Patents

Literature

136 results about "Oxalomalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

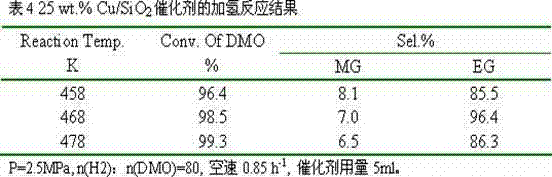

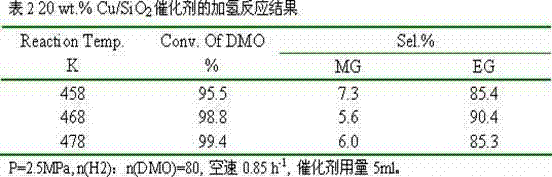

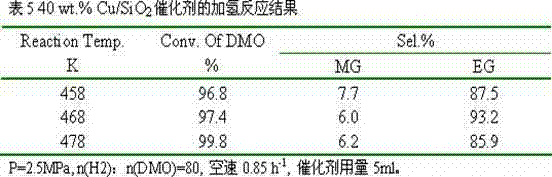

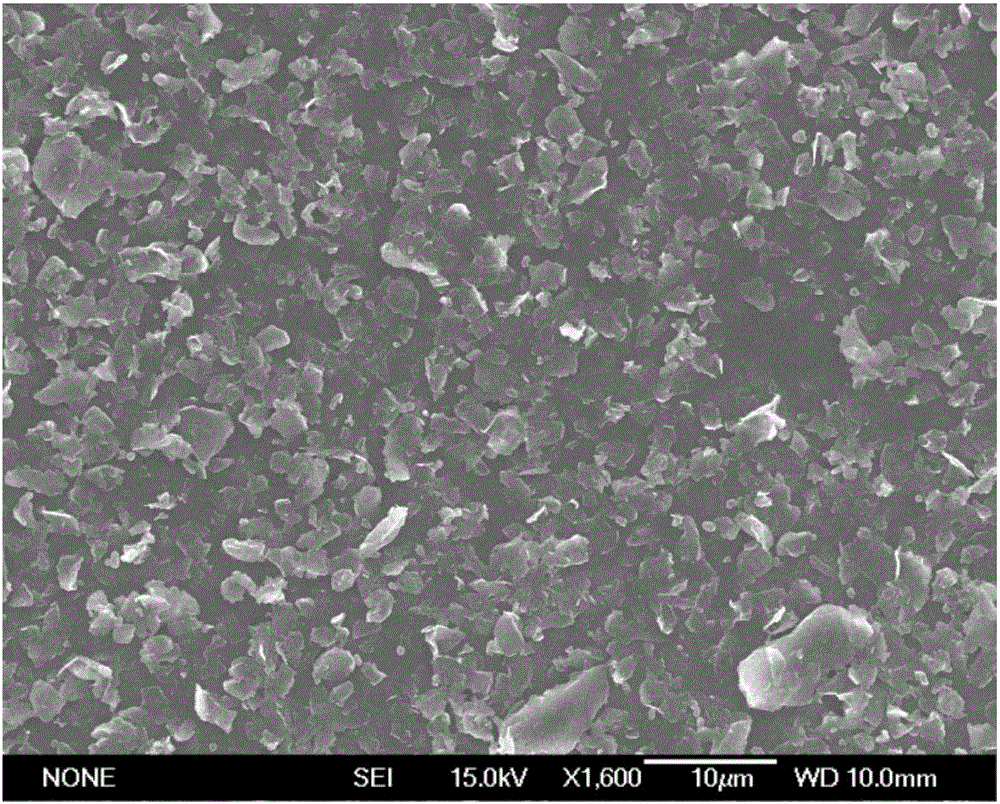

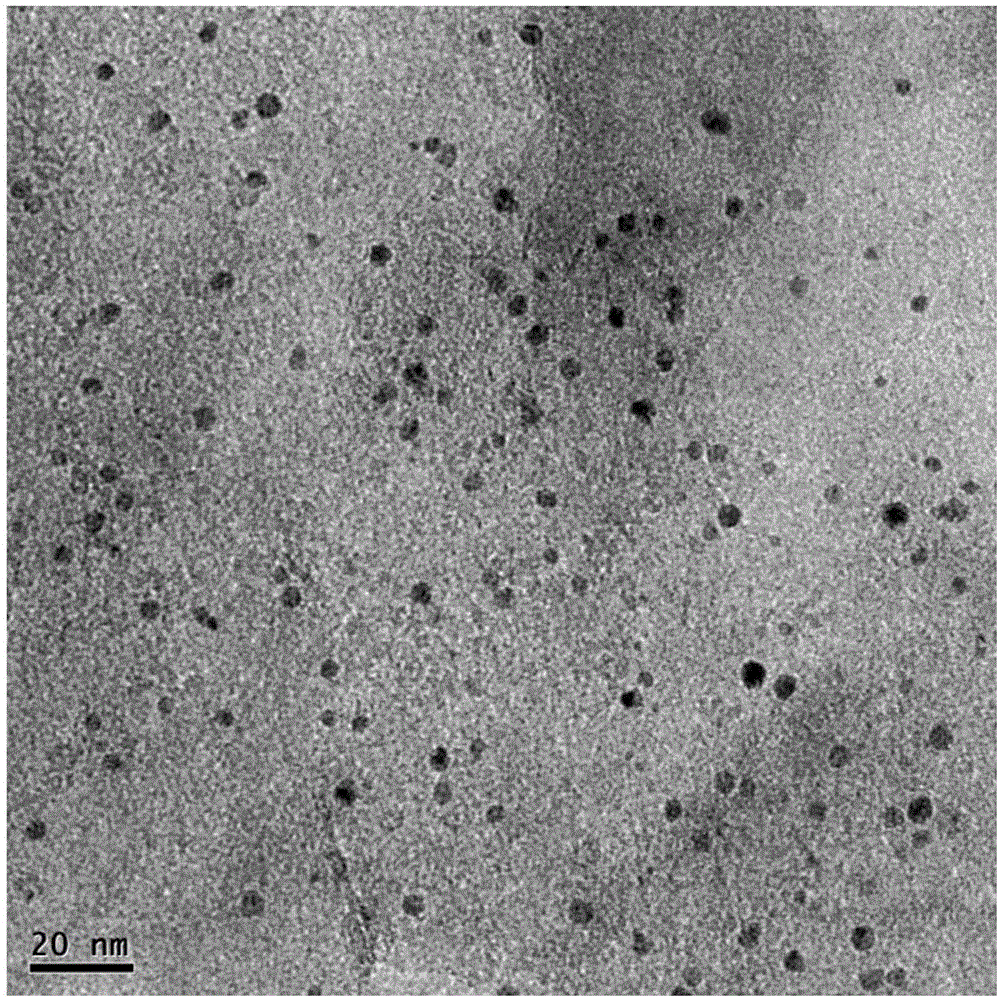

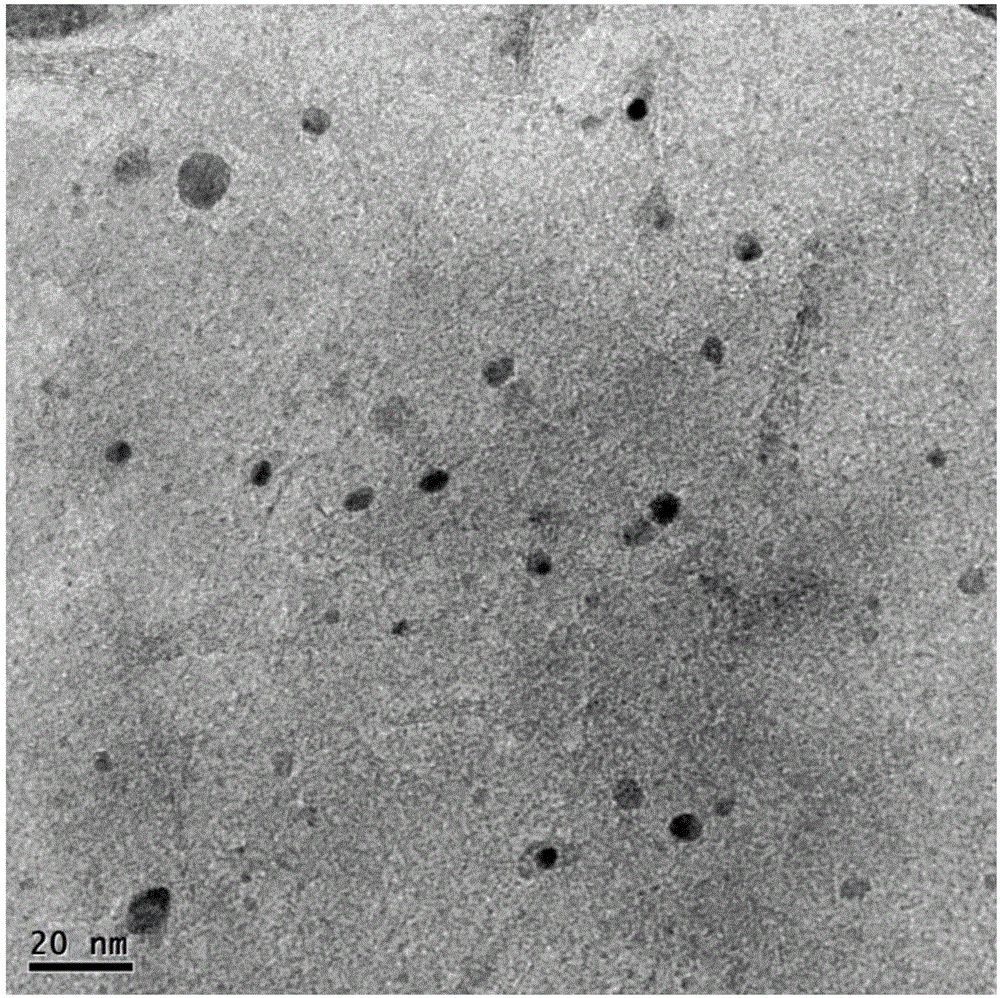

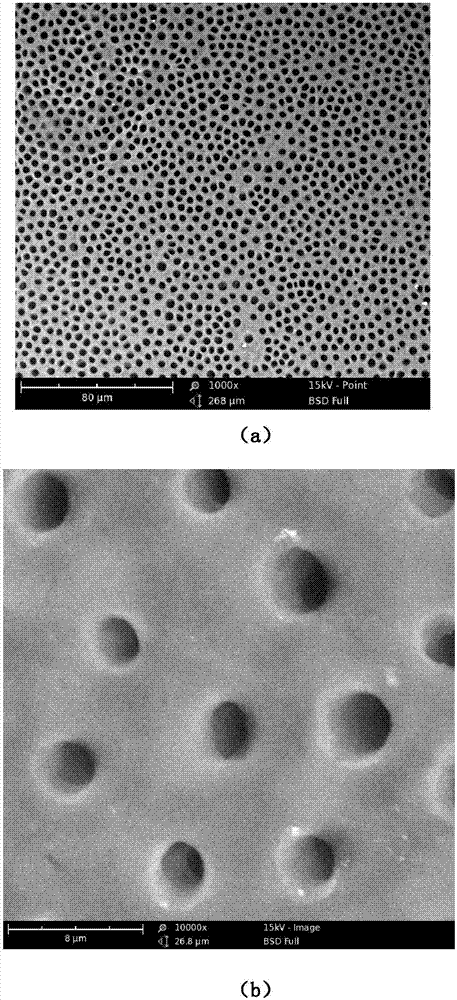

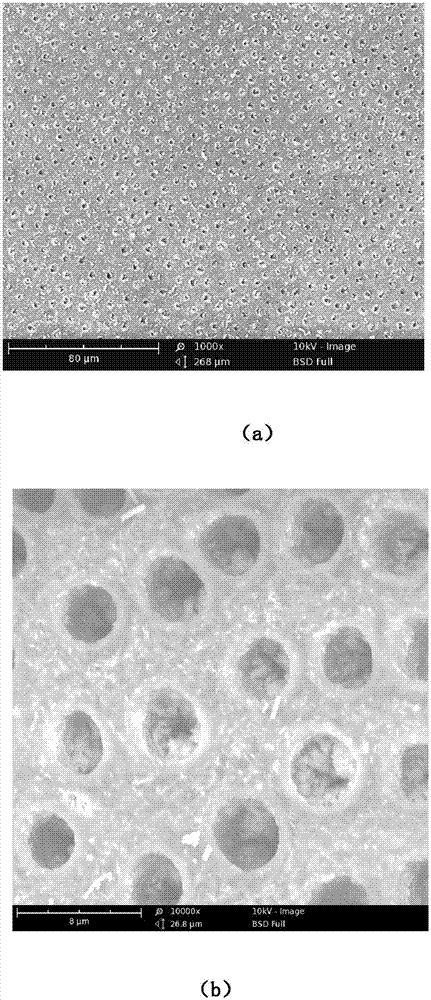

Copper-based catalyst used in preparation of glycol by catalytic hydrogenation of oxalate ester and preparation method thereof

