

The invention relates to a preparation method using starch as a carbon-based load, and relates to the technical field of supercapacitors. The method includes the following steps: S1, uniformly mixing a starch solution and a cobalt source solution to obtain a mixed solution; wherein, the cobalt source solution It is an aqueous solution containing a cobalt compound, and the cobalt-containing compound is selected from one or more of cobalt nitrate, cobalt chloride or cobalt oxalate; S2, carbonizing the mixed solution to obtain a carbon template; S3, applying to the The carbon template is added with deionized water to carry out a hydrothermal reaction, and the reaction product is cooled and dried to obtain a composite material. The present invention also relates to the starch-based carbon-supported composite material prepared by the above method and its application in supercapacitors. The starch-based carbon-supported composite material provided by the invention has excellent electrochemical performance, and has great application prospects in energy storage, conversion, catalyst and other related application fields.

Owner:厦门睿珩兴能源科技有限公司

Cobaltosic oxide preparation method for lithium ion battery

ActiveCN1274602CImprove conversion rateUniform particle sizeOrganic chemistryCell electrodesAir atmosphereCobalt hydroxide

The invention discloses a process for preparing cobalto-cobaltic oxide for used in lithium ion battery, wherein cobalt oxalate or cobalt hydroxide or cobaltous carbonate is used as raw material for three segment calcinations, during which the thermal cracking and oxidization of cobalt salt are divided into two procedures, no oxidation agent is provided during the thermal cracking of the cobalt salt, thus converting all of them into cobaltous oxide, then temperature is elevated to oxidization temperature and oxygen of air atmosphere is provided, so as to converting all cobaltous oxide into cobaltic-cobaltous oxide. The product made thereby has high conversion rate of cobaltic-cobaltous oxide, less cobalt oxidates of other forms, epigranularity and apparent density. íí

