A Pipeline Conveyor for Hydrogenation Stations Facilitating Pipeline Replacement

A technology of pipeline transportation and hydrogen refueling station, which is applied in pipeline heating/cooling, pipeline system, pipe/pipe joint/pipe fitting, etc. The effect of reducing the generation of static electricity and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

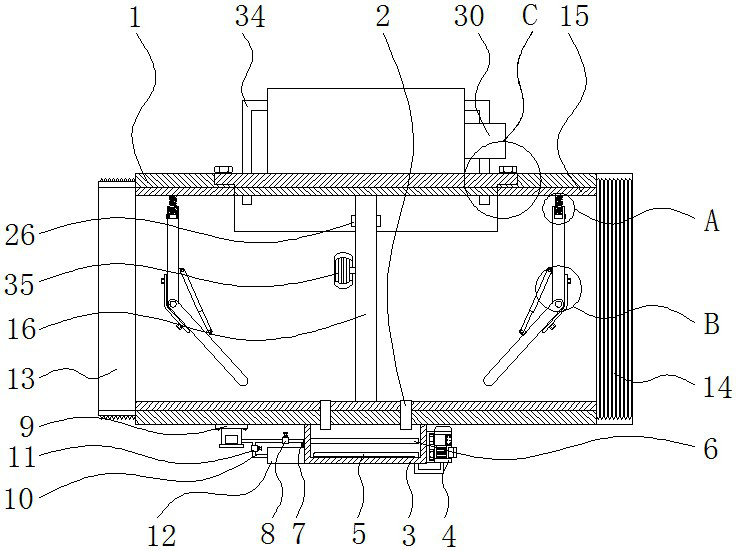

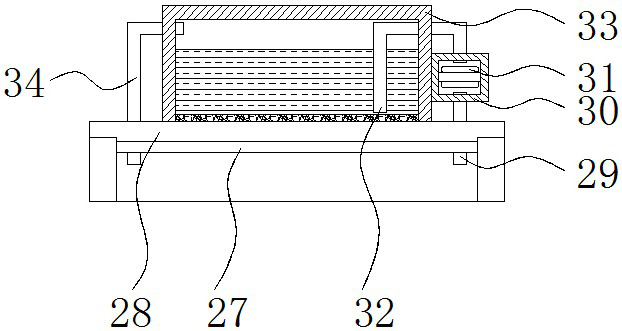

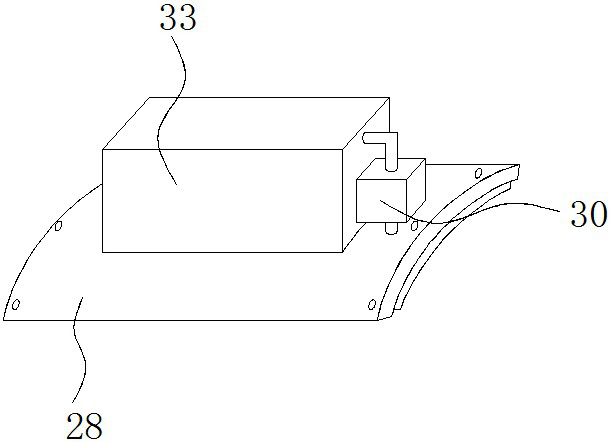

[0060] see Figure 1-5 , the present invention provides a technical solution: a pipeline conveyor for hydrogen refueling stations that facilitates pipeline replacement, including:

[0061] Pipe body 1, the left side of the pipe body 1 is fixed with a threaded connector 13, and the right side of the pipe body 1 is welded with a threaded connection sleeve 14;

[0062]The first connecting conduit 2, which runs through the lower wall of the pipeline body 1, and two first connecting conduits 2 are arranged symmetrically with respect to the central axis of the pipeline body 1;

[0063] Cooling box 3, which is fixed at the lower end of pipeline body 1;

[0064] Condenser 4, which is installed on the right side of cooling box 3;

[0065] The condenser tube 5 is connected to the lower end of the condenser 4, and the liquid hydrogen inside the equipment can be transported to the cooling box 3 through the first connecting conduit 2, and the liquid hydrogen inside the pipeline body 1 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com