Method and device for conveying combustible gas generated in leachate treatment

A conveying device and leachate technology, which is used in gas/liquid distribution and storage, pipes/pipe joints/fittings, and pipe heating/cooling, etc. To reduce the possibility of spontaneous combustion and explosion, improve the absorption effect, and reduce the effect of spontaneous combustion or explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

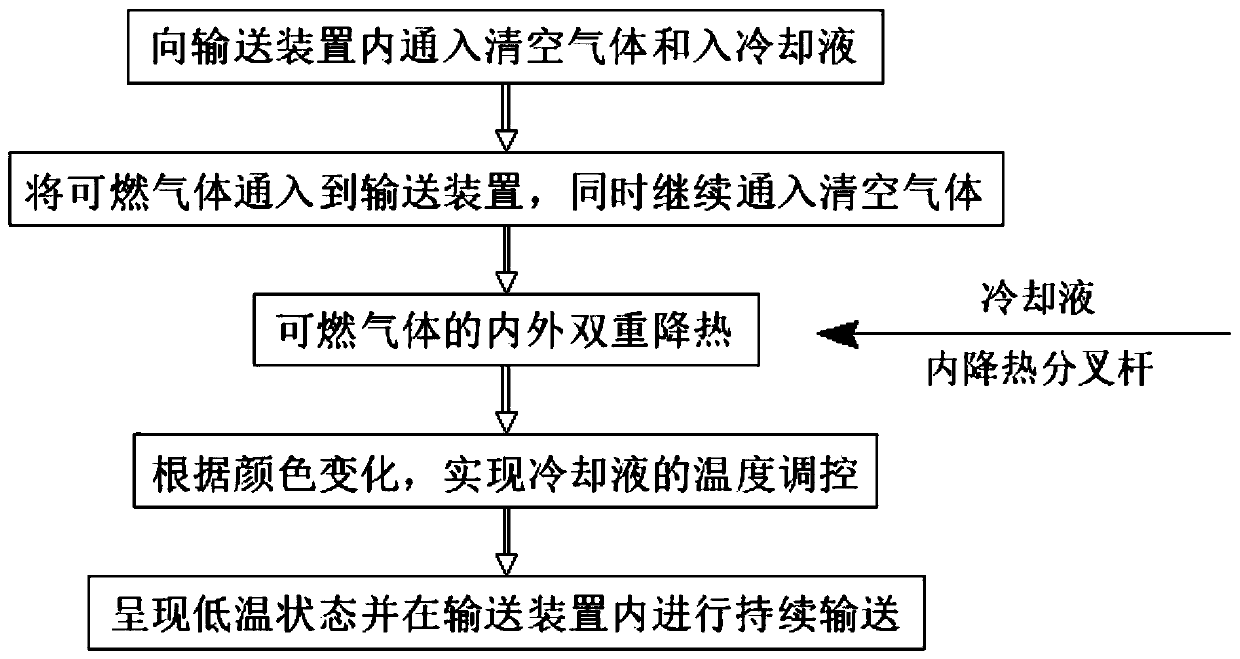

[0048] see figure 1 , a method for transporting combustible gas produced by leachate treatment, comprising the following steps:

[0049] S1. First, pass clear air into the conveying device, discharge the air inside, and pass coolant into the conveying device;

[0050] S2. Pass the combustible gas produced by the incinerator waste incineration into the conveying device, and continue to pass in the clear gas at the same time;