Owner:GEM CO LTD

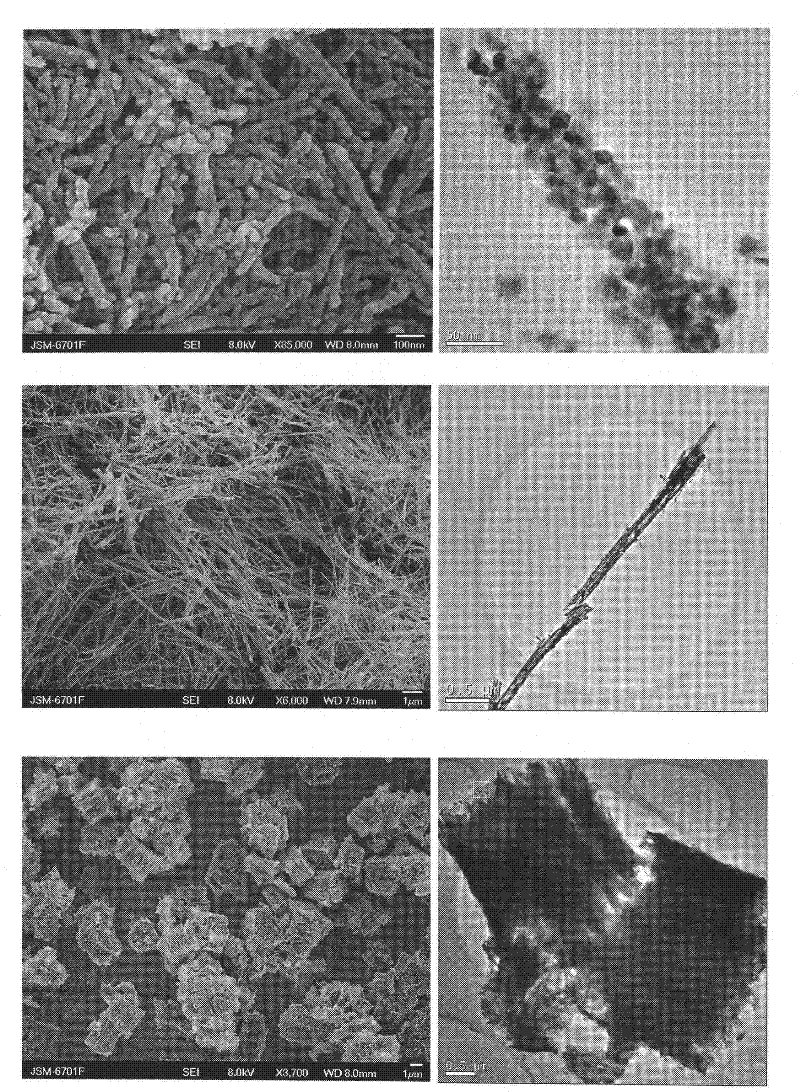

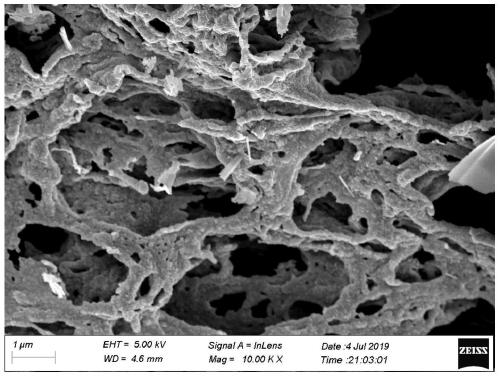

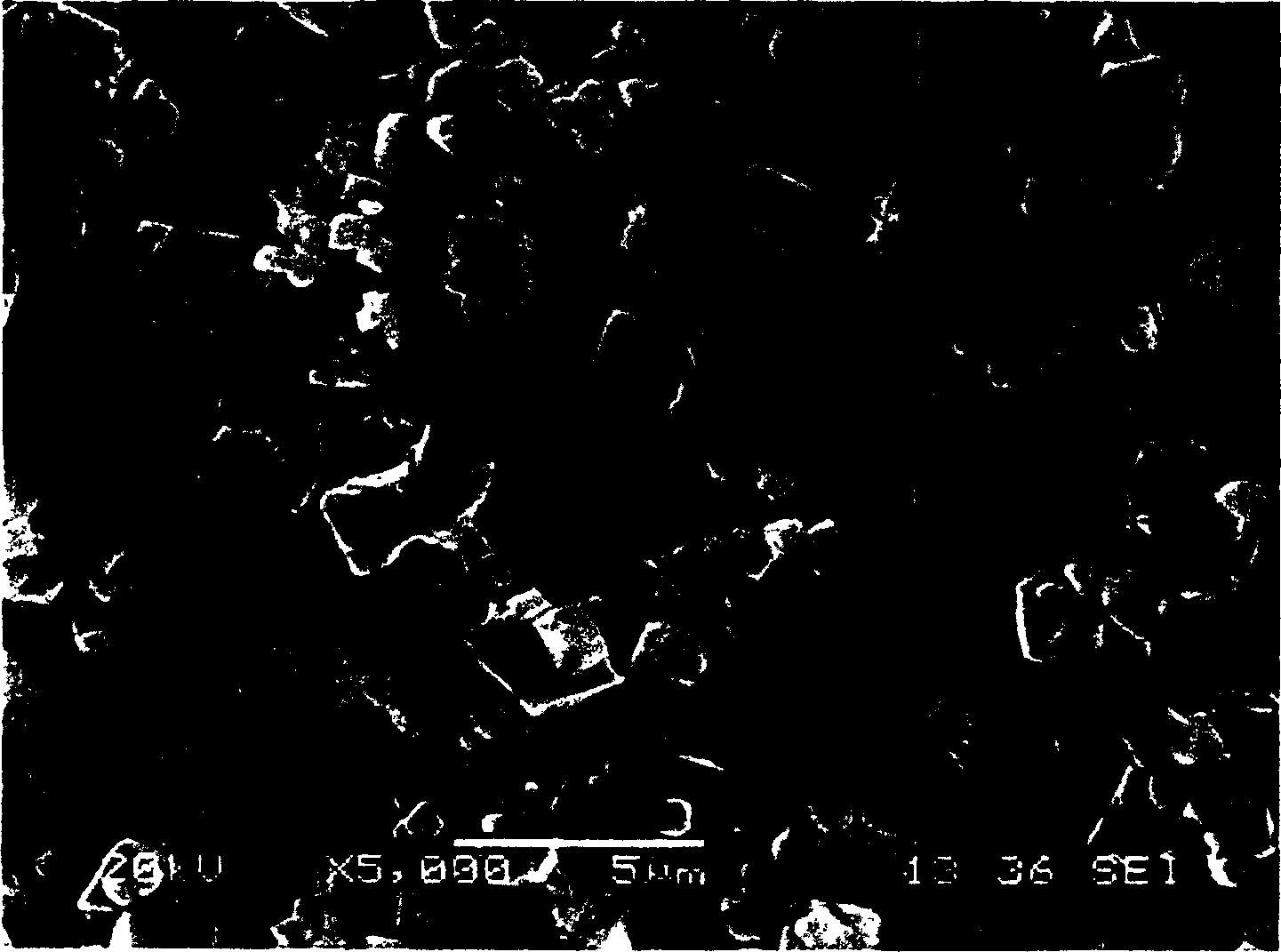

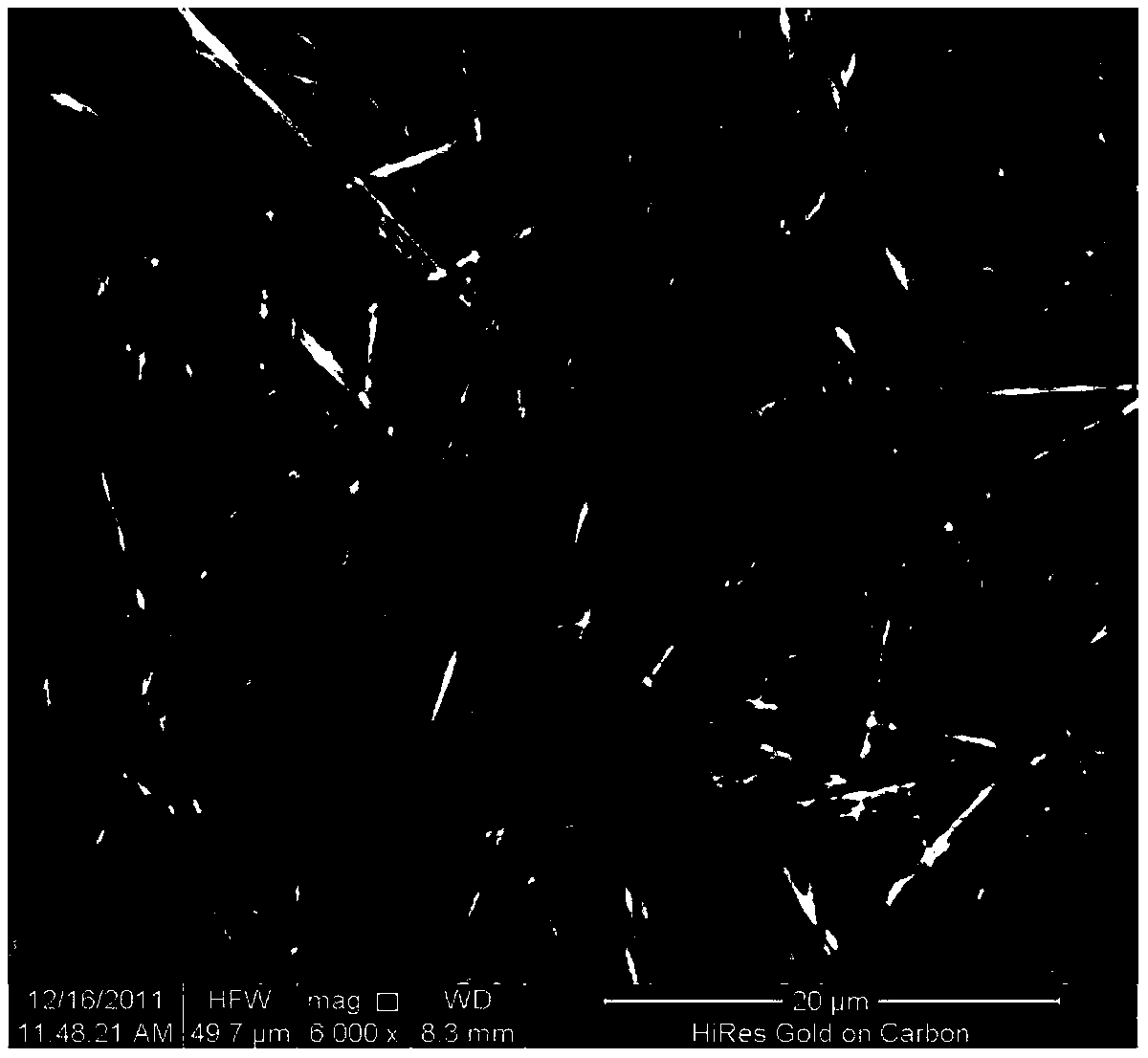

A kind of preparation method of cobalt oxalate nanowire

ActiveCN107032982BHigh purityEasy to operateOrganic compound preparationNanotechnologyOXALIC ACID DIHYDRATEHydration reaction

