A kind of treatment and purification process of cobalt oxalate defective product

A cobalt oxalate and defective technology, which is applied in the field of processing and purification of defective cobalt oxalate products, can solve problems such as poisoning, and achieve the effects of reducing costs, recycling costs, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

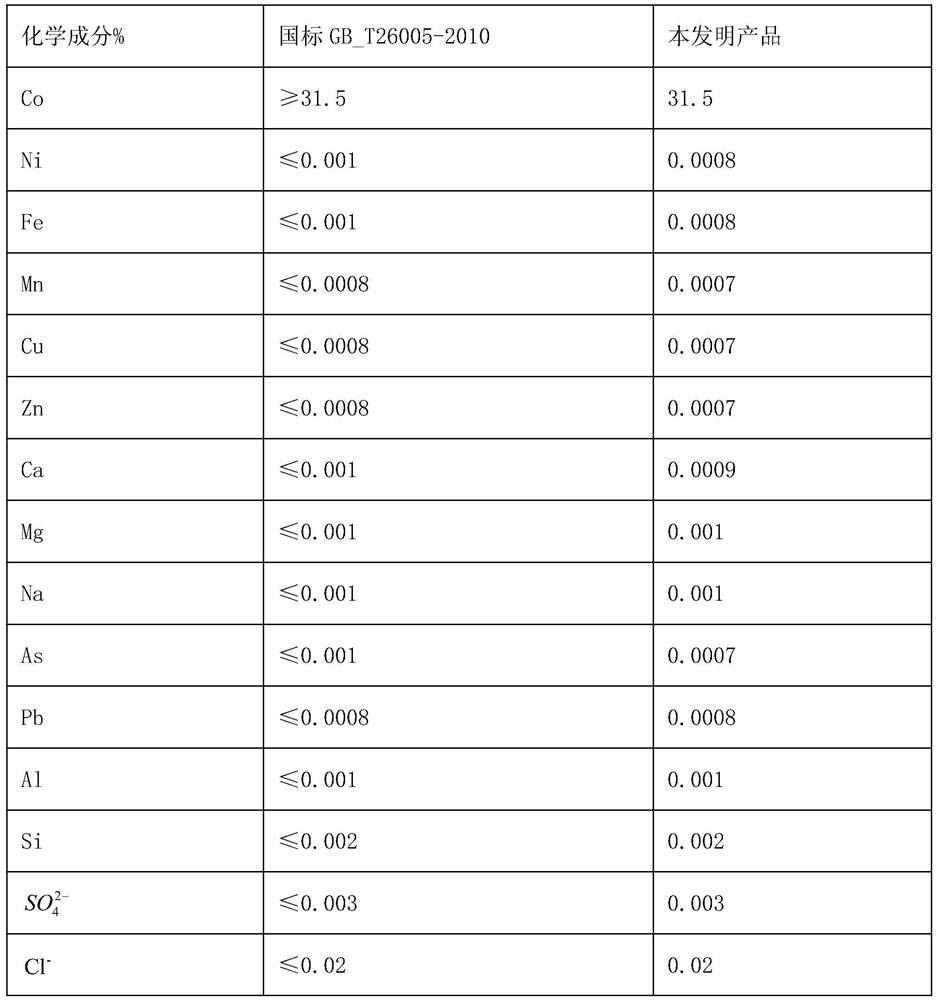

Embodiment 1

[0061] A treatment and purification process for cobalt oxalate defective products, comprising the following steps:

[0062] Step 1. Slurry waste cobalt oxalate with water according to the solid-to-liquid ratio of 1:9, then add ammonium carbonate according to the molar ratio of cobalt to ammonium carbonate of 1:1.3, react at 70-99°C for 2-4 hours, and then filter to obtain Cobalt filter residue and ammonium oxalate solution;

[0063] Step 2: Add water to the filter residue of Step 1 according to the solid-to-liquid ratio of 1:11, and add hydrochloric acid at the same time to maintain the pH of the reaction at 0.5-1.5, react at 60-99°C for 1-3 hours, and filter for many times, the filtrate For cobalt chloride solution;

[0064] Step 3, extracting the cobalt chloride solution of step 2 to remove impurities:

[0065] Specifically include the following steps: 1. Sodium saponification of P204: mixing the P204 extractant and solvent oil to form an organic phase, and fully reacting ...