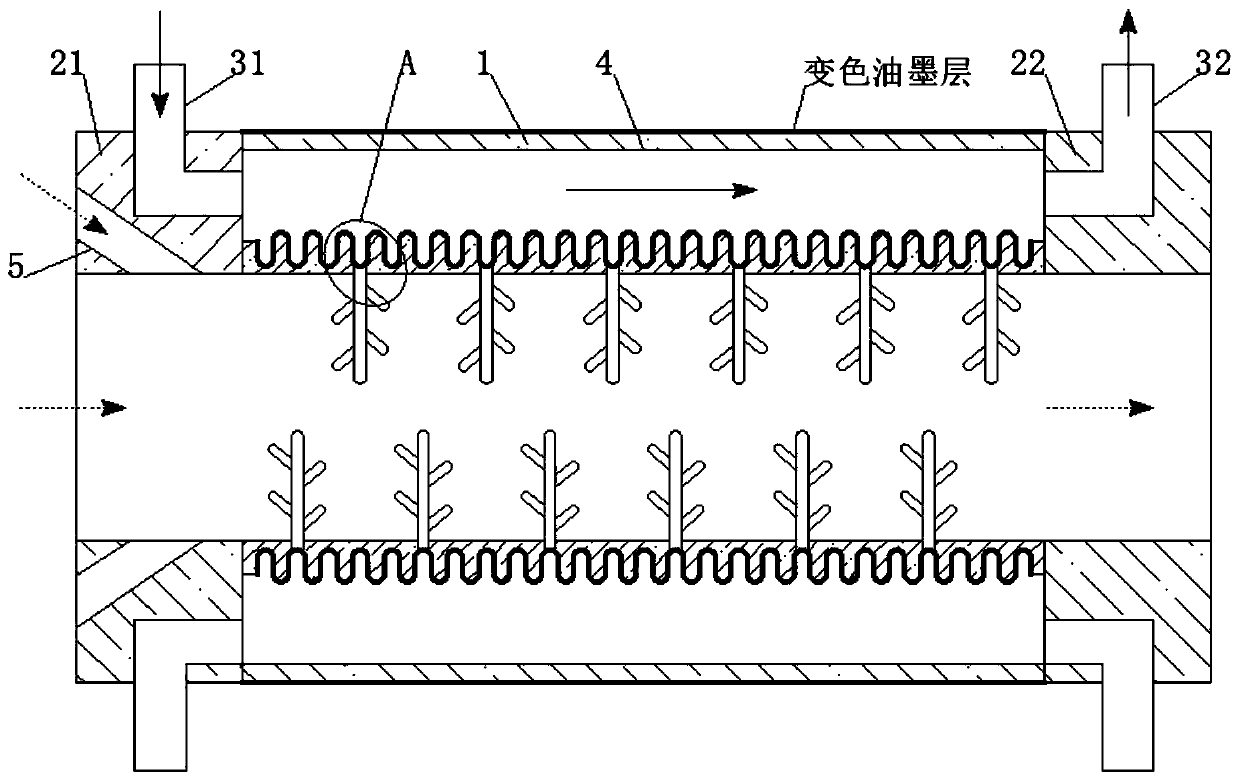

[0051] S3. Under the action of multiple sets of internal heat-reducing bifurcation rods and cooling liquid in the conveying device, double heat-reducing of combustible gas is achieved for safe conveying;

[0052] S4. Through the color change on the surface of the conveying device, the temperature regulation of the cooling liquid is realized during the conveying process;

[0053] S5. After the combustible gas undergoes double cooling, it is in a low-temperature state and is continuously transported in the transport device.

[0054] The clear air gas is ...