The invention relates to a method for preparing cobalt oxalate nano-wires. The method includes steps of 1), dissolving cobalt nitrate hexahydrate and surfactants in solvents to prepare solution A and dissolving oxalic acid in solvents to prepare solution B; 2), mixing the solution A and the solution B with each other and carrying out water bath reaction. The method has the advantages that the method is easy to implement and high in yield, and cobalt oxalate nano-wire products with high purity, regular morphology and good distribution uniformity can be prepared by the aid of the method.

Owner:CHONGQING UNIV OF ARTS & SCI

Cobalt oxalate coarseness prediction technique in hydrometallurgy synthesis course

InactiveCN101482750BComplex process monitoringImplement inputOrganic chemistryTotal factory controlSoftware systemInteraction interface

The present invention provides a cobalt oxalate granularity real-time prediction method in hydrometallurgy synthesis process. The method comprises the steps of data collecting, auxiliary variable selecting, standardized processing, hybrid model establishing, etc. The invention is characterized in that a parallel-connected structure hybrid model composed based on mechanism model and based on data driving model is established. A genetic algorithm is adopted for confirming the related model parameter in the mechanism model. A model based on data driving is used as an error compensating model of mechanism model. The invention also provides a software system which actualizes the cobalt oxalate granularity prediction. The software system comprises a main program, a database and a human-machine interaction interface. The system software uses a microcomputer of hydrometallurgy synthesis process control system as a hardware platform. When the cobalt oxalate granularity real-time prediction method is used for the cobalt oxalate synthesis process of a certain hydrometallurgy factory for predicting the granularity of cobalt oxalate, the prediction result is in the preset error range. The cobalt oxalate granularity real-time prediction method according to the invention has the advantages of simple model, strong interpretability, good extrapolation property and higher prediction precision.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

A kind of method that recovers cobalt from lithium battery cathode material

ActiveCN103474718BHigh recovery rateLow powder impurity contentWaste accumulators reclaimingBattery recyclingSolid matterMaterials science

The invention discloses a method for recovering cobalt from a lithium battery anode material. The method is characterized by comprising the following steps of: (1) removing aluminum foil from the anode material, obtaining a black solid matter containing lithium cobalt oxide, roasting the black solid matter to form lithium cobalt oxide powder, (2) weighing and adding the lithium cobalt oxide powder into 119-240g / L of citric acid according to a solid-to-liquid ratio of (20-30):1g / L, adding hydrogen peroxide at a mass fraction of 30% according to a mole ratio of 2:(1-1.05), performing stirring leaching for 5-7h at 80-90 DEG C, filtering to form filtrate containing the cobalt, (3) adding an ammonium oxalate solution into the filtrate to form a cobalt oxalate precipitate, and (4) after drying the cobalt oxalate precipitate, adding lithium carbonate powder according to a mole ratio (1:(1-1.05)) of the cobalt to lithium, grinding uniformly, roasting for 6-8h at 800-850 DEG C, and obtaining lithium cobalt oxide powder capable of directly serving as the electrode material. The method is easy to operate and high in recovery rate, equipment is simple, waste liquid is easy to treat, and the pollution of waste lithium batteries to an environment can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH WUCHANG BRANCH

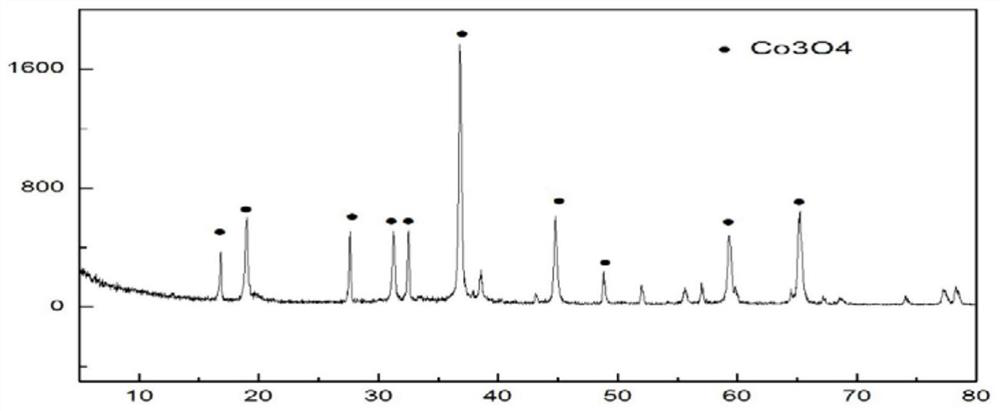

Method for preparing cobaltosic oxide by calcinating cobalt oxalate with microwave

