Arc-type sprue mould

A mold and gate technology, which is applied in the field of light guide plate forming equipment and molds, can solve the problems of cutting head scrapping, balance, and inability to respond to glue discharge, etc., and achieve the effect of uniform injection and increased flow ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

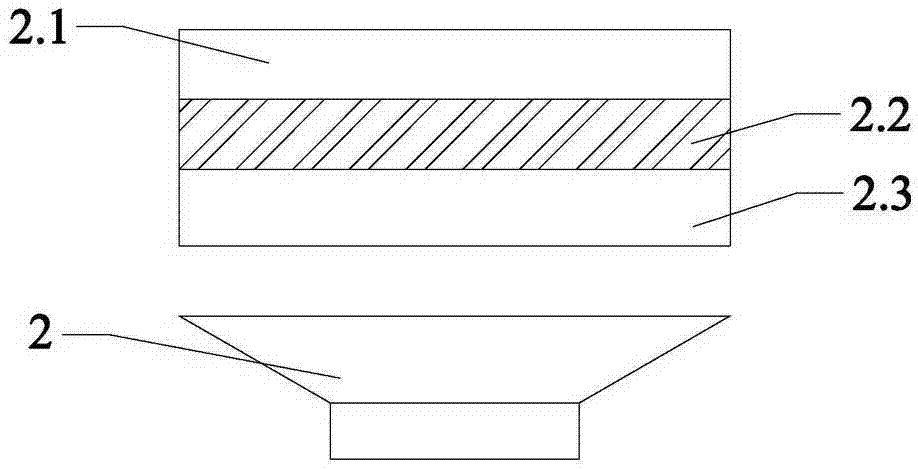

[0011] Depend on figure 1 It can be seen that the existing gate 2, its glue inlet 2.2 is: the depth of glue inlet in the middle and both ends is equal, preferably 4.6mm;

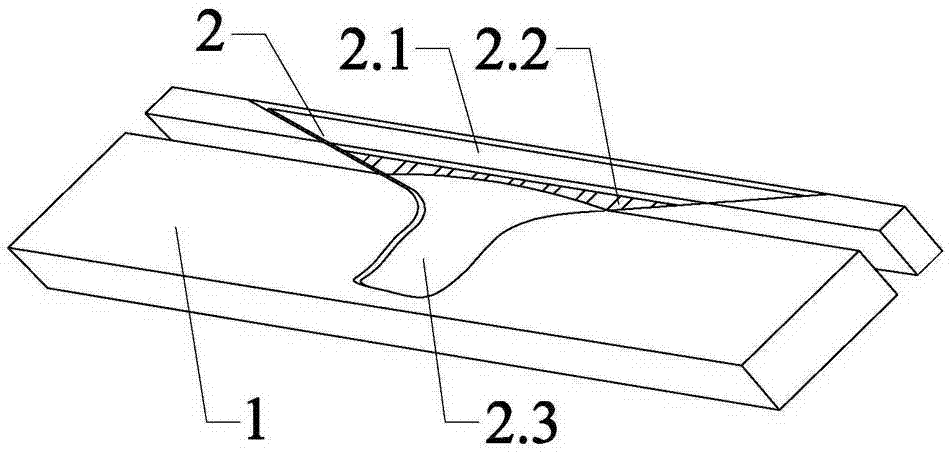

[0012] Depend on figure 2 It can be seen that the present invention includes a mold body 1 and a gate 2, the gate 2 is arranged on the mold body 1, the opening of the gate 2 has a smooth arc of 0.10mm, and the front end of the gate 2 is filled with glue It includes: fixed side 2.1, movable side 2.3, glue inlet 2.2 located between the fixed side 2.1 and movable side 2.3, the movable side 2.3 is an arc structure bent toward the glue inlet 2.2, It can be adjusted according to the size variation of the finished product, so as to facilitate injection adjustment and mass production.

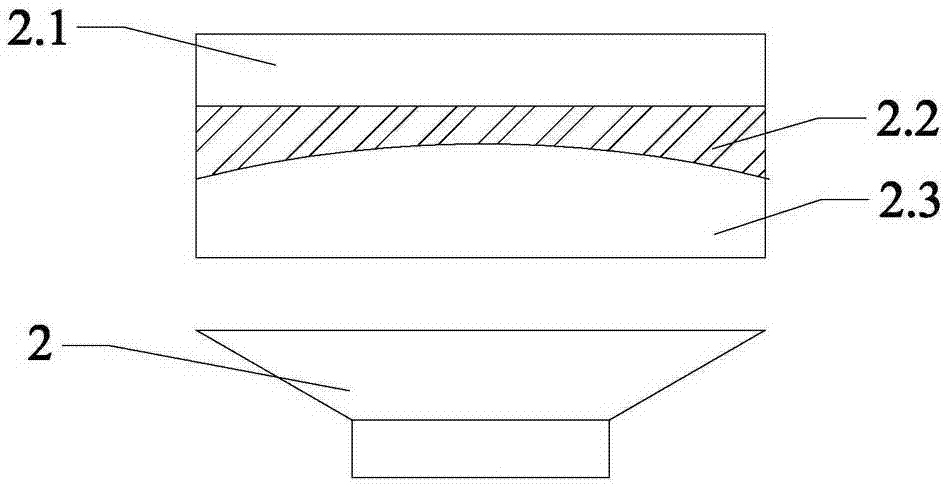

[0013] Depend on image 3 It can be seen that the glue feeding depth at both ends of the glue inlet 2.2 is 0.4-0.5 mm, preferably 0.46 mm; the glue feeding depth in the middle of the glue inlet 2.2 is 0.3-0.4 mm, preferably 0.36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com