Preparation method of superfine cobalt powder

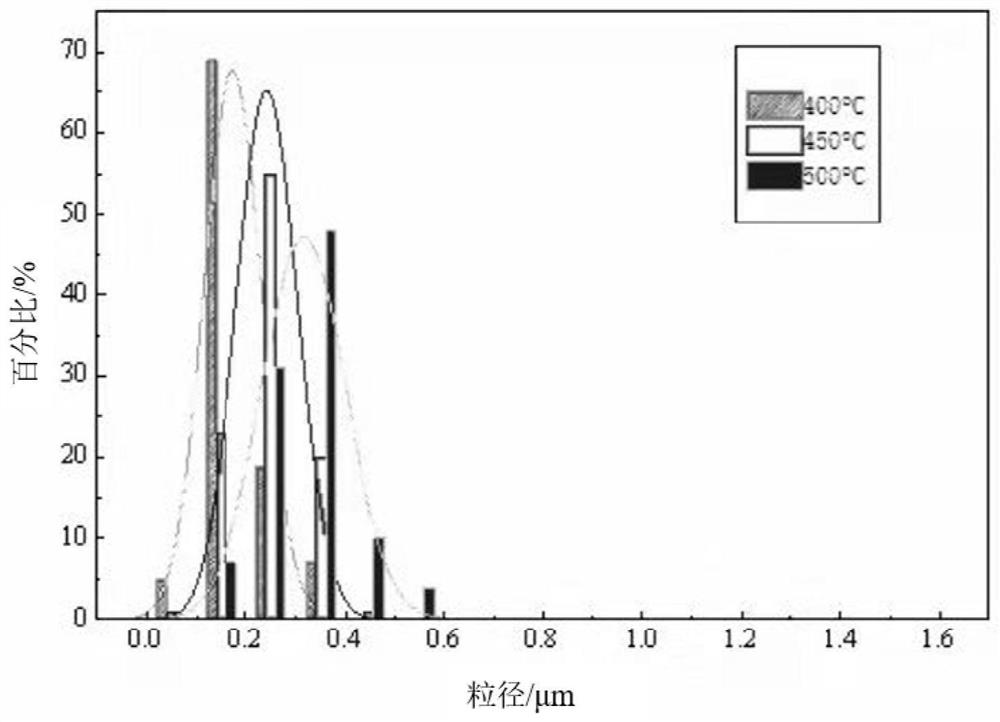

A technology of ultra-fine cobalt powder and cobalt powder, which is applied in the field of metal processing, can solve the problems of high production cost, large Co powder particles, and difficulty in mass production, and achieve the effects of preventing spontaneous combustion, low reduction temperature, and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

