Bottom shape structure of thin-walled and thin-walled multi-layer co-injected plastic container

A plastic container and thin-wall technology, which is applied in the field of thin-wall and thin-wall multi-layer co-injection plastic containers, can solve the problems of uneven wall thickness, abrupt connection flow corners, increased energy consumption, etc., and achieve easy molding and uniform material distribution , the effect of increasing the flow length ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be explained more clearly and completely through the description of preferred embodiments of the present invention in conjunction with the accompanying drawings.

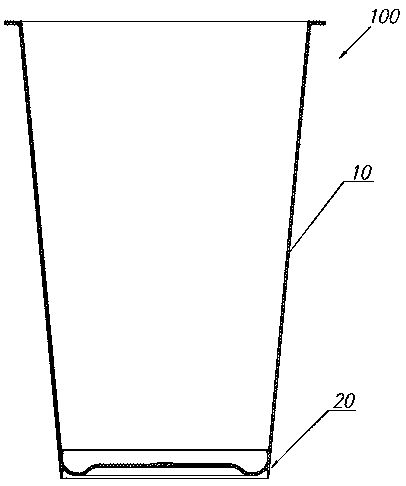

[0030] Such as figure 1 As shown, the thin-walled and thin-walled multi-layer co-injection plastic container 100 of the present invention includes a container side wall 10 and a container bottom 20 .

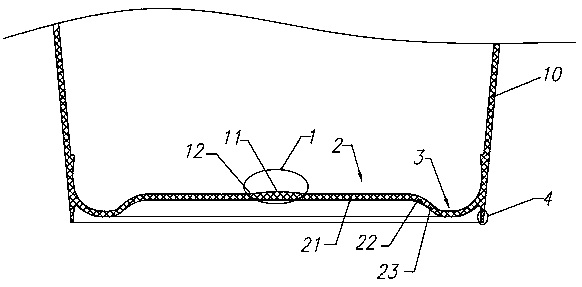

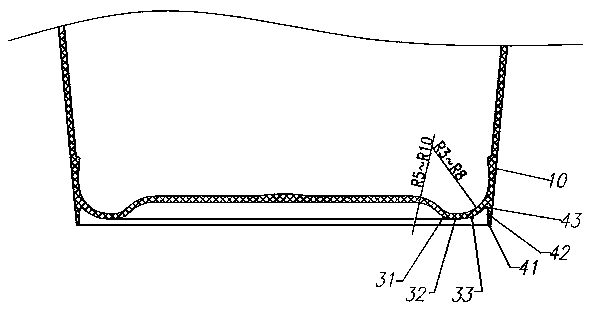

[0031] The shape and structure of the container bottom 20 includes a bottom central depression area 2 , bottom transition bottom corners 3 , and feet 4 . The feet 4 are in contact with a desktop or other supports, and are used to support the plastic container 100 on the supports. The bottom central recessed area 2 is located in the circular area surrounded by the feet 4 and is recessed toward the opening of the plastic container 100 . The bottom central recessed area 2 is connected to the bottom foot 4 through the bottom surface transition corner 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com