Low-oxygen content submicron cobalt powder and cobalt oxalate precursor and manufacturing method thereof

A technology of micron cobalt powder and manufacturing method, which is applied in the field of metallurgy and chemical industry, can solve problems such as difficult stable operation, easy fire, poor stability, etc., and achieve the effect of easy and stable control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

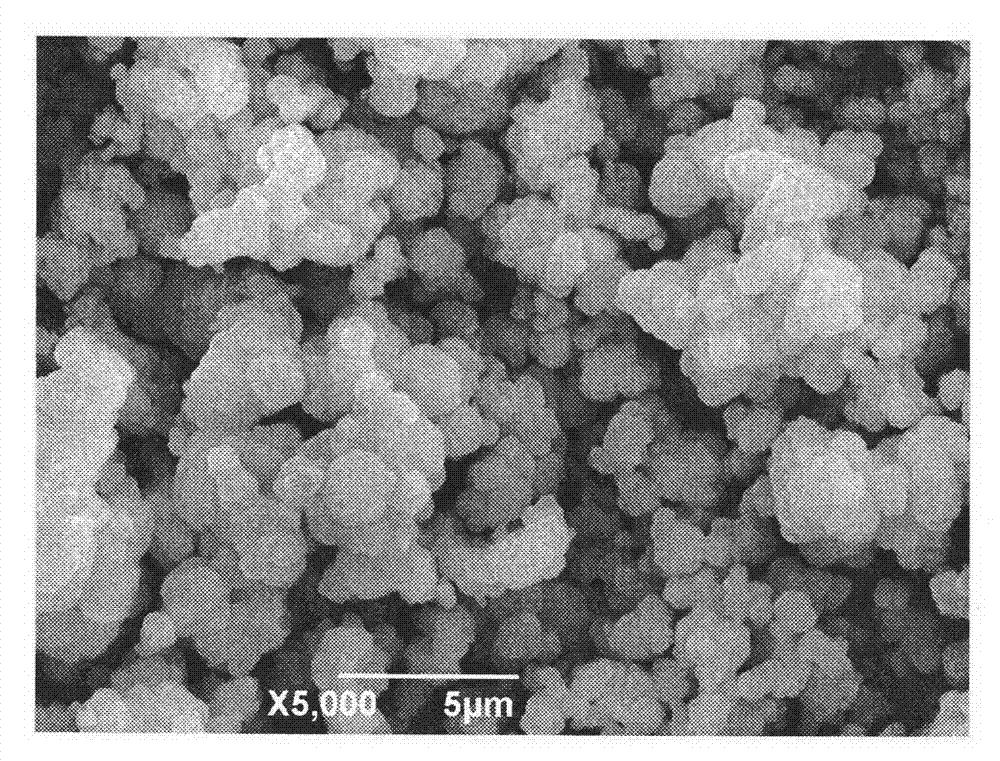

Embodiment 1

[0040] Implement CoCO 3 Wet slurry, solid-liquid ratio 1:2; oxalic acid solution with a concentration of 0.8mol / L, molar ratio n CoCO 3 : N H 2 C 2 O 4 =1∶2 ready to mix, preheat the solution to 25°C before the reaction, and reduce H within 15 minutes 2 C 2 O 4 CoCO solution added 3 In the slurry, react with constant temperature stirring for 3 hours. Separate the precipitate from the solution, filter and wash with clean water, dry at 100-150°C for 15-18 hours, grind and crush the dry powder and pass it through a 100-mesh sieve to detect the obtained cobalt oxalate precursor The cobalt content is 32.96%wt, and the loose density is 0.19g / cm 3 , D 50 The cobalt oxalate precursor is reduced at 300-350°C to obtain cobalt powder. The Fischer particle size of the unbroken cobalt powder is 0.86 μm and the oxygen content is 0.52%wt. The whole process is stable and not easy to catch fire.

