Tech. of extracting metallic cobait from magnetic-iron ore tailing slag

A technology for extracting metals and magnetite, which is applied in the field of cobalt metal extraction technology, can solve problems such as large gap between supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

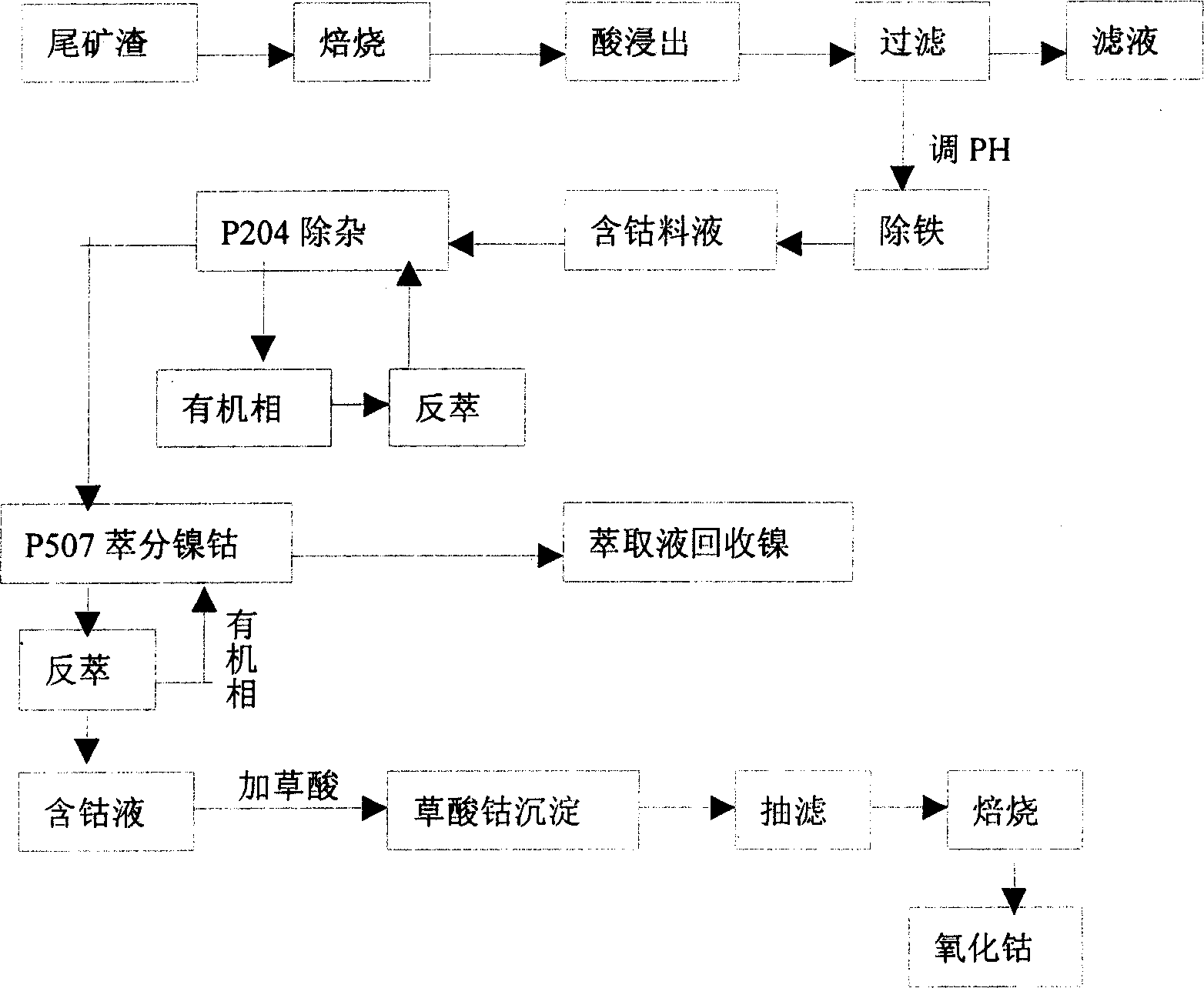

Method used

Image

Examples

Embodiment 1

[0030] The magnetite tailings are subjected to high-temperature roasting at 600°C for about 2.5 hours. The roasted solid slag is ground to a particle size of more than 200 mesh, and the powder is leached with 30% sulfuric acid to make the liquid-solid ratio 2:1, the temperature is 80°C, and the time is 1 hour. Add 10% sodium carbonate to the obtained solution to adjust the pH value of the solution to 10, and remove iron in the form of insoluble salt. After the reaction was completed, it was filtered, and the filter residue was washed twice with water. Take a certain amount of solution after iron removal, add Na 2 S 2 o 3 , so that Cu and Na 2 S 2 o 3 The mass ratio of the mixture is about 1:8, heated to make the temperature reach 90, the pH is 2.5, and the reaction time is 1.0h. Add NaF according to the total content of Ca and Mg, so that the molar ratio of the two reaches 1:1.2, and react for about 1.5h. Use organic phosphine extractants P204 and P507 to further remov...

Embodiment 2

[0032]The magnetite tailings were roasted at a high temperature of 700°C for 3.5 hours. The roasted solid is ground to a particle size of more than 200 mesh, and the powder is leached with 33% sulfuric acid to make the liquid-solid ratio 2.5:1, the temperature is 90° C., and the time is 1.2 hours. Adding 12% sodium carbonate to the obtained solution to adjust the pH value of the solution to 12, the iron can be removed in the form of insoluble salt. After the reaction was completed, it was filtered, and the filter residue was washed with water for 3 times. Take a certain amount of solution after iron removal, add Na 2 S 2 o 3 , so that Cu and Na 2 S 2 o 3 The mass ratio of the mixture is about 1:9, heated to make the temperature reach 93°C, the pH is 2.8, and the reaction time is 1.2h. Add NaF according to the total content of Ca and Mg therein, so that the molar ratio of the two reaches 1:1.4, and react for about 1.8 hours. Use organic phosphine extractants P204 and P5...

Embodiment 3

[0034] The magnetite tailings were roasted at a high temperature of 750°C for 4.5 hours. The calcined solid is ground to a particle size of more than 200 mesh, and the powder is leached with 35% sulfuric acid to make the liquid-solid ratio 3:1, the temperature is 100° C., and the time is 1.5 hours. Adding 15% sodium carbonate to the obtained solution to adjust the pH value of the solution to 15, the iron can be removed in the form of insoluble salt. After the reaction was completed, it was filtered, and the filter residue was washed with water for 3 times. Take a certain amount of solution after iron removal, add Na 2 S 2 o 3 , so that Cu and Na 2 S 2 o 3 The mass ratio of the mixture is about 1:10, heated until the temperature reaches 95°C, the pH is 3.0, and the reaction time is 1.5h. Add NaF according to the total content of Ca and Mg therein, so that the molar ratio of the two reaches 1:1.5, and react for about 2.0 hours. Use organic phosphine extractants P204 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com