Patents

Literature

40results about How to "Lower injection temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene

The invention discloses an environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene and belongs to the technical field of high polymer materials. The environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene is characterized by comprising copolypropylene and / or homopolypropylene, one or more fire retardants, one or more ultraviolet absorbers, one or more light stabilizers, one or more antioxidants, one or more copper toxicity-resistant agents and one or more processing auxiliary agents according to a certain weight part ratio. The environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene has excellent mechanical properties and effects of high fire resistance and high seawater resistance.

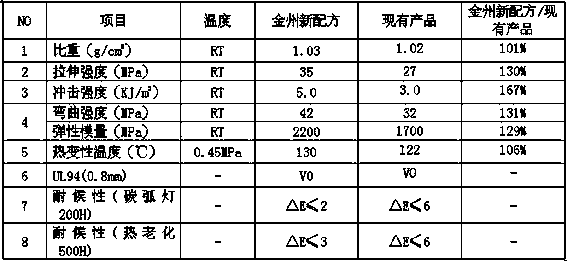

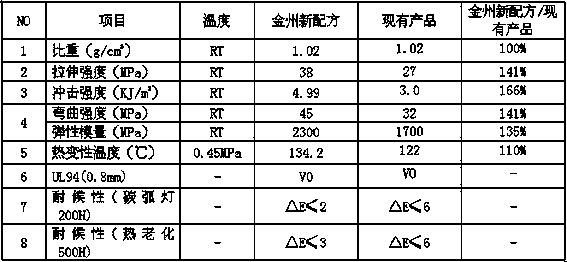

Owner:杭州金州高分子科技有限公司

Modified injection-molding zipper and production technology thereof

ActiveCN107337896ALower injection temperatureReduce energy consumptionDomestic slide fastenersPolyurethane elastomerMixed materials

The invention provides a production technology of a modified injection-molding zipper. The production technology comprises steps as follows: A), copolyoxymethylene, polyurethane elastomers, a compatibilizer and auxiliaries are mixed, and a mixed material is obtained, wherein the polyurethane elastomers account for 3wt%-8wt% of copolyoxymethylene; B), after granulating extrusion, the mixed material is subjected to injection molding, modified injection-molding particles are obtained, and the temperature of the injection molding is 180-220 DEG C; C), the modified injection-molding particles are subjected to color matching, injection molding of zipper teeth is performed, the modified injection-molding zipper is obtained, and the temperature of the injection molding of the zipper teeth is 180-220 DEG C. The modified injection-molding zipper has higher hardness, better wear resistance, higher corrosion resistance and better impact resistance, and furthermore, single-tooth strength and single-tooth displacement strength of the zipper are higher, so that the problem that the zipper teeth are prone to embrittlement and falling in a use process is solved; besides, the temperature of the injection molding is lower, therefore, the phenomenon of high-temperature oxidation discoloration of toner in a molding process is eliminated, and energy consumption is low.

Owner:ZHEJIANG WEIXING IND DEV

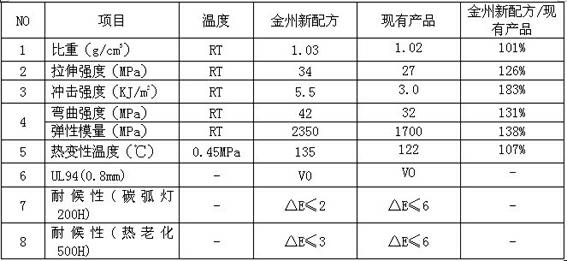

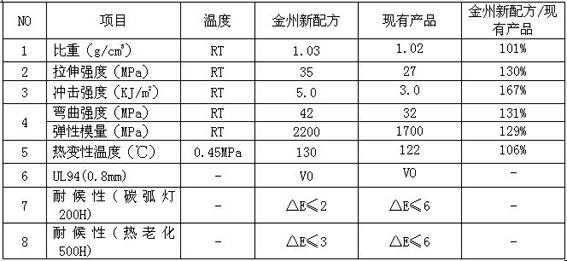

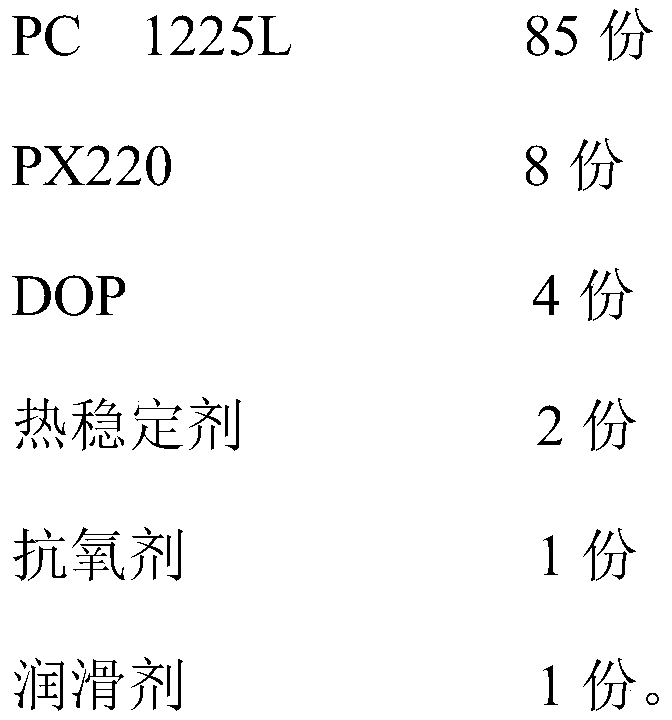

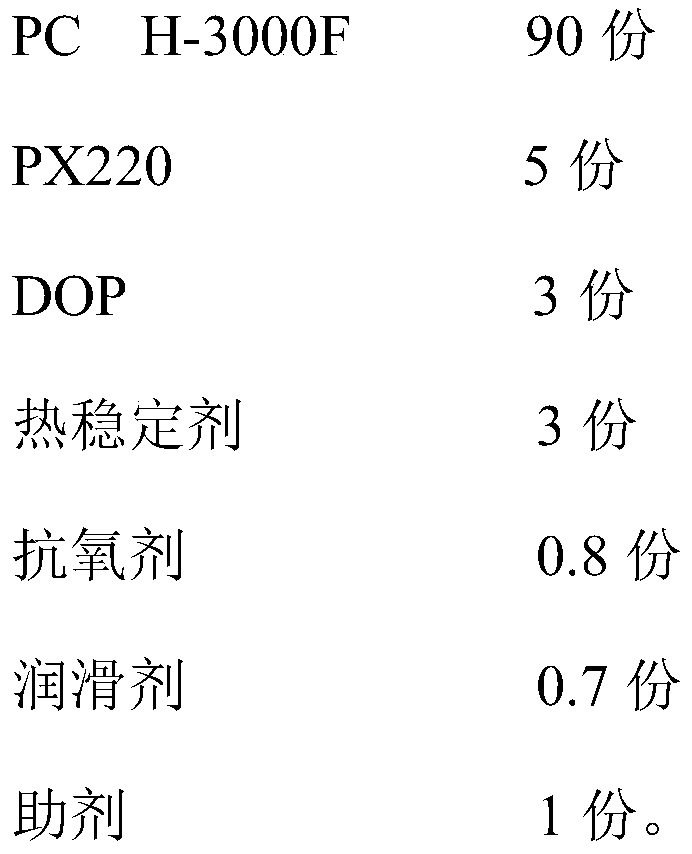

Special low-temperature injection-molded transparent PC (Polycarbonate) material for IMD (In-Mold Decoration) and preparation method therefor

