Composite material loaded by taking starch as carbon base as well as preparation method and application of the composite material

A composite material and starch technology, which is used in the preparation/purification of carbon, hybrid capacitor electrodes, cobalt oxide/cobalt hydroxide, etc. The effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

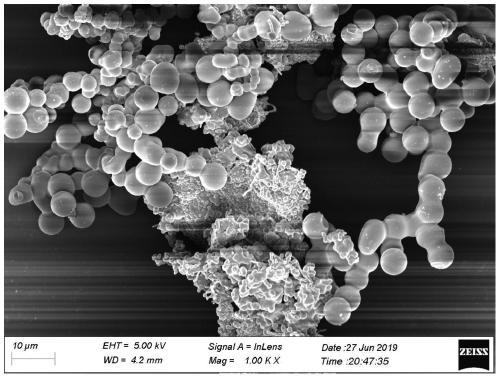

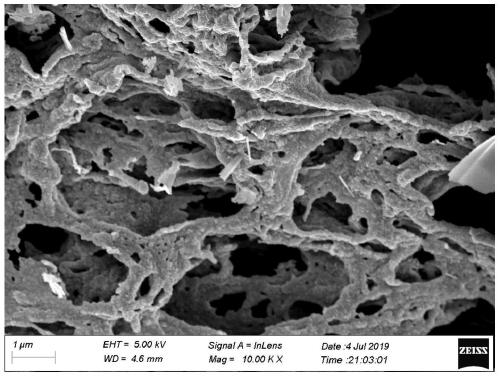

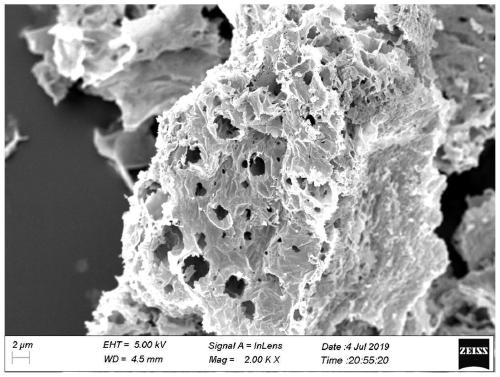

Image

Examples

preparation example Construction

[0038] An embodiment of the present invention provides a method for preparing a composite material with starch as a carbon-based load, which includes the following steps:

[0039] S1. Uniformly mixing the starch solution and the cobalt source solution to obtain a mixed solution; wherein the cobalt source solution is an aqueous solution containing a cobalt compound.

[0040] In this embodiment, the starch solution is used as a conductive 3D carbon network and mixed with other heteroatom-containing precursors to obtain a nanocomposite electrode material with a special structure and excellent performance. Optionally, the starch and the cobalt source can be dissolved in deionized water respectively to obtain a starch solution and a cobalt source solution, which are evenly stirred to obtain a mixed solution. By adjusting the concentration of the starch solution, the viscosity of the starch solution can be changed, and then the pore size of the carbon template obtained after carboni...

Embodiment 1

[0054] This embodiment provides a method for preparing a composite material with starch as a carbon-based load, comprising the following steps:

[0055] S1. Add starch and deionized water with a mass ratio of 3:1 into a beaker and mix evenly to obtain a starch solution with a mass concentration of 75 wt%. 4.37 g of cobalt nitrate hexahydrate was dissolved in deionized water and uniformly stirred and dissolved to obtain a 0.15 mol / L cobalt source solution. The starch solution and the cobalt source solution are uniformly mixed in a mass ratio of 3:1 to obtain a mixed solution;

[0056] S2. Put the mixed solution in a crucible, transfer the crucible to a muffle furnace, and take it out after a carbonization reaction at 500° C. for 0.5 h to obtain a carbon template;

[0057] S3. Put the carbon template in the reactor, add 2 / 3 of the volume of the reactor with deionized water, then react at 120° C. for 12 hours, rapidly cool and dry the reaction product to obtain a composite mater...

Embodiment 2

[0059] This embodiment provides a method for preparing a composite material with starch as a carbon-based load, comprising the following steps:

[0060] Steps S1 and S2 of this embodiment are the same as in Embodiment 1;

[0061] S3. Put the carbon template in the reactor, add 2 / 3 of the volume of the reactor with deionized water, then react at 150° C. for 12 hours, cool the reaction product rapidly, and dry to obtain a composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com