Special low-temperature injection-molded transparent PC (Polycarbonate) material for IMD (In-Mold Decoration) and preparation method therefor

A low-temperature injection molding and transparent technology, applied in the field of IMD special low-temperature injection molding transparent PC material and its preparation, can solve the problems of inability to produce transparent or light-transmitting functional parts for automobile interiors, and high PC injection temperature, and achieve lower injection temperature, The effect of improving flow length ratio and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

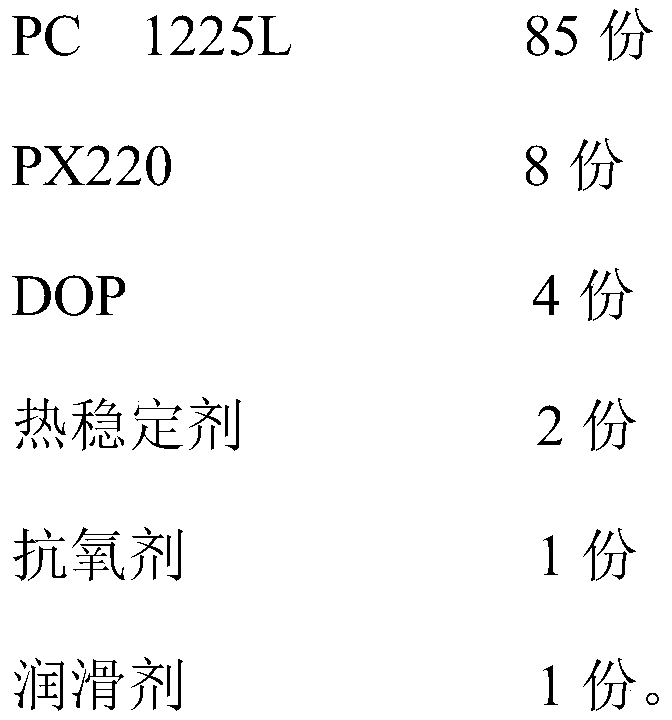

[0034] The low-temperature injection-molded transparent PC material dedicated to IMD of this embodiment is made of the following raw materials in parts by weight:

[0035]

[0036] The preparation method of the IMD-specific low-temperature injection-molded transparent PC material of this embodiment comprises the following steps:

[0037] S1. Weigh the raw materials according to the weight of the raw materials, and sequentially add them into a high-speed mixer with a rotating speed of 500rpm / min, mix for 4min, and discharge to obtain a mixture;

[0038] S2. Put the mixture prepared in step S1 into the hopper of the twin-screw extruder, wherein the twin-screw extruder selects a screw combination with strong shear, set the screw speed of the twin-screw extruder to 500r / min, and the main feed 20HZ , the degree of vacuum is -0.06MPa, the temperature is 255°C, after extrusion granulation, the speed of the granulator is 800rpm, and the pellets can be collected.

