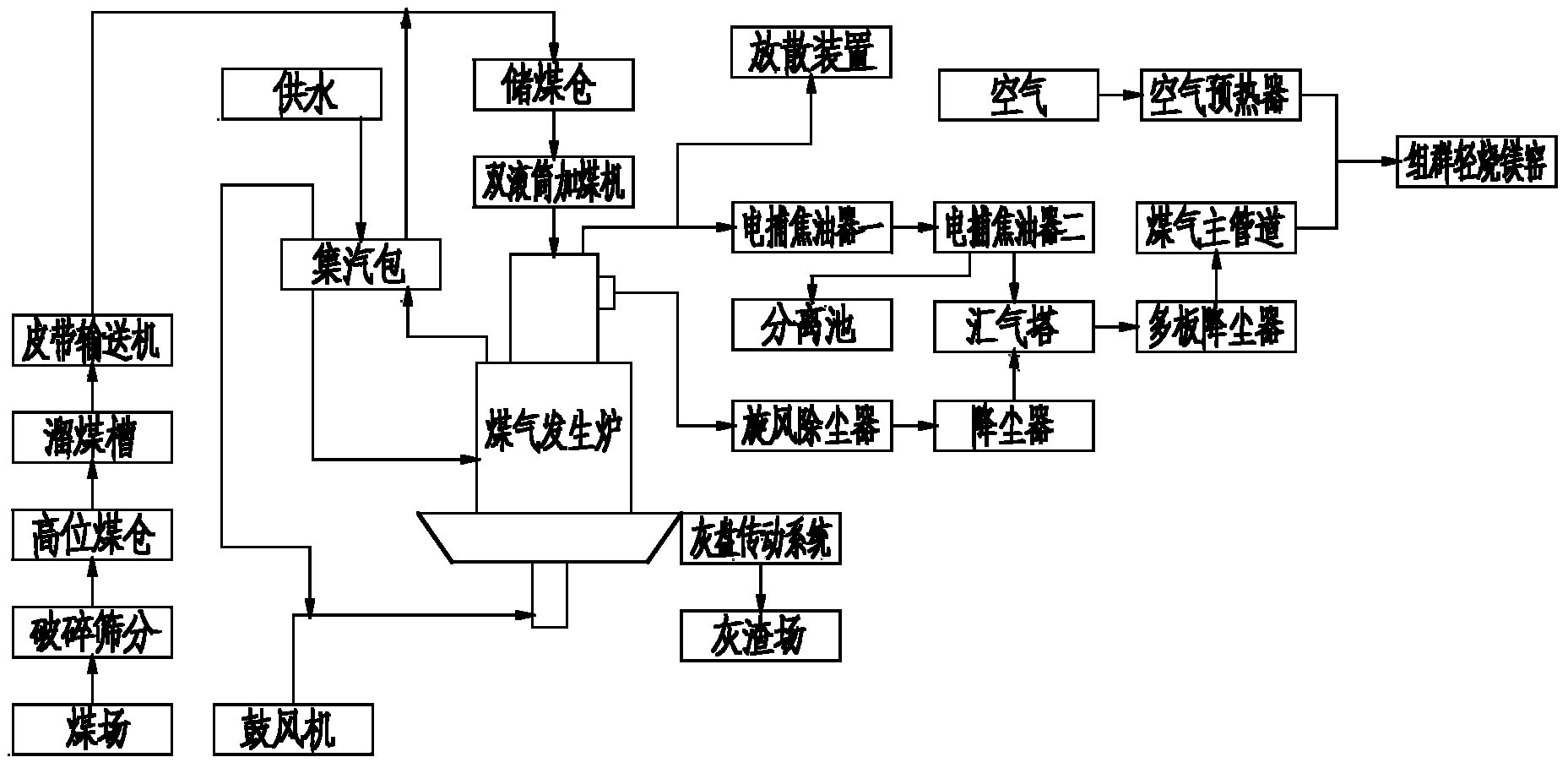

Grouped lightly-calcined magnesium kiln heating process and device

A heating device and heating process technology, applied in the field of lightly burned magnesium, can solve the problems of unpurified gas, low economic benefits, and large energy waste, and achieve the effects of improving gas cleanliness, high degree of automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