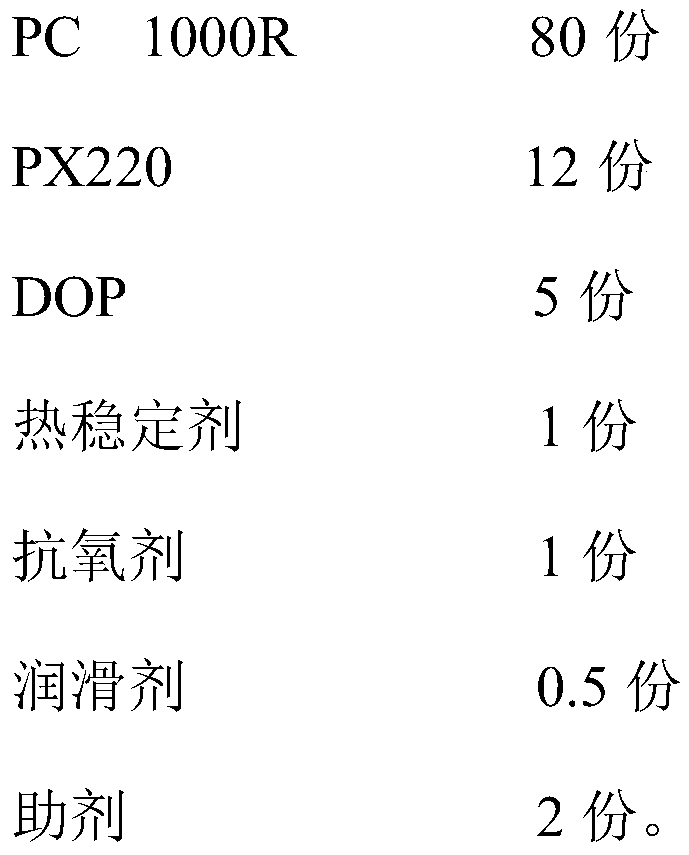

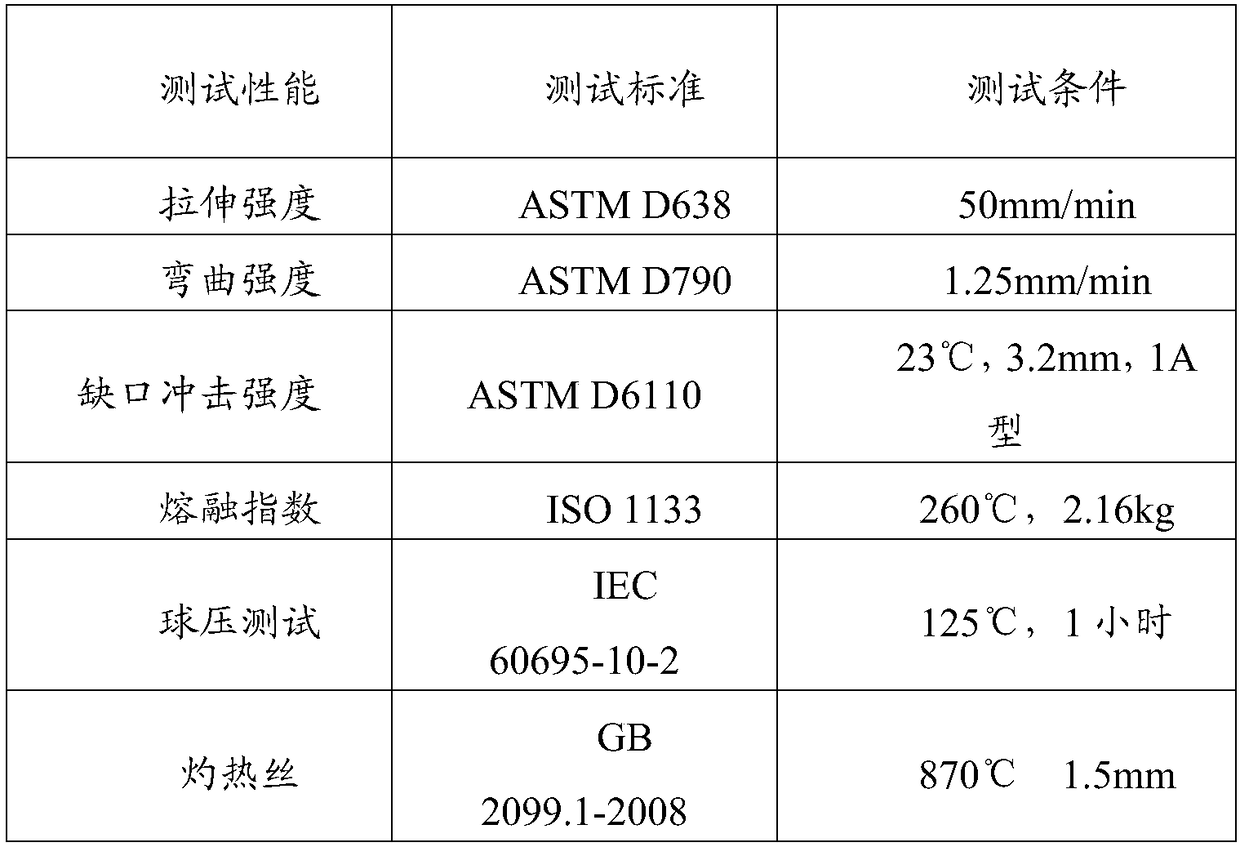

The invention discloses a special low-temperature injection-molded transparent PC (Polycarbonate) material for IMD (In-Mold Decoration) and a preparation method therefor and belongs to the technical field of macromolecular materials. The special low-temperature injection-molded transparent PC material for IMD is prepared from the following raw materials in parts by weight: 70-90 parts of PC resin,5-20 parts of phosphate compounds, 3-8 parts of phthalate, 1-3 parts of thermal stabilizer, 0.5-1 part of antioxidant, 0.5-1 part of lubricant and 0-3 parts of auxiliaries. According to the special low-temperature injection-molded transparent PC material for IMD and the preparation method therefor, through plasticization of the phosphate compounds and the phthalate, the injection molding temperature of the PC material is lowered, and meanwhile, the transparency and rigidity / toughness of the PC material are not affected, so that the prepared alloy material has the characteristics of low injection molding temperature, high material flow length ratio, high transparency, high thermal stability and the like. According to the special low-temperature injection-molded transparent PC material forIMD, the density is 1.18g / cm<3> to 1.20g / cm<3>, the flow length ratio is 150 to 250, the gap impact of a cantilever beam is higher than 50KJ / m<2>, and thus, the special low-temperature injection-molded transparent PC material is extremely applicable to low-temperature injection molding processes of IMD.

Owner:ORINKO NEW MATERIAL CO LTD

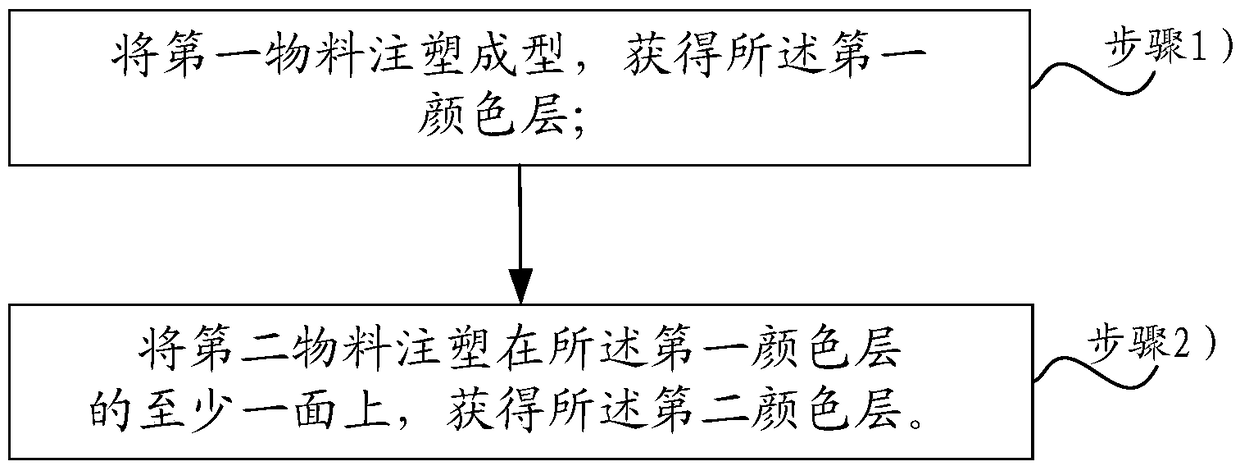

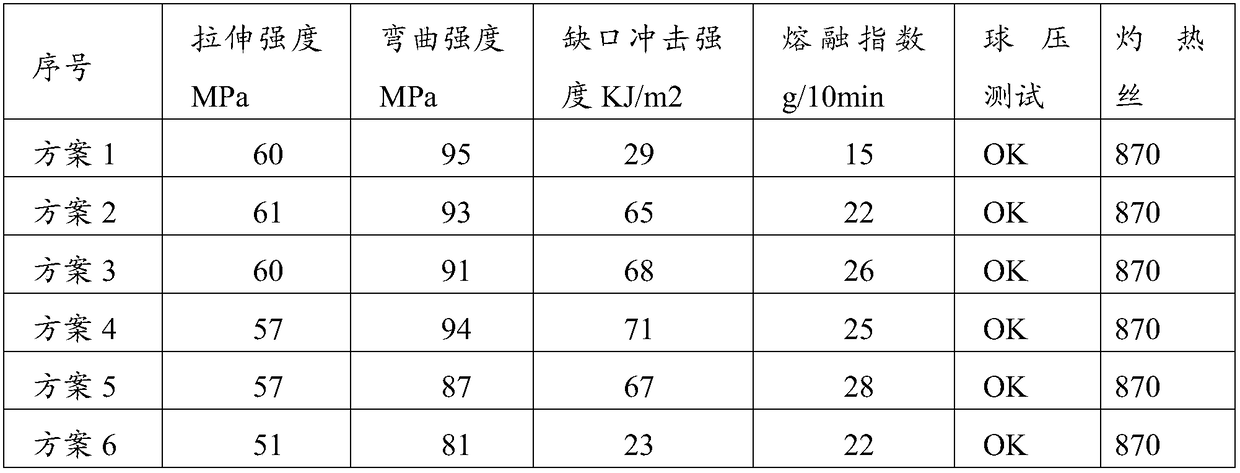

Modified resin and application thereof as well as two-color injection molding part and preparation method of two-color injection molding part