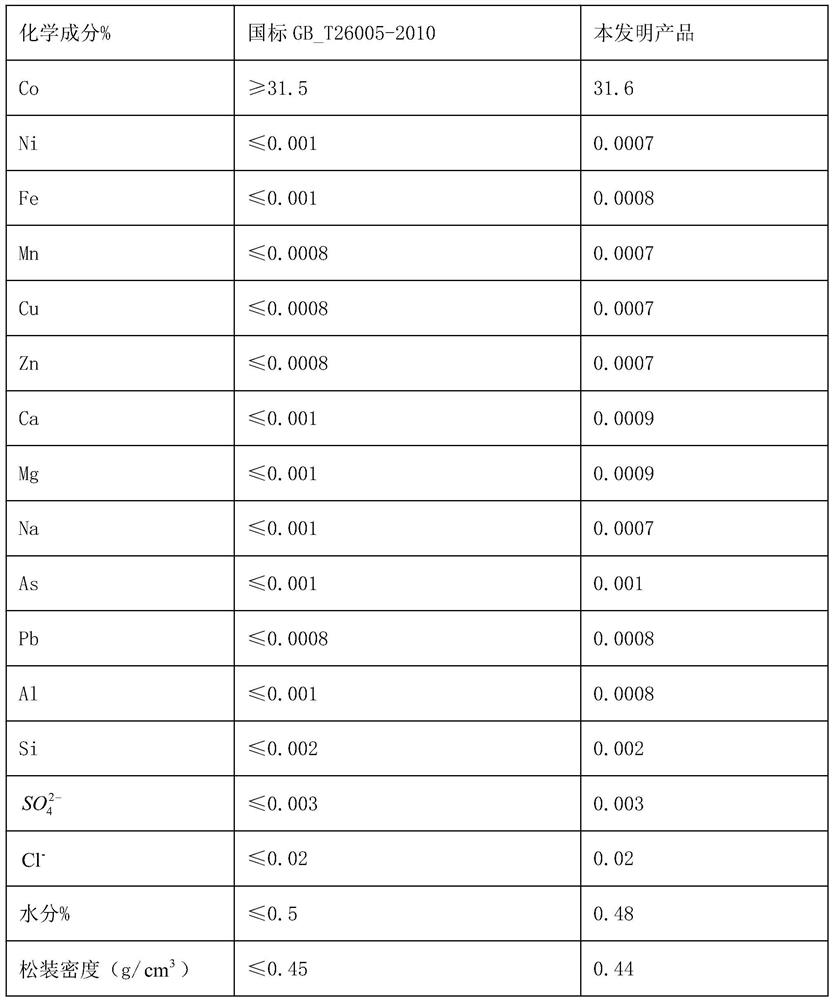

Embodiment 2

[0075] A treatment and purification process for cobalt oxalate defective products, comprising the following steps:

[0076] Step 1. Slurry waste cobalt oxalate with water according to the solid-to-liquid ratio of 1:9, then add ammonium carbonate according to the molar ratio of cobalt to ammonium carbonate of 1:1.4, react at 70-99°C for 2-4 hours, and then filter to obtain Cobalt filter residue and ammonium oxalate solution;

[0077]Step 2: Add water to the filter residue of Step 1 according to the solid-to-liquid ratio of 1:11, and add hydrochloric acid at the same time to maintain the pH of the reaction at 0.5-1.5, react at 60-99°C for 1-3 hours, and filter for many times, the filtrate For cobalt chloride solution;

[0078] Step 3, extracting the cobalt chloride solution of step 2 to remove impurities:

[0079] Specifically include the following steps: 1. Sodium saponification of P204: mixing the P204 extractant and solvent oil to form an organic phase, and fully reacting w...

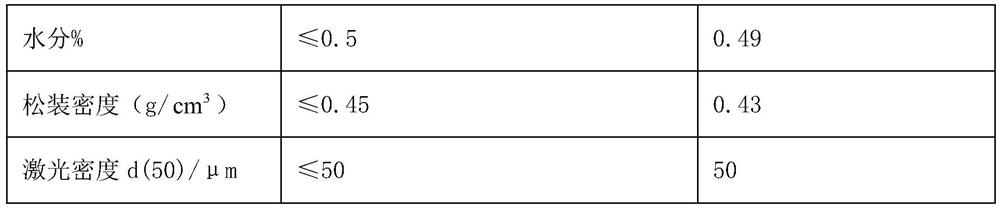

Embodiment 3

[0089] A treatment and purification process for cobalt oxalate defective products, comprising the following steps:

[0090] Step 1. Slurry waste cobalt oxalate with water according to the solid-to-liquid ratio of 1:9, then add ammonium carbonate according to the molar ratio of cobalt to ammonium carbonate of 1:1.5, react at 70-99°C for 2-4 hours, and then filter to obtain Cobalt filter residue and ammonium oxalate solution;

[0091] Step 2: Add water to the filter residue of Step 1 according to the solid-to-liquid ratio of 1:11, and add hydrochloric acid at the same time to maintain the pH of the reaction at 0.5-1.5, react at 60-99°C for 1-3 hours, and filter for many times, the filtrate For cobalt chloride solution;

[0092] Step 3, extracting the cobalt chloride solution of step 2 to remove impurities:

[0093] Specifically include the following steps: 1. Sodium saponification of P204: mixing the P204 extractant and solvent oil to form an organic phase, and fully reacting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com