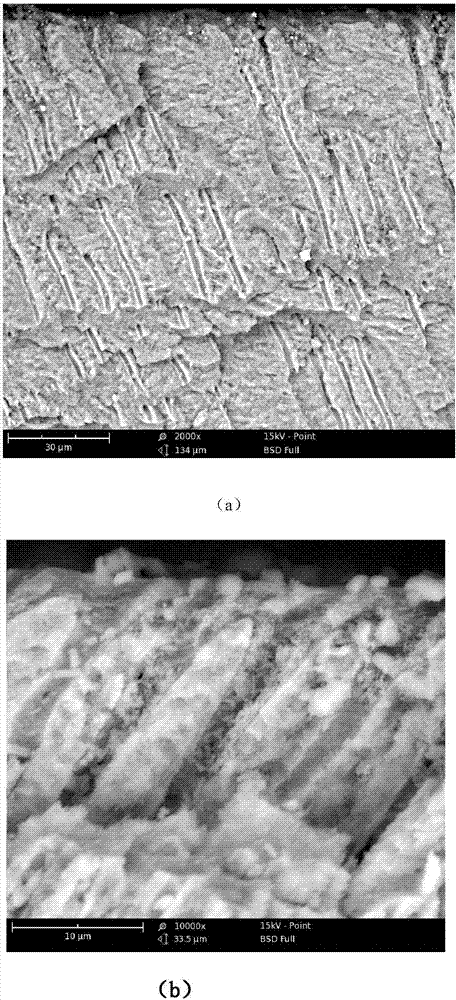

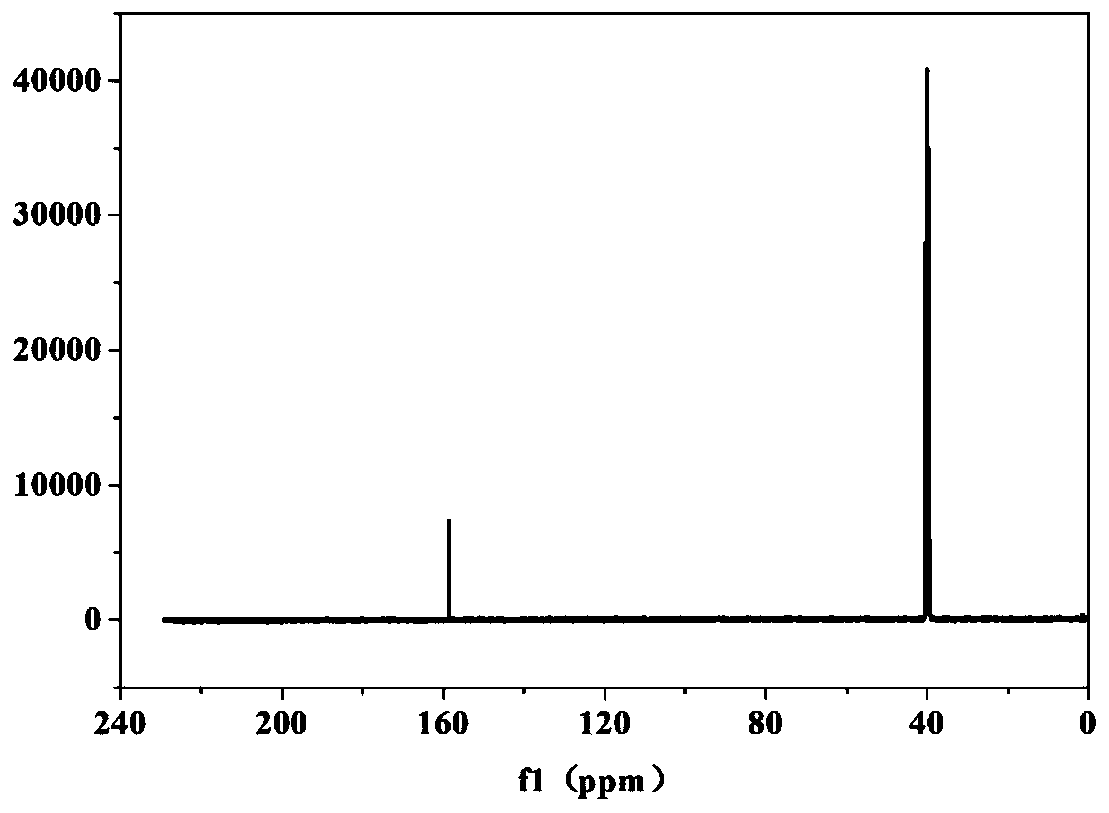

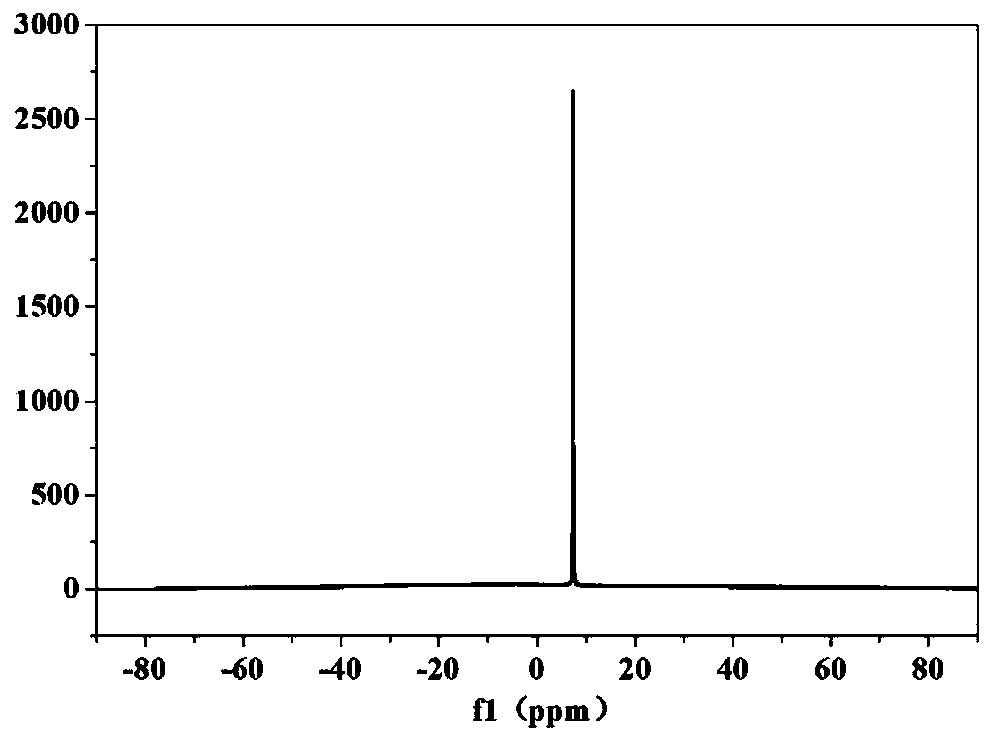

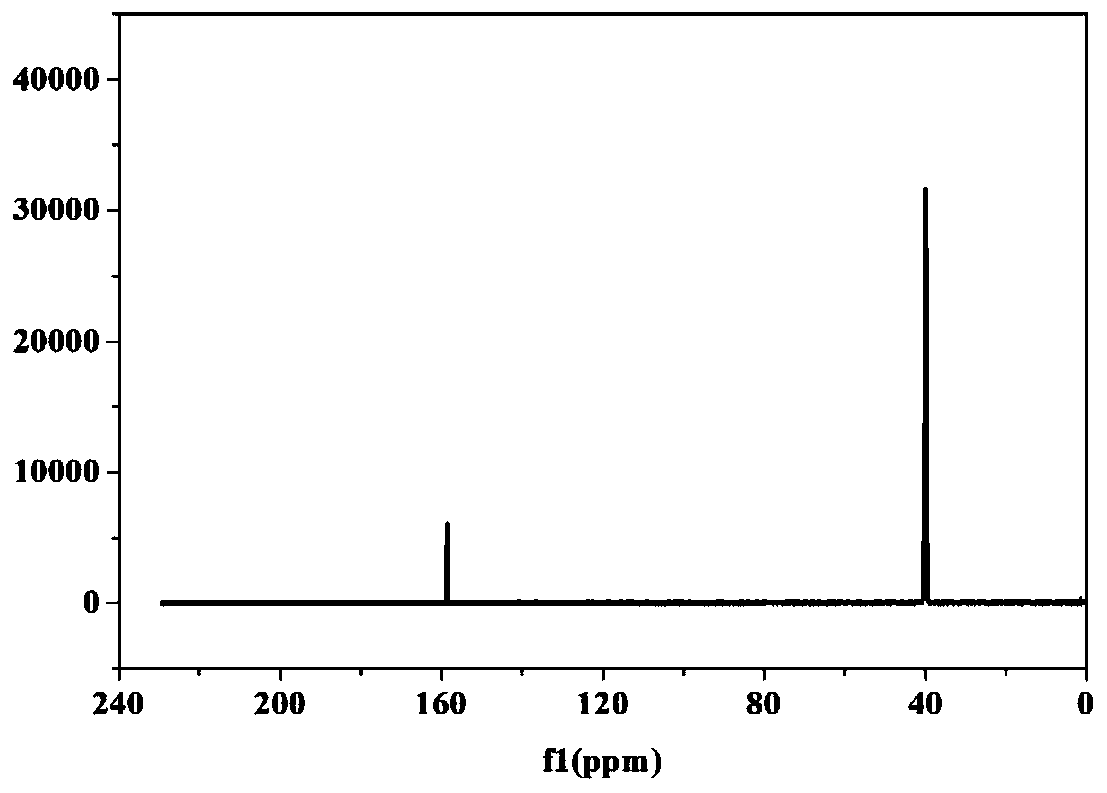

InactiveCN102350348ASmall particlesUniform particle size distributionOrganic compound preparationHydroxy compound preparationPtru catalystCopper oxide nanoparticles

The invention provides a copper-based catalyst used in preparation of glycol by catalytic hydrogenation of oxalate ester and a preparation method thereof. The catalyst comprises 10 to 50 wt% of copper and 50 to 90 wt% of silica, and has a specific surface area of 200 to 1200 m<2> / g, a pore volume of 0.5 to 1.4 cm<3> / g, an average aperture of 1.5 to 15 nm and a particle size below 100 nm; copper oxide nanoparticles are cladded by a mesoporous silicon shell, and a core-shell structure is formed. The catalyst provided in the invention has the advantages of a small particle size, uniform particlesize distribution, good dispersibility, and high activity, high selectivity and a long life when used in preparation of glycol by catalytic hydrogenation of oxalate ester. The preparation method has the advantages of simple operation and high yield.

Owner:河南能源化工集团研究总院有限公司

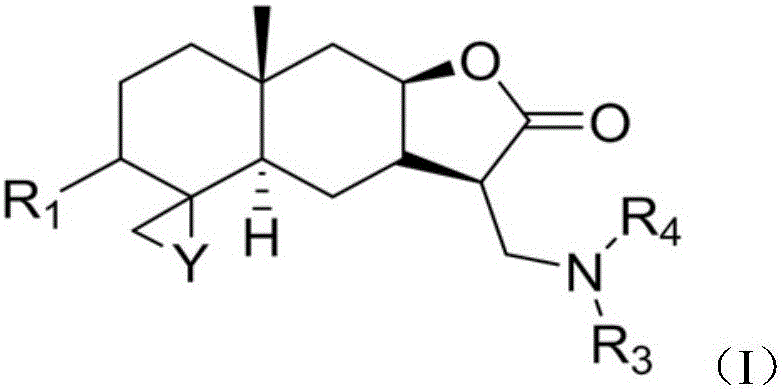

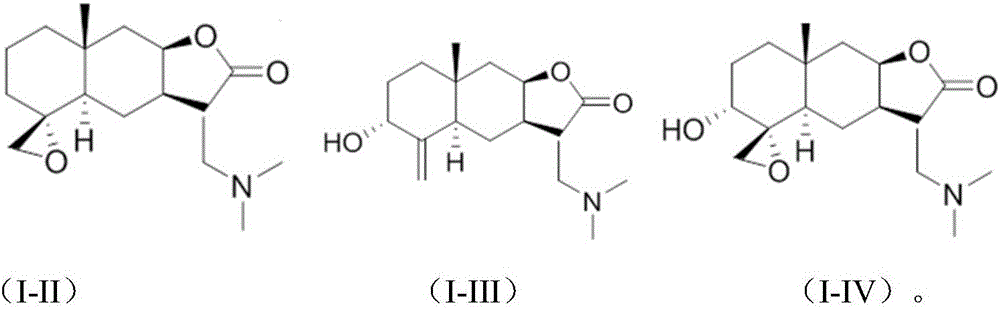

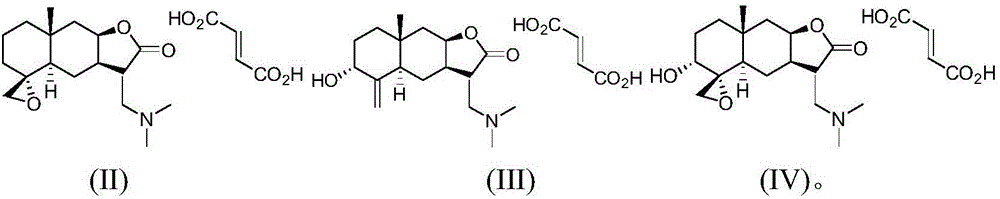

Isoalantolactone derivative and salt thereof

InactiveCN106478569AImprove tumor inhibition rateProlong lifeOrganic active ingredientsAntipyreticBenzoic acidPhosphomolybdic acid

The invention relates to isoalantolactone derivatives and salts thereof and provides an isoalantolactone derivative as shown in a formula (I). Salification acids are selected from inorganic acids or organic acids; the inorganic acids are selected from hydrofluoric acid, hydrochloric acid, hydrobromic acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, carbonic acid, boric acid, seleninic acid, phosphomolybdic acid, phosphorous acid and sulphurous acid; the organic acids are selected from citric acid, maleic acid, D-malic acid, L-malic acid, DL-malic acid, L-lactic acid, D-lactic acid, DL-acid, oxalic acid, methylsulfonic acid, pentanoic acid, oleic acid, lauric acid, p-toluene sulfonic acid, 1-naphthalenesulfonic acid, 2-naphthalenesulfonic acid, phthalic acid, tartaric acid, malonic acid, succinic acid, fumaric acid, glycolic acid, mercaptan acid, glycine, sarcosine, sulfonic acid, nicotinic acid, methylpyridine acid, isonicotinic acid, benzoic acid or substituted benzoic acid.

