Preparation method and application of spherical cobalt oxalate

A cobalt oxalate, spherical technology, applied in the field of preparation of spherical cobalt oxalate, can solve the problems of large differences in particle shape and size, poor material repeatability, etc., and achieve the effect of easy control and good lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) First prepare 250mL of 0.033mol / L cobalt acetate solution, then add 3g of CTAB powder to it to obtain mixed solution "A"; prepare 0.3mol / L H 2 C 2 o 4Solution 250mL;

[0042] (2) Set the flow rate of the constant flow pump to 5mL / min, pour 100mL of the mixed solution "A" into the beaker, and then pump 0.3mol / L of H through the constant flow pump 2 C 2 o 4 The solution was added dropwise into the mixed solution "A", and stirred while adding dropwise, until the pH of the suspension in the beaker = 4.2 and the titration was stopped.

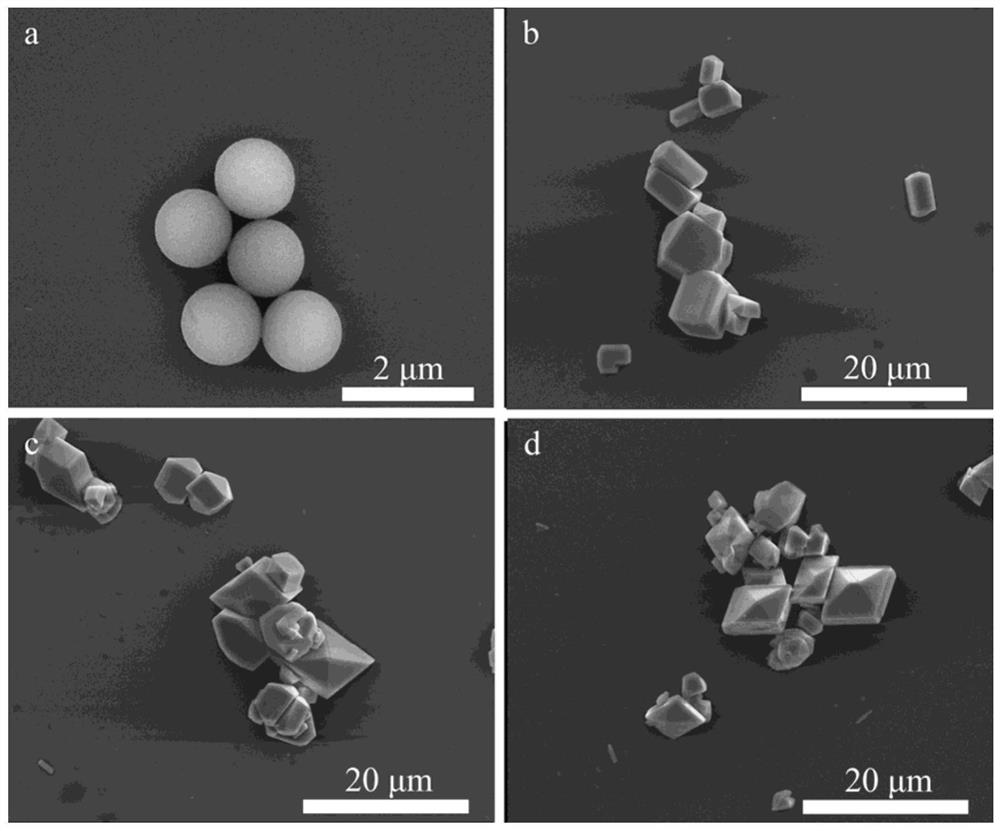

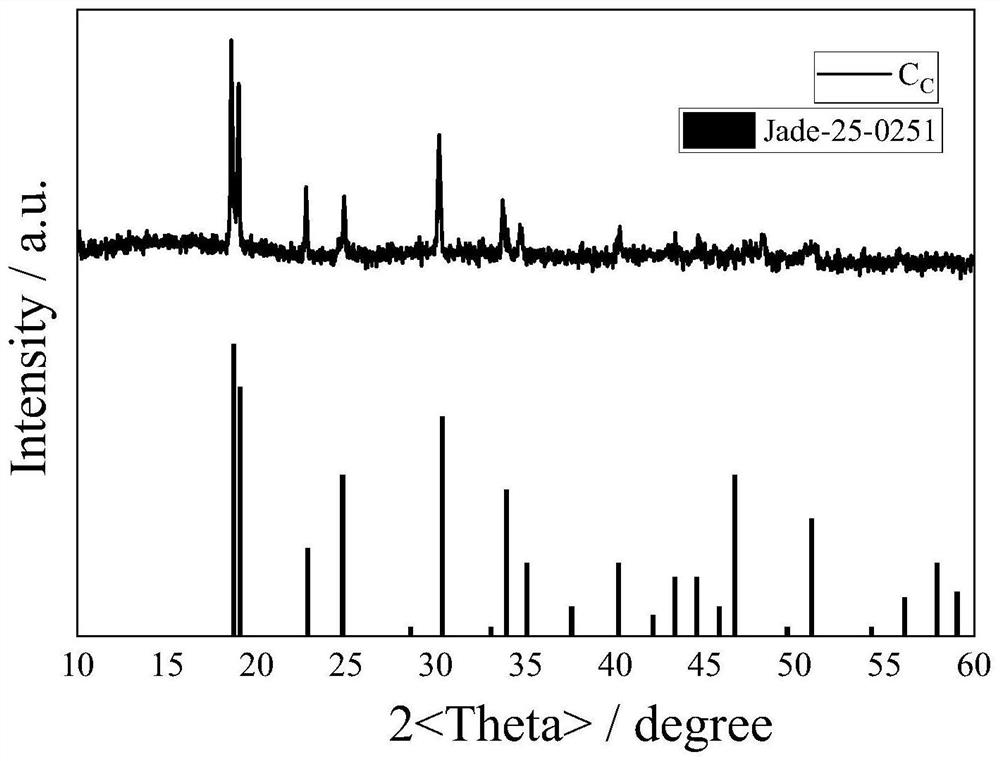

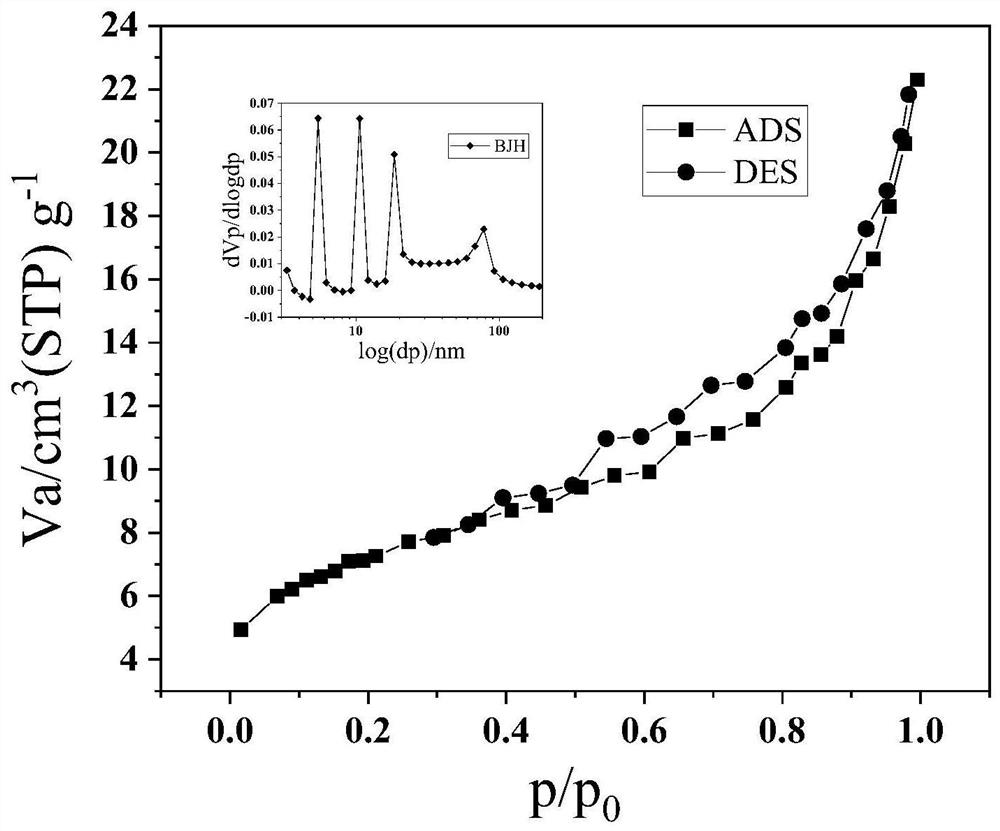

[0043] (3) Heat the suspension in water at 160°C for 15 hours, then filter it with suction, wash it with water three times, and wash it with alcohol three times, and then dry it under vacuum at 180°C for 12 hours to obtain CoC 2 o 4 Powder "C c ".

[0044] The above embodiments of the present invention are preferred embodiments.

[0045] In addition, it is also possible to modify specific parameters and materials on the basis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com