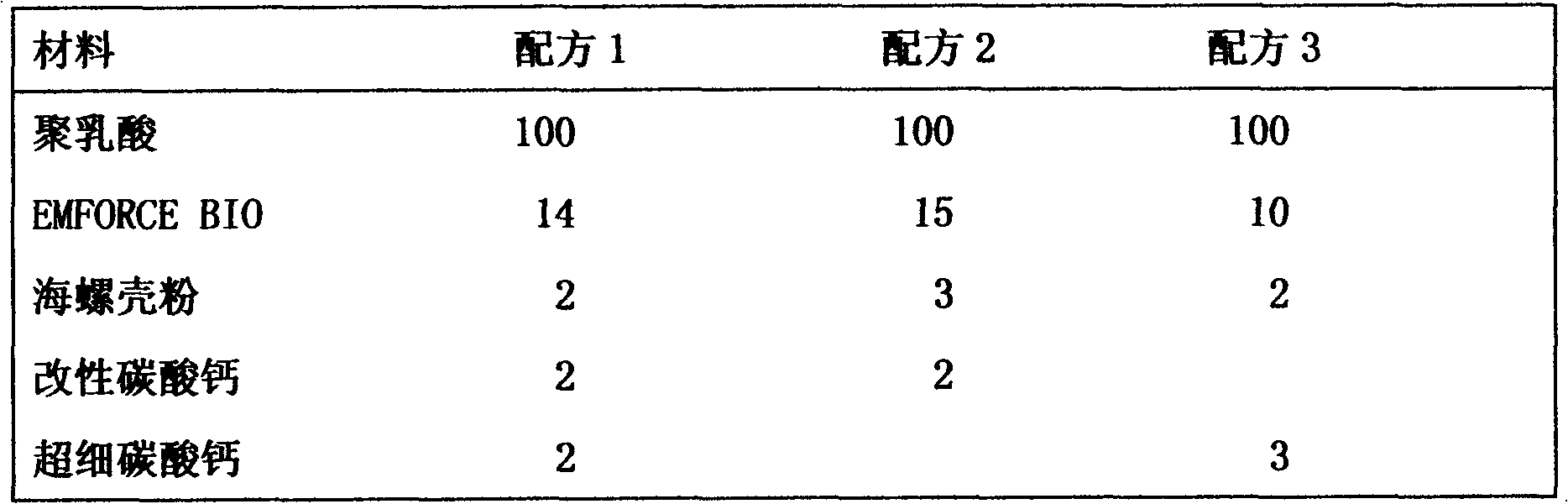

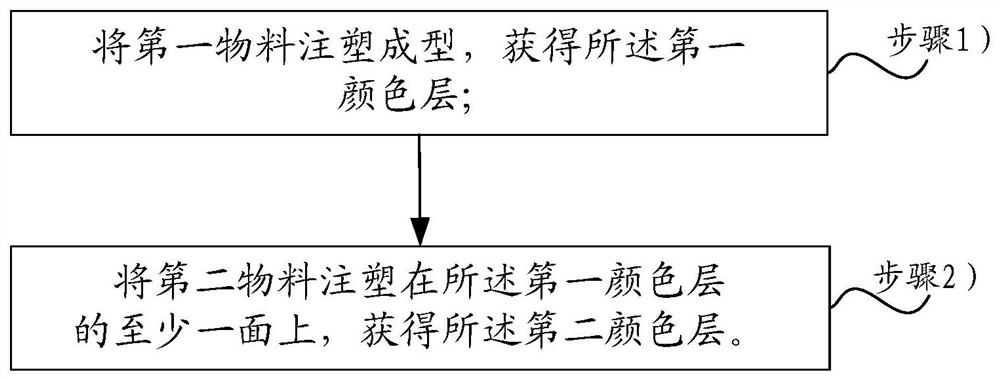

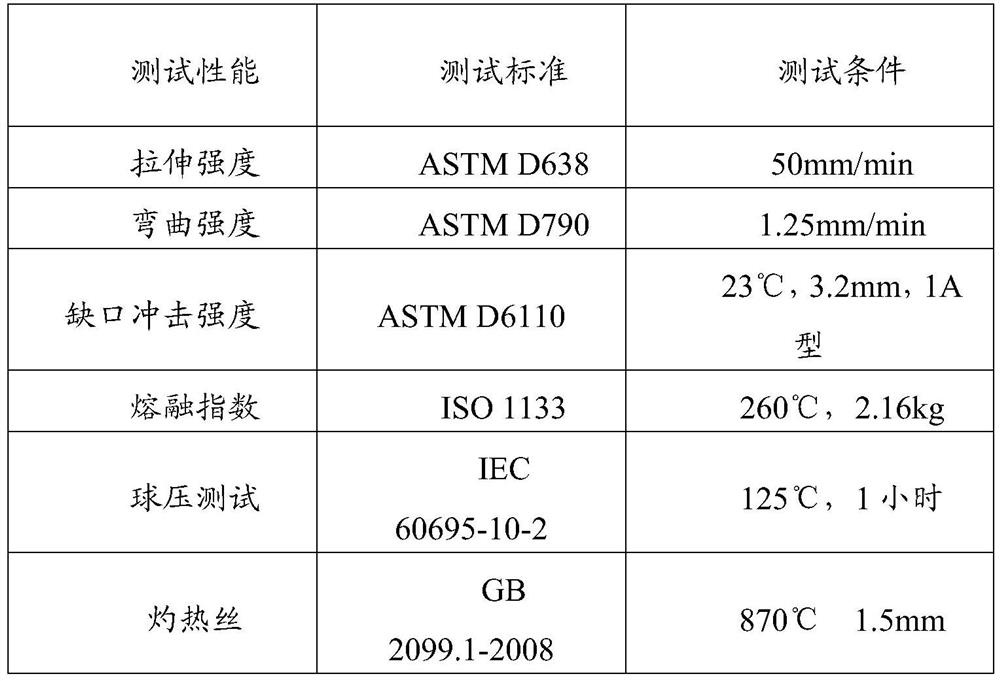

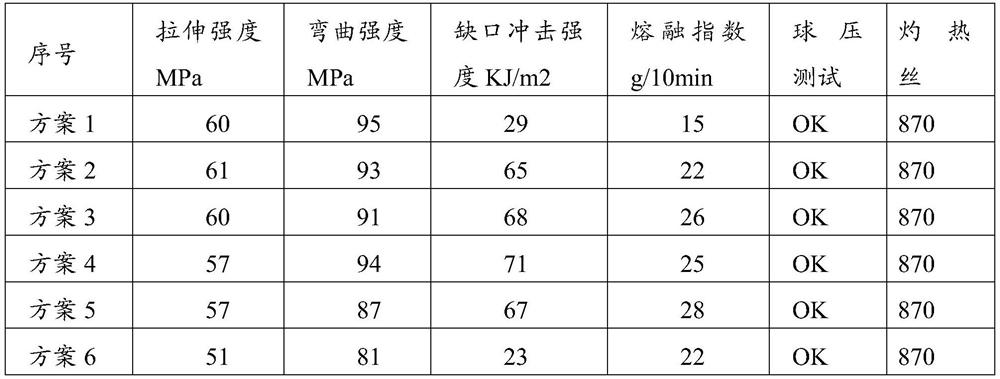

The invention relates to the technical field of injection molding and in particular relates to a modified resin and application thereof as well as a two-color injection molding part and a preparationmethod of the two-color injection molding part. A certain toughening effect can be achieved when the liquidity of the modified resin is improved, the thermal stability of the modified resin is improved, and the application range of the modified resin is widened. The modified resin provided by the embodiments of the invention comprises 80-90 weight parts of a resin matrix and 8-12 weight parts of aflow modifier, wherein the flow modifier refers to acrylic resin / montmorillonoid nano composite microspheres. The modified resin provided by the embodiment of the invention is used for preparing thetwo-color injection molding part.

Owner:NINGBO BULL ELECTRIC CO LTD

Low-cost low-odor degradable natural-fiber-reinforced polycarbonate reclaimed material capable of achieving light weight and preparation method thereof

The invention discloses a low-cost low-odor degradable natural-fiber-reinforced polycarbonate reclaimed material capable of achieving light weight and a preparation method thereof. The reclaimed material is prepared from the following raw materials in percentage by weight: 34-99 wt% of a polycarbonate reclaimed material, 1-50 wt% of natural fibers, 0.1-5 wt% of foaming agent masterbatch, and 0.01-1 wt% of an antioxidant. The polycarbonate reclaimed material, the antioxidant and the like are added from a main feeding port of a double-screw extruder, and the natural fibers and the foaming agentmasterbatch are added from a melting section in the middle of a screw to obtain the natural-fiber-reinforced polycarbonate reclaimed material. The natural-fiber-reinforced polycarbonate composite material is prepared into a low-cost, low-odor and degradable natural-fiber-reinforced polycarbonate product under a secondary mold opening condition or an under-injection condition by adopting an injection molding method. The disclosed material is endowed with the characteristics of low density, low odor, high performance and degradability while the problem of resource waste is solved, and a new wayis provided for lightweight and environment-friendly development of automobiles.