Owner:NANKAI UNIV

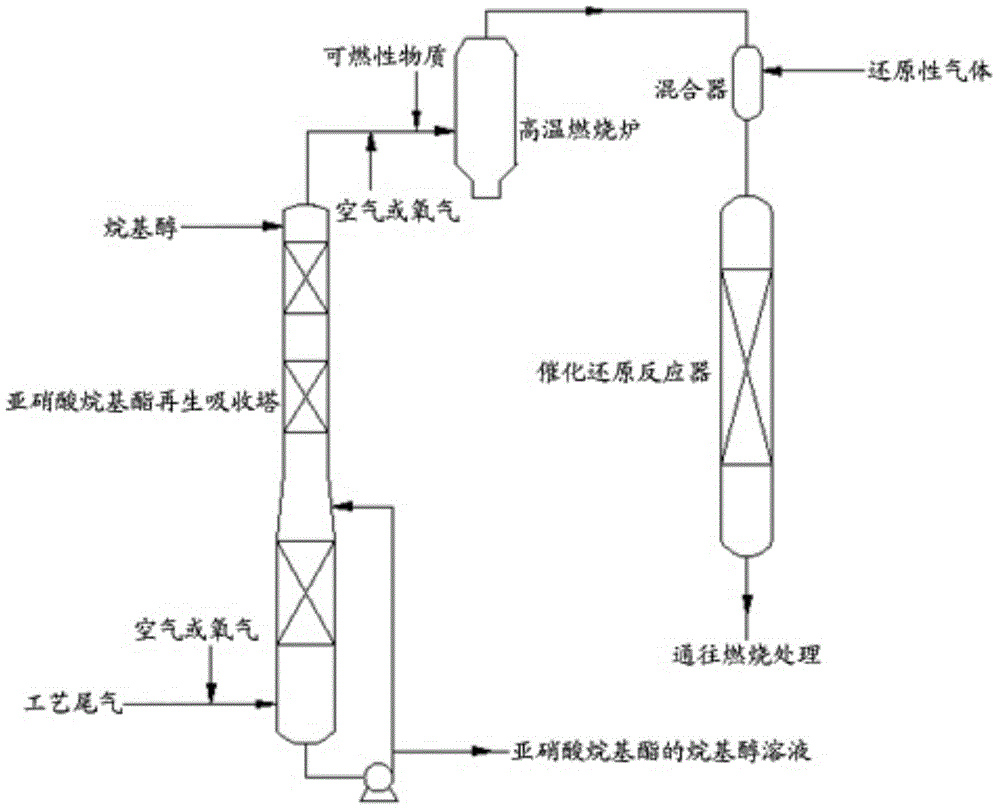

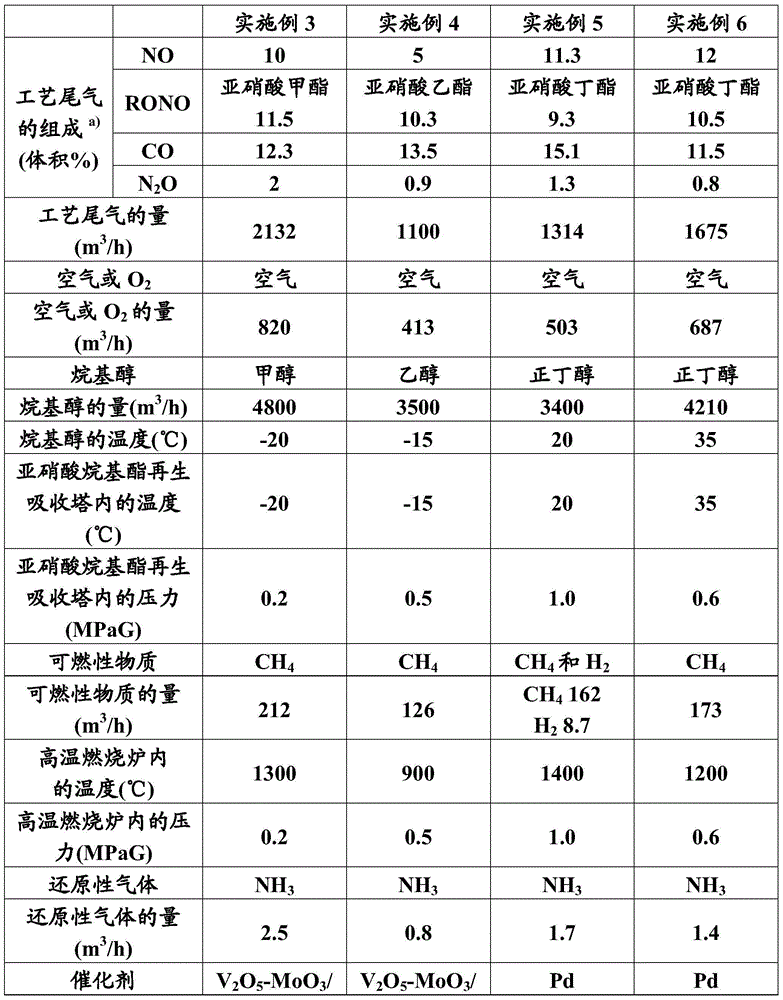

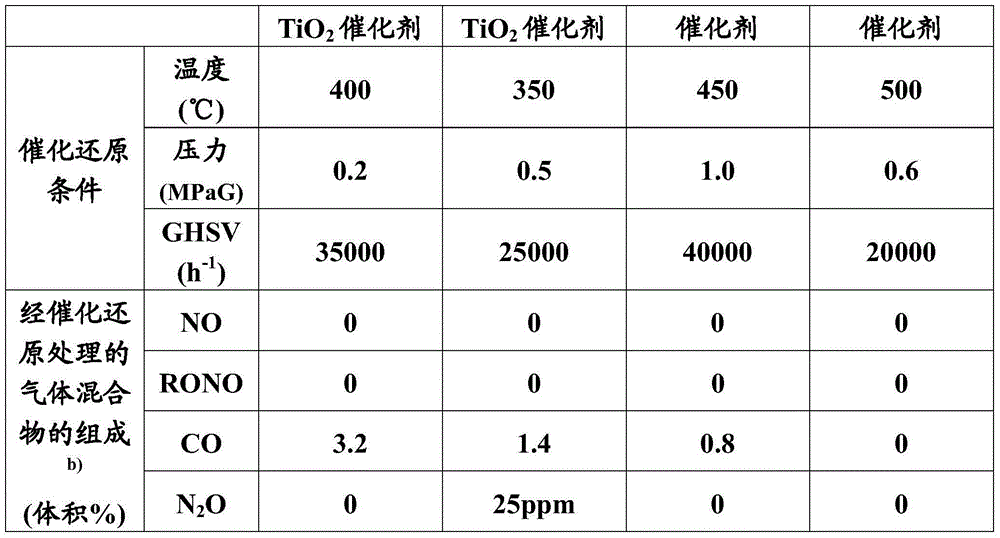

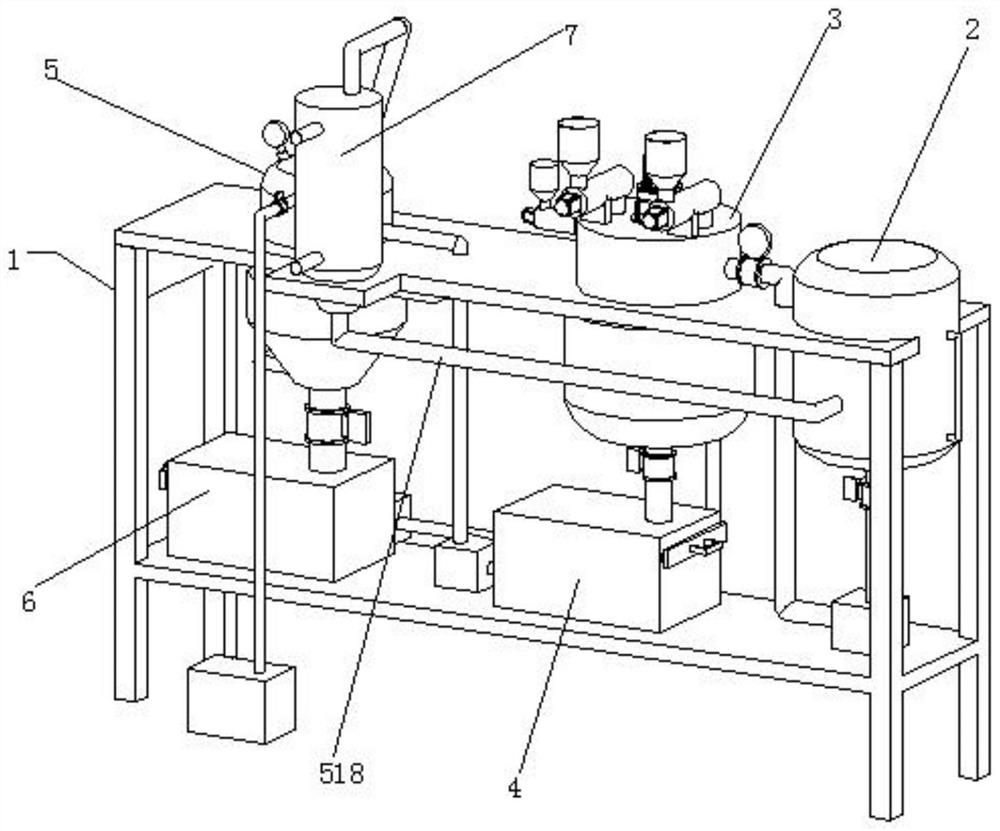

Method for regeneration, absorption and removal of NO, alkyl nitrite, CO and N2O in tail gas from oxalate synthesis process adopting CO carbonyl coupling

ActiveCN106139898AAvoid pollutionThe method is simple and reliableDispersed particle separationIncinerator apparatusSocial benefitsNitrite

The invention relates to a method for regeneration, absorption and removal of NO, alkyl nitrite, CO and N2O in tail gas from an oxalate synthesis process adopting CO carbonyl coupling. The method is characterized in that before emptying, tail gas from the oxalate synthesis process adopting CO carbonyl coupling is subjected to the following process steps: a) regeneration and absorption in an alkyl nitrite regeneration and absorption tower; b) high-temperature combustion in a high-temperature combustion furnace; c) catalytic reduction in a catalytic reduction reactor; d) combustion in a combustion device. The invention also relates to a system comprising the alkyl nitrite regeneration and absorption tower, the high-temperature combustion furnace, the catalytic reduction reactor and the combustion device. The method is simple and reliable, can recover NO and alkyl nitrite in the tail gas from the oxalate synthesis process adopting CO carbonyl coupling and reduces the operation cost, thereby having quite good economic benefit. Besides, CO and N2O in the tail gas can be removed, atmospheric pollution is prevented, and accordingly, good social benefit is realized.

Owner:HIGHCHEM TECH CO LTD +1

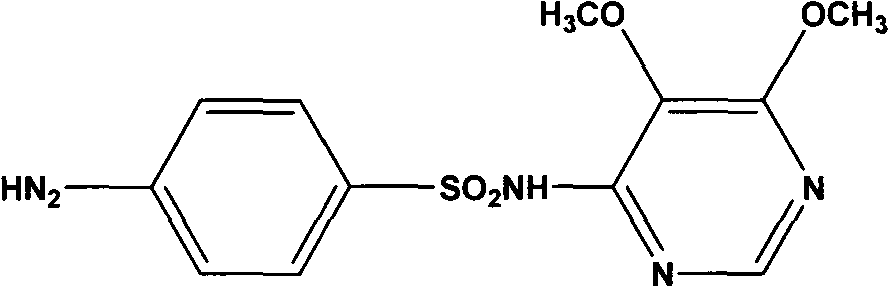

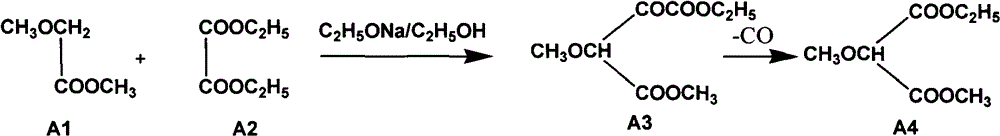

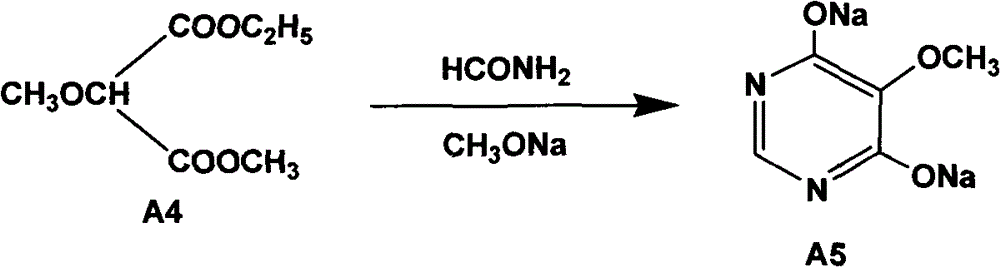

Preparation method of sulfadoxine

InactiveCN102304095BHigh melting pointReduce usageOrganic chemistrySodium methoxideDimethylaniline N-oxide