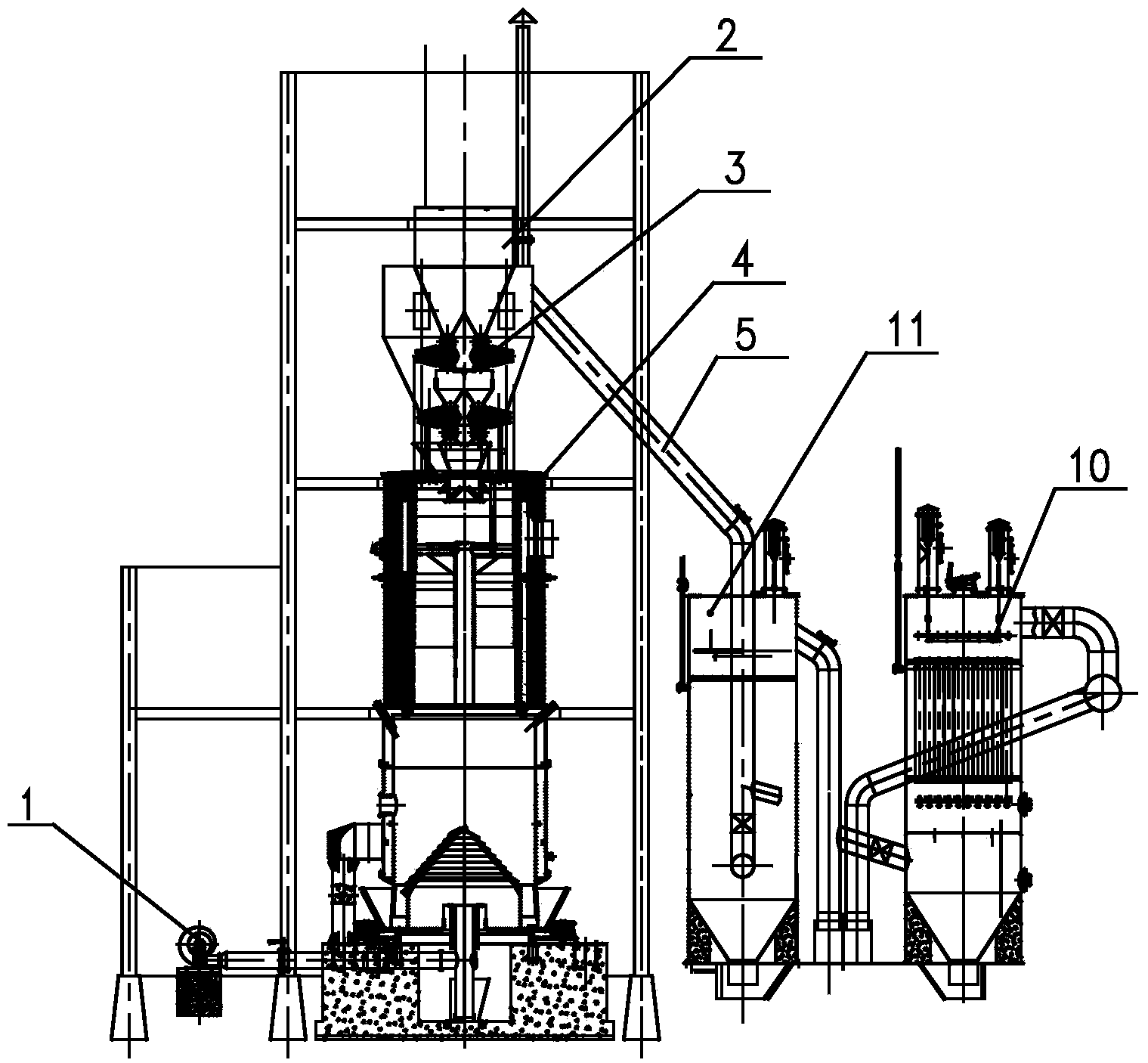

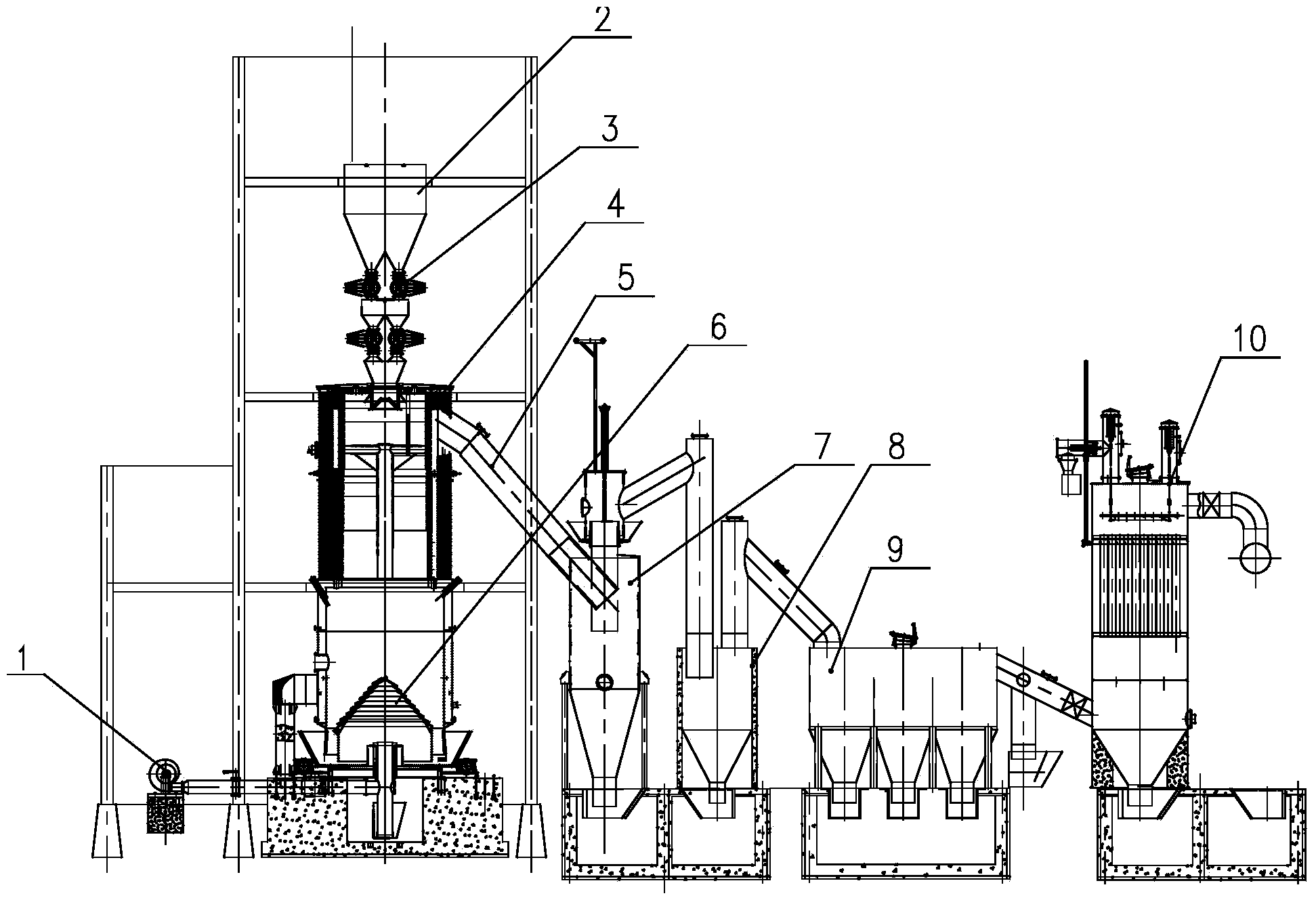

[0086] [Example 1] Applying the process and device described in the present invention to provide heat for 14 light-fired magnesium kilns in a magnesium factory in Haicheng, operate according to the aforementioned process, the main device and equipment parameters are as follows:

[0087] 1) Drum stoker: Double-drum stoker is driven by hydraulic pressure, and it is turned off alternately when adding coal;

[0088] 2) Gas generator: Lignite gas-making two-stage gas generator is used, the grate is hexahedron, eight spirals, honeycomb ventilation hole grate, and ash removal on both sides;

[0089] 3) Cyclone dust collector: adopt XFCQ2.4 type, main body diameter ¢2400mm; gas handling capacity: 5500~9000Nm 3 / h; Dust removal efficiency: 50-60%;

[0090] 4) Electric tar remover: adopt C-72 type, maximum gas processing capacity: 70000Nm 3 / h; rated voltage 60000V; working current: 150mA; gas flow rate: 0.6m / s; sedimentation pole diameter: ¢253mm; dust removal efficiency: 98-99%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com