Method for preparing super-fine cobalt powder

A technology of ultra-fine cobalt powder and fine powder, which is applied in the field of metal powder production, can solve problems such as waste of manpower, high production cost, and complicated means, and achieve the effects of reducing production cost, improving production efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

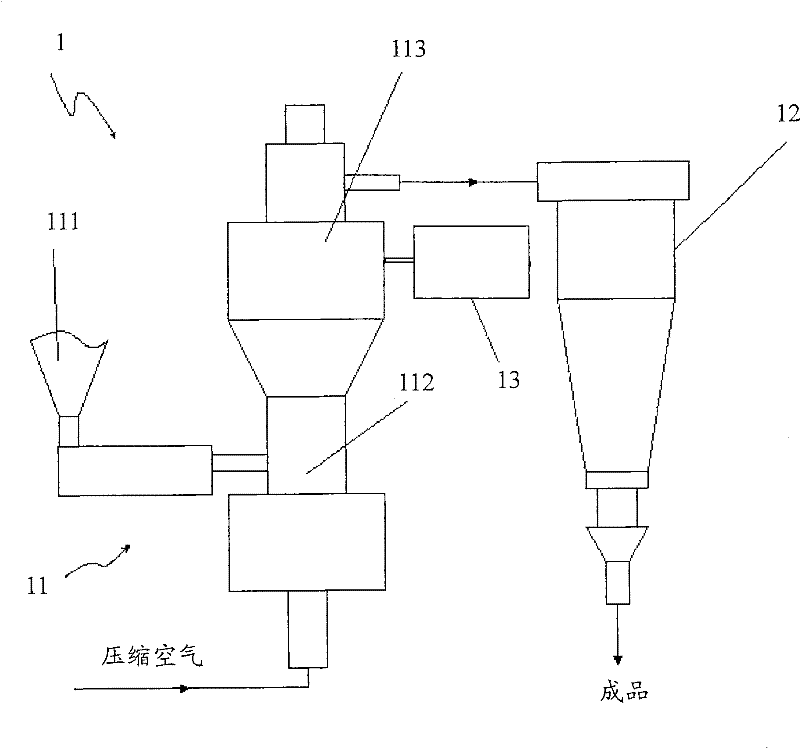

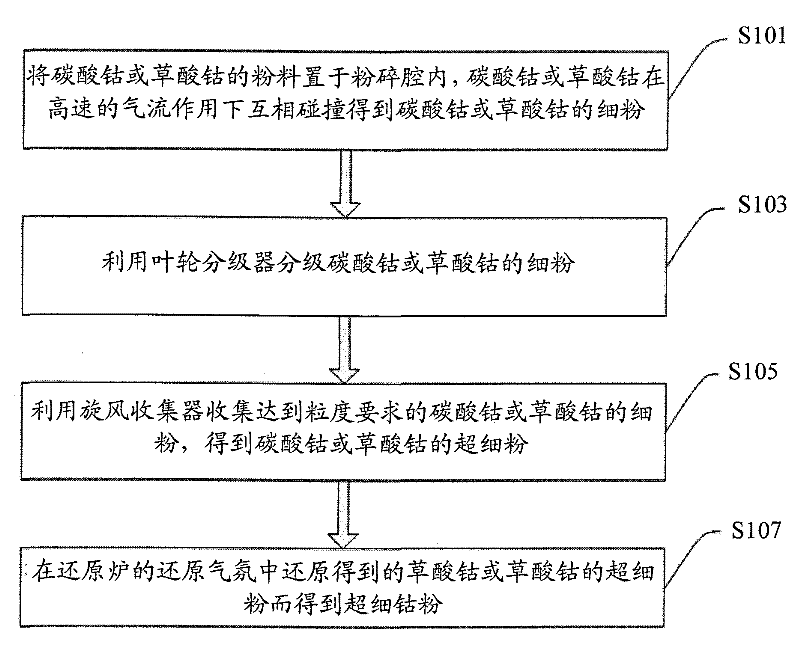

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

[0017] According to the depth of crushing processing technology and the changes in the physical and chemical properties of powder materials and application performance, fine powder and fine powder are generally divided into 10-1000μm (fine powder), 0.1-10μm (ultrafine powder) and 0.001-0.1 μm (ultrafine powder).

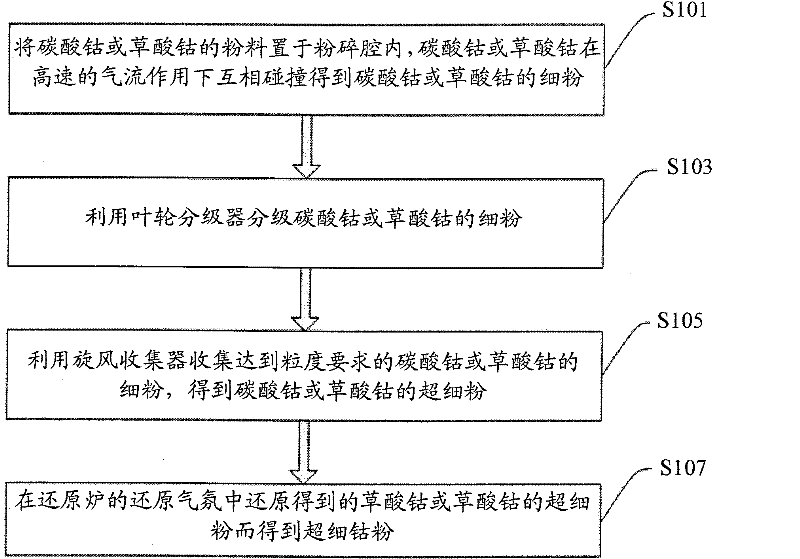

[0018] figure 1 A schematic diagram of a jet milling system is shown. like figure 1 As shown, the jet mill system 1 includes a jet mill 11 , a cyclone collector 12 and a control system 13 . The jet mill 11 includes a feeding device 111 , a grinding chamber 112 , and an impeller classifier 113 . The electrical appliances of the control system 13 are connected to the impeller classifier 113 of the above-mentioned jet milling. The jet pulverization system is well ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com