InactiveCN101830519BFast heating rateAchieve microwave calcinationCobalt oxides/hydroxidesMicrowaveDecomposition

The present invention relates to a method for preparing cobaltosic oxide by calcinating cobalt oxalate with microwave. A hearth of a microwave rotary kiln adopts a composite microwave heating pipe, and the high wave absorbing property of silicon carbide is utilized to perform auxiliary heating, so that the cobalt oxalate is decomposed partially in a silicon carbide section, and then materials decomposed partially pass through a special microwave ceramic section with high wave-transmitting performance to accelerate the temperature rate of the cobalt oxalate and continue to calcine the cobalt oxalate for decomposition, so that the defects of high energy consumption, long production period and the like in the conventional calcining method are overcome, and the microwave calcination of weak wave absorbing substances is realized. The method realizes the continuous and large-scale calcination of the cobalt oxalate, and the granularity and the cobalt content of the cobalt oxalate products, namely cobaltosic oxide reach the YS / T256-2000 standard.

Owner:KUNMING UNIV OF SCI & TECH

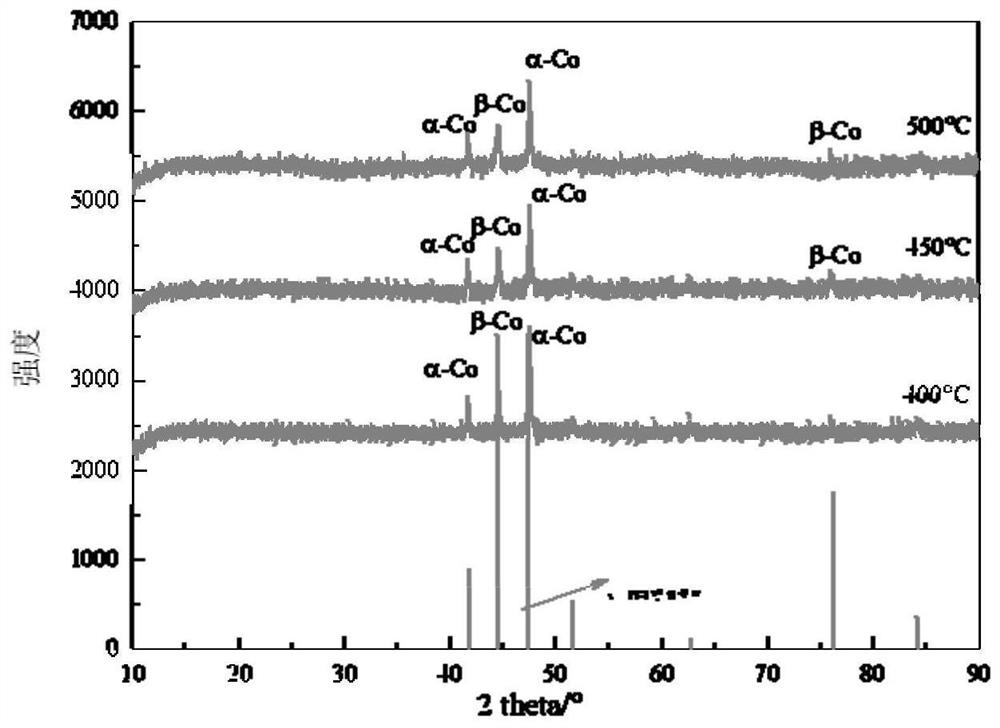

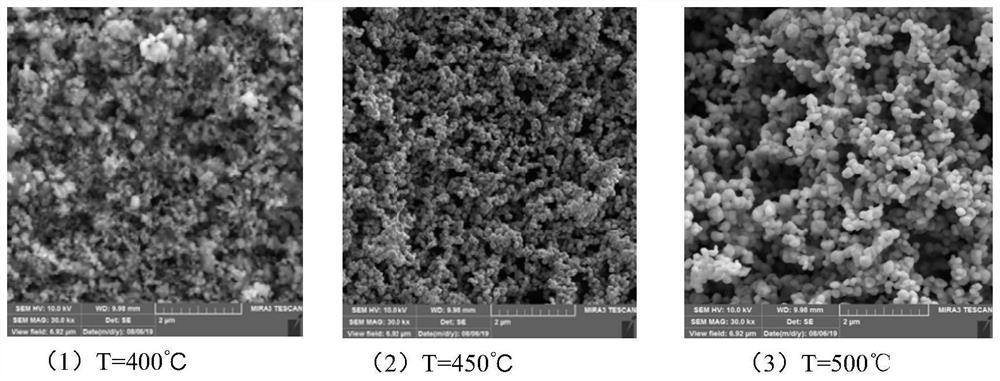

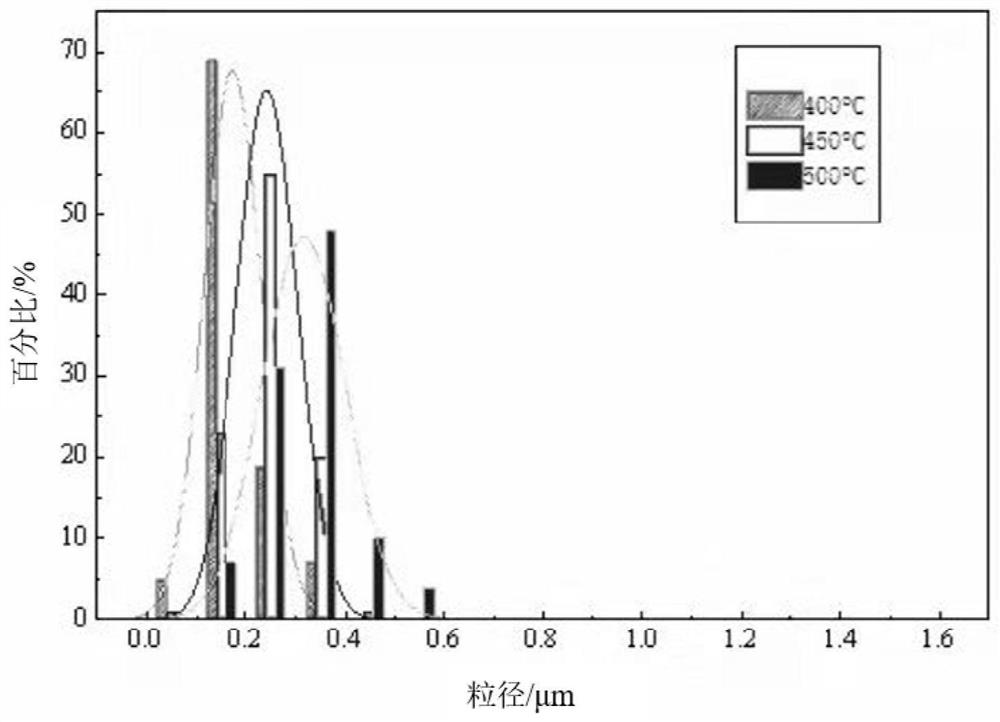

Method for preparing cobalt powder from cobalt oxalate

ActiveCN114433861AHighlight substantive featuresSignificant progressPhysical chemistryMaterials science

The invention provides a method for preparing cobalt powder from cobalt oxalate. The method comprises the following steps that firstly, the cobalt oxalate powder is heated to the reduction temperature under the condition that hydrogen is introduced; and secondly, the cobalt oxalate powder and hydrogen react at the reduction temperature to prepare cobalt powder, and then the cobalt powder is cooled to the normal temperature. The reduction temperature corresponds to the crystal form content in the cobalt powder, and the crystal form of the cobalt powder is controlled within a certain proportion range by controlling the reduction temperature. The preparation method provided by the invention has the advantages of simple process and relatively accurate crystal form proportion control.

