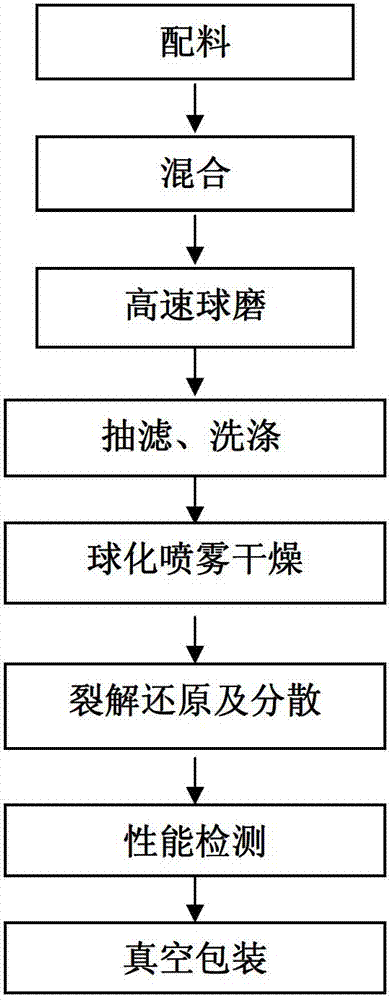

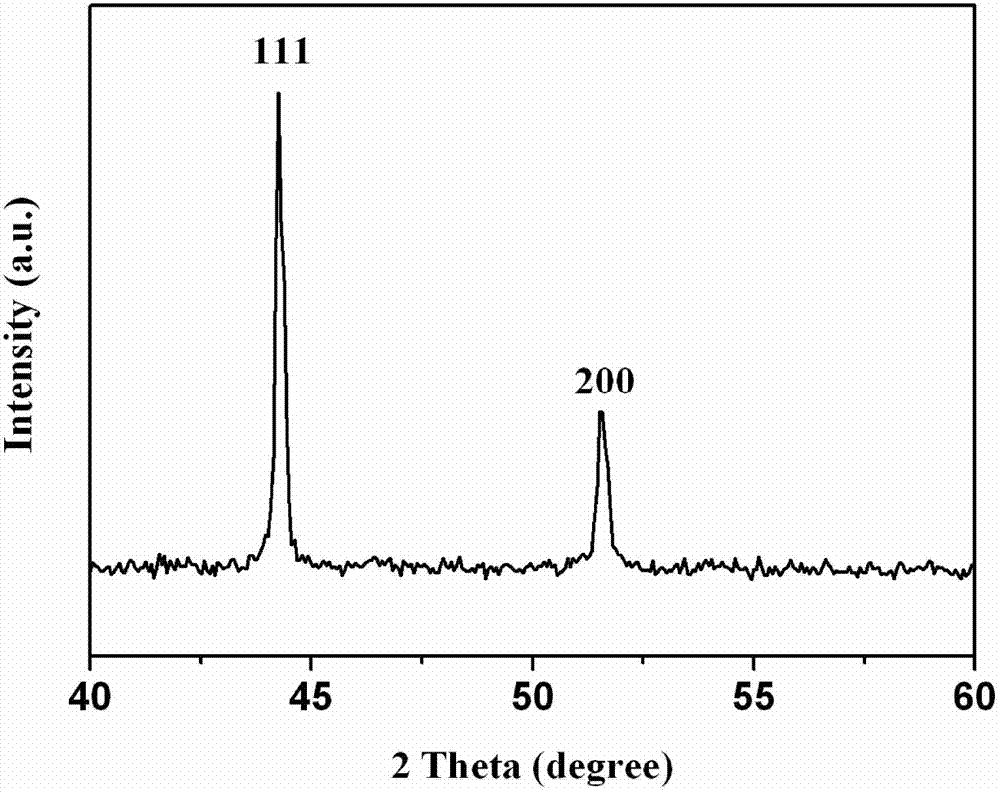

Method for preparing nanometer cobalt powders with spherical face-centered cubic structures by using mechano-chemical method

A mechanochemical method and cubic structure technology, which is applied in the field of preparing nano-spherical face-centered cubic structure cobalt powder by mechanochemical method, can solve the problems of poor polymer compatibility, affect the actual effect, easy to agglomerate, etc., and reduce ball milling. Mixing time, low processing cost, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Ingredients:

[0030] According to the stoichiometric ratio of each element in the chemical formula, weigh the corresponding oxalic acid H 2 C 2 o 4 2H 2 O2mol, cobalt nitrate Co(NO 3 ) 2 ·6H 2 01mol; Then take respectively surfactant cetyltrimethylammonium bromide and Polyethylene Glycol 1000 of 0.2wt% of the total mass of the above medicines;

[0031] 2. Ball milling:

[0032] The weighed oxalic acid H 2 C 2 o 4 2H 2 O, cobalt nitrate Co(NO 3 ) 2 ·6H 2 O. Cetyltrimethylammonium bromide and polyethylene glycol 1000 are fully mixed; then ball milled (ball-to-material ratio 3:1), absolute ethanol is added during ball milling, and the amount of ethanol added is kept dispersed by the ball milling system After 2 hours of ball milling time, suction filtration was performed, and an appropriate amount of alcohol was added after washing to obtain a precursor solution.

[0033] 3. Spheroidizing spray drying:

[0034] The prepared solution was dried with a sphe...

Embodiment 2

[0040] 1. Ingredients:

[0041] According to the stoichiometric ratio of each element in the chemical formula, weigh the corresponding oxalic acid H 2 C 2 o 4 2H 2 O1.5mol, cobalt nitrate Co(NO 3 ) 2 6H O1mol; Then take respectively the surfactant cetyltrimethylammonium bromide and polyethylene glycol 1000 of 0.3wt% of the total mass of the above medicines;

[0042] 2. Ball milling:

[0043] The weighed oxalic acid H 2 C 2 o 4 2H 2 O, cobalt nitrate Co(NO 3 ) 2 ·6H 2 O. Cetyltrimethylammonium bromide and polyethylene glycol 1000 are fully mixed; then ball milled (ball-to-material ratio 3:1), absolute ethanol is added during ball milling, and the amount of ethanol added is kept dispersed by the ball milling system After 3 hours of ball milling, suction filtration was added, and an appropriate amount of alcohol was added after washing to obtain a precursor solution.

[0044] 3. Spheroidizing spray drying:

[0045] The prepared solution was dried with a spheroidizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com