Owner:CHANGSHU NANHU INDAL CHEM

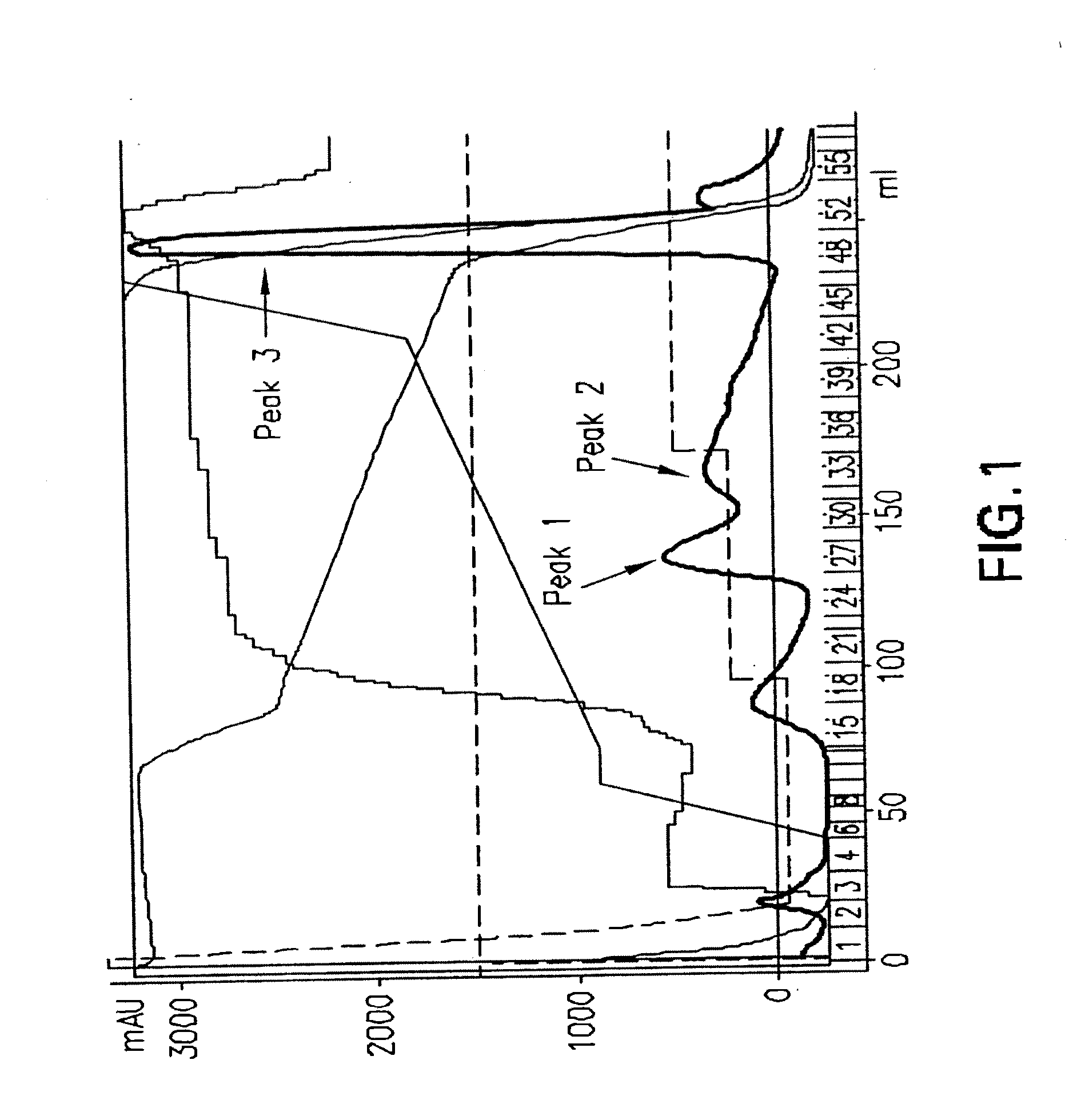

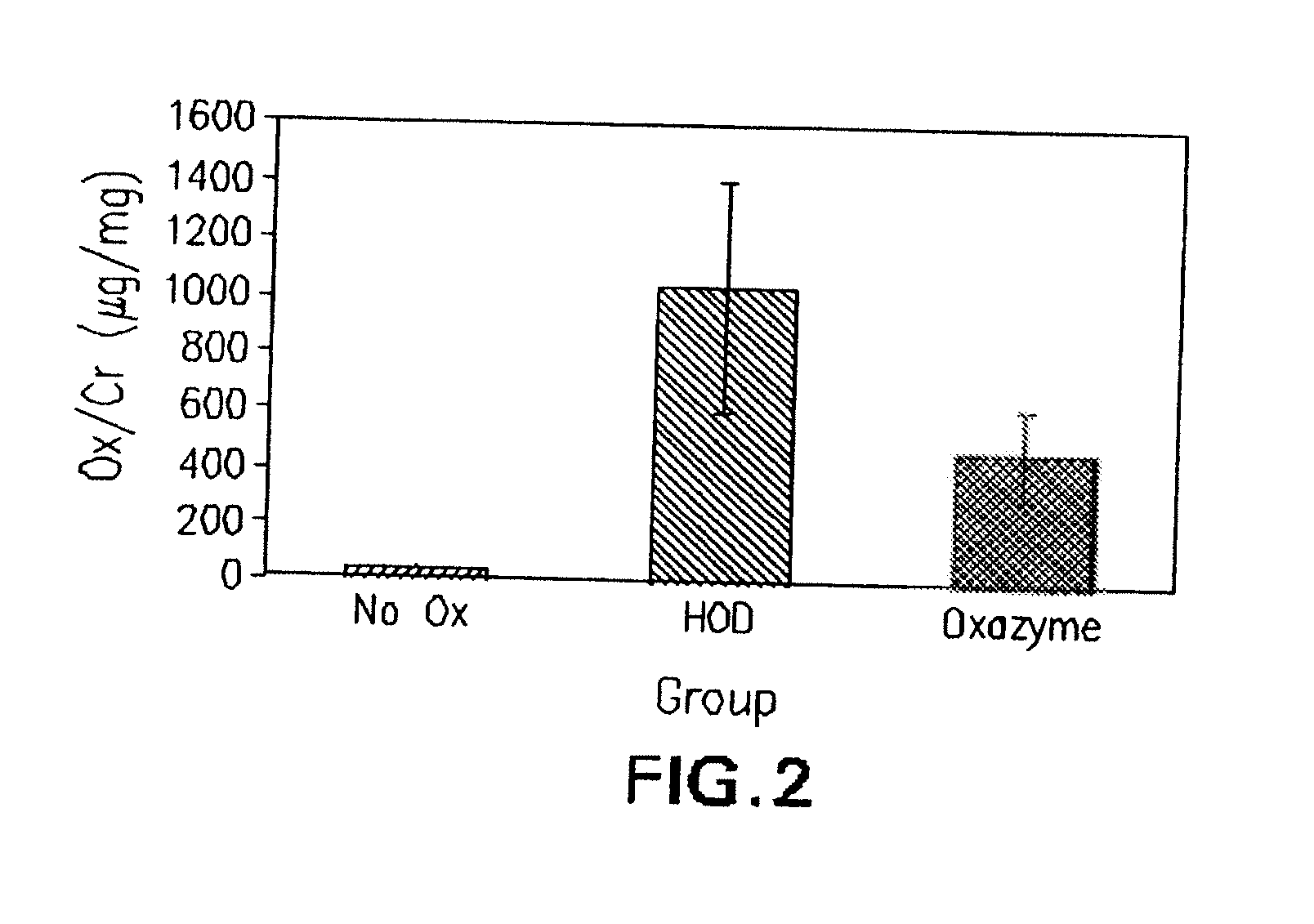

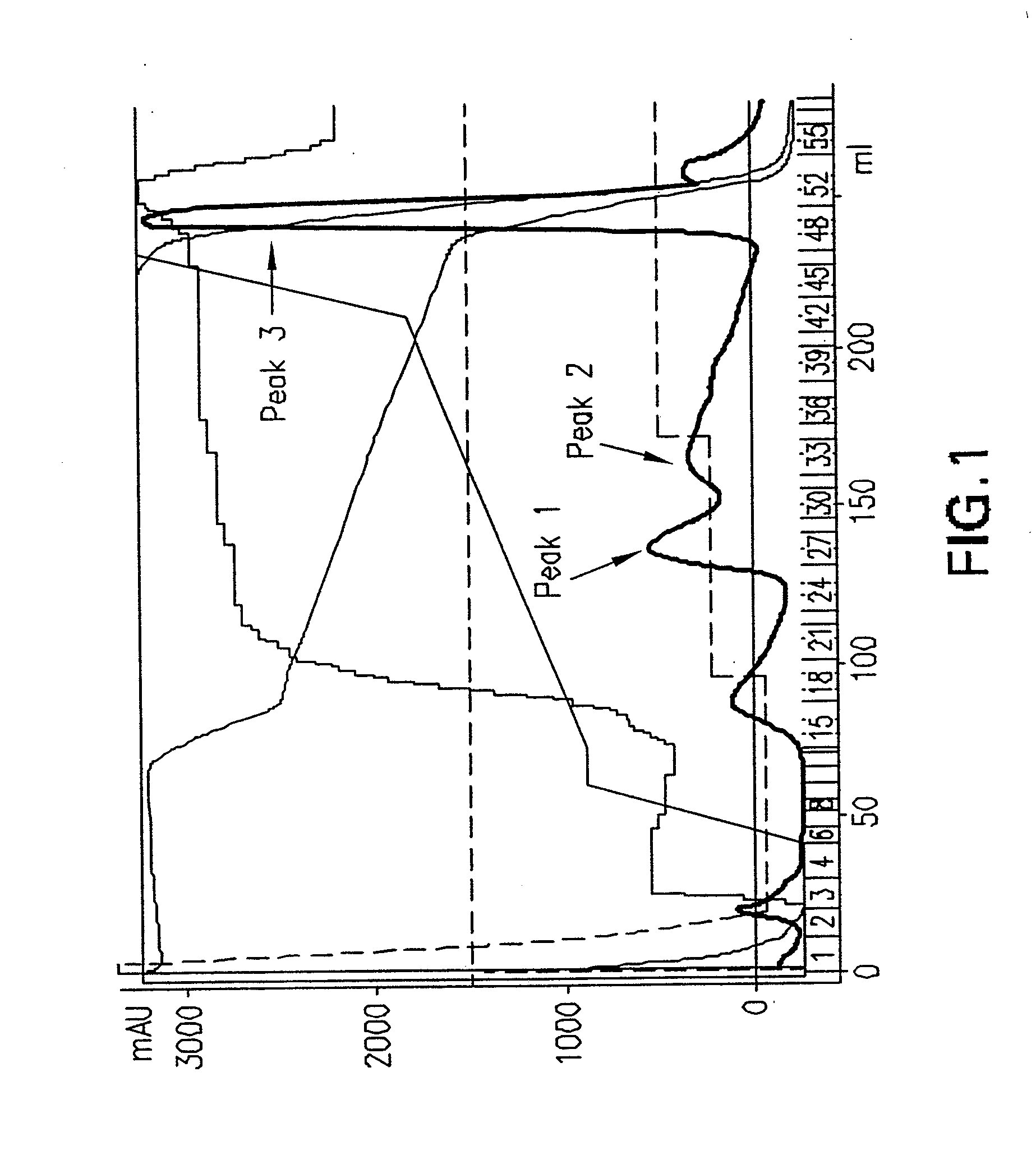

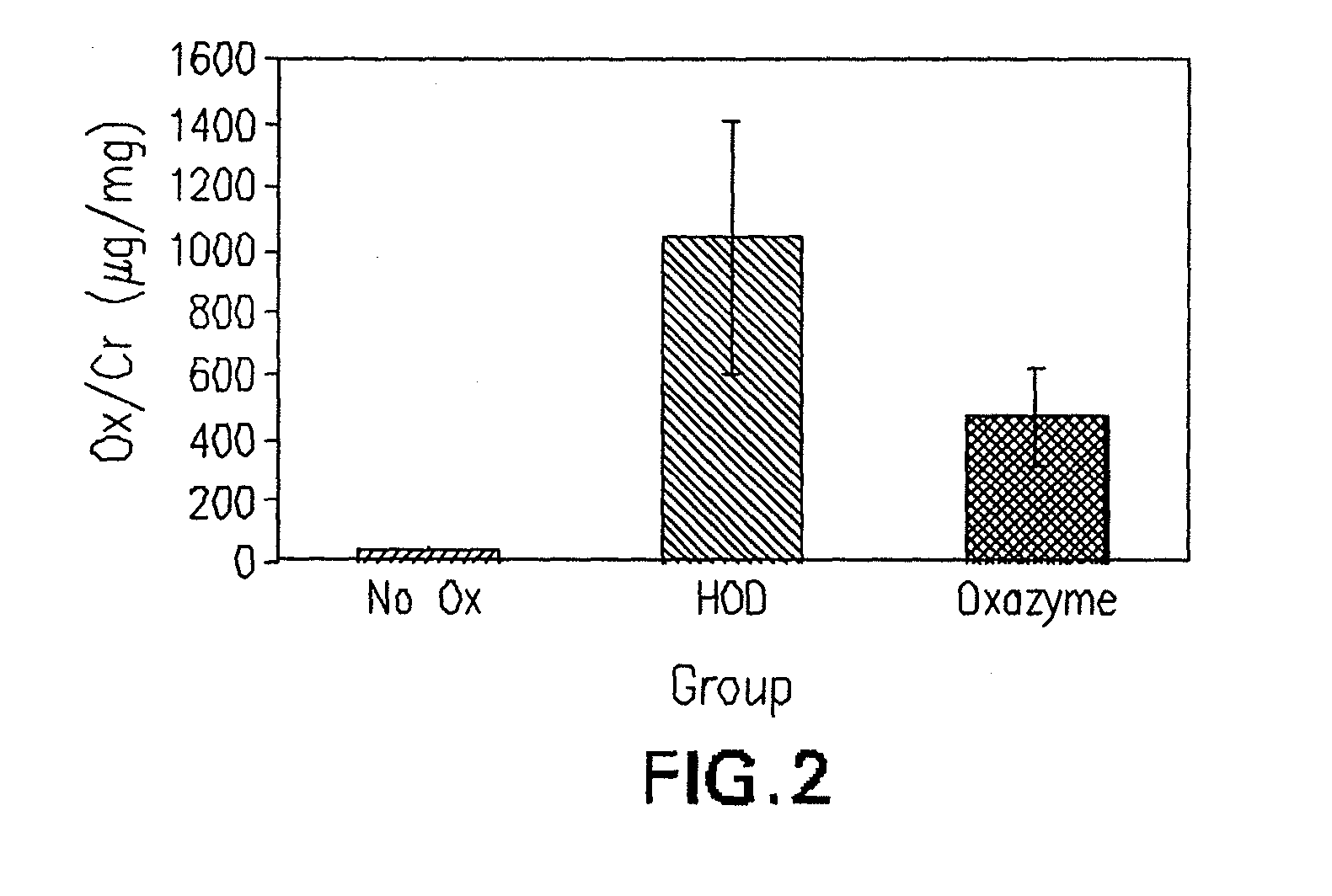

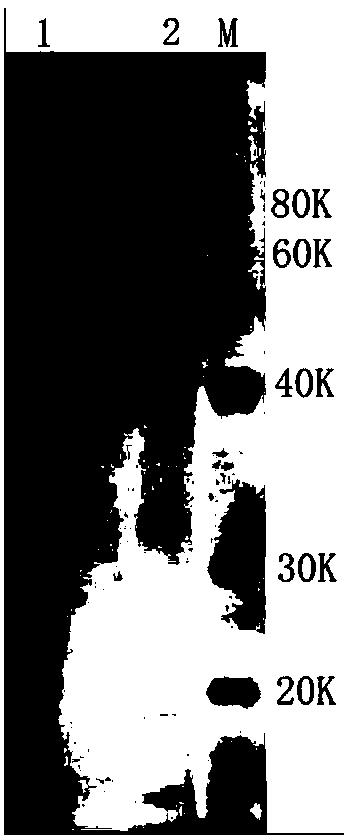

Purification and isolation of recombinant oxalate degrading enzymes and spray-dried particles containing oxalate degrading enzymes

The present invention comprises methods and compositions for the reduction of oxalate in humans, and methods for the purification and isolation of recombinant oxalate reducing enzyme proteins. The invention provides methods and compositions for the delivery of oxalate-reducing enzymes in particle compositions. The compositions of the present invention are suitable in methods of treatment or prevention of oxalate-related conditions.

Owner:OXTHERA INTPROP

Preparation method of TTZ (thiotriazinone)

The invention discloses a preparation method of TTZ (thiotriazinone), which comprises the following steps: 1) adding 5-10 kg of acetic acid and 50-150 kg of ammonium acetate into 1,800-2,200 kg of ethyl alcohol to prepare a buffer system with the pH value of 6-7; 2) adding 480-500 kg of 2-methyl-3-thiosemicarbazide, boron tribromide and diethyl oxalate, heating to 80-82 DEG C, and performing circulation reflux reaction for 4-6 hours, wherein the molar ratio of 2-methyl-3-thiosemicarbazide to diethyl oxalate is 1:(1.15-1.25), and the dosage of boron tribromide is 4-6% of the weight of 2-methyl-3-thiosemicarbazide; 3) cooling for crystallization, and separating to obtain a TTZ crude product and a mother liquor; 4) adding 1,800-2,200 kg of water in the TTZ crude product, heating to 70-80 DEG C, then adding 1,250-1,400 kg of hydrochloric acid with the concentration of 30%, cooling for crystallization, separating and drying to obtain the TTZ finished product. The preparation method has the advantages that the common problems of high cost, low yield, large yield variability, instability of product quality, difficulty in solvent recovery, large amount of waste water and the like in the prior art can be solved.