Embodiment 2

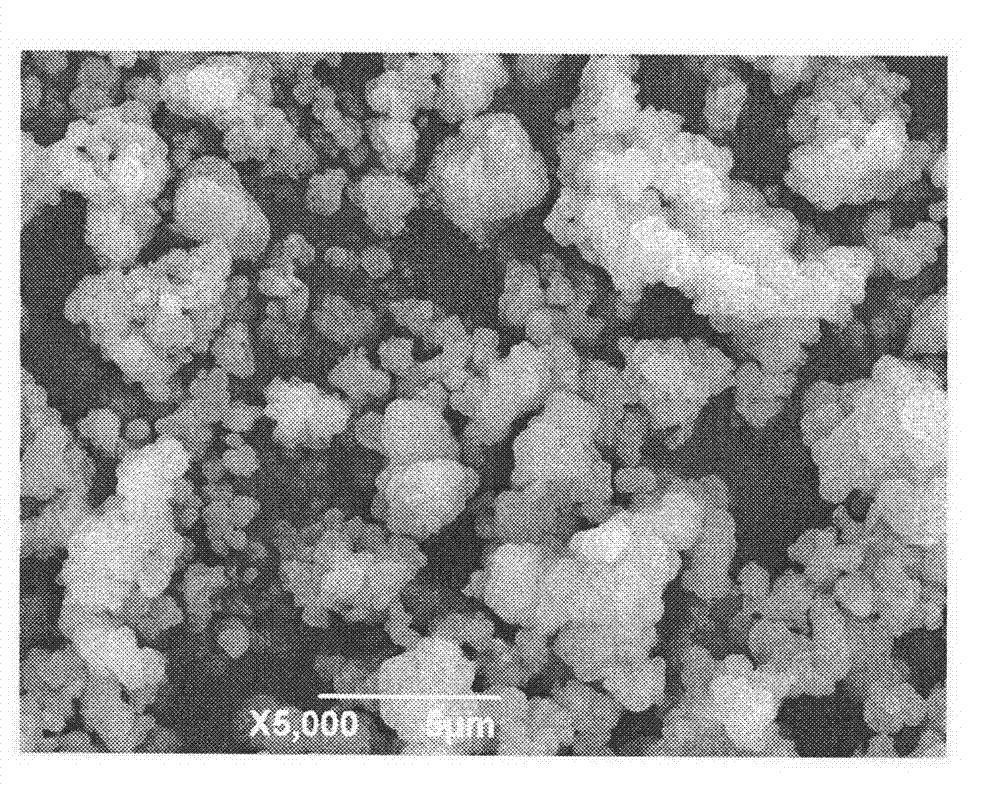

[0042] Implement CoCO 3 Wet slurry, solid-liquid ratio 1:4; preparation of oxalic acid solution with a concentration of 0.8mol / L, molar ratio n CoCO 3 : N H 2 C 2 O 4 =1:1.3 is ready to be mixed, the solution is preheated to 25 ℃ before the reaction, and the H 2 C 2 O 4 CoCO solution added 3 In the slurry, react with constant temperature stirring for 3 hours. Separate the precipitate from the solution, filter and wash with clean water, dry at 80-120°C for 15-18 hours, grind and crush the dry powder and pass it through a 100-mesh sieve to detect the obtained cobalt oxalate precursor The cobalt content is 32.79%wt, and the loose density is 0.14g / cm 3 , D 50 The cobalt oxalate precursor is reduced at 300-350°C to obtain cobalt powder. The Fischer particle size of the unbroken cobalt powder is 0.60 μm and the oxygen content is 0.43%wt. The whole process is stable and not easy to catch fire.

Embodiment 3

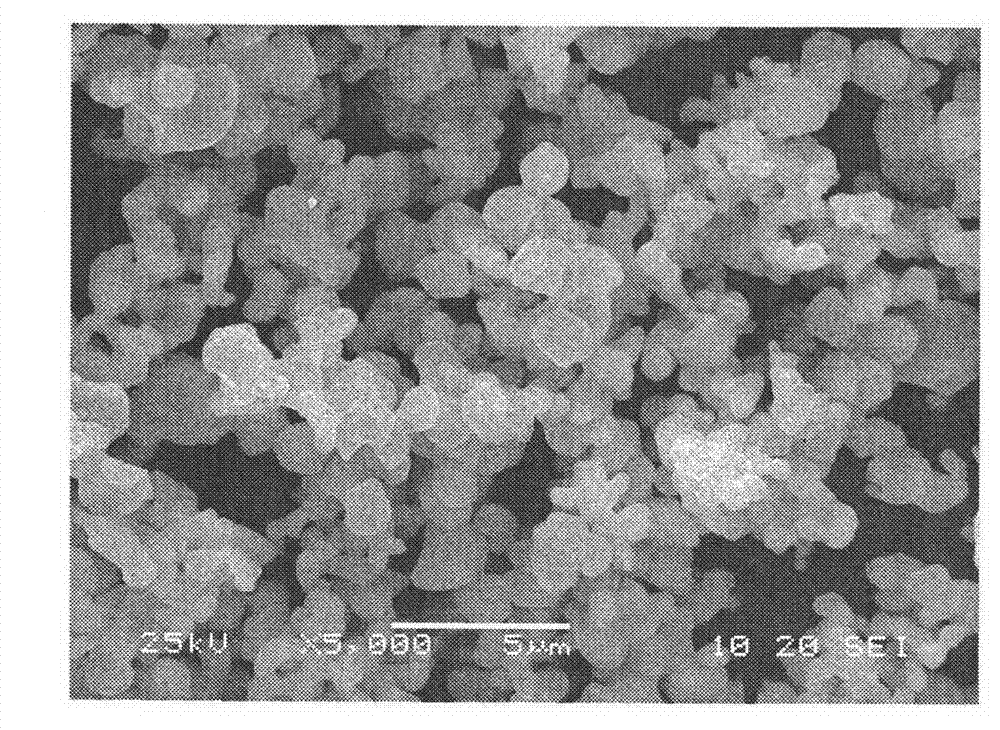

[0044] Implement CoCO 3 Wet slurry, solid-liquid ratio 1:4; preparation of oxalic acid solution with a concentration of 0.8mol / L, molar ratio n CoCO 3 : N H 2 C 2 O 4 =1:1.3 is ready to mix, preheat the solution to 25°C before the reaction, and remove H within 40min 2 C 2 O 4 CoCO solution added 3 In the slurry, react with constant temperature stirring for 3 hours, separate the precipitate from the solution, filter and wash with clean water, dry at 100-150°C for 15-18 hours, grind and crush the dry powder and pass it through a 100-mesh sieve to detect the obtained cobalt oxalate precursor The content of cobalt is 32.67%wt, and the bulk density is 0.22g / cm 3 , D 50 The cobalt oxalate precursor is reduced at 300-350°C to obtain cobalt powder. The Fischer particle size of the unbroken cobalt powder is 0.55 μm and the oxygen content is 0.61%wt. The whole process is stable and not easy to catch fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com