A kind of preparation method of cobalt oxalate nanowire

A technology of cobalt oxalate nanometer and oxalic acid is applied in the preparation of carboxylates, carboxylates, organic compounds, etc., and can solve the problems of complicated operation, low product purity, multiple reaction steps, etc., and achieve simple operation steps. , the effect of high product purity and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of cobalt oxalate nanowires, comprising the following steps:

[0028] 1) Weigh 0.291g cobalt nitrate hexahydrate and 0.05g Span-40, dissolve in a mixture of 25ml ethylene glycol and 25ml deionized water to form solution A; weigh 0.5g oxalic acid and dissolve it in 25ml ethylene glycol and Prepare solution B in a mixture composed of 25ml deionized water;

[0029] 2) Mix solutions A and B for water bath reaction, and react at room temperature for 20 hours to obtain a suspension containing cobalt oxalate nanowires;

[0030] 3) After the water bath reaction, the suspension is centrifuged, and then the precipitate is washed with deionized water and absolute ethanol;

[0031] 4) The precipitate was dried in a vacuum oven at 50° C. for 5 hours to finally obtain 0.145 g of pink cobalt oxalate powder with a yield of 98.6%.

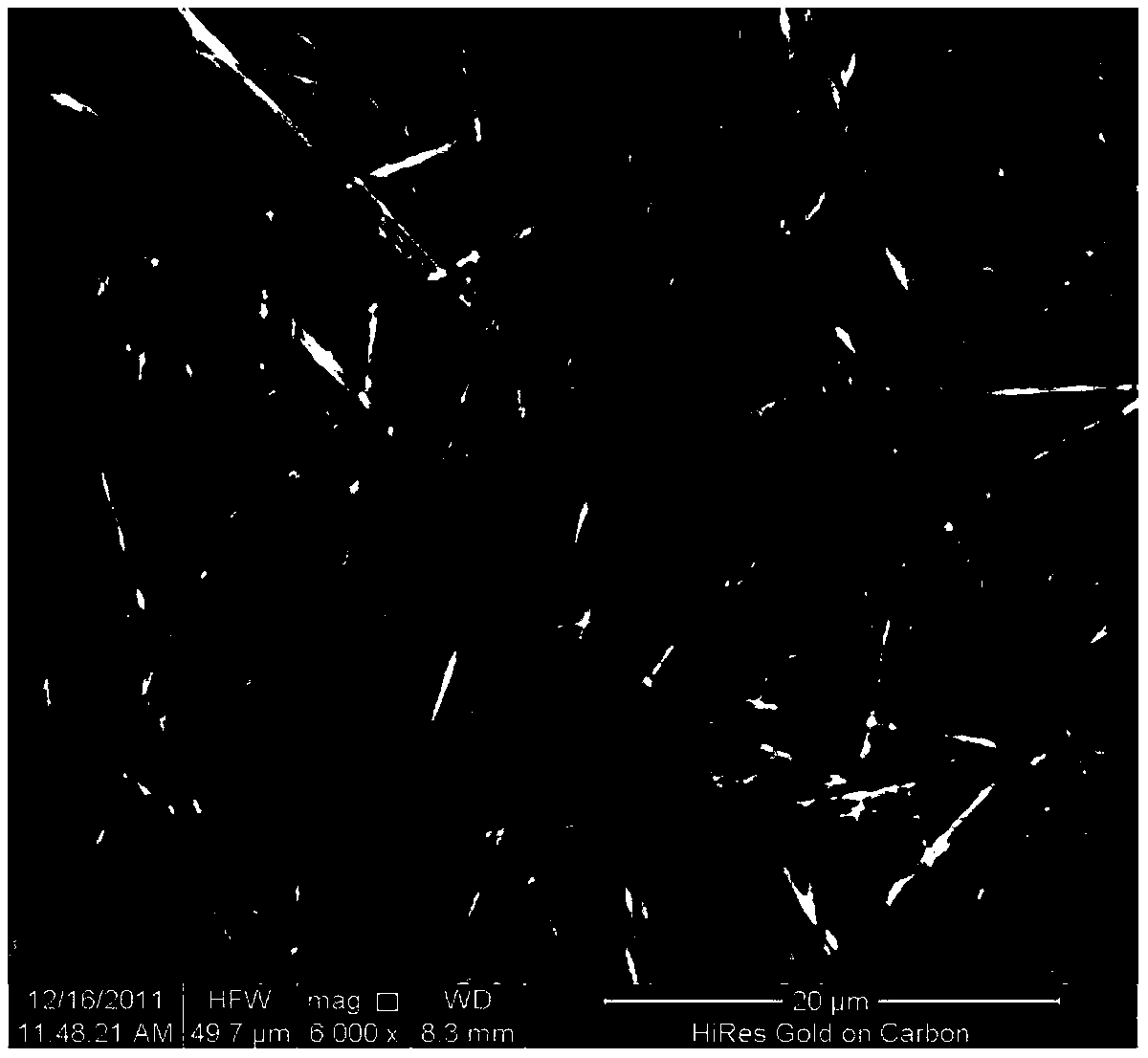

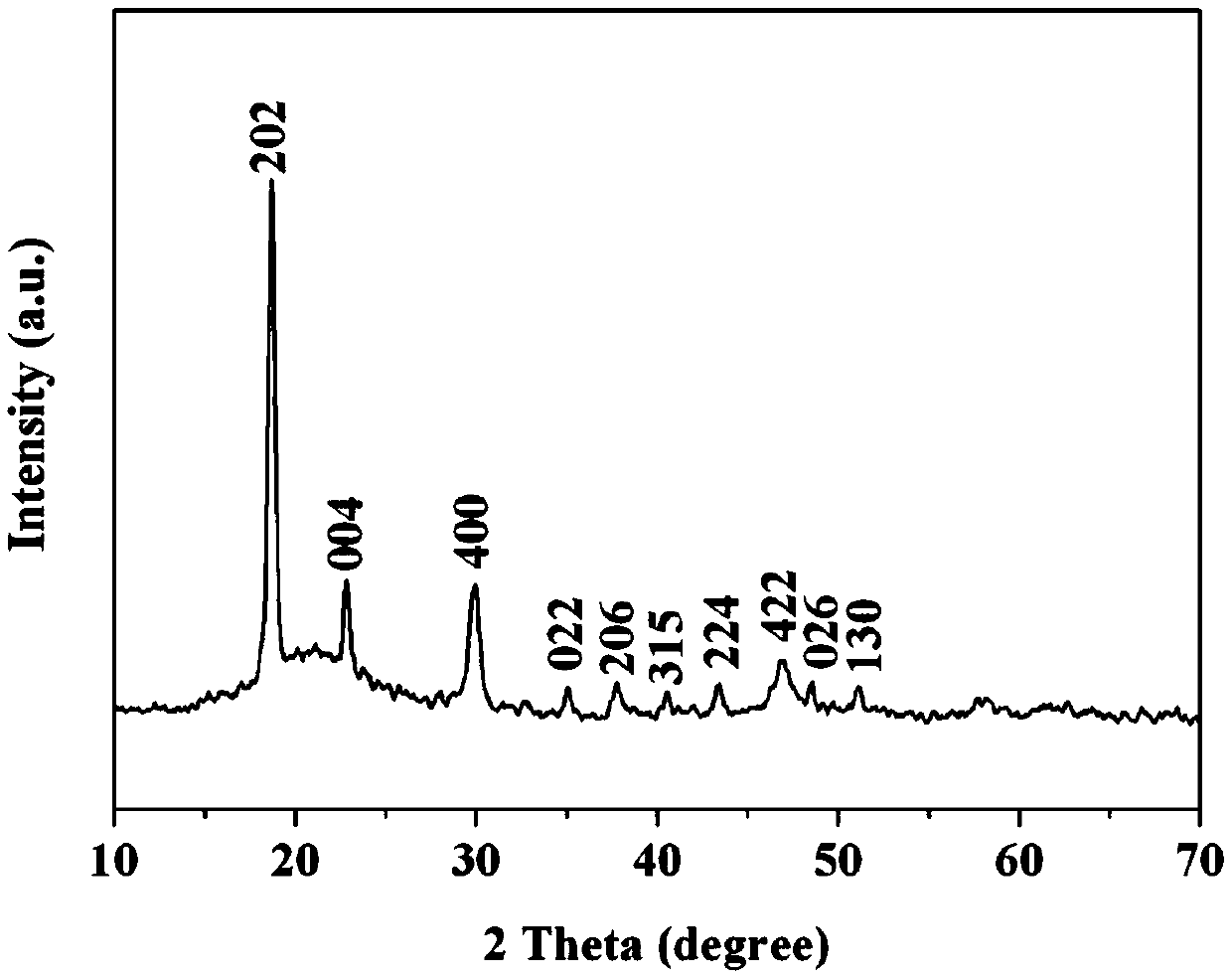

[0032] The scanning electron microscope picture and the XRD picture of the cobalt oxalate nanowire prepared in the present embodiment...

Embodiment 2

[0034] A preparation method of cobalt oxalate nanowires, comprising the following steps:

[0035] 1) Weigh 0.291g cobalt nitrate hexahydrate and 0.05g Span-40, dissolve in a mixture of 25ml ethylene glycol and 25ml deionized water to form solution A; weigh 0.25g oxalic acid and dissolve it in 25ml ethylene glycol and Prepare solution B in a mixture composed of 25ml deionized water;

[0036] 2) Mix solutions A and B to react in a water bath, and react at 20° C. for 21 hours to prepare a suspension containing cobalt oxalate nanowires;

[0037] 3) After the water bath reaction, the suspension is centrifuged, and then the precipitate is washed with deionized water and absolute ethanol;

[0038] 4) The precipitate was dried in a vacuum drying oven at 45° C. for 5.5 hours to finally obtain 0.143 g of pink cobalt oxalate powder with a yield of 97.3%.