Owner:安徽寒锐新材料有限公司

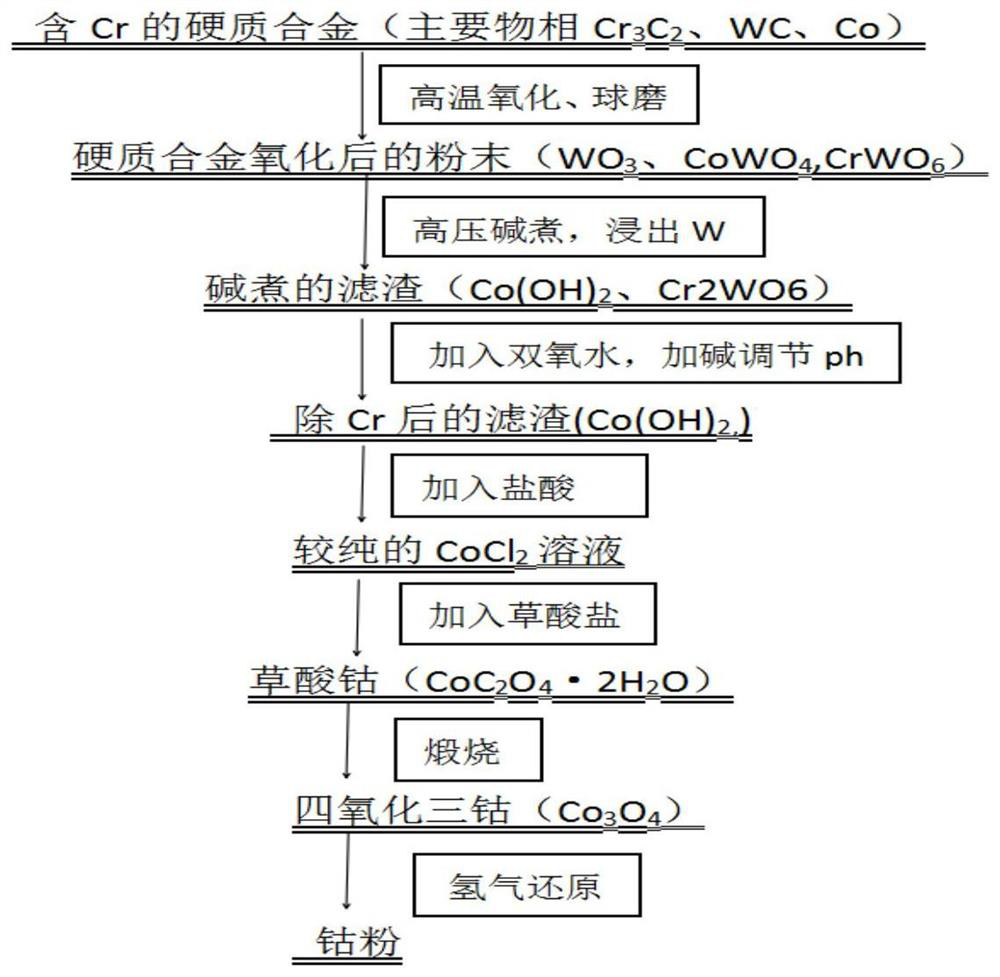

Method for separating and recovering cobalt from chromium-containing waste hard alloy

PendingCN113430378ASolve hard-to-break problemsHigh purityProcess efficiency improvementOXALIC ACID DIHYDRATECobalt(II,III) oxide

The invention discloses a method for separating and recovering cobalt from a chromium-containing waste hard alloy. The method comprises the following steps: taking the chromium-cobalt-tungsten-containing waste hard alloy; performing 800-900 DEG C high-temperature oxidation and ball milling on the waste hard alloy , and obtaining oxidized powder; carrying out alkali boiling on the oxidized powder, and filtering; washing and drying obtained filter residues to obtain powder; adding hydrogen peroxide into the obtained powder, adding alkali to adjust the pH value to 11 + / -0.5, stirring for 2-4 hours, and filtering; adding hydrochloric acid into the obtained filter residues for soaking until the filter residues are completely dissolved, and filtering; reacting the obtained filtrate with an oxalate / oxalic acid solution to generate cobalt oxalate precipitate, filtering and washing; and calcining the obtained cobalt oxalate into cobaltosic oxide powder, and carrying out reduction reaction to obtain cobalt powder. The recovery process is environmentally friendly, the technological process is short, equipment investment is low, energy consumption is low, operation is easy, implementation is easy, the recovery cost is low, the requirement for the cobalt content of the hard alloy is avoided, and the application range is wide.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com