Owner:SHANDONG HUIHAI PHARMA & CHEM

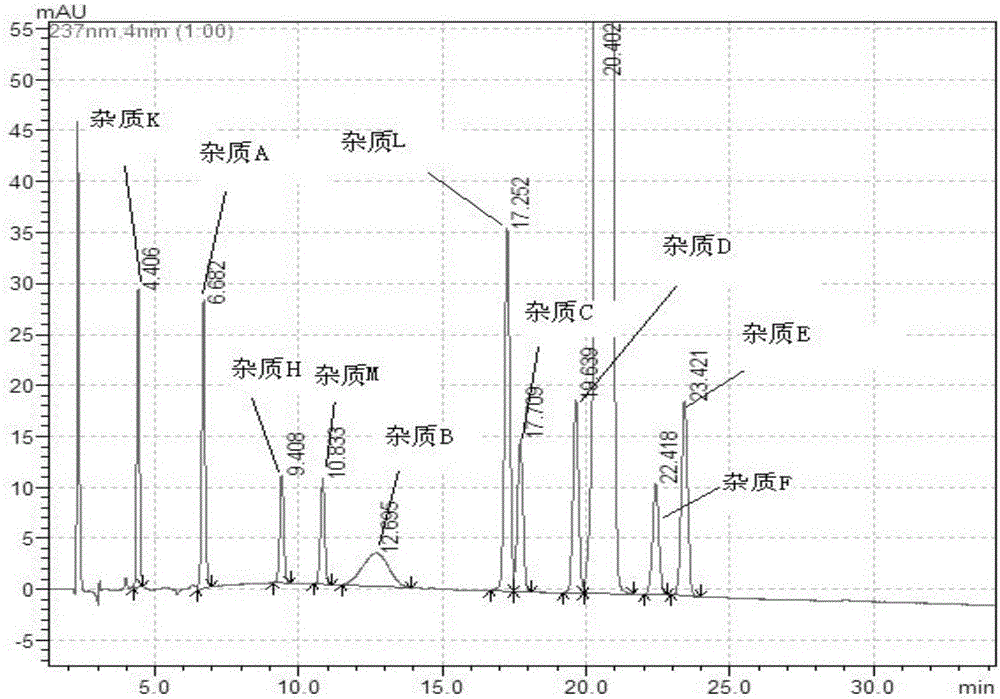

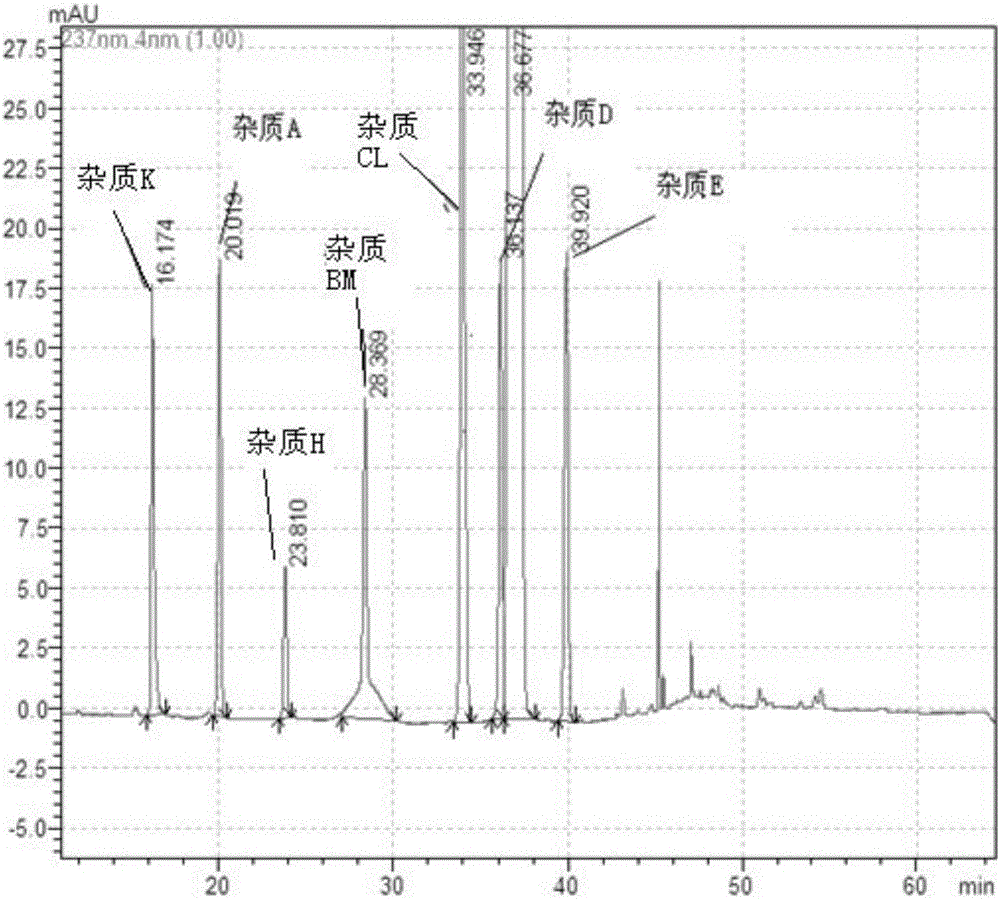

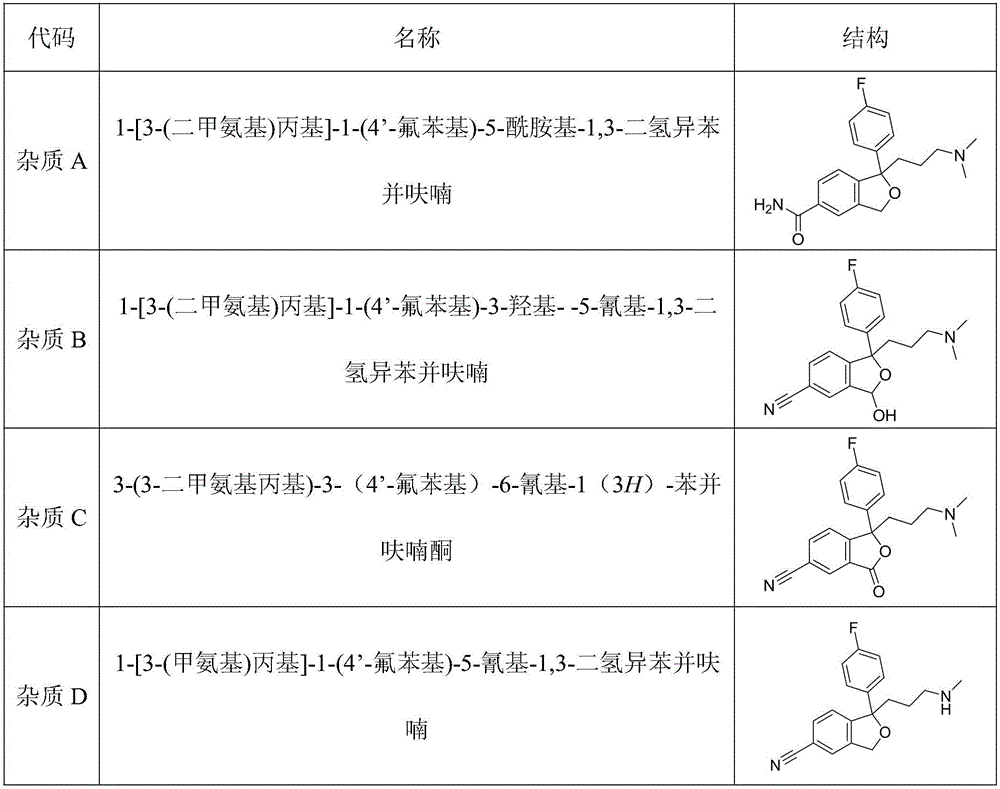

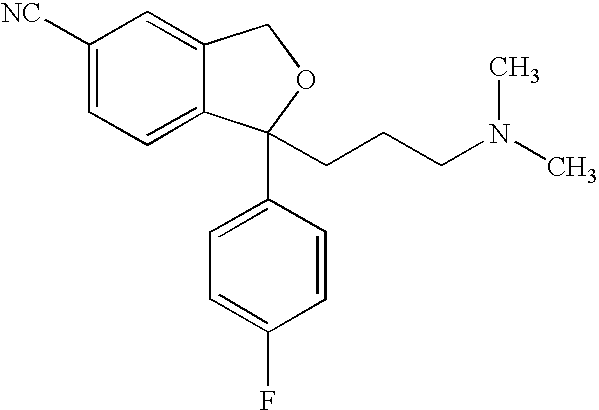

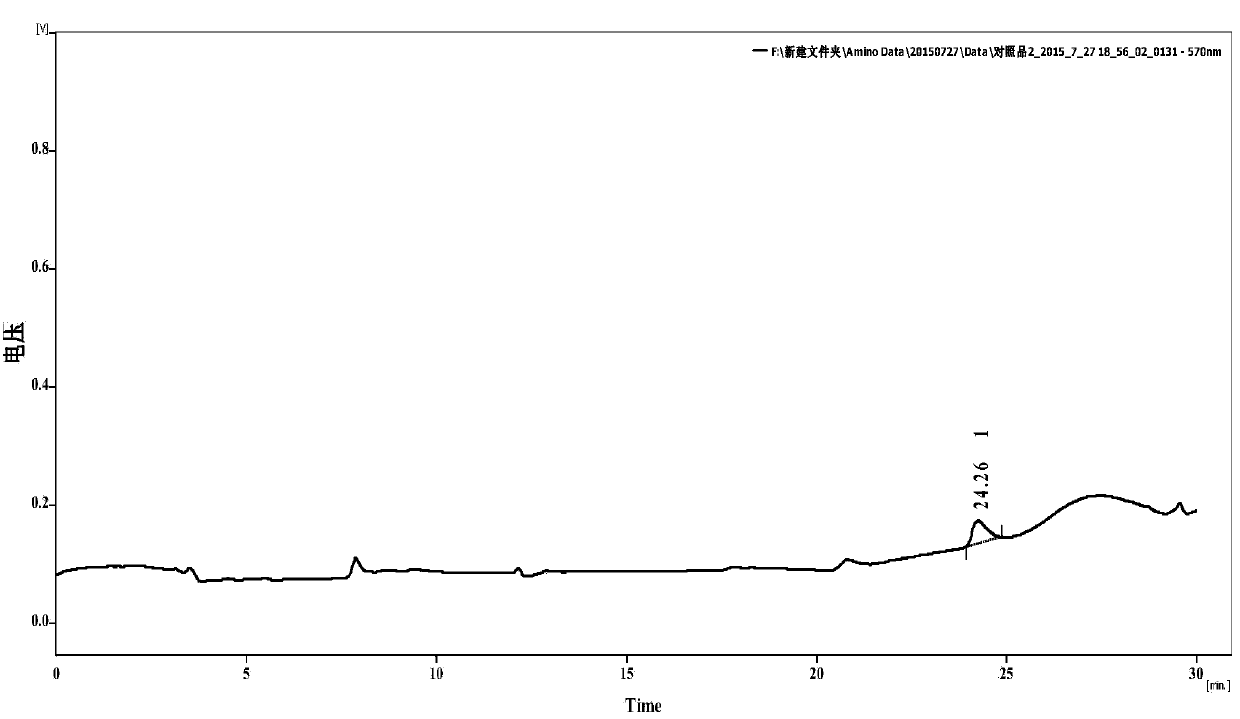

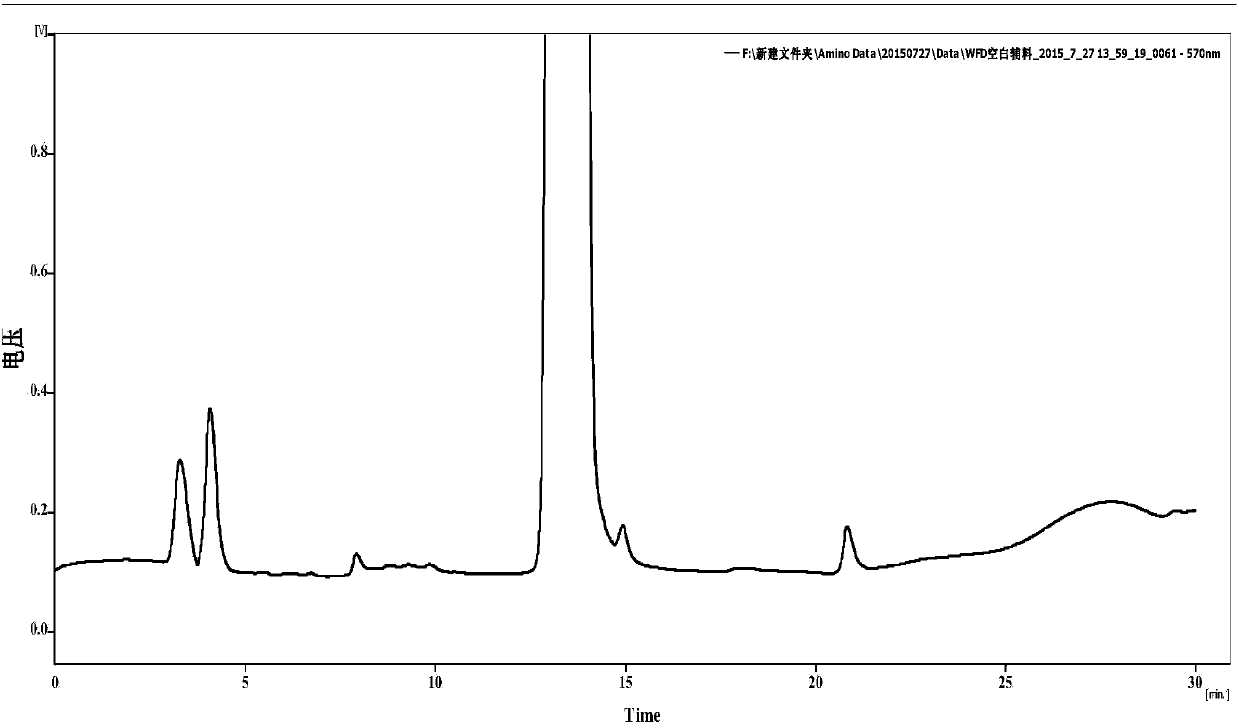

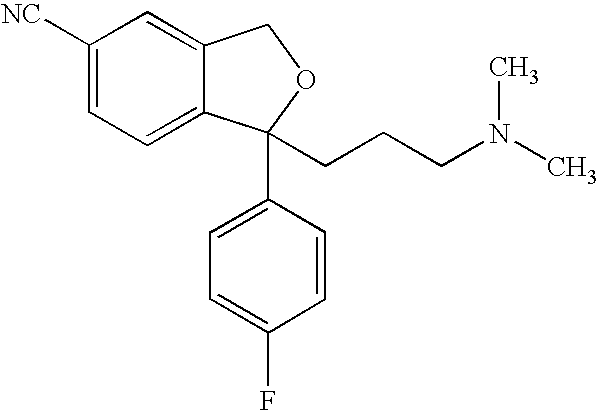

HPLC (high-performance liquid chromatography) detection method for escitalopram oxalate related substances

ActiveCN106324141AGood linear relationshipStrong specificityComponent separationAcetonitrileGradient elution

The invention belongs to the field of pharmaceutical analysis and particularly relates to a HPLC (high-performance liquid chromatography) detection method for escitalopram oxalate related substances. The escitalopram oxalate related substances are determined with HPLC, a C18 column is taken as a chromatographic column, a phosphate buffer solution is taken as a mobile phase A, the mobile phase A and an acetonitrile solution are mixed in a certain ratio to form a mobile phase B, the mobile phase A and the acetonitrile solution are mixed in a certain ratio to form a mobile phase C, and the escitalopram oxalate related substances are detected with a gradient elution method. The method can separate impurities, is high in specificity and sensitivity and good in repeatability and durability, can well control known impurities and unknown impurities of escitalopram oxalate and guarantees safety of escitalopram oxalate.

Owner:山东锐顺药业有限公司

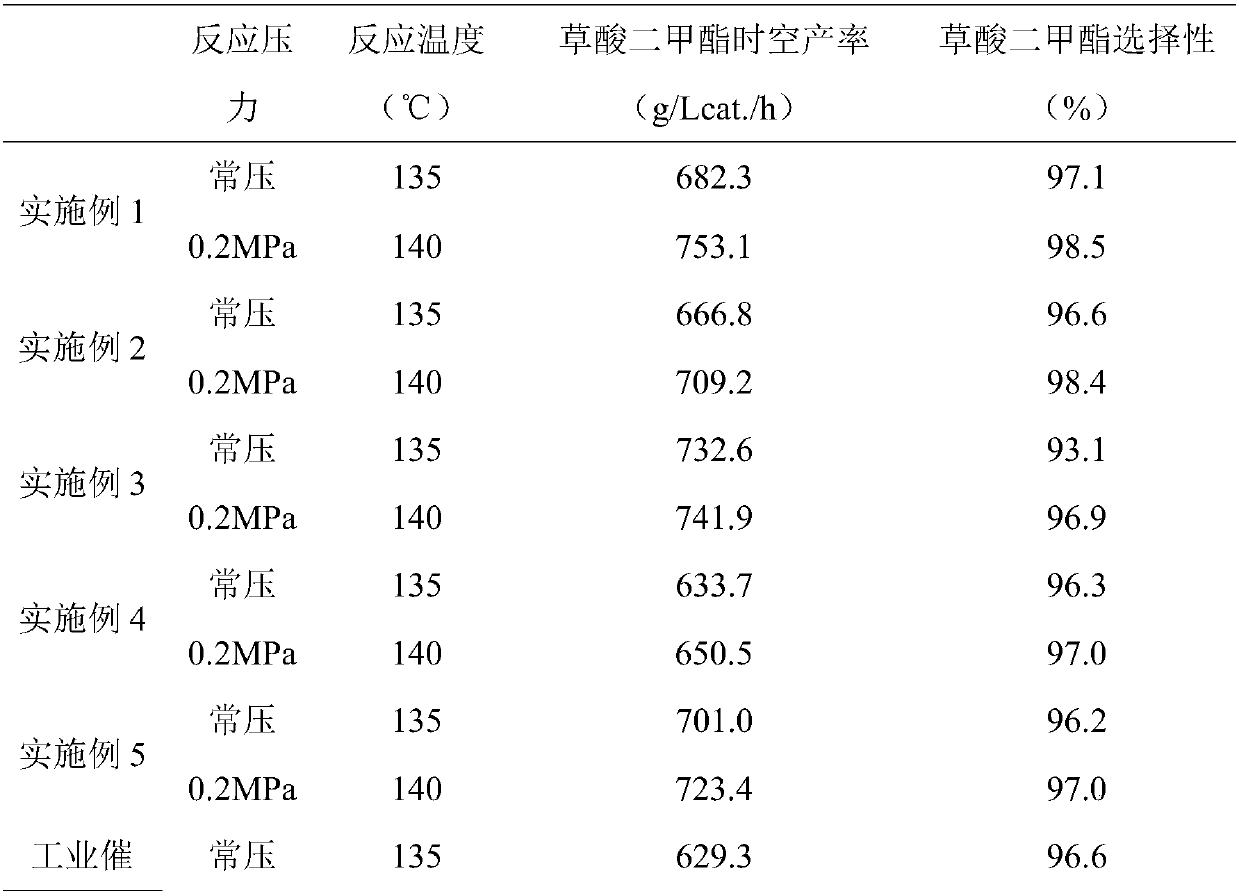

Catalyst, preparation method thereof and application in preparation of oxalate

ActiveCN106582763AOvercome the loadOvercome yieldCatalyst activation/preparationPreparation by carbon monoxide or formate reactionNitrogen doped grapheneBULK ACTIVE INGREDIENT

The invention discloses a catalyst, a preparation method thereof and application in preparation of oxalate. The catalyst comprises a carrier and an active ingredient, and is characterized in that the carrier comprises nitrogen doped graphene nano-sheets, and the active ingredient comprises nano-palladium. The content of the active ingredient palladium in the catalyst is 0.03-2wt%, and the defects of high loading capacity of precious metals, low space time yield of oxalate and the like in production of an oxalate catalyst through CO coupling in the prior art are overcome when the catalyst is used in a CO coupling oxalate production technology.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Purification and Isolation of Recombinant Oxalate Degrading Enzymes and Spray-Dried Particles Containing Oxalate Degrading Enzymes

ActiveUS20110002906A1Sugar derivativesPeptide/protein ingredientsParticle compositionOxalate degradation

The present invention comprises methods and compositions for the reduction of oxalate in humans, and methods for the purification and isolation of recombinant oxalate reducing enzyme proteins. The invention provides methods and compositions for the delivery of oxalate-reducing enzymes in particle compositions. The compositions of the present invention are suitable in methods of treatment or prevention of oxalate-related conditions.

Owner:OXTHERA INTPROP

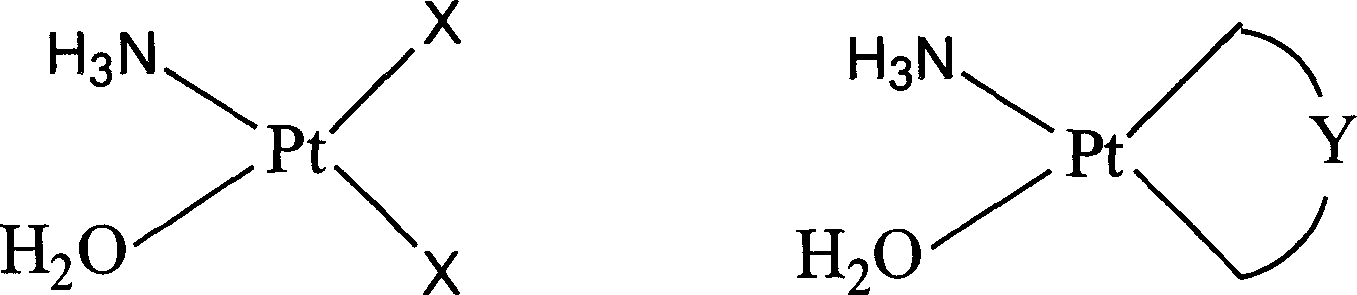

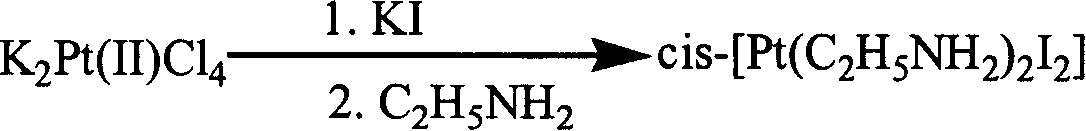

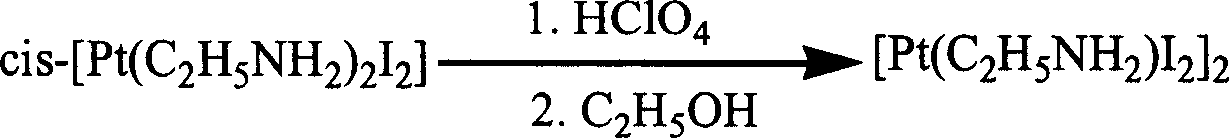

Antineoplastic platinum complex

InactiveCN1634947AGroup 8/9/10/18 element organic compoundsAntineoplastic agentsDrugCis-Butenedioic Acid

The invention relates to an antineoplastic medicine platinum complex. The structural general formula of the platinum complex is shown as the right formula, wherein the substituent X is a monobasic carboxylic acid radical; Y is a dibasic carboxylic acid radical. The invention also discloses a preparation method of the complex, uses of the complex in preparation of cancer treatment drugs and pharmaceutical composition containing the same.

Owner:张金超 +1

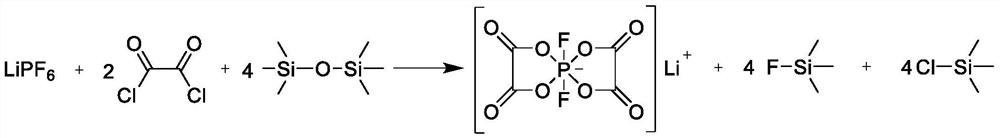

Lithium difluoro-bis(oxalate)phosphate as well as preparation method and application thereof

ActiveCN113336793AEasy to operateFew reaction stepsGroup 5/15 element organic compoundsSecondary cellsOxalatePhosphate

The invention provides lithium difluoro-bis(oxalate)phosphate as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing oxalyl chloride and lithium hexafluorophosphate with a non-aqueous solvent, adding siloxane, and reacting to obtain a lithium difluoro-bis (oxalate)phosphate solution; and (2) adding a poor solvent into the lithium difluoro-bis(oxalate)phosphate solution for crystallization treatment to obtain the lithium difluoro-bis(oxalate)phosphate. According to the method, lithium hexafluorophosphate, oxalyl chloride, hexamethyldisiloxane and other raw materials are adopted for preparing the difluoro-bis (oxalate)phosphate, and the method is few in side reaction, few in impurities, high in product purity and suitable for industrial production.