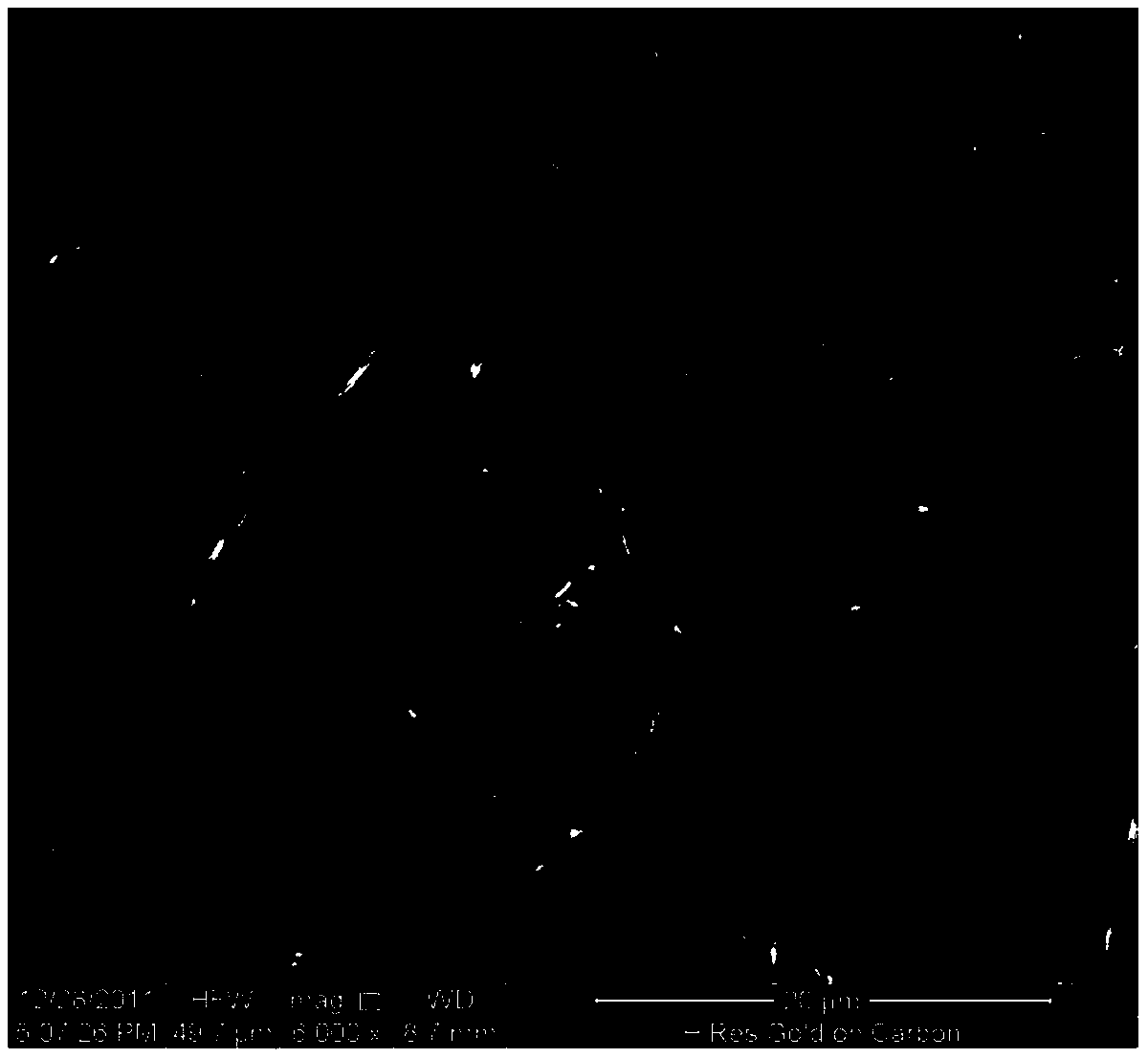

[0039] The scanning electron microscope picture of the cobalt oxalate nanowire prepared in the present embodiment is as follows i...

Embodiment 3

[0041] A preparation method of cobalt oxalate nanowires, comprising the following steps:

[0042] 1) Weigh 0.291g of cobalt nitrate hexahydrate and 0.05g of Span-40, dissolve in a mixture of 25ml of ethylene glycol and 25ml of deionized water to form solution A; weigh 1g of oxalic acid and dissolve in 25ml of ethylene glycol and 25ml of deionized water Prepare solution B in the mixed solution composed of deionized water;

[0043] 2) Mix solutions A and B for water bath reaction, and react at 24°C for 20 hours to prepare a suspension containing cobalt oxalate nanowires;

[0044] 3) After the water bath reaction, the suspension is centrifuged, and then the precipitate is washed with deionized water and absolute ethanol;

[0045] 4) The precipitate was dried in a vacuum oven at 40° C. for 6 hours to finally obtain 0.144 g of pink cobalt oxalate powder with a yield of 97.9%.

[0046] The scanning electron microscope picture of the cobalt oxalate nanowire prepared in the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com