Preparation method based on solid-phase reaction for capacitor electrode material

A capacitor electrode, solid-phase reaction technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, vanadium halide and other directions, can solve problems such as poor conductivity of cobalt tetroxide, restricting electrochemical performance, and large electrode resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

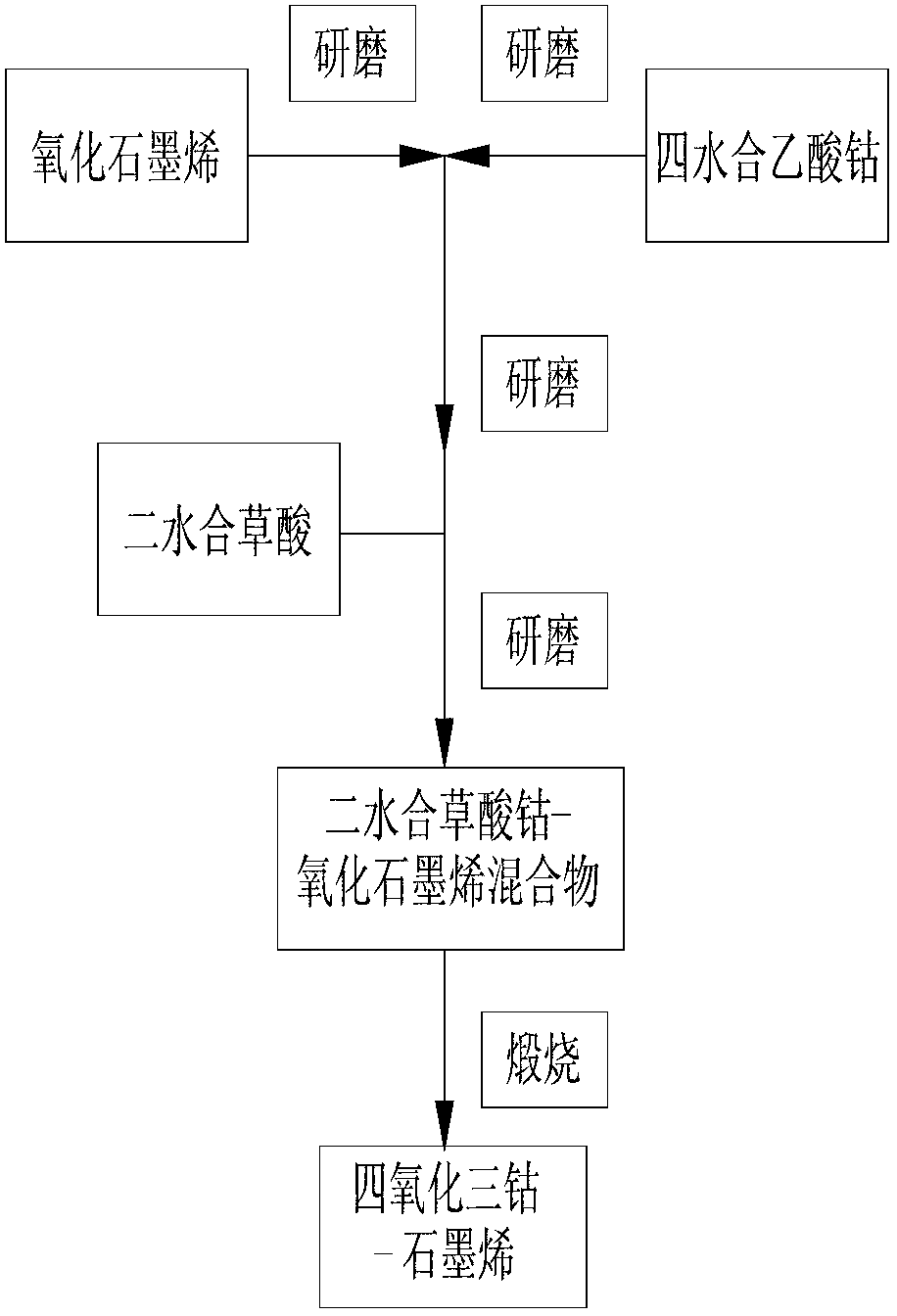

[0044] Such as figure 1 Shown, this capacitor electrode material preparation method based on solid phase reaction comprises the following steps:

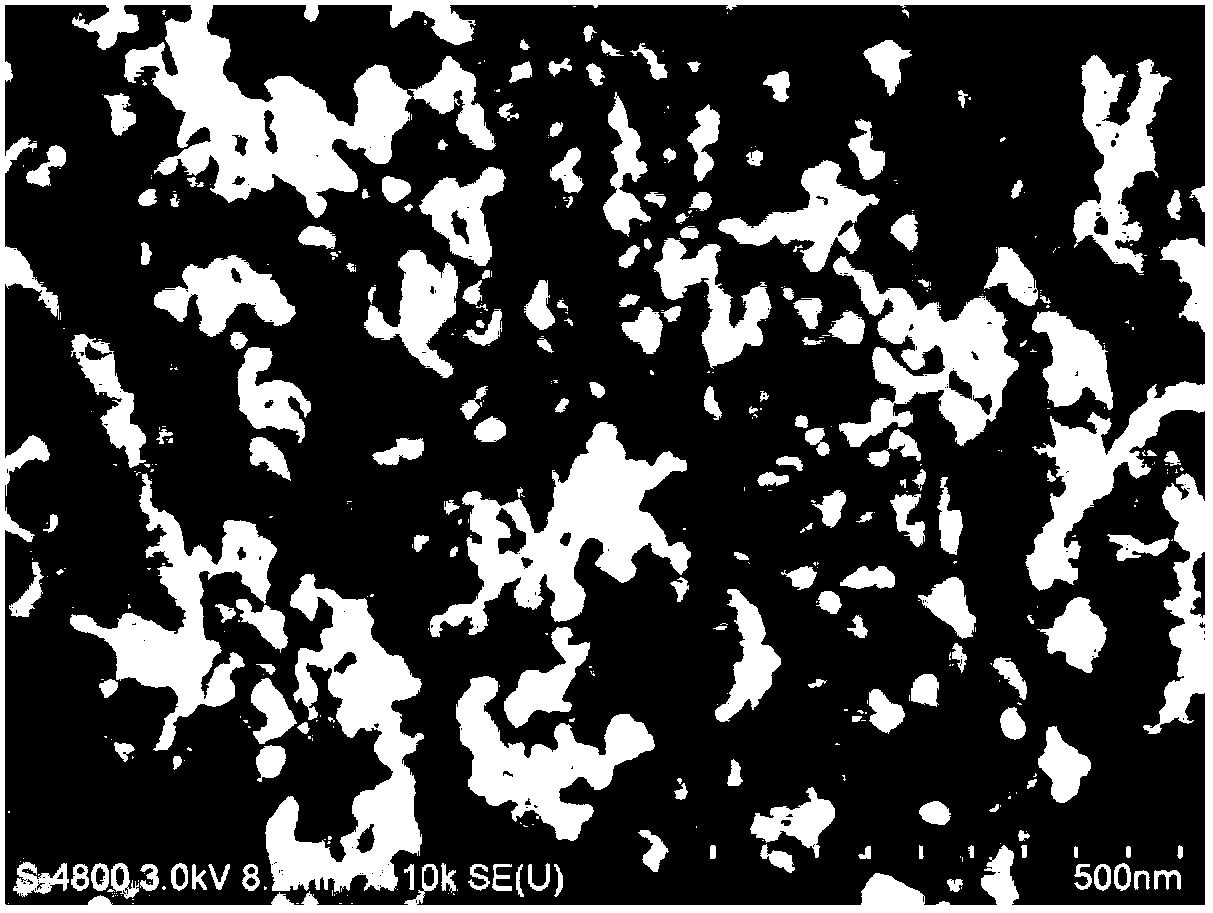

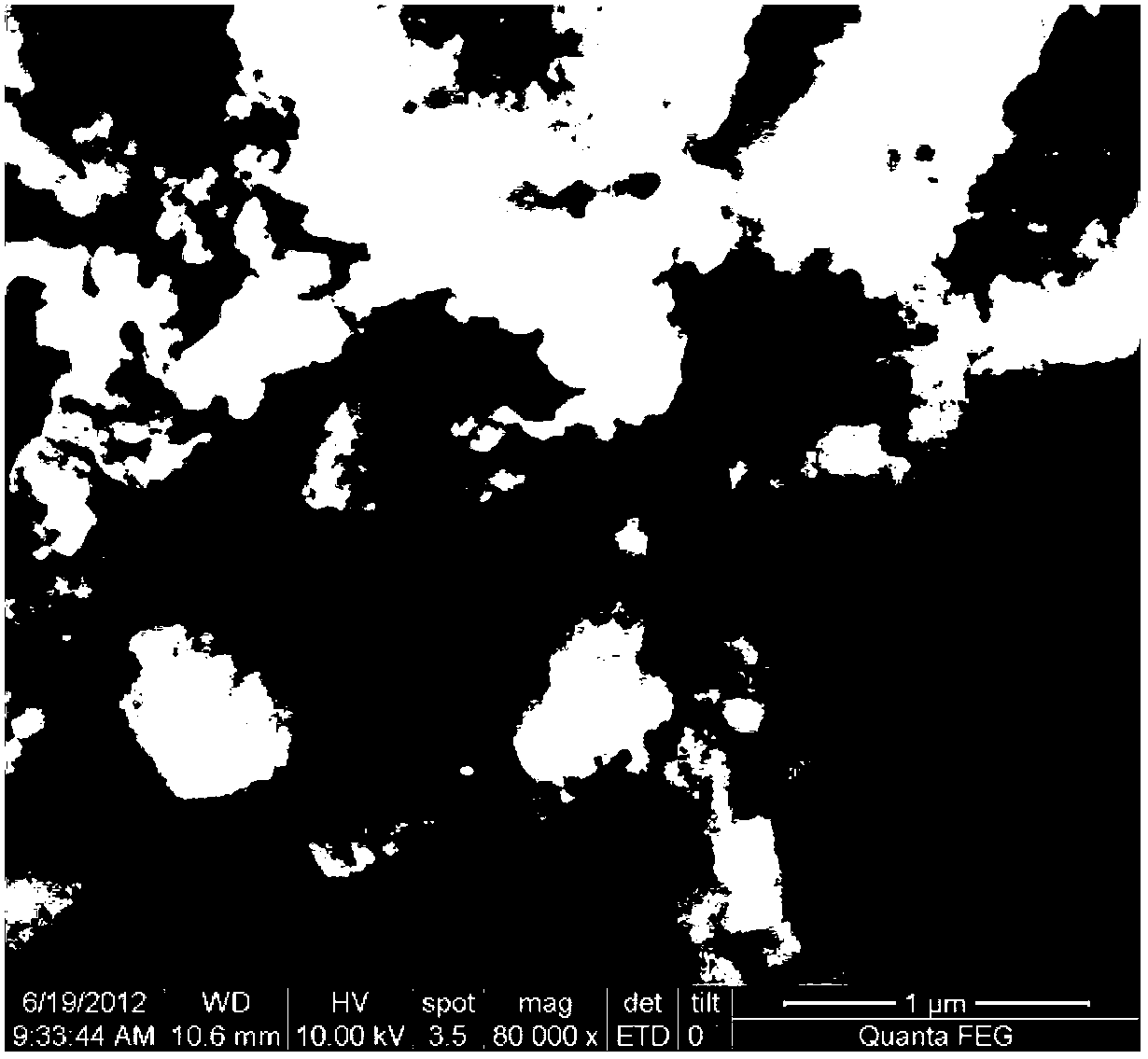

[0045] 1. First, weigh the raw materials cobalt acetate tetrahydrate and oxalic acid dihydrate in a molar ratio of 1:1, for example, weigh 0.747g of cobalt acetate tetrahydrate and 0.378g of oxalic acid dihydrate, and grind them in an agate mortar for 0.5h respectively , to ensure that the reactants are fully refined; 2, then, take graphene oxide 0.06g (the amount of graphene oxide is preferably 5% to 30% of the quality of the final cobalt tetroxide obtained, and the present embodiment takes 0.06g to be about the final obtained 25% of the quality of tricobalt tetroxide), mixed evenly with the above-mentioned ground cobalt acetate tetrahydrate, and then ground for about 0.25h; Until the gas with a pungent smell is released, a black paste precursor is obtained, the main component of which is a cobalt oxalate-graphene oxide mixture. ...

Embodiment 2

[0054] Such as figure 1 As shown, the method for preparing the capacitor electrode material in this embodiment differs in step 2:

[0055] The precursor was placed in a tube furnace, raised from room temperature to 300° C. over 0.5 h, and continued to be calcined at this temperature for 0.5 h to obtain a black tricobalt tetroxide-graphene composite material. Comparing the three cobalt tetroxide-graphene composite materials calcined under two kinds of temperature conditions, its properties are as follows: image 3 As shown, the integral area of the cyclic voltammetry curve of the sample at the calcination temperature of 275°C is greater than that at the calcination temperature of 300°C, indicating that the specific capacitance of the sample at the calcination temperature of 275°C is greater than that at the calcination temperature of 300°C.

Embodiment 3

[0057] The capacitor electrode material preparation method of the present embodiment, see Figure 4 , including the following steps:

[0058] 1. First weigh the raw materials cobalt acetate tetrahydrate and citric acid monohydrate in a molar ratio of 1:1, for example, weigh 0.747g of cobalt acetate tetrahydrate and 0.627g of citric acid monohydrate, and grind them in an agate mortar 1h to ensure that the reactant is fully refined; 2. Then, take 0.072g of graphene oxide (according to 30% of the mass of cobalt tetroxide finally obtained), mix it with the above-mentioned ground cobalt acetate tetrahydrate, and then grind for about 0.5h; 3. Finally, continue grinding with the above-mentioned ground citric acid monohydrate for 0.5h at room temperature until the gas without pungent odor in the mixture is released, and a black paste precursor is obtained. The main component is cobalt citrate-graphite oxide Alkene mixture.

[0059] A chemical reaction occurs in the above grinding, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com