Owner:SHENZHEN YANYI NEW MATERIALS CO LTD

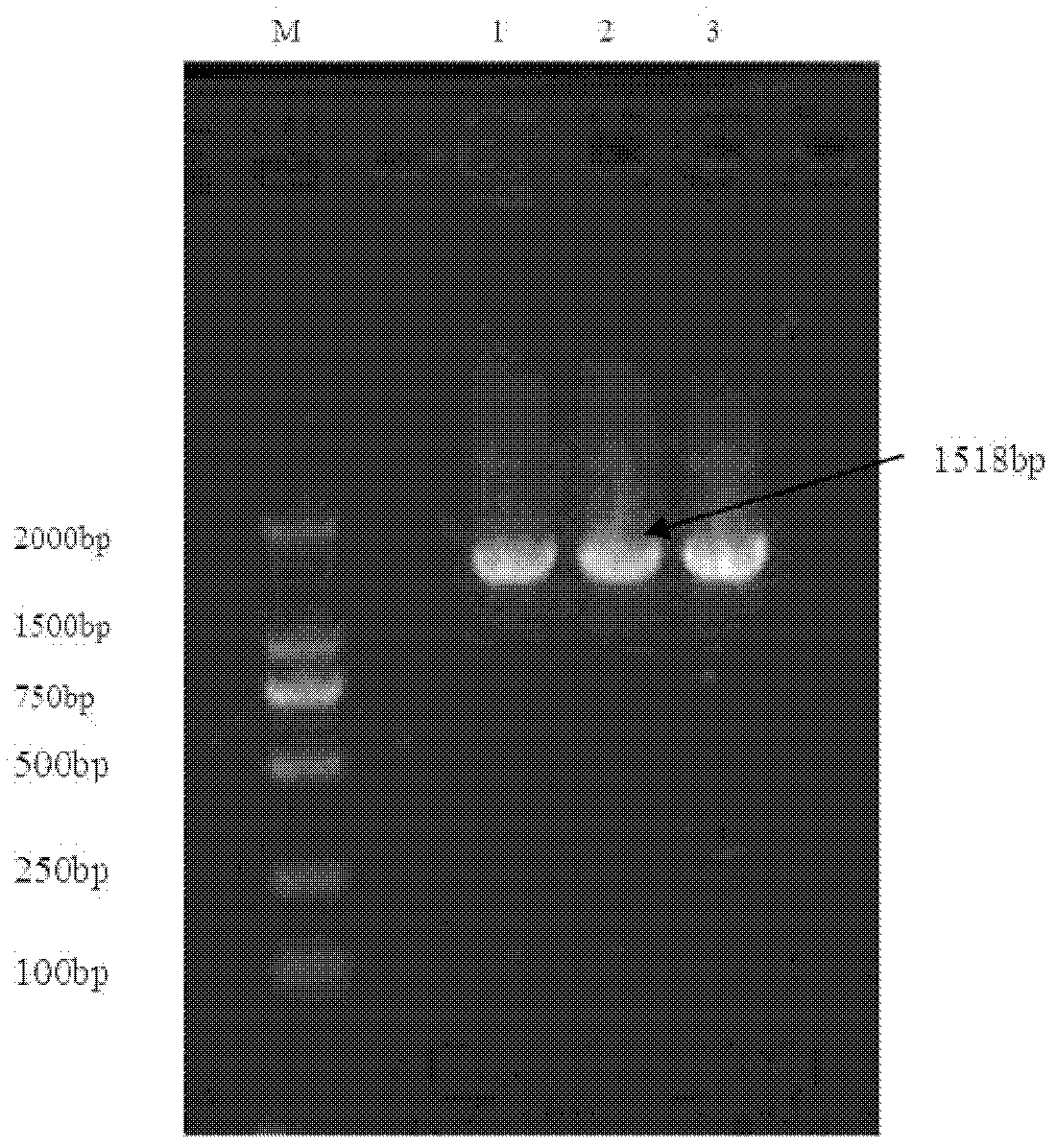

Oxalate-degrading strain NJODE1 and application thereof

ActiveCN102250799AGood acid and bile salt resistanceNo antibiotic resistanceMilk preparationBacteriaAntibiotic resistanceGastrointestinal absorption

The invention discloses an oxalate-degrading strain NJODE1 and application thereof. The oxalate-degrading strain NJODE1 has a classification name of Enterococcus faecium with the preservation number of CGMCC NO. 4581. The oxalate-degrading strain NJODE1 has good tolerance to acids and bile salts, has no antibiotic resistance to most non-antibiotics, is safe for mice and can be colonized in dogs. The NJODE1 can reduce gastrointestinal absorption of oxalate in foods, thereby reducing the content of oxalate in urine, and thus reducing the incidence of canine calcium oxalate calculus. Whether thefinished product of the strain is food or pharmaceutical products or yogurt and fermented milk, the strain has good resistance to acids and bile salts, contains safe enterococci, and has significant effects on lowering the urinary oxalate content and preventing and treating calcium oxalate calculus of pets, thus having broad application prospects.

Owner:NANJING AGRICULTURAL UNIVERSITY

Pharmaceutical Dosage Form of an Antidepressant

The present invention relates to pharmaceutical dosage forms of an antidepressant. More particularly, the present invention relates to pharmaceutical dosage forms of Escitalopram oxalate. The present invention also relates to a process for the preparation of pharmaceutical dosage forms of Escitalopram oxalate.

Owner:AUROBINDO PHARMA LTD

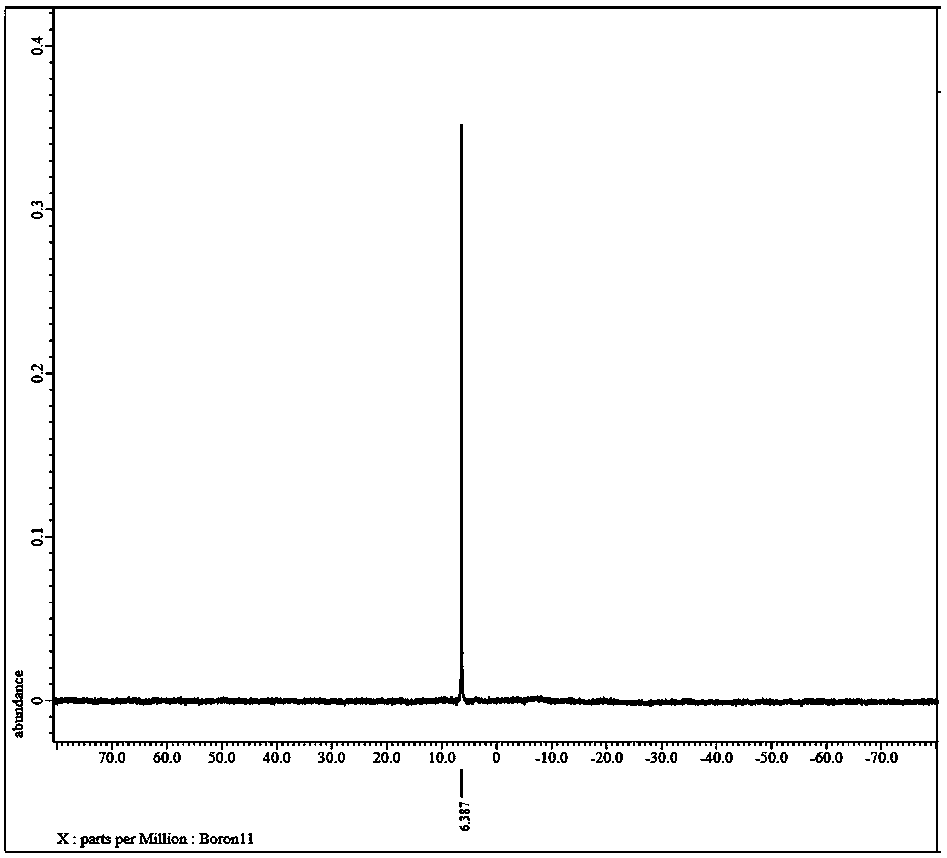

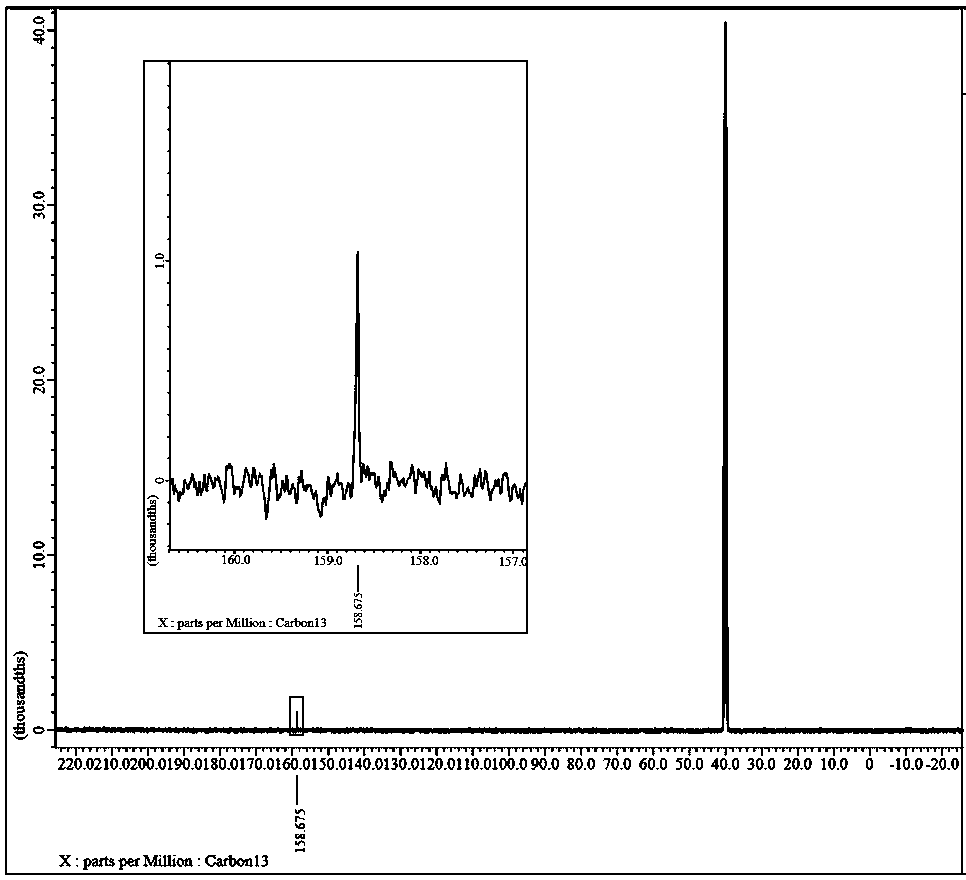

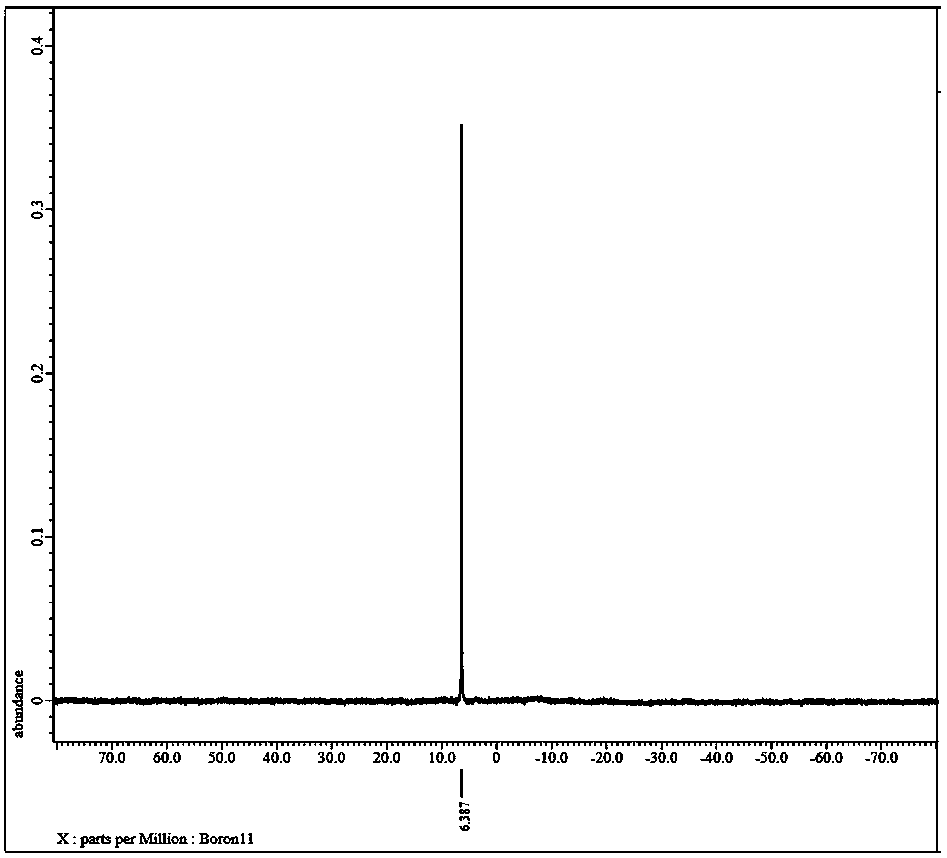

Preparation method of lithium bis(oxalato)borate

InactiveCN111153918AIncrease water speedWell mixedChemical analysis using titrationAnalysis by thermal excitationElectrolytic agentDiethyl carbonate

The invention relates to a preparation method of lithium bis(oxalato)borate. The preparation method comprises the following steps: A, completely dissolving an oxalate-containing compound and a boron source compound; B, dissolving lithium carbonate in excessive ethylene carbonate completely; and C, mixing a solution obtained in step A and a solution obtained in step B, and pumping the obtained mixture into a tubular reactor, performing a heating reaction to obtain a diethyl carbonate solution dissolved with lithium bis(oxalato)borate, evaporating under reduced pressure to obtain a lithium bis(oxalato)borate crude product, drying the lithium bis(oxalato)borate crude product, dissolving the crude product in an acetonitrile solution, performing dehydration treatment, performing evaporative concentrating on the obtained filtrate, carrying out cooling crystallization, carrying out solid-liquid separation, and drying to obtain purified lithium bis(oxalato)borate. The method has the followingadvantages: the process is simple, the cost is low, the yield is very high, the water content is effectively reduced, and the influence of water on the electrolyte is reduced; and the solvent is easyto recover, the repeated utilization rate is high, the treatment is simple, and the lithium bis(oxalato)borate with excellent properties and high purity can be prepared.

Owner:DONGGUAN UPC IND & TRADE +1

Meldonium salts, method of their preparation and pharmaceutical composition on their basis

New salts of Meldonium, the method of their preparation, and pharmaceutical formulation on their basis have been described. The general formula of these salts is X−(CH3)3N+NHCH2CH2COOH where X− is an acid anion selected from the group of pharmaceutically acceptable acids. Practically non-hygroscopic and / or increased thermal stability and / or lasting action Meldonium hydrogen salts of fumaric acid, phosphoric acid, oxalic acid, maleic acid, and pamoic acid as well as Meldonium orotate and galactarate are especially suitable. Novel pharmaceutical formulations containing non-hygroscopic and / or increased thermal stability and / or and / or lasting action 3-(2,2,2-trimethylhydrazinium) propionate salts for oral parenteral, rectal, and transdermal introduction are concurrently described.

Owner:GRINDEKS

Catalyst carrier and catalyst for synthesizing dimethyl oxalate

InactiveCN111185192AHigh catalytic activityExtended service lifePreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to a catalyst carrier and a catalyst for synthesizing dimethyl oxalate. The preparation method of the catalyst carrier comprises the following steps: 1) reacting NaOH with excessive Al(OH)3 in water, adding an acid to adjust the pH value to 7-9, and filtering to obtain a wet filter cake; 2) adding an auxiliary agent metal salt into the wet filter cake, uniformly mixing, drying, roasting, and crushing to obtain powder; 3) carrying out ball rolling treatment on part of the powder obtained in the step (2), spraying a NaAlO2 solution during the ball rolling treatment, and drying to obtain small seed balls; and 4) carrying out ball rolling treatment on the seed balls, spraying a NaAlO2 solution during the ball rolling treatment, adding the powder obtained in the step 2), drying, and roasting to obtain the catalyst carrier. According to the preparation method, the alpha-Al2O3 carrier is prepared while the auxiliary agent precursor is doped into the alpha-Al2O3 carrier,so that the dispersity of the auxiliary agent is improved, the bonding strength of the auxiliary agent and the carrier is improved, and the preparation of the catalyst with good catalytic activity andlong service life is facilitated.