Owner:CHONGQNG PRET NEW MATERIAL +3

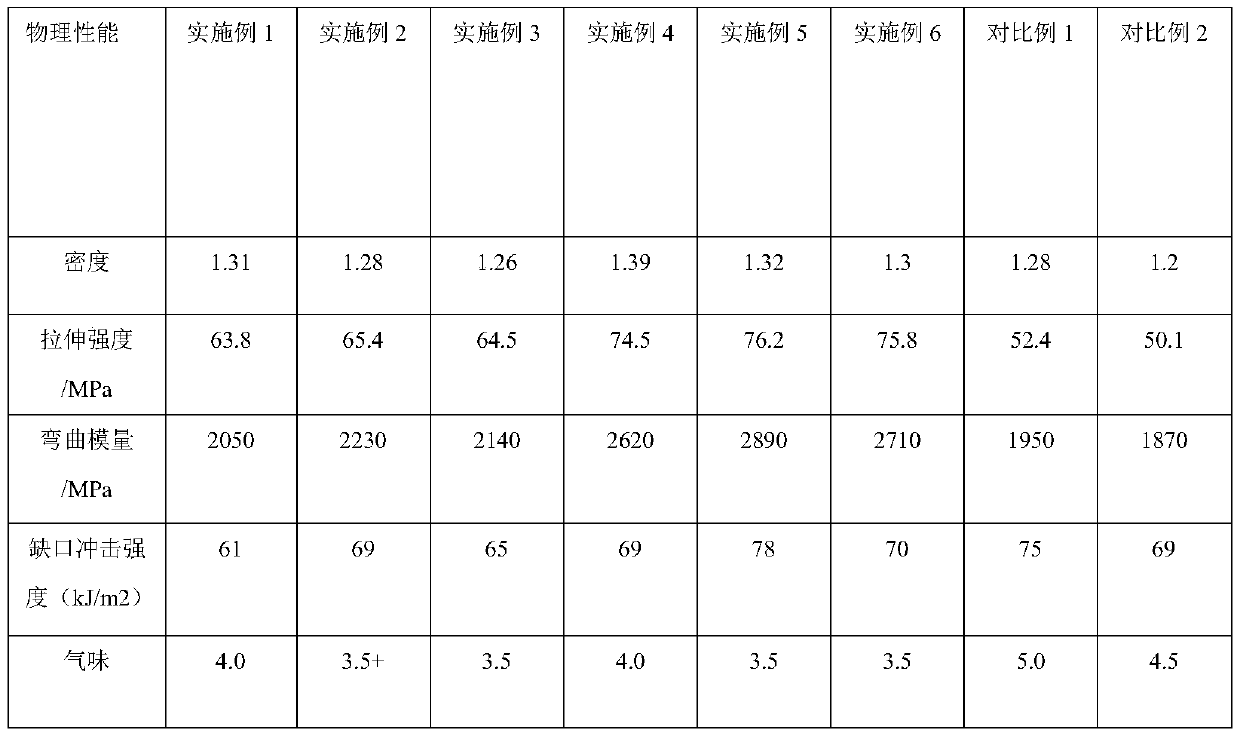

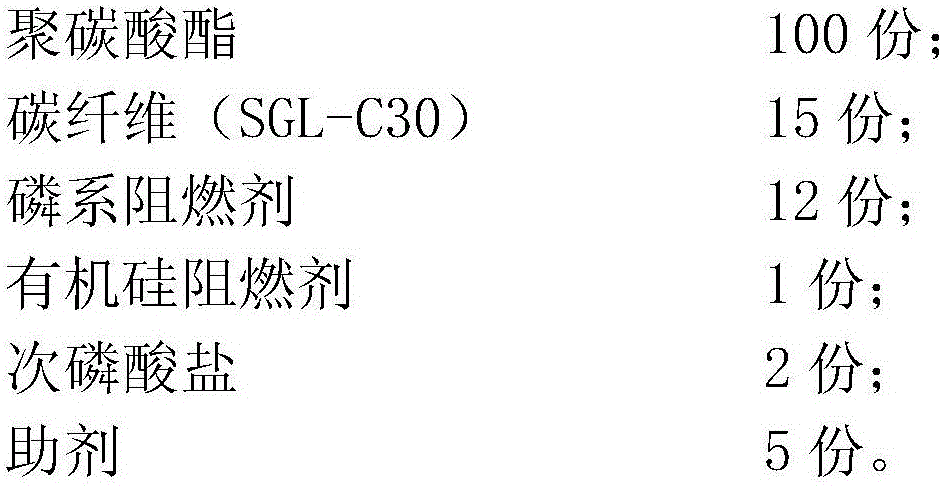

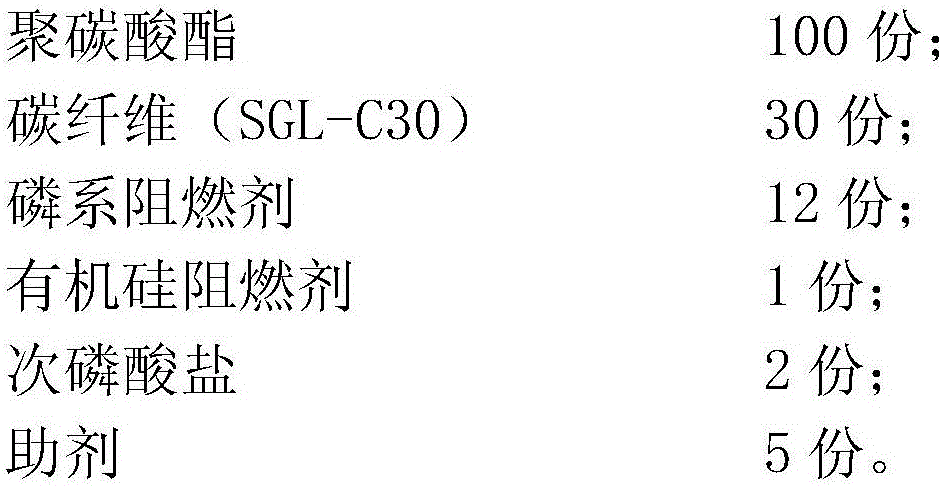

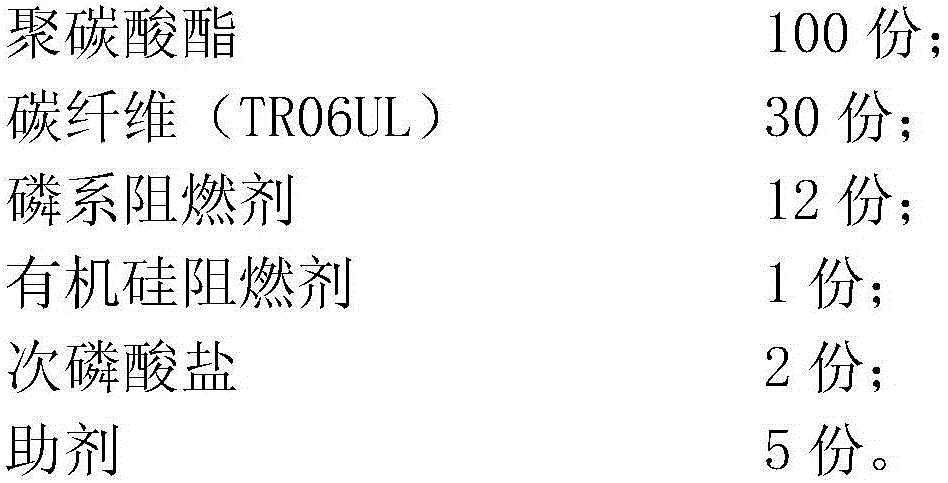

Carbon fiber reinforced polycarbonate composite material and product thereof

InactiveCN107177179AGuaranteed flame retardant performanceGuaranteed liquidityFiberCarbon fiber reinforced composite

The invention relates to the technical field of polymer materials, in particular to a carbon fiber reinforced polycarbonate composite material used in IMR molding and its products. The composite material includes by weight parts: 100 parts of polycarbonate resin; 10-60 parts of carbon fiber; 5-30 parts of flame retardant; the flame retardant is two or more compound flame retardants . The product is a product produced by molding the carbon fiber reinforced polycarbonate composite material. The carbon fiber reinforced polycarbonate composite material and its products of the present invention can not only ensure the flame retardancy and fluidity of the composite material, but also reduce the injection molding temperature of the composite material, so that the composite material can be applied to IMR molding, and the application of IMR film In high-end ultra-thin products, it can also injection mold structural parts with beautiful appearance.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

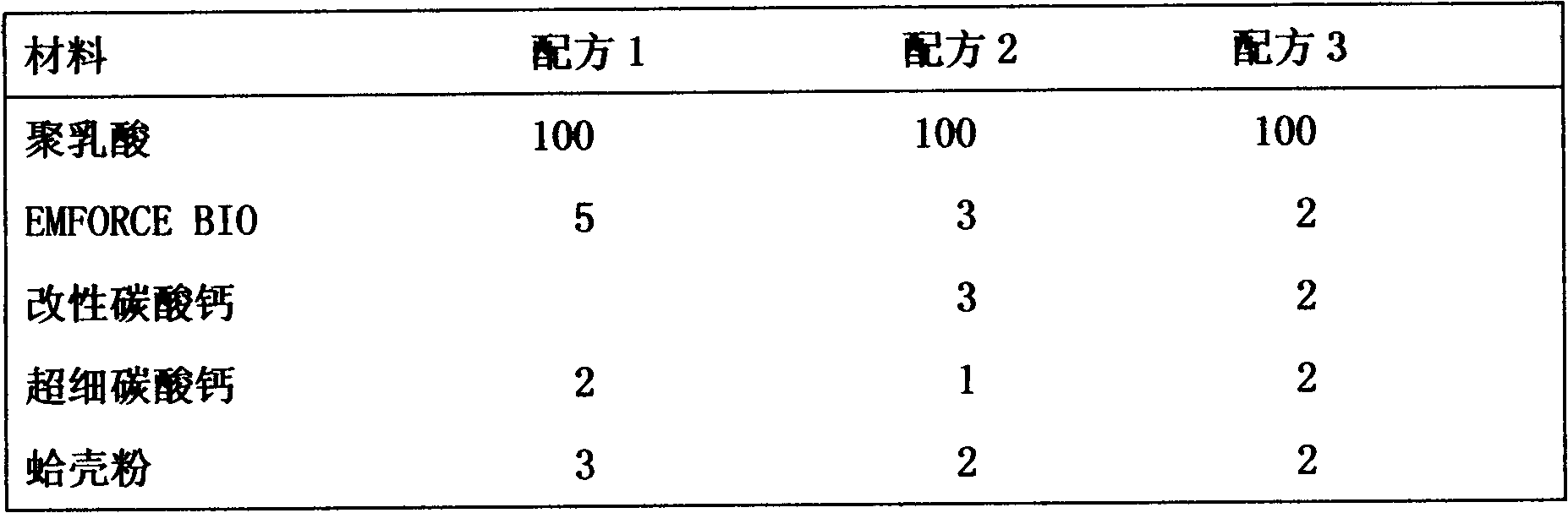

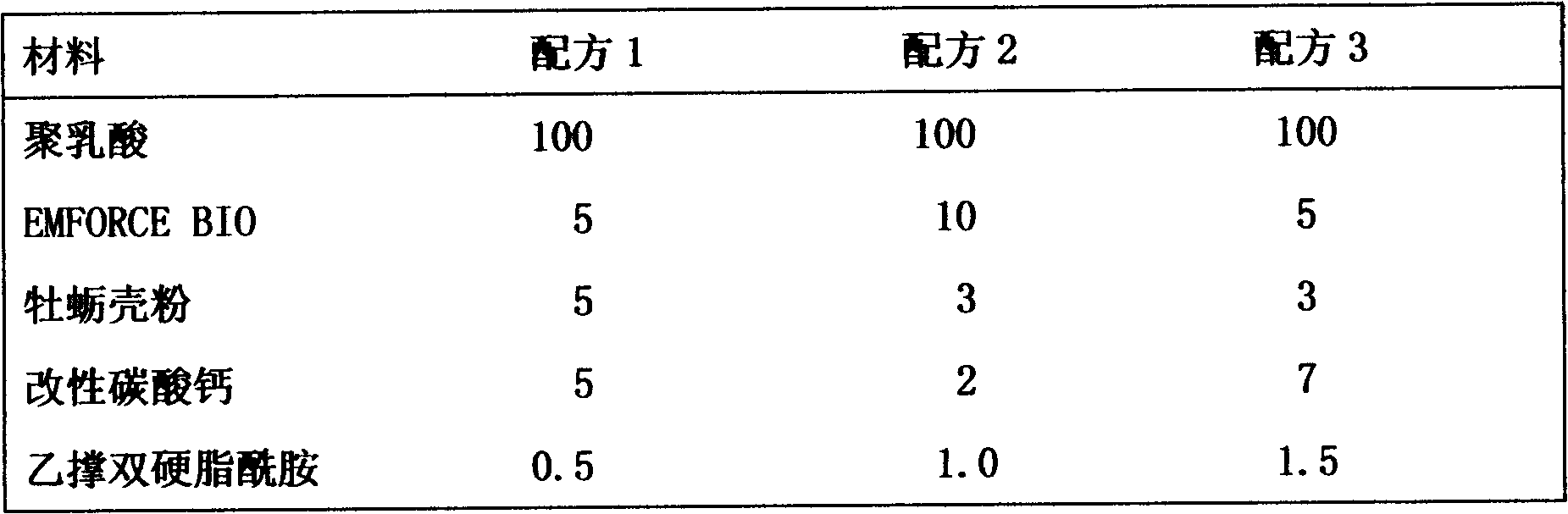

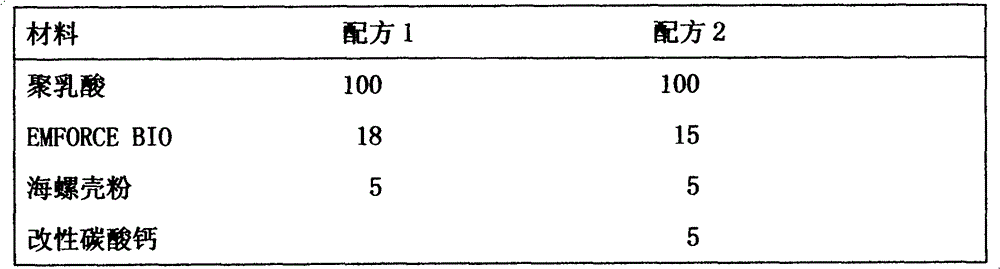

Polylactic acid-polypropylene composite material, and preparation method and application thereof

InactiveCN106883510AImprove mechanical propertiesImprove other propertiesPolypropylene compositesMaterials science

The invention provides a polylactic acid-polypropylene composite material, and a preparation method and application thereof. The polylactic acid-polypropylene composite material is prepared from the following components in parts by weight: 25 to 40 prats of polylactic acid, 60 to 70 parts of polypropylene and 5 to 10 parts of maleic anhydride. The polylactic acid-polypropylene composite material is low in injection molding temperature and has the advantages of environmental friendliness, environmental protection, low smell, stable size and the like.

Owner:BAIC MOTOR CORP LTD

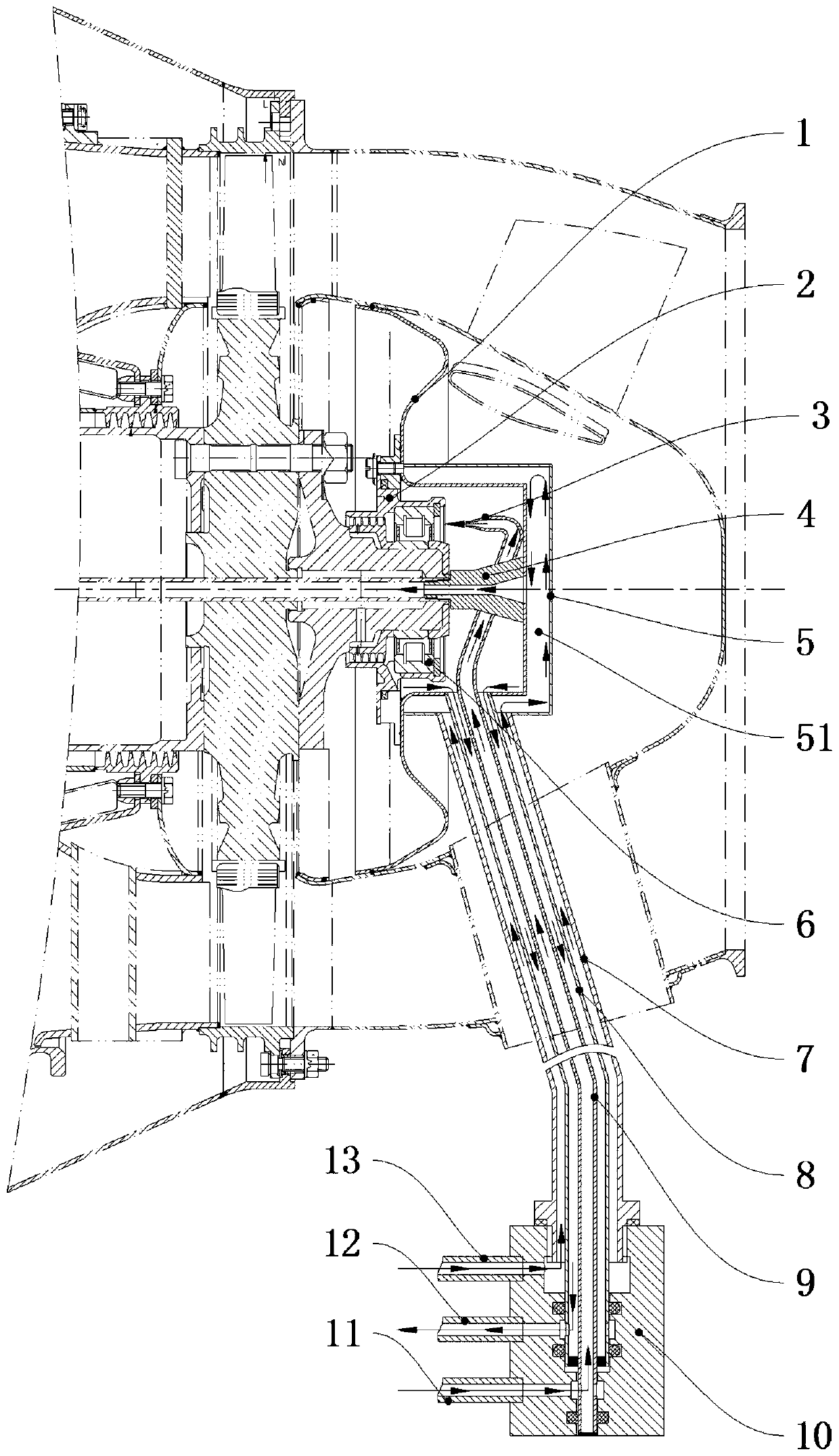

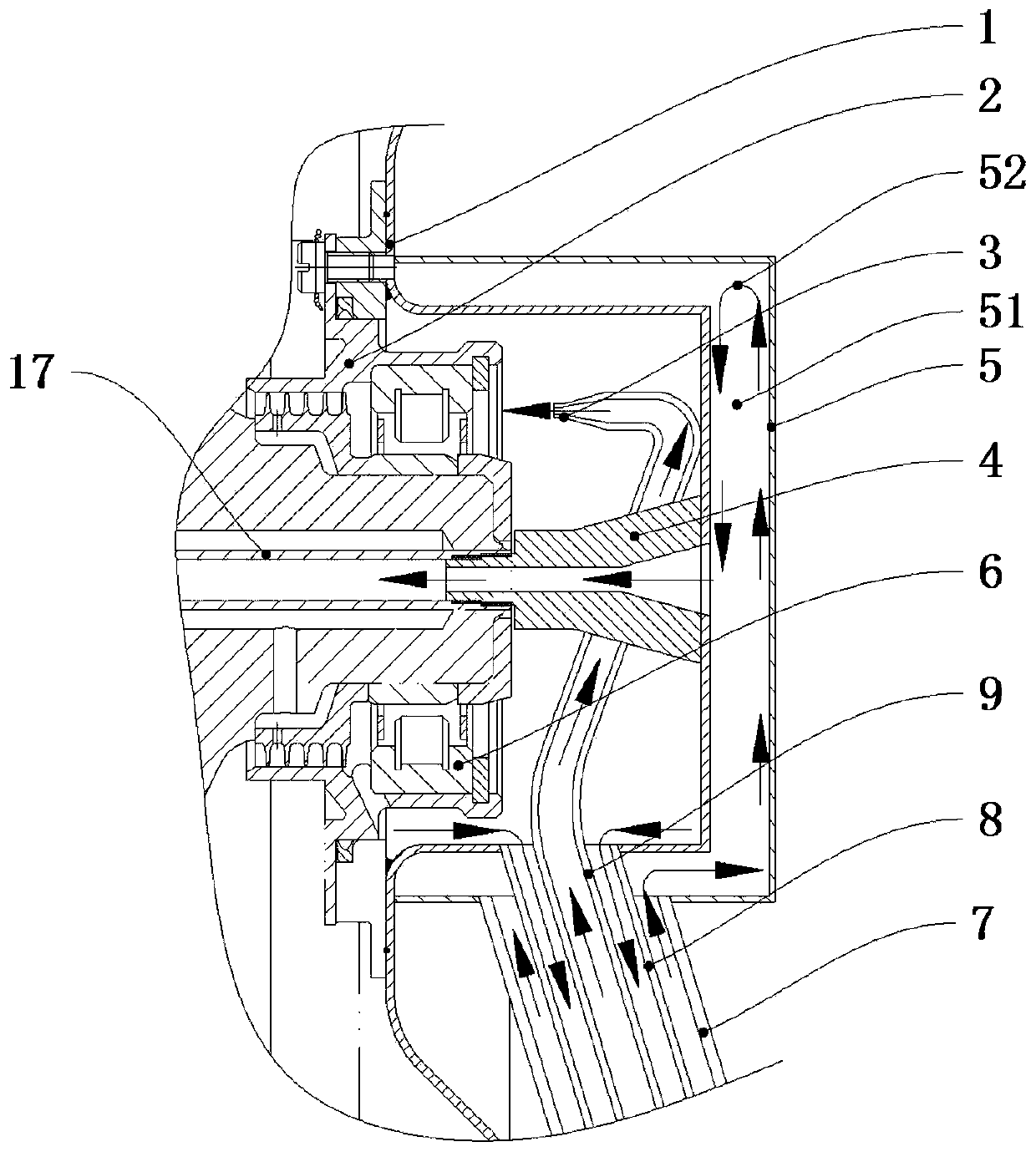

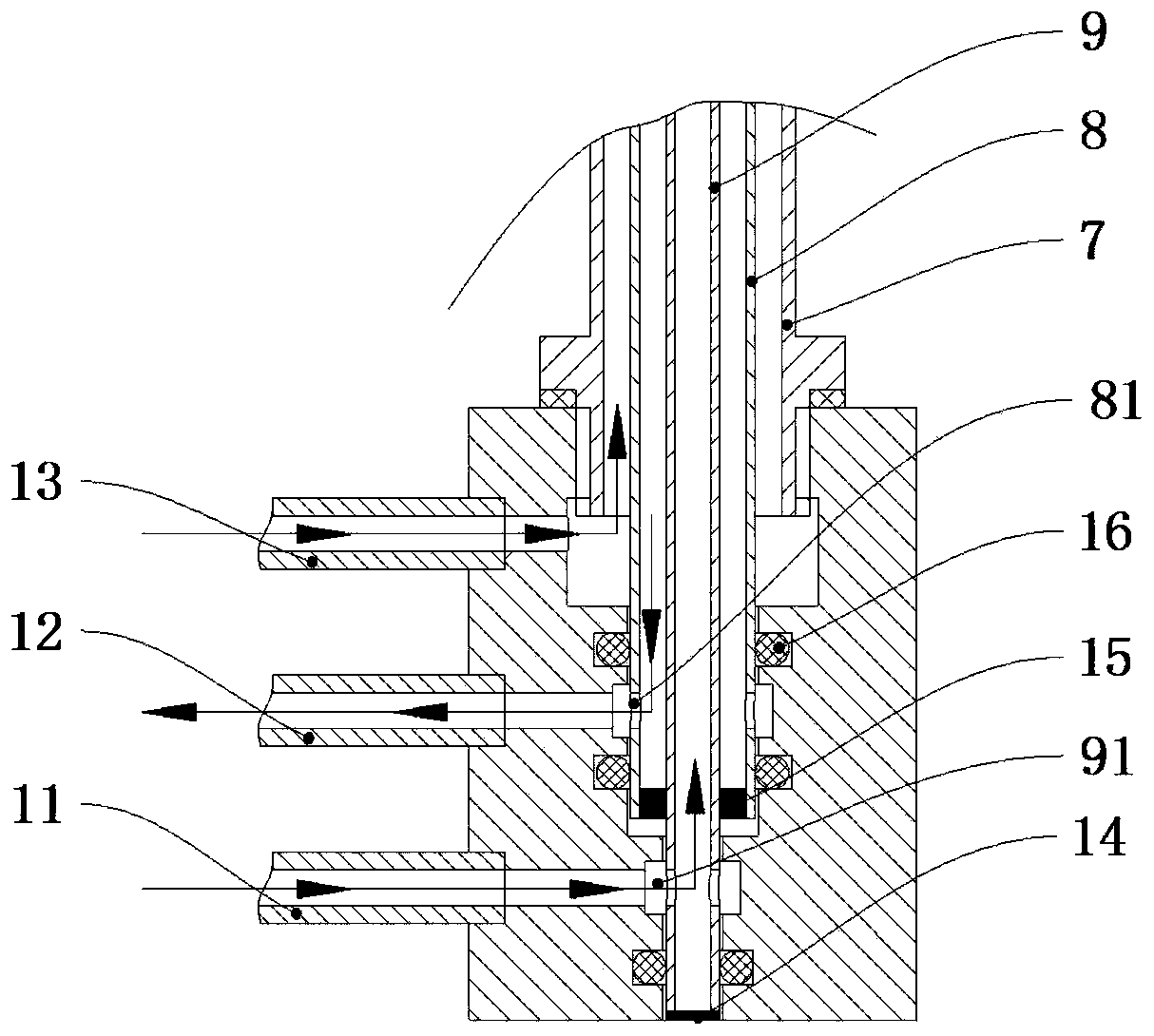

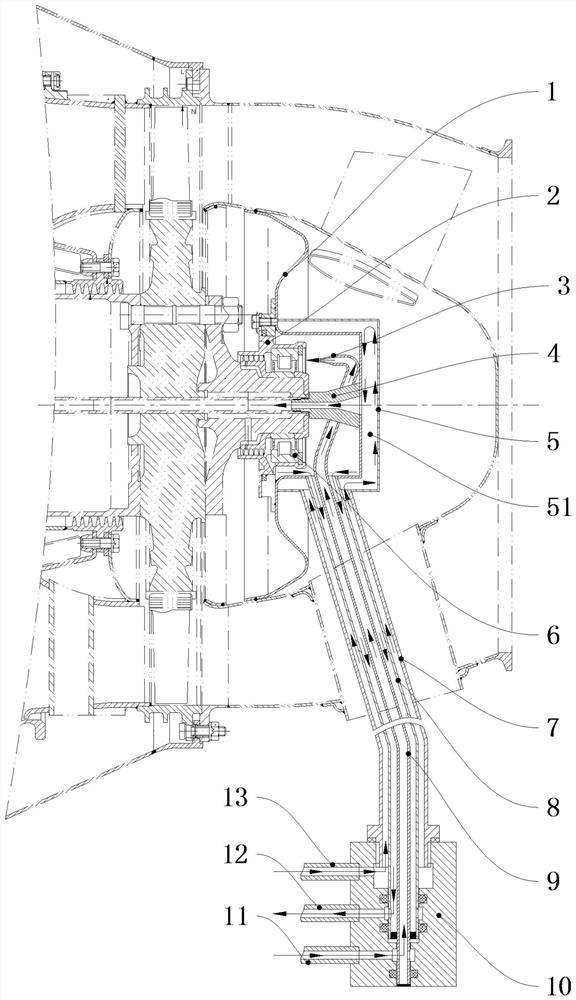

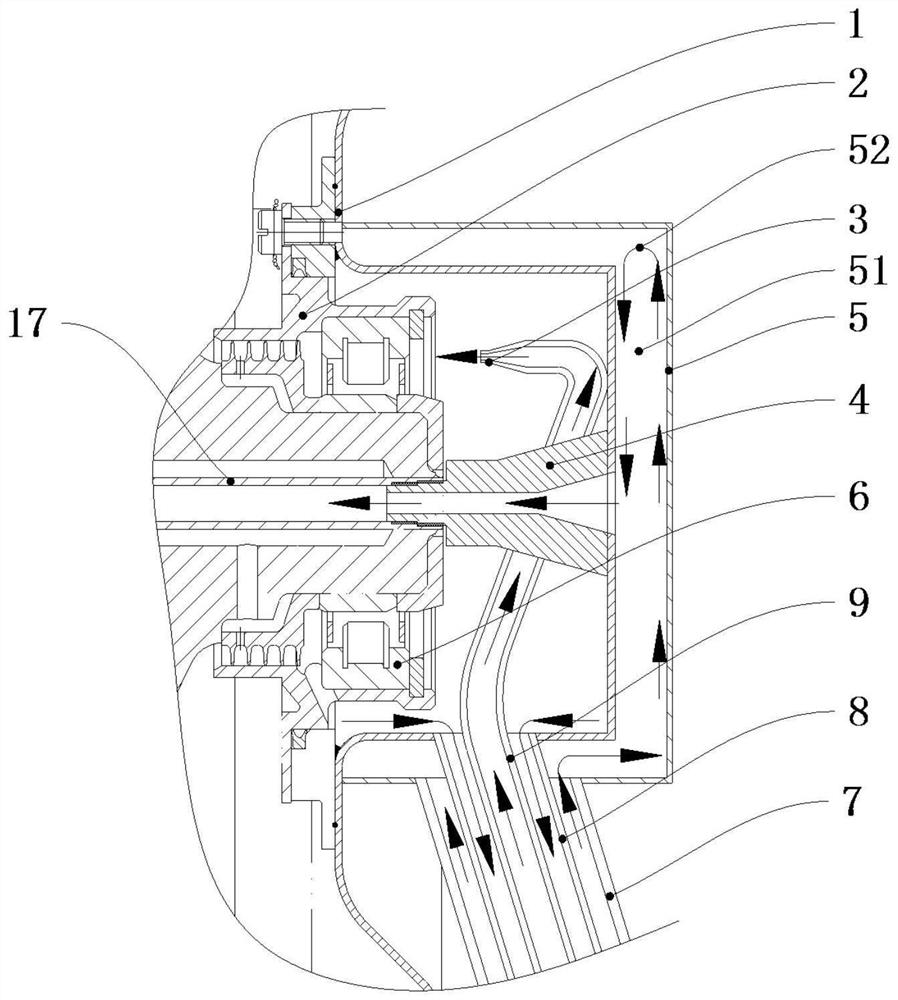

Hot end fuel and lubricating oil pipeline structure of turbine engine

ActiveCN110821581AReduce temperature riseReduce coking rateMachines/enginesEngine componentsCooling effectFuel oil

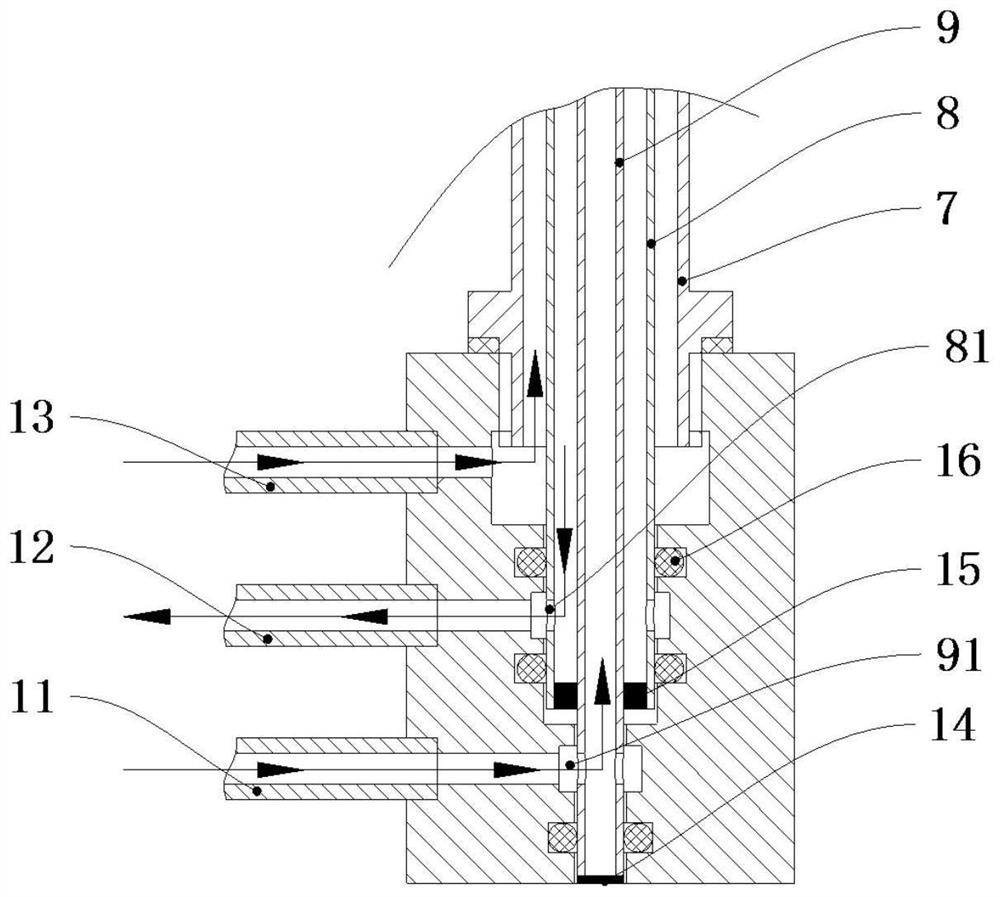

The invention relates to the technical field of turbine engines, in particular to a hot end fuel and lubricating oil pipeline structure of a turbine engine, and aims to solve the problems that in theprior art, the heat efficiency of the engine cannot be better improved and a better cooling effect on a bearing cannot be achieved. The hot end fuel and lubricating oil pipeline structure comprises alubricating oil return cavity shell, a fuel oil preheating cavity shell, a fuel oil preheating cavity, a fuel oil inlet pipe, a lubricating oil return pipe and a lubricating oil inlet pipe, wherein the fuel oil inlet pipe, the lubricating oil return pipe and the lubricating oil inlet pipe are sequentially nested from outside to inside and are reserved with gaps among one another; one end of the fuel oil inlet pipe sequentially communicates with the fuel oil preheating cavity and a fuel oil supply pipe; one end of the lubricating oil return pipe communicates with the inside of the lubricating oil return cavity shell; and one end of the lubricating oil inlet pipe is positioned inside the lubricating oil return cavity shell and is opposite to the upper part of the bearing. According to the hot end fuel and lubricating oil pipeline structure, the fuel oil inlet pipe, the lubricating oil return pipe and the lubricating oil inlet pipe are sequentially nested from outside to inside, and the temperatures of the fluids in the three pipelines are sequentially reduced from outside to inside, so that the cooling effect on the bearing is improved and the heat efficiency of the engine is improved.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Dual nozzle cap for thermal spray coating

Disclosed is a dual nozzle cap for thermal spray coating to which both a thermal spray coating method and a kinetic spray coating method are applied. The dual nozzle cap includes a nozzle unit including inner and outer nozzles, a gun insertion hole, into which the front end of a spray gun is inserted, and a gas connection hole, into which a gas connector to supply the gas is inserted, formed through one surface of the nozzle unit. In a space between the inner and outer nozzles, a gas collection part to uniformly distribute the high-pressure subsidiary gas injected through the connection hole, a neck part to apply pressure to the high-pressure subsidiary gas to accelerate the subsidiary gas, and a gas spray hole to spray the subsidiary gas supplied from the neck part together with a material sprayed from the spray gun are sequentially formed.

Owner:金炳斗

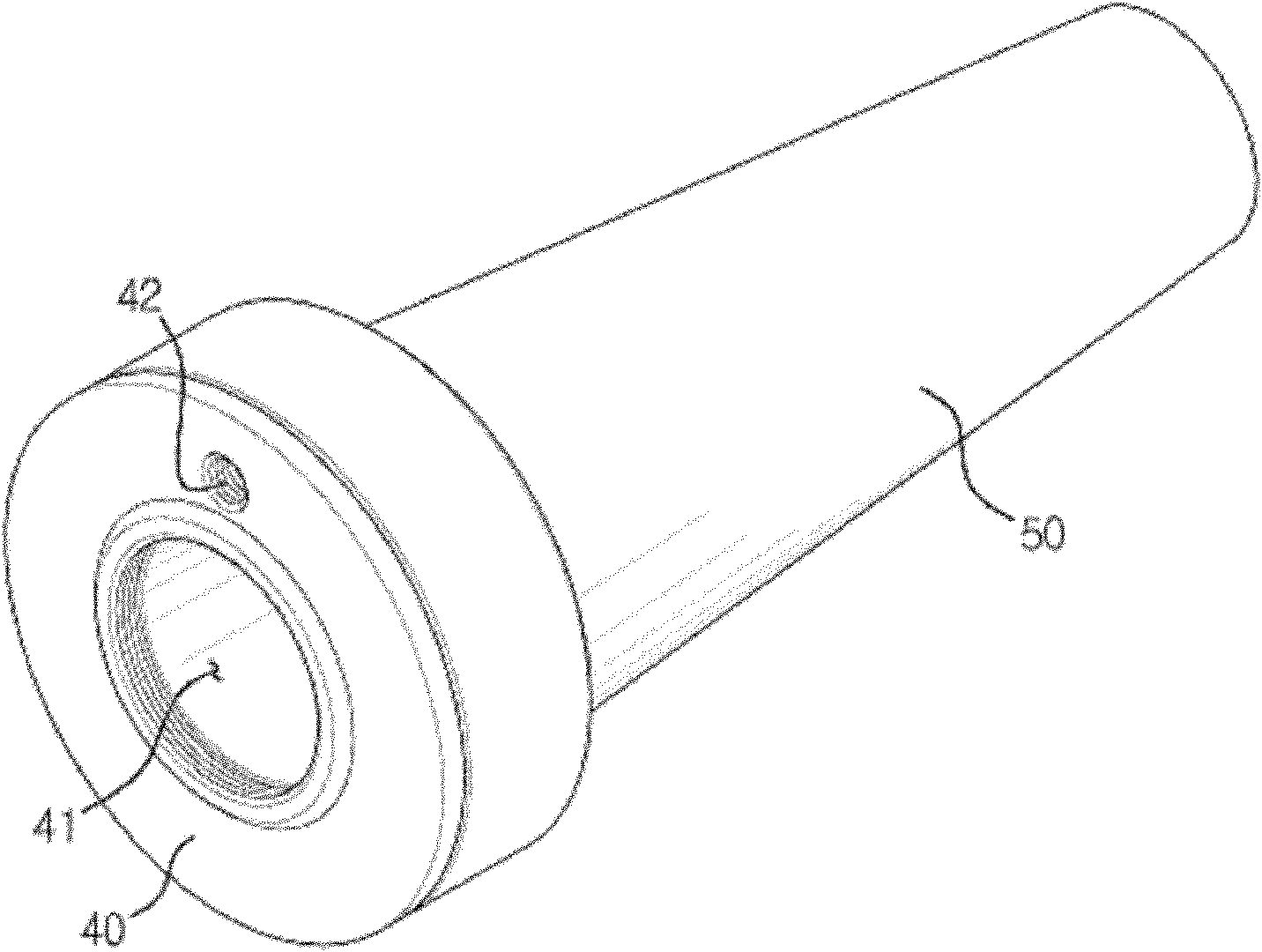

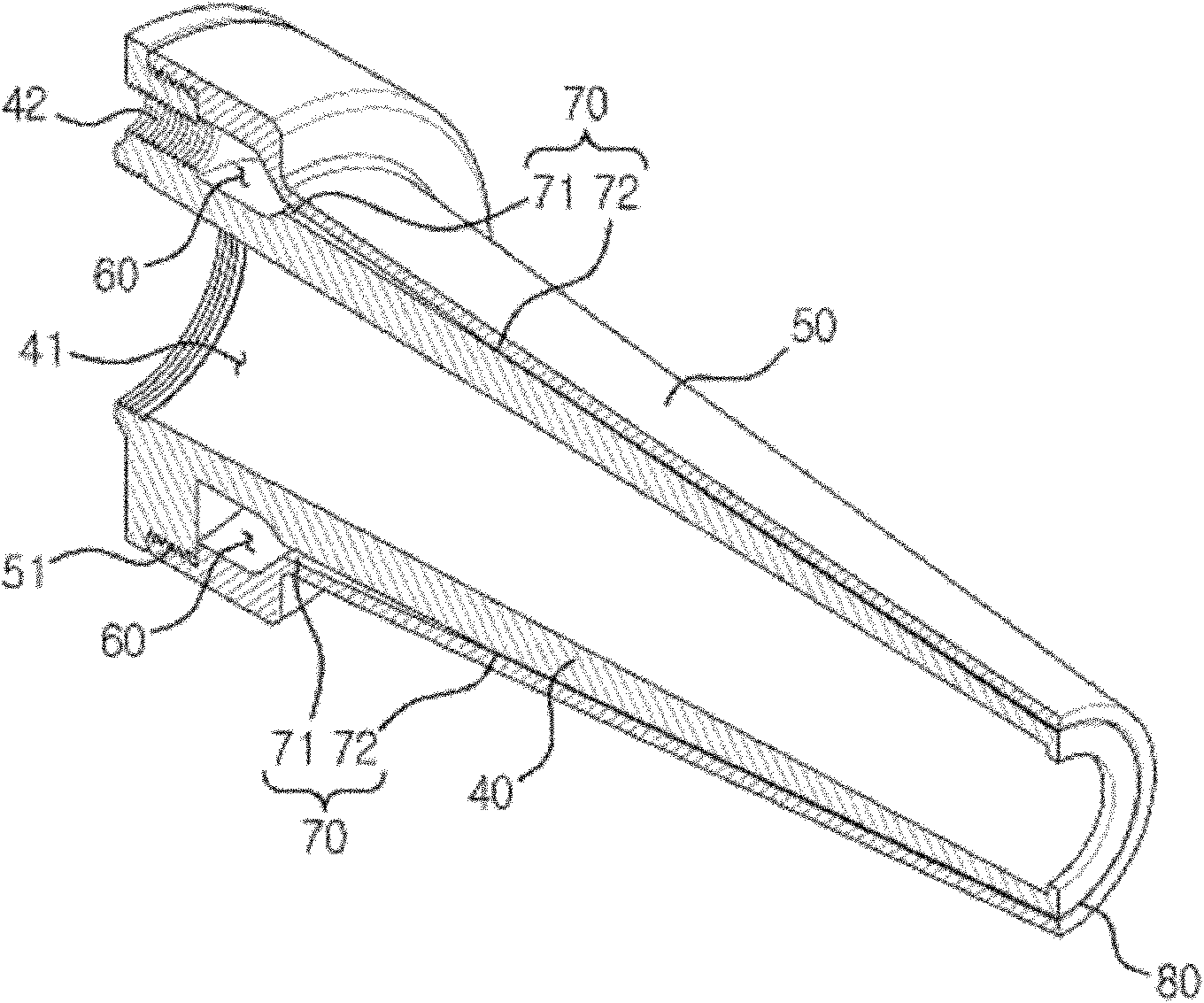

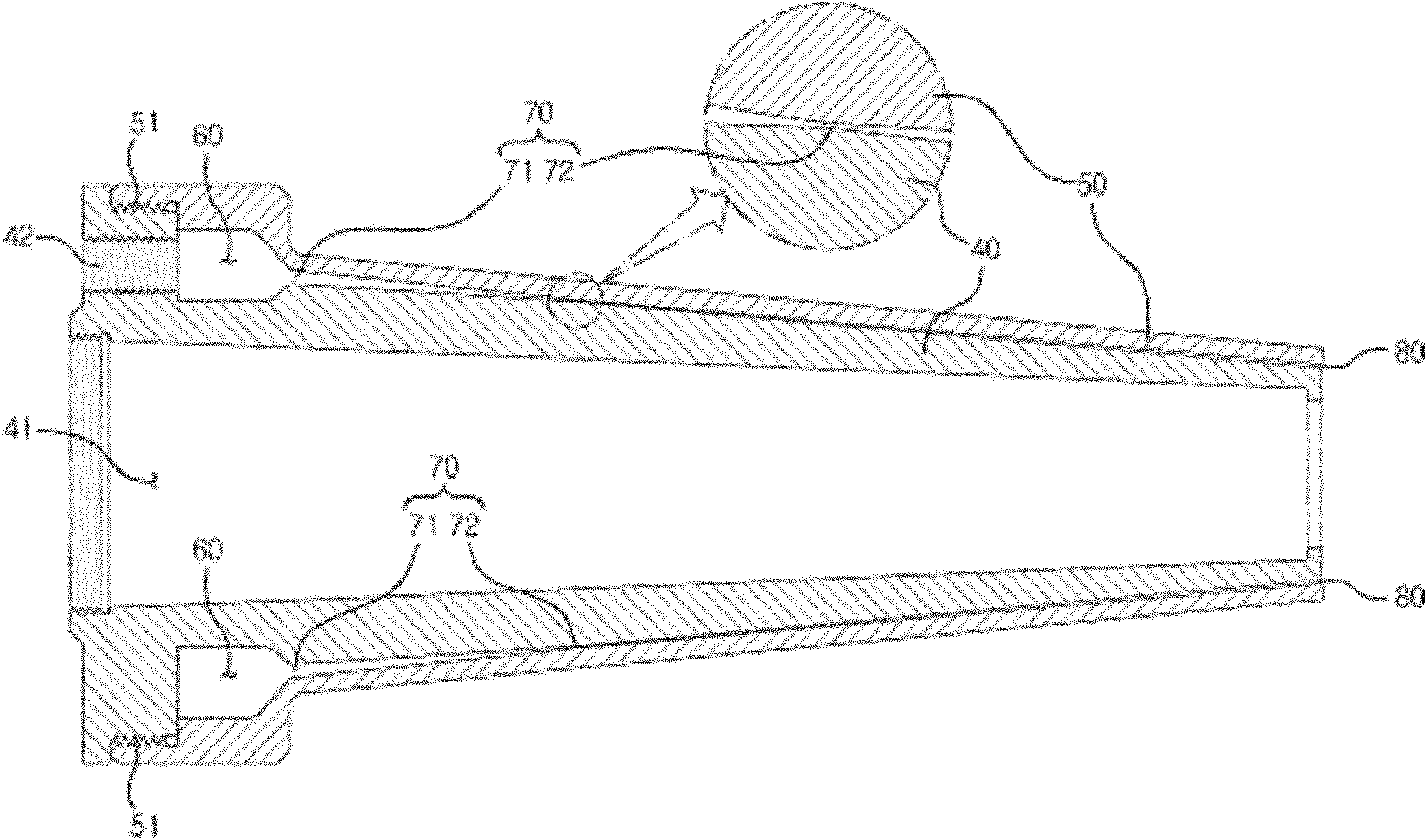

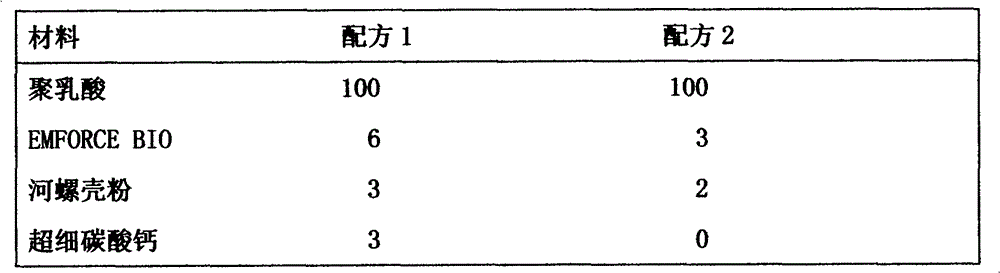

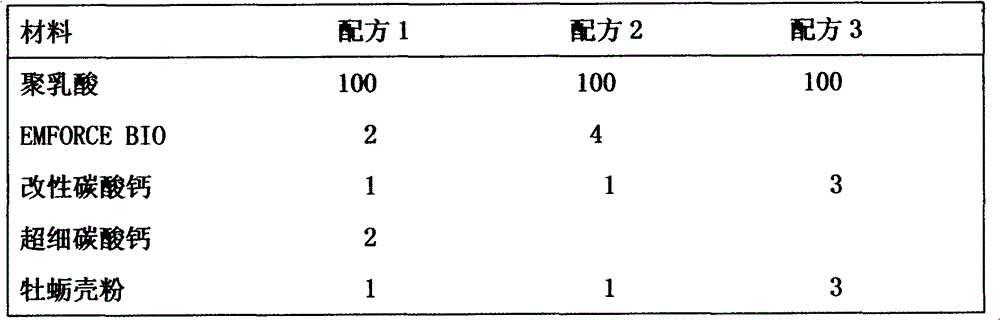

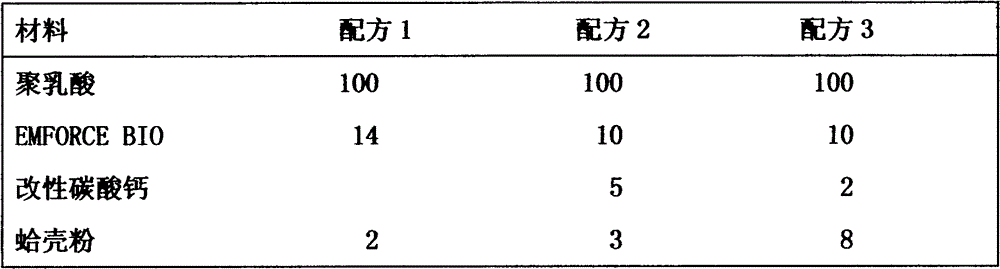

Degradable disposable mouthpiece and preparation method

ActiveCN103030940ALower injection temperatureReduce power consumptionSurgeryDilatorsArthropod mouthpartsInjection pressure

The present invention provides a degradable disposable mouthpiece and a preparation method. The degradable disposable mouthpiece is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section of 160-185 DEG C, a metering section of 165-175 DEG C, a nozzle is of 160-170 DEG C, the mold temperature is 20-30 DEG C, the injection pressure is 45-90 Mpa, the injection time is 38-41 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The performances of the degradable disposable mouthpiece are in line with the requirements of medical apparatus and instruments. The degradable disposable mouthpiece can completely degrade by landfill in the natural environment after being used without burning to achieve low-carbon, energy-saving, and environmental protective purposes.

Owner:江苏奥博金医药科技有限公司

Degradable disposable oropharyngeal airway and preparation method

ActiveCN103030947ASave electricity consumption in productionLow input costInjection molding processInjection pressure

The present invention provides a degradable disposable oropharyngeal airway and a preparation method. The degradable disposable oropharyngeal airway is composed of a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 145-165 DEG C, a compression section is of 155-170 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 160-170 DEG C, the mold temperature is 15-30 DEG C, the injection pressure is 45-80 Mpa, the injection molding time is 41-45 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The used degradable disposable oropharyngeal airway can completely degrade in the natural environment by landfill without burning to achieve low-carbon, energy-saving and environmental protective purposes.

Owner:江苏奥博金医药科技有限公司

Plastic injection process

The invention relates to a plastic injection process which comprises the following steps: (1) carrying out primary injection molding by adopting first soft rubber, wherein the hardness of the first soft rubber is 65-85 degrees; and (2) carrying out secondary injection molding by adopting secondary soft rubber, wherein the hardness of the secondary soft rubber is 65-75D. According to the plastic injection process, the two plastic injection processes both adopt the soft rubber (the first and second soft rubber); as the injection molding temperature and the injection molding pressure of the soft rubber are both lower than those of hard rubber, and in addition, the temperature and the pressure of the second soft rubber adopted by the secondary injection molding are low, the forming purpose can be reached, and thus the first soft rubber adopted by the primary injection molding cannot be burnt yellow or deform by extrusion.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

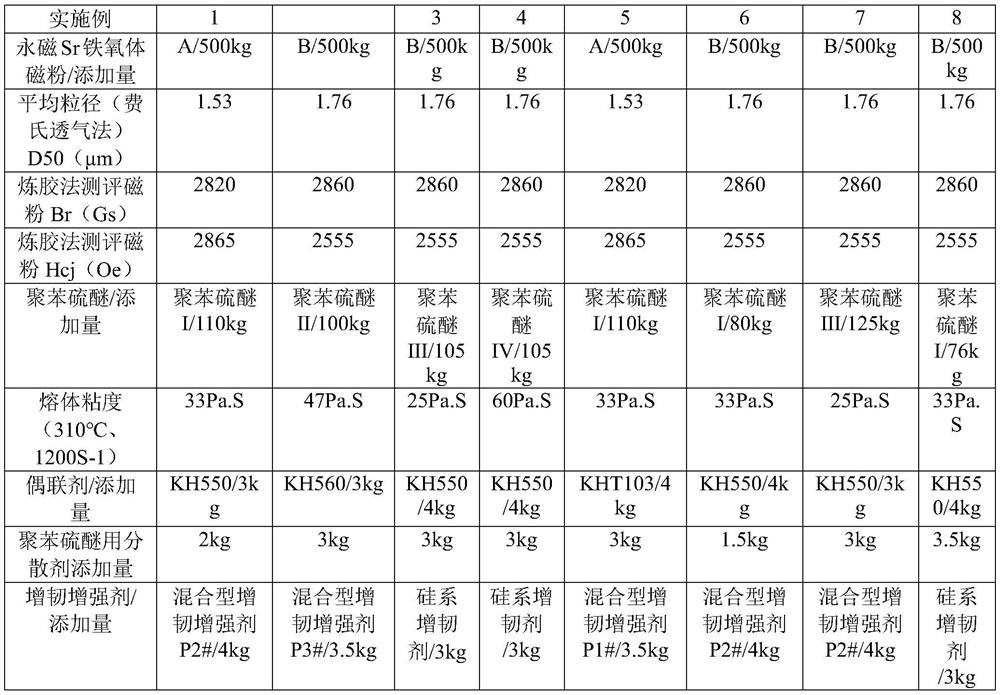

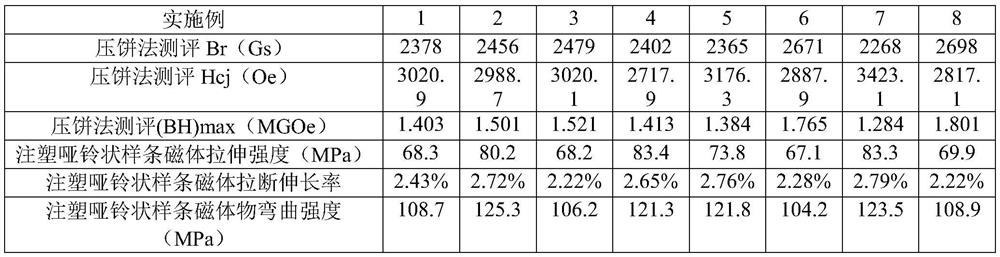

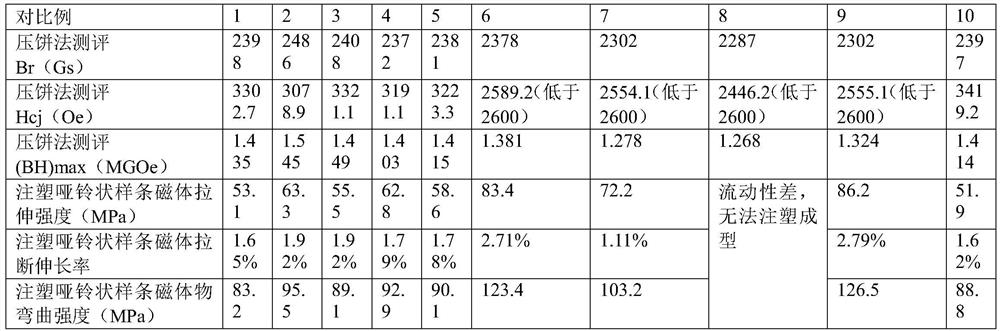

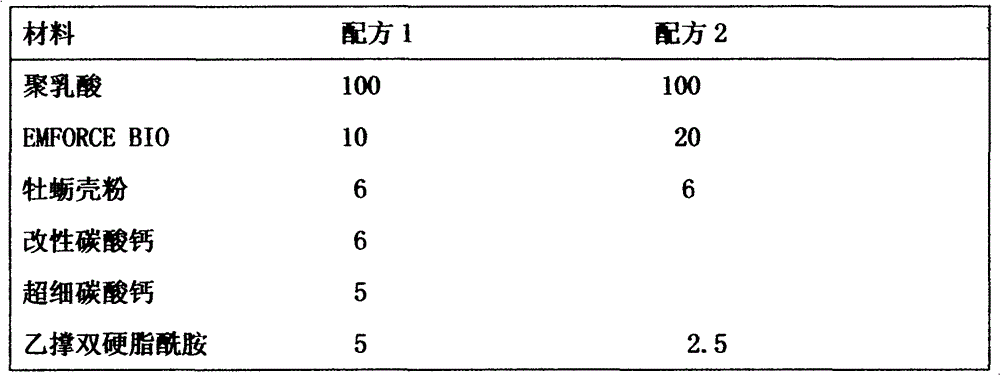

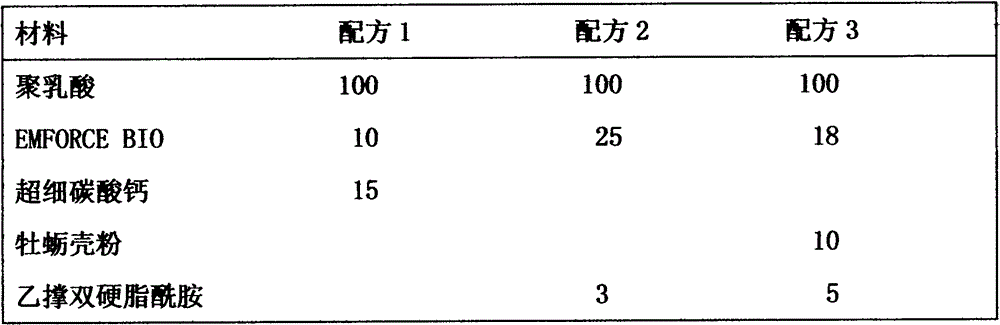

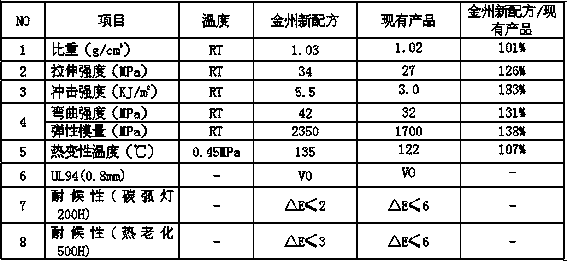

A kind of injection molding permanent ferrite magnet and preparation method thereof

ActiveCN111210964BHigh tensile strengthImprove bending strengthInductances/transformers/magnets manufactureMagnetic materialsRotor magnetsElectric machine

The invention relates to the technical field of injection molding permanent magnet materials, and provides an injection molding permanent ferrite magnet and a preparation method thereof in order to solve the problems that existing water pump rotor magnets are easy to crack and cause coolant pump failure and engine overheating. The permanent ferrite magnet is made of the following components by weight percentage: permanent ferrite magnetic powder 75-90%, polyphenylene sulfide 9-22%, coupling agent 0.2-2.0%, toughening enhancer 0.2-1.5% %, the dispersant is 0.2-1.0%, and the melt viscosity of the polyphenylene sulfide is controlled at 22-75 Pa.S. The injection molded permanent ferrite magnet of the present invention has high tensile strength