3D-printed high-specific-energy lithium ion battery positive and negative electrode material and preparation method and application thereof

A lithium-ion battery and 3D printing technology, applied in the field of electrochemical energy storage, can solve problems such as the difficulty in realizing the printing accuracy of materials, and achieve the effects of small ion transport resistance, short diffusion path, and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

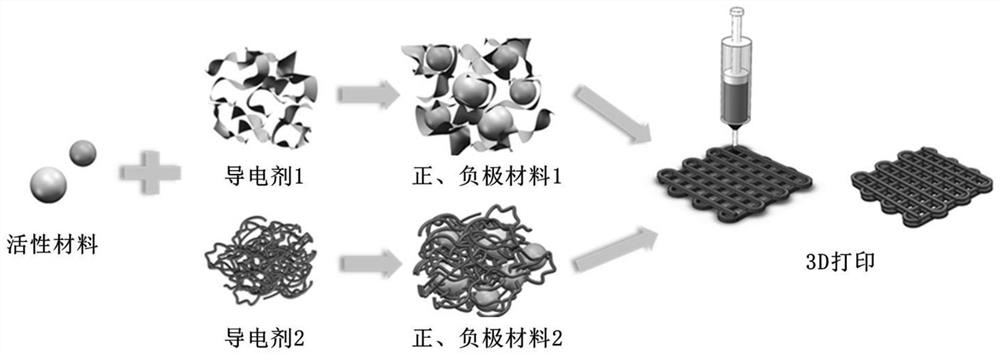

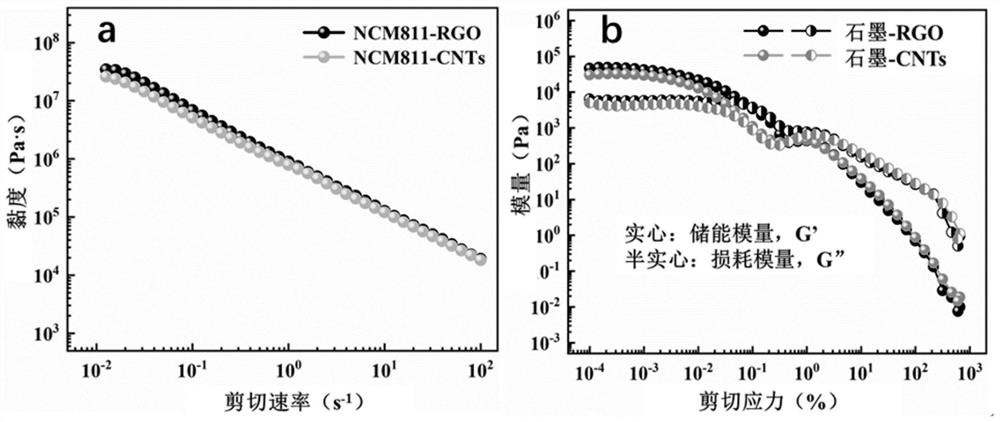

[0030] 350 mg of NCM811, 100 mg of carbon nanotubes and 50 mg of polyvinylidene fluoride were weighed and mixed, respectively, and the solid components were taken into the mortar for dry grinding for 10 minutes, and then 1 mL of N-methylpyrrolidone solvent was added for further grinding for 20 minutes. Finally, using a high-speed mixer for 15 minutes to obtain sufficient mixing, a paste-like 3D printing ink, namely NCM811-CNTs, was synthesized. figure 1 As shown, the rheological properties of the fabricated 3D printed battery cathode slurry are as follows figure 2 As shown in a, it can be seen from the figure that the apparent viscosity of the prepared slurry decreases with the increase of shear rate, showing obvious shear thinning behavior. Necessary for printability.

Embodiment 2

[0032] Weigh 250 mg of NCM811, 150 mg of acetylene black and 100 mg of sodium alginate and mix, respectively, take the solid components and put them in the mortar for dry grinding for 10 minutes, and then add 2 mL of pure water for further grinding for 20 minutes. Finally, using a high-speed mixer for 15 minutes to obtain sufficient mixing, a paste-like 3D printing ink, namely NCM811-acetylene black, was synthesized.

Embodiment 3

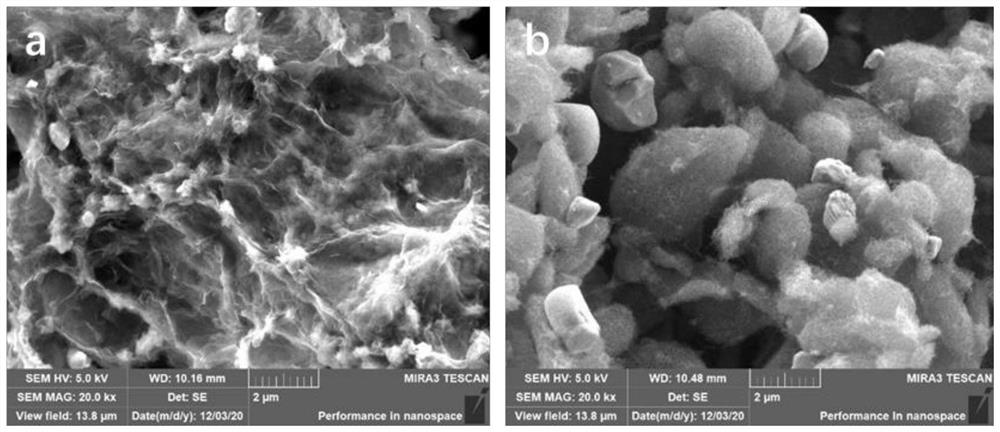

[0034] 350 mg of NCM811, 100 mg of reduced graphene oxide and 50 mg of polyvinylidene fluoride were respectively weighed and mixed, and the solid components were put into the mortar for dry grinding for 10 minutes, and then 1.5 mL of N-methylpyrrolidone solvent was added for further grinding for 20 minutes. Finally, using a high-speed mixer for 15 minutes to obtain sufficient mixing, a paste-like 3D printing ink NCM811-rGO was synthesized. image 3 a shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com