Embodiment 2

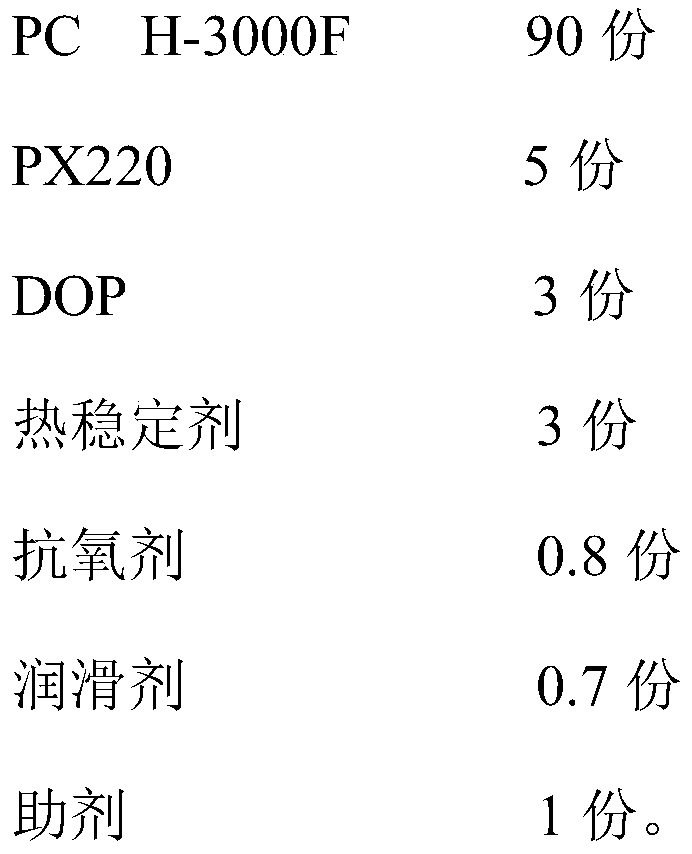

[0040] The low-temperature injection-molded transparent PC material dedicated to IMD of this embodiment is made of the following raw materials in parts by weight:

[0041]

[0042] The preparation method of the IMD-specific low-temperature injection-molded transparent PC material of this embodiment comprises the following steps:

[0043] S1. Weigh the raw materials according to the weight of the raw materials, and sequentially add them to a high-speed mixer with a rotating speed of 500 rpm / min, mix for 4 minutes, and discharge to obtain a mixture;

[0044] S2. Put the mixture prepared in step S1 into the hopper of the twin-screw extruder, wherein the twin-screw extruder selects a screw combination with strong shear, set the screw speed of the twin-screw extruder to 500r / min, and the main feed 20HZ , the degree of vacuum is -0.06MPa, the temperature is 255°C, after extrusion granulation, the speed of the granulator is 850rpm, and the pellets can be collected.

Embodiment 3

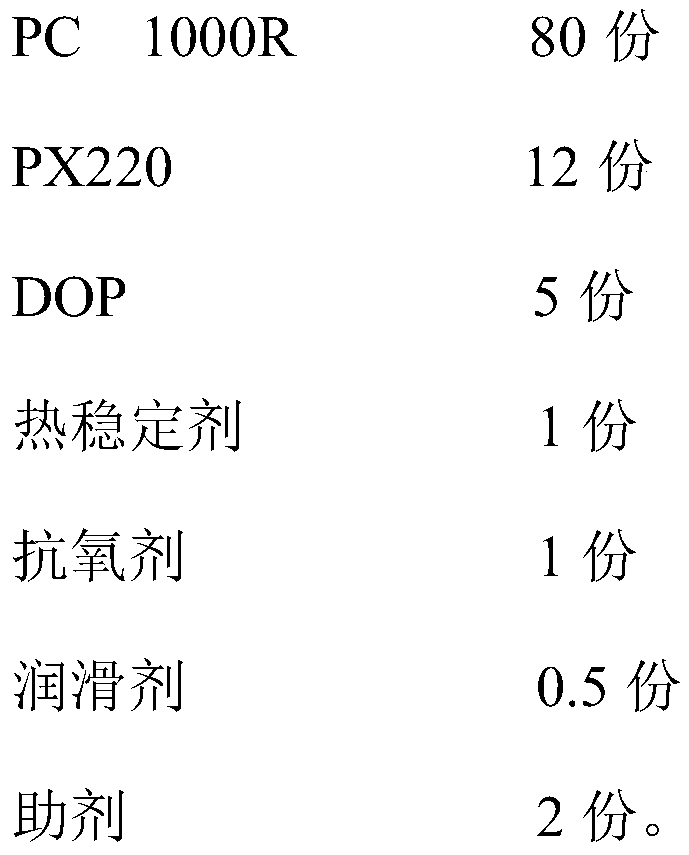

[0046] The low-temperature injection-molded transparent PC material dedicated to IMD of this embodiment is made of the following raw materials in parts by weight:

[0047]

[0048] The preparation method of the IMD-specific low-temperature injection-molded transparent PC material of this embodiment comprises the following steps:

[0049] S1. Weigh the raw materials according to the weight of the raw materials, and sequentially add them into a high-speed mixer with a rotating speed of 400rpm / min, mix for 6min, and discharge to obtain a mixture;

[0050] S2, put the mixture prepared in step S1 into the hopper of the twin-screw extruder, wherein the twin-screw extruder selects a screw combination with strong shear, set the screw speed of the twin-screw extruder to 400r / min, and the main feed 25HZ , the degree of vacuum is -0.04MPa, the temperature is 270°C, after extrusion granulation, the speed of the granulator is 700rpm, and the pellets can be collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com