Pipeline conveyor capable of achieving pipeline replacement conveniently and for hydrogen refueling station

A technology for pipeline transportation and hydrogen refueling stations, applied in pipeline heating/cooling, pipeline systems, pipes/pipe joints/fittings, etc., can solve problems such as temperature reaching, liquid gas spontaneous combustion, liquid hydrogen heating, etc., to prevent heat from spontaneous combustion, Reduce the generation of static electricity and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

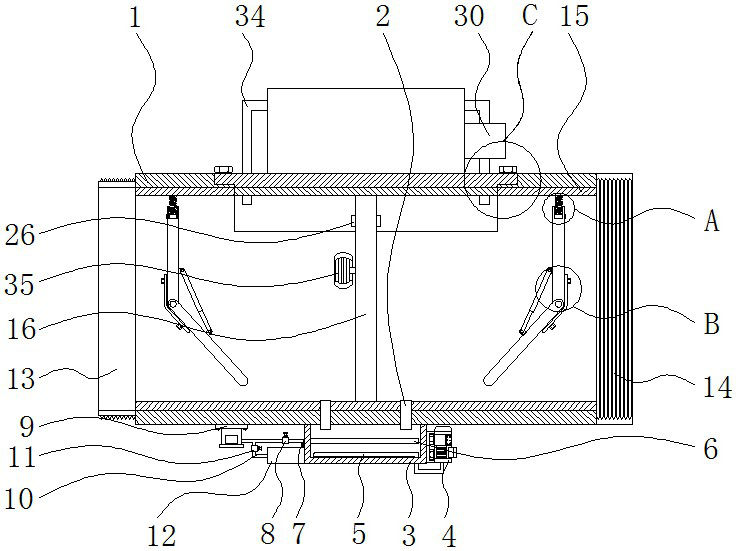

[0060] See Figure 1-5 The present invention provides a technical solution: a pipe conveyor for a hydrogen station for pipe replacement, including:

[0061] The pipe body 1, the left side of the conduit body 1 fixes the threaded joint 13, and the right side of the pipe body 1 has a threaded joint 14;

[0062]The first connecting conduit 2 is formed through the lower wall of the conduit body 1, and the first connecting conduit 2 is provided with a central axis symmetry of the conduit body 1;

[0063] Cooling the casing 3, which is fixed to the lower end of the pipe body 1;

[0064] The condenser 4 is mounted on the right side of the cooling casing 3;

[0065] The condenser 5 is attached to the lower end of the condenser 4, and the liquid hydrogen inside the apparatus can be delivered to the cooling casing 3 through the first connecting conduit 2, and the liquid hydrogen inside the pipe body 1 is passed through the condenser 4 and the condenser 5. The cooling treatment can prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com