Owner:HENAN UNIV OF URBAN CONSTR

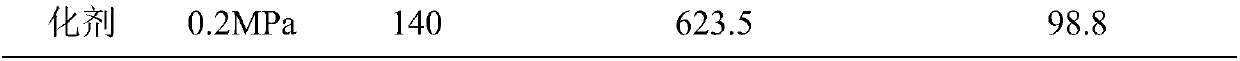

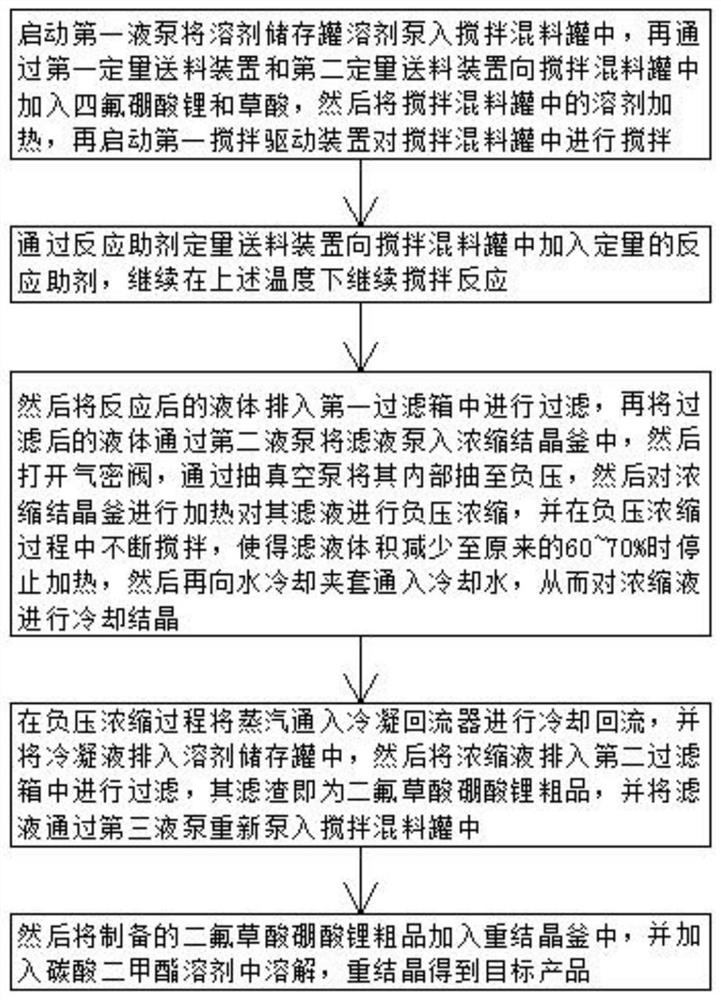

Preparation method of lithium difluoro(oxalato)borate

InactiveCN112778345AImprove efficiencyReduce manufacturing costGroup 3/13 element organic compoundsSolution crystallizationAccelerantVacuum pump

The invention relates to the technical field of lithium difluoro(oxalato)borate production, and particularly discloses a preparation method of lithium difluoro(oxalato)borate. The method comprises the following steps: 1) heating and mixing raw materials; 2) adding a reaction accelerator, and continuously conducting stirring for reaction; (3) discharging the reacted liquid into a filter tank for filtering, pumping the filtered liquid into a concentration and crystallization kettle, pumping the inside of the concentration and crystallization kettle to negative pressure through a vacuumizing pump, conducting heating to perform negative pressure concentration on the filtrate, and then introducing cooling water into a water cooling jacket so as to perform cooling crystallization on the concentrated solution; and 4) in the negative pressure concentration process, introducing steam into a condensation reflux device for cooling reflux, then filtering the concentrated solution, and re-pumping the filtrate into a stirring and mixing tank through a third liquid pump. According to the preparation method of the lithium difluoro(oxalato)borate, disclosed by the invention, the efficiency of producing the lithium difluoro(oxalato)borate is higher, the utilization rate of raw materials is also greatly improved, and the production cost of preparing the lithium difluoro(oxalato)borate is reduced.

Owner:王志坚

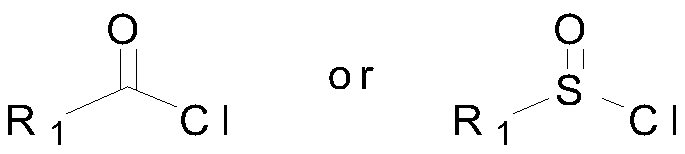

Purification method of lithium bis(oxalato) borate and lithium bis(oxalato)borate

InactiveCN111057079ANo pollutionComply with battery-grade quality requirementsSecondary cellsGroup 3/13 element organic compoundsOrganosolvBoronic acid

The invention discloses a purification method of lithium bis(oxalato)borate and the lithium bis(oxalato)borate, wherein the purification method comprises the steps: dissolving a lithium bis(oxalato)borate crude product in an organic solvent, and filtering to remove insoluble substances after the lithium bis(oxalato)borate crude product is completely dissolved; putting the filtered filtrate into areaction bottle, calculating the moisture content in the filtrate according to the moisture content in the lithium bis(oxalato)borate crude product and the dilution ratio after dissolution; then adding acyl chloride or thionyl chloride compounds in a certain proportion; after addition of the acyl chloride or thionyl chloride compound is finished, heating the mixture to any temperature between 35 DEG C and 70 DEG C; carrying out a heating reaction for any time between 3 hours and 9 hours; evaporating the reaction solution under reduced pressure to remove the solvent to obtain a semi-finished product, and recrystallizing the semi-finished product by using a mixed solvent to finally obtain the electronic-grade lithium bis(oxalate)borate of which the purity is more than 99.9 percent, the watercontent is less than 50 ppm, the acid value is less than 10 ppm, and the contents of potassium ions, sodium ions, calcium ions, magnesium ions and the like are all less than 10 ppm. The method has the beneficial effect of reducing water residue and impurity content.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD

Crystalline composition containing escitalopram

InactiveUS20050147674A1Granulation avoidedReduce stepsBiocidePowder deliveryCrystallographyCrystalline particle

Crystalline particles of escitalopram oxalate with a particle size of at least 40 μm is disclosed. Method for the manufacture of said crystalline particles and pharmaceutical compositions comprising said crystalline particles are also disclosed.

Owner:H LUNDBECK AS

Cotton fabric finishing liquor

InactiveCN104532585AImprove hydrophilicityImprove tensile propertiesVegetal fibresSulfonatePolypropylene glycol

The invention discloses cotton fabric finishing liquor which is prepared from the following components in parts by weight: 0.6 part of calcium dodecyl benzene sulfonate, 1.3 parts of methoxypolyethylene glycol, 1.9 parts of lauric acid, 2.4 parts of polypropylene glycol, 0.7 part of potassium oxalate and 0.6 part of fatty acid methyl ester sulfonate. The cotton fabric finishing liquor disclosed by the invention is good in hydrophilicity and permeability and can be used for enhancing the tensile resistance and the antifouling property of the cotton fabric.

Owner:常熟市海虞富盛经纬编织造厂

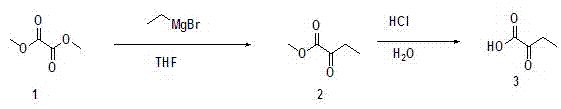

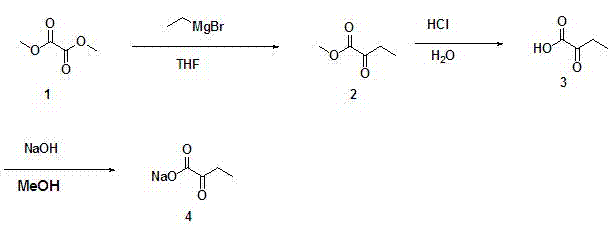

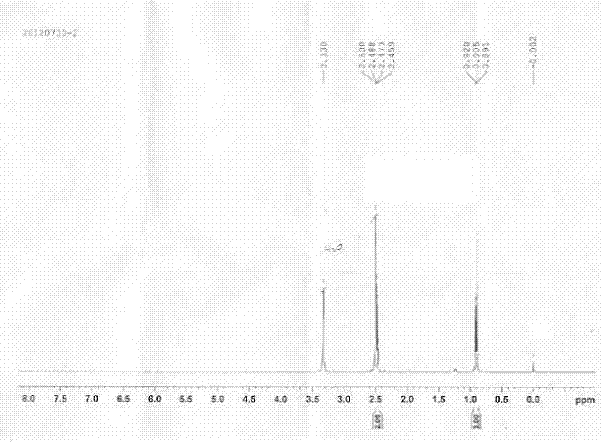

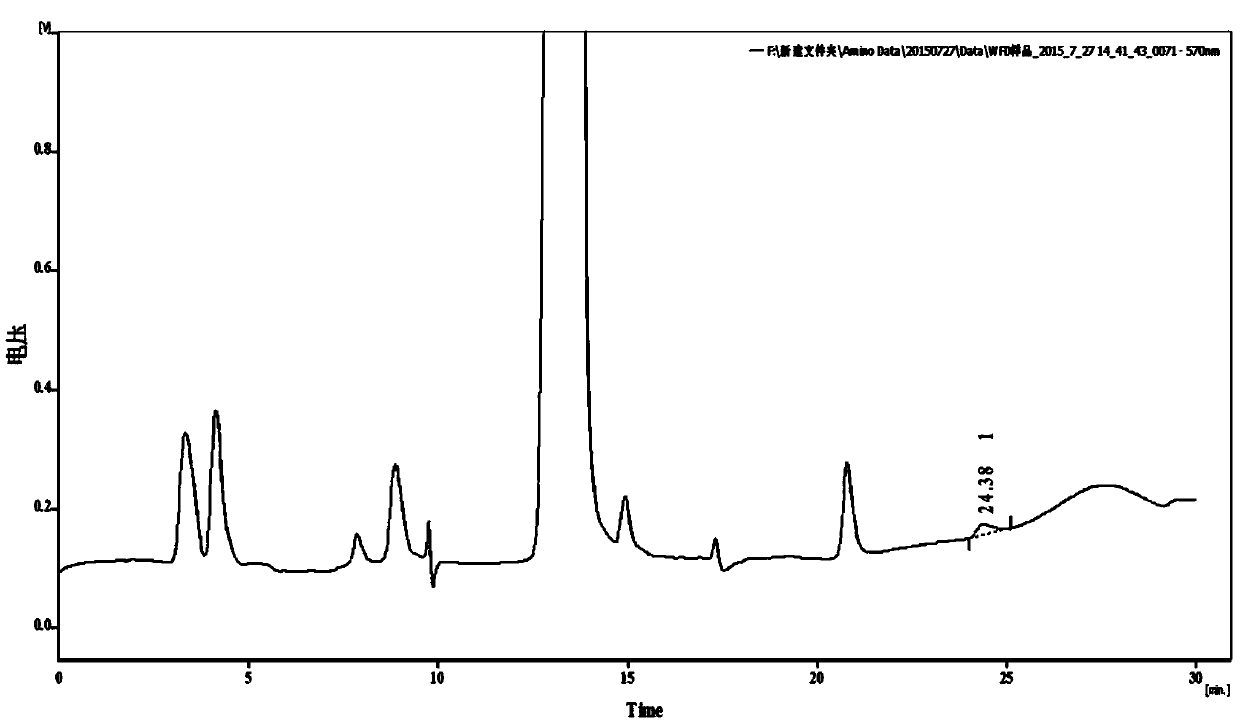

Ketobutyric acid and preparation method for ketobutyric acid salt

ActiveCN103073411AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationEthyl group

The invention provides an Alpha-ketobutyric acid preparation method which comprises the following steps: A), taking dimethyl oxalate or diethyl oxalate as raw materials to solve in anhydrous furanidine, cooling, adding ethylmagnesium bromide solution, stirring, removing solvent through distillation under reduced pressure after reaction termination, allowing residual mixture to be subjected to rectification under reduced pressure, and collecting intermediate product 2-oxo methyl butyrate or 2-oxo ethyl butyrate; B), solving the intermediate product in a hydrochloric acid, heating, reflowing, stirring, performing extraction by vinegar naphtha after the completion of the reaction, collecting organic phase, drying, filtering, and removing the solvent through allowing the filtrate to be subjected to distillation under reduced pressure, so as to obtain a coarse product Alpha-ketobutyric acid; and c), allowing the coarse product Alpha-ketobutyric acid to be subjected to rectification under the reduced pressure, and collecting the Alpha-ketobutyric acid. The method provided by the invention has the advantages of inexpensive and easy-to-get raw materials, lower toxicity, simple preparation process, easiness in control, no complex purification process, high product purity, high productivity, and greatly reduced manufacturing cost, and is suitable for large scale industrialized application.

Owner:广东派特埃尔生物科技有限公司

Detection method of multivitamin injection impurities

The invention relates to an analysis and detection method of multivitamin injection impurities, belongs to the field of medicine analysis, and mainly relates to a detection method of oxalic acid, 3-aminopropanol, retinol, alpha-tocopherol, menadione and vitamin K1 cis-isomer impurities in a multivitamin injection.

Owner:北京藏卫信康医药研发有限公司 +1

Material for forming mineral substance in dentinal tubule by use of delayed reaction and application of material

ActiveCN106974834ASmooth penetrationPromote formationImpression capsMedical preparationsN-Butyl AlcoholSodium hydroxide

The invention discloses a material for forming mineral substance in a dentinal tubule by use of delayed reaction and application thereof, and belongs to the technical field of dentistry repairing materials. The material is characterized by comprising a reagent A, wherein the reagent A is EDTA-2Na, calcium chloride and sodium fluoride aqueous solution, the pH value is regulated by the sodium hydroxide and the hydrochloric acid; a reagent B is the mixed solution of potassium oxalate aqueous solution and n-butyl alcohol; the reagent A and the reagent B are mixed, continuously and quickly stirred to obtain a reagent C; the reagent C is immediately painted on the dental face for exposing the dentinal tubule, so that the reagent C can smoothly enter the dentinal tubule or a deep layer; the delayed reaction is started, the insoluble calcium oxalate and like mineral substances are gradually generated in the tubule of the dentinal tubule so as to block the dentinal tubule.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV

Acid removal method of lithium salt, non-aqueous electrolyte and battery

ActiveCN110911755ALow in free acidsHigh acid removal rateSecondary cellsOrganic electrolytesElectrolytic agentOrganic solvent

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

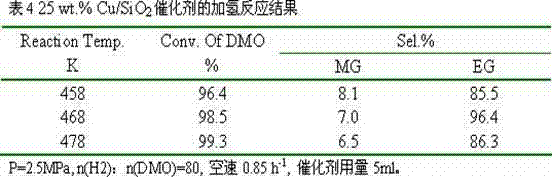

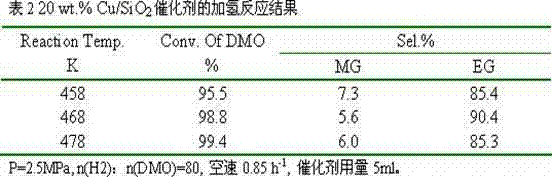

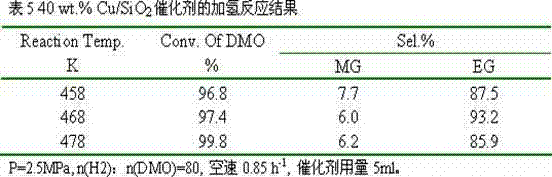

Copper-based catalyst used in preparation of glycol by catalytic hydrogenation of oxalate ester and preparation method thereof

InactiveCN102350348BSmall particlesUniform particle size distributionOrganic compound preparationHydroxy compound preparationPtru catalystCopper oxide nanoparticles

The invention provides a copper-based catalyst used in preparation of glycol by catalytic hydrogenation of oxalate ester and a preparation method thereof. The catalyst comprises 10 to 50 wt% of copper and 50 to 90 wt% of silica, and has a specific surface area of 200 to 1200 m<2> / g, a pore volume of 0.5 to 1.4 cm<3> / g, an average aperture of 1.5 to 15 nm and a particle size below 100 nm; copper oxide nanoparticles are cladded by a mesoporous silicon shell, and a core-shell structure is formed. The catalyst provided in the invention has the advantages of a small particle size, uniform particlesize distribution, good dispersibility, and high activity, high selectivity and a long life when used in preparation of glycol by catalytic hydrogenation of oxalate ester. The preparation method has the advantages of simple operation and high yield.