Embodiment 2

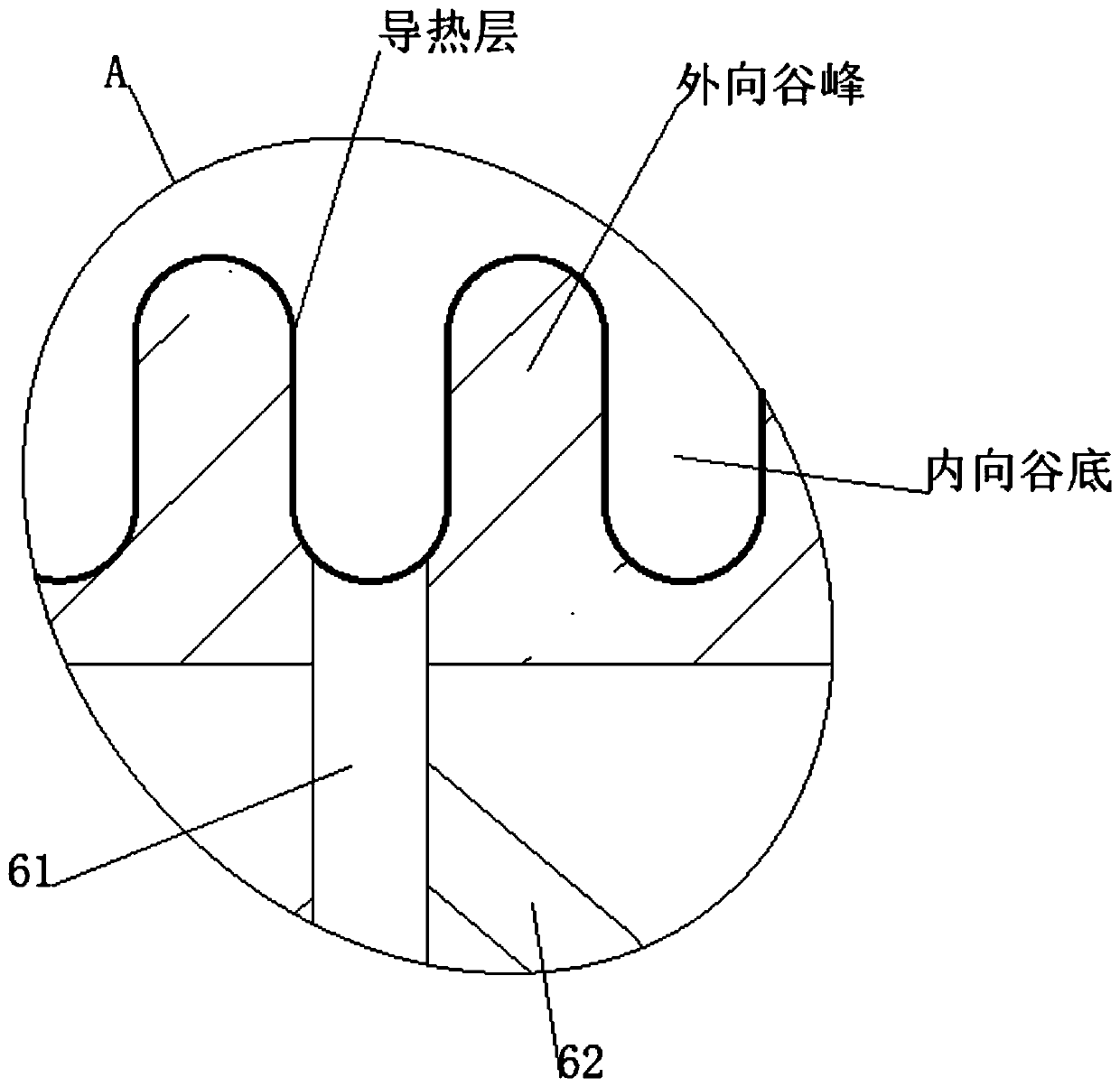

[0059] The inward valley bottom can be set as a special-shaped structure with a wide bottom and a narrow mouth. A water-repellent lodging rod is placed in the inward valley bottom. When the coolant is introduced, the water-repellent lodging rod can swing left and right in the inward valley bottom, thereby accelerating the inward valley bottom. The fluidity of the coolant improves the absorption efficiency of the coolant for this part of the heat, thereby accelerating the reduction of the overall heat of the combustible gas. The water-repellent lodging rod includes a swing fulcrum ball 7 placed inward toward the bottom of the valley, and the upper end of the swing fulcrum ball 7 is fixedly connected. There is an elastic lodging main rod 8, and the ends of the elastic lodging main rod 8 are fixedly connected with a plurality of flexible water-repelling rods 9. When the water-repelling and lodging rods swing left and right with the cooling liquid, the elastic lodging main rods 8 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com