Method for separating and recovering cobalt from chromium-containing waste hard alloy

A cemented carbide, separation and recycling technology, applied in the direction of improving process efficiency, can solve problems such as large limitations, and achieve the effects of reducing recycling cost, low energy consumption, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

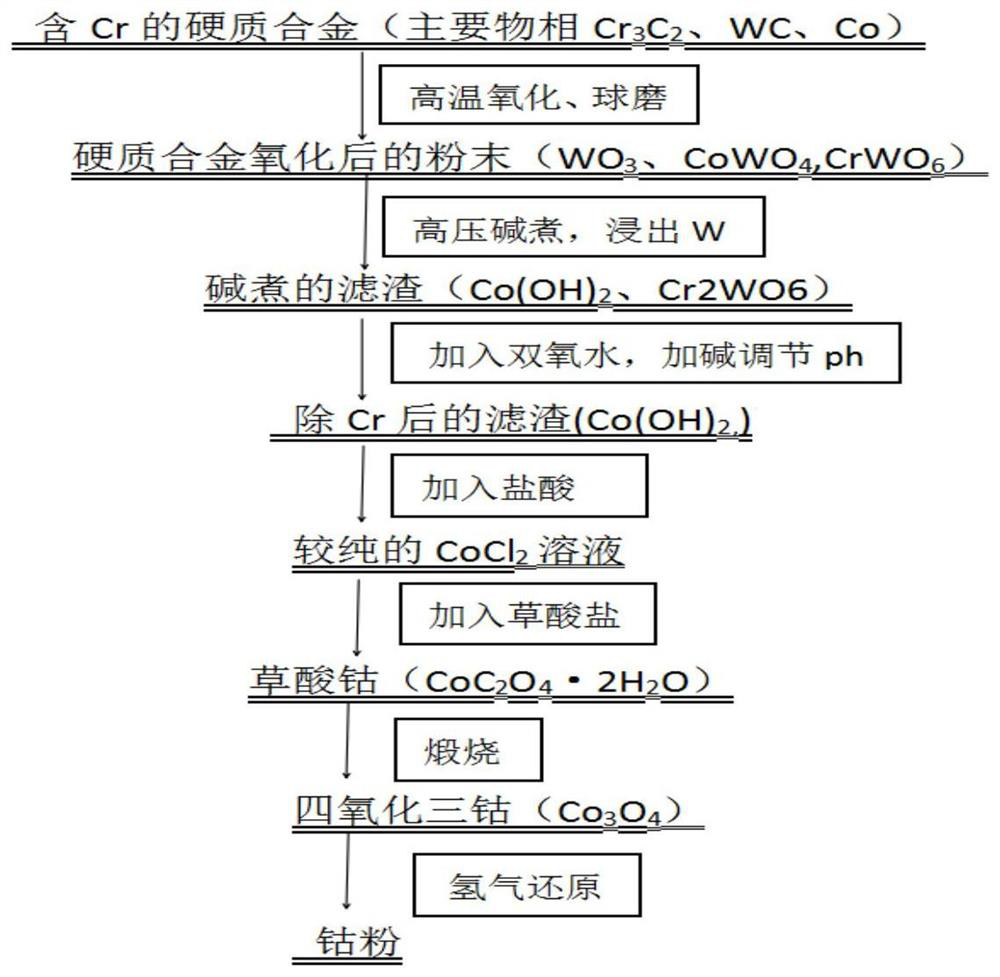

Method used

Image

Examples

Embodiment 1

[0043] A method for separating and recovering cobalt from chromium-containing waste cemented carbide, the steps are as follows:

[0044] (1) Take waste cemented carbide and waste cemented carbide, the main phase of which is Cr 3 C 2 (accounting for about 1% of the alloy mass), WC and Co;

[0045] (2) calcining the waste cemented carbide at 850° C. for 4 hours, and rolling ball milling for 12 hours to obtain oxidized powder;

[0046] (3) Mix the oxidized powder and sodium hydroxide evenly at a mass ratio of 1:2, then add 4 times the volume of deionized water, place it in a high-pressure reactor, adjust the pressure to 1.0MPa, and the stirring speed is 200r / min, pressure cook at 150°C for 6 hours, filter after completion of pressure cooking;

[0047] (4) Wash the filter residue obtained in step (3) with deionized water for 3 times, then wash with ethanol once, and then dry at 120° C. for 4 hours to obtain a loose and uniform powder;

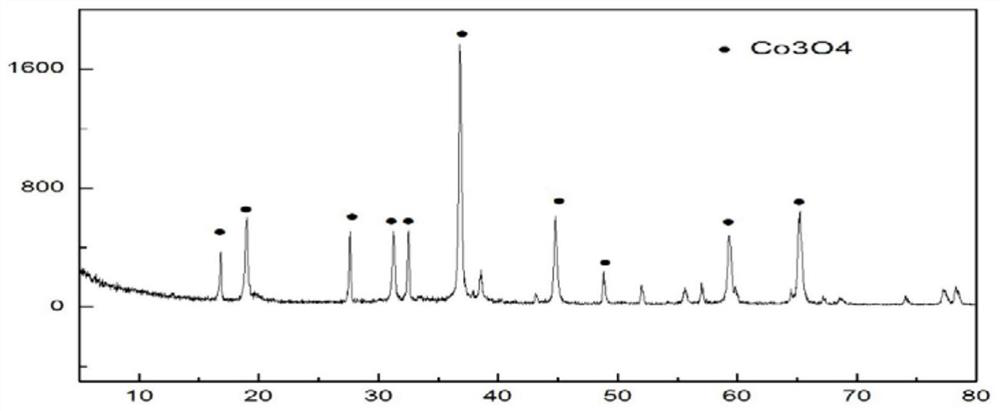

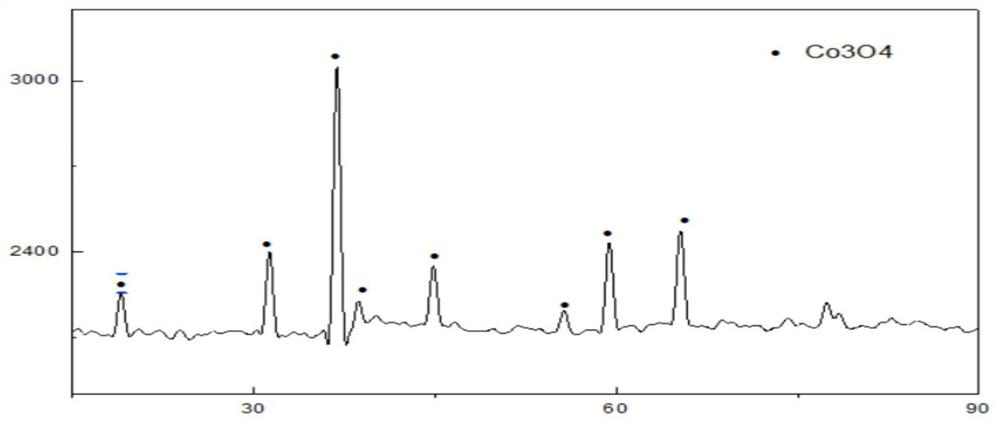

[0048] (5) Take 50 g of the powder obta...

Embodiment 2

[0056] A method for separating and recovering cobalt from chromium-containing waste cemented carbide, the steps are as follows:

[0057] (1) Take waste and old cemented carbide Take waste and old cemented carbide Take waste and old cemented carbide, its main phase is Cr 3 C 2 (about 2% of the alloy mass), WC and Co;

[0058] (2) calcining the waste cemented carbide at 850° C. for 5 hours, and rolling ball milling for 24 hours to obtain oxidized powder;

[0059] (3) Mix the oxidized powder and sodium hydroxide evenly with a mass ratio of 1:1.2, then add 2 times the volume of deionized water, place it in a high-pressure reactor, adjust the pressure to 1.5MPa, and the stirring speed is 200r / min, pressure cook at 100°C for 4 hours, filter after completion of pressure cooking;

[0060] (4) Wash the filter residue obtained in step (3) with deionized water for 3 times, then wash with ethanol once, and then dry at 120° C. for 4 hours to obtain a loose and uniform powder;

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com