Owner:河南能源集团研究总院有限公司

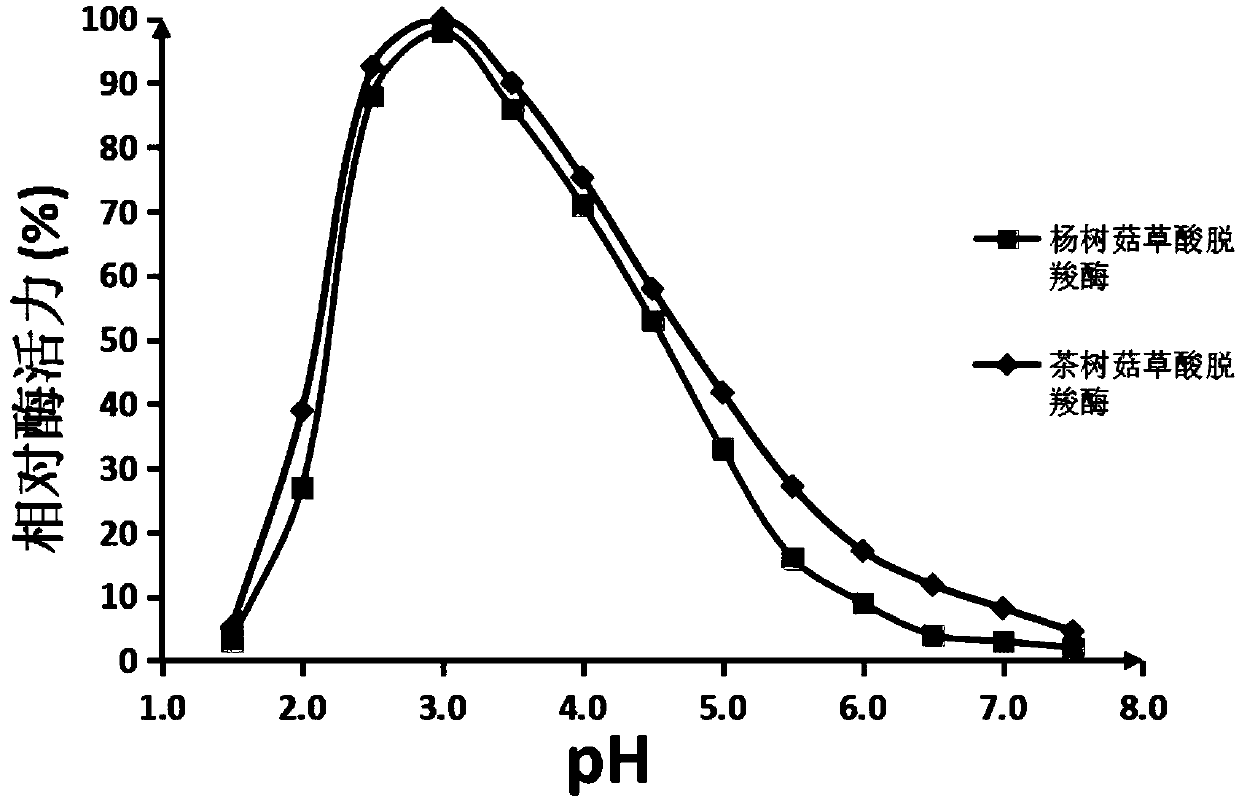

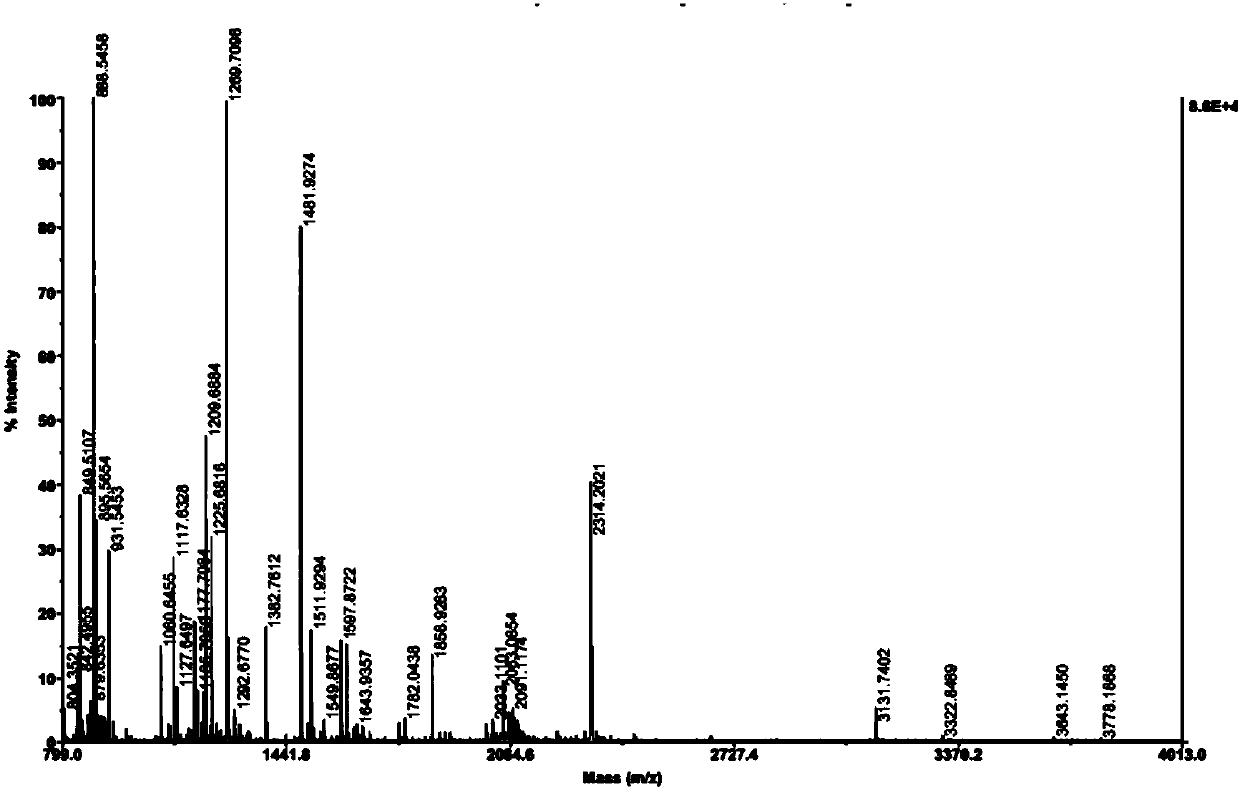

Glycosylated oxalate decarboxylase as well as preparation and application of glycosylated oxalate decarboxylase

PendingCN107868776AIncrease vitalityImprove degradation efficiencyFungiPeptide/protein ingredientsKidney stoneOxalate decarboxylase

The invention discloses glycosylated oxalate decarboxylase. The oxalate decarboxylase is derived from edible basidiomycete; the glycosylated oxalate decarboxylase has enzymatic activity in an environment that pH value is 1.5-7.5; and the activity is 10% greater than optimum activity in an environment that pH value is 1.5-2.0, which is 2U / mg greater than an activity unit. The invention also discloses a preparation method and an application of the glycosylated oxalate decarboxylase. The glycosylated oxalate decarboxylase provided by the invention can keep activity under a low-pH condition; and the glycosylated oxalate decarboxylase can be used for effectively preventing and treating kidney stone.

Owner:WUHAN KANGFUDE BIOTECH CO LTD

Application of commercially available yoghourt in preventing urinary calculus

The invention relates to application of yoghourt in the field of preventing urinary calculus. Lactobacillus in the yoghourt has the effect of resolving oxalic acid, can degrade food-borne oxalic acid in intestinal tract, and reduce absorptive amount of the intestinal tract to the oxalic acid, so the yoghourt has the efficacy of preventing urinary calculus of the oxalic acid; and the yoghourt has important application in the fields of medicines, foods and health products. Through animal experiments, the invention provides that urinary oxalate excretion can be effectively reduced by drinking commercial yoghourt, thereby exploring a practical approach in preventing relapse of oxalate calcium calculus. The yoghourt has a plurality of obvious characteristics in health-care function and medicine-food homologization, and has the advantages of low cost, convenient taking and high compliance degree compared with a patient taking drugs, and does not have any side effect, so the yoghourt has better potential of prevention use.

Owner:上海交通大学医学院附属第三人民医院

Crystalline composition containing escitalopram

InactiveUS20030212128A1Granulation avoidedReduce stepsPowder deliveryBiocideCrystallographyCrystalline particle

Crystalline particles of escitalopram oxalate with a particle size of at least 40 mum is disclosed. Method for the manufacture of said crystalline particles and pharmaceutical compositions comprising said crystalline particles are also disclosed.

Owner:H LUNDBECK AS

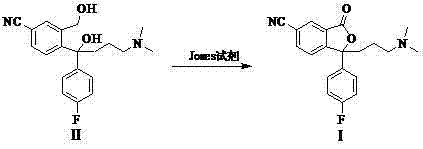

Preparation method of escitalopram oxalate impurity C

InactiveCN102952106AReduce processing costsGood stability and reproducibilityOrganic chemistryIsobenzofuranPhenyl group

Owner:BEIJING VENTUREPHARM BIOTECH

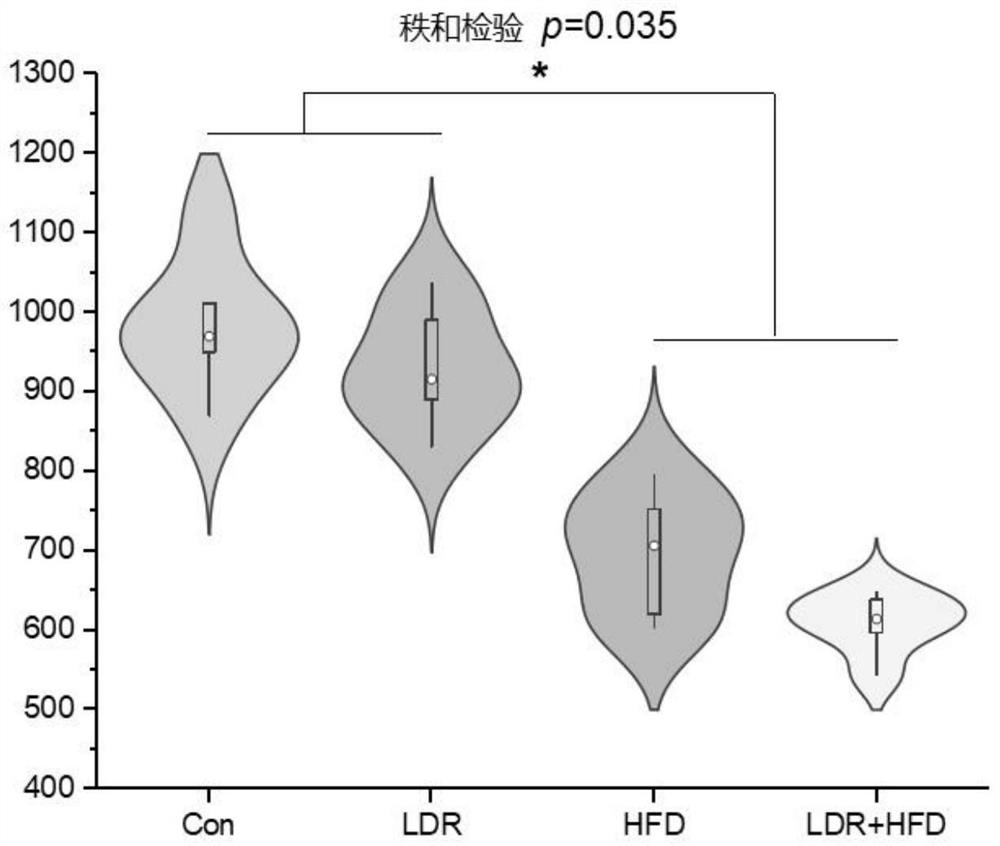

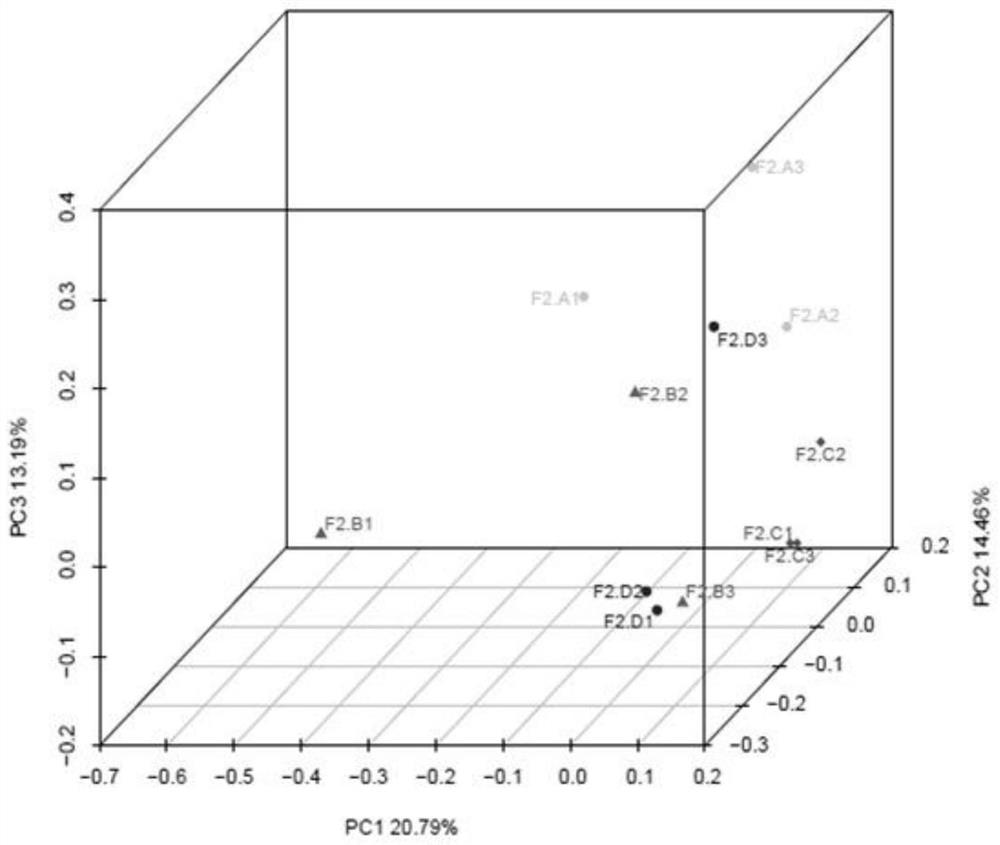

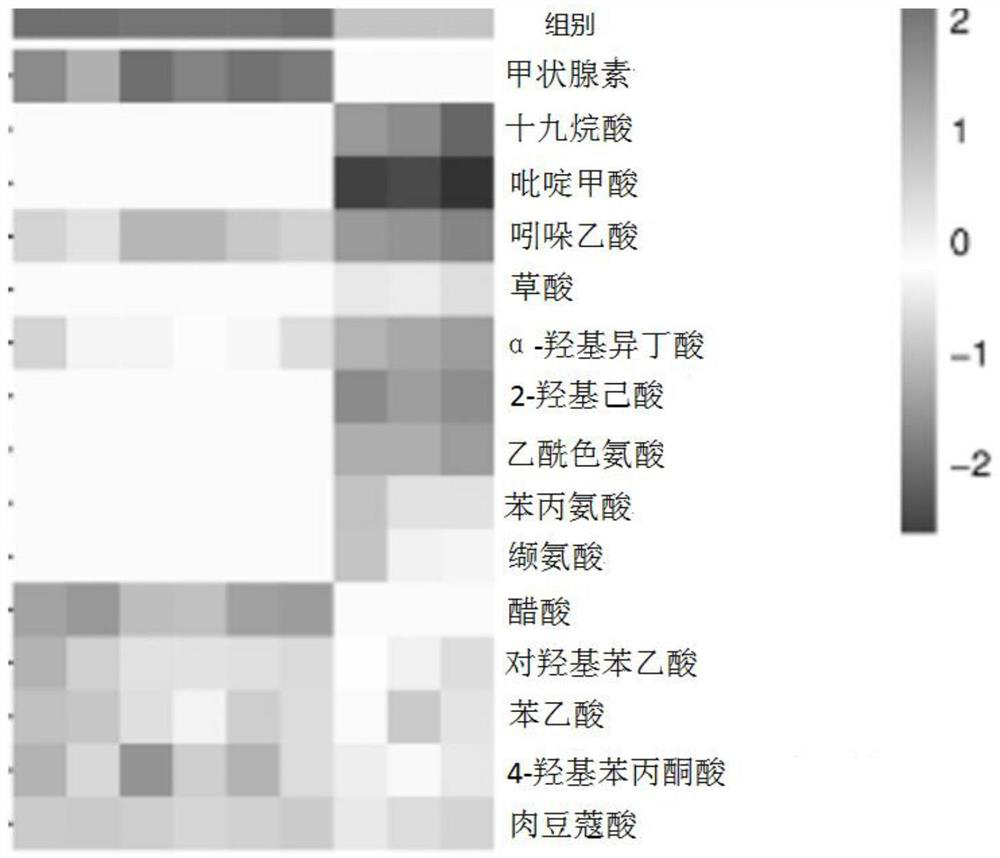

Fecal biomarker for diagnosing or preventing diabetes mellitus, detection reagent and application of fecal biomarker

PendingCN114324711AGood forecastStrong specificityComponent separationOXALIC ACID DIHYDRATEAklanonic acid

The invention relates to a fecal biomarker for diagnosing or preventing diabetes mellitus, a detection reagent and application of the fecal biomarker. The excrement biomarker for diagnosing or preventing diabetes mellitus provided by the invention comprises one or more of 2-hydroxyhexanoic acid, phenylalanine, valine, acetyltryptophan, nonadecanoic acid, oxalic acid, picolinic acid, alpha-hydroxyisobutyric acid, indoleacetic acid, p-hydroxyphenylacetic acid, acetic acid, thyroxine, 4-hydroxyphenylpyruvic acid, myristic acid or phenylacetic acid. The fecal biomarker provided by the invention is high in sensitivity and specificity and good in predictability, and can be used for early diagnosis or prevention of diabetic people, especially diabetic people exposed by combination of long-term low-dose radiation and high-glucose and high-fat diet.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com