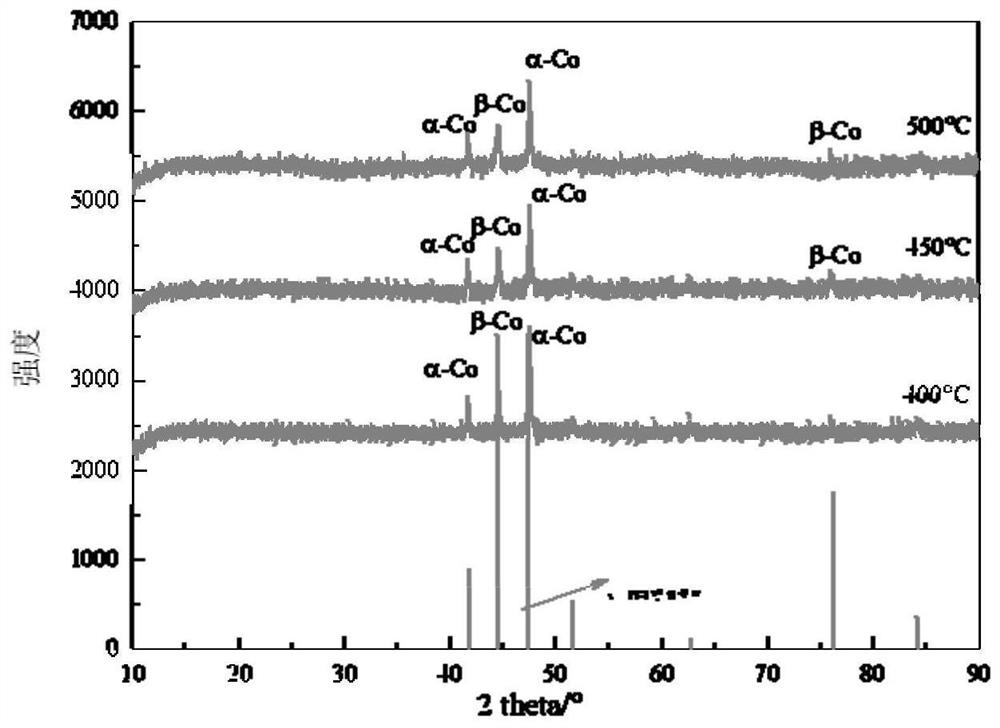

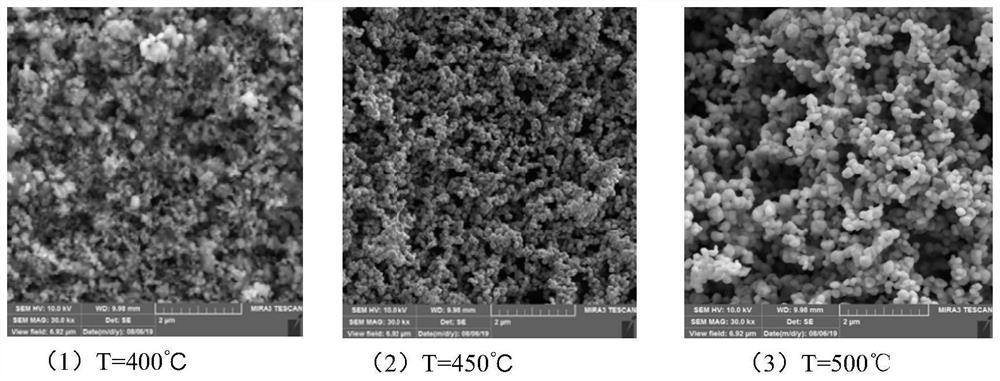

[0027] A kind of embodiment of the preparation method of ultrafine cobalt powder described in the present invention, the preparation method described in this embodiment comprises the following steps:

[0028] (1) configuration oxalate ion concentration is that the concentration of sodium oxalate solution of 1.6mol / L and cobalt ion is the cobalt nitrate solution of 0.8mol / L; Wherein, the massfraction that also contains accounting for cobalt nitrate is 3% Complexing agent ammonium nitrate.

[0029] (2) The sodium oxalate solution and the cobalt nitrate solution flow into the sodium nitrate mother liquor (the concentration of nitrate ion is 0.8mol / L) through the co-current method, and the co-current precipitation process is carried out under the ultrasonic and microwave environment, and the ultrasonic and microwave functions are simultaneously Turn on, wherein, the ultrasonic frequency is 90Hz, the microwave power is 3kW, the flow rate ratio of sodium oxalate solution and cobalt ...

Embodiment 2

[0033] An embodiment of the preparation method of the ultrafine cobalt powder of the present invention, the difference between the preparation method described in this embodiment and Example 1 is that in the step (4), the reduction temperature is 450°C, and the reduction time is 70min.

Embodiment 3

[0035] An embodiment of the preparation method of the ultrafine cobalt powder of the present invention, the difference between the preparation method described in this embodiment and Embodiment 1 is that in the step (2), the ultrasonic frequency is 80 Hz, and the microwave power is 2 kW; In the step (4), the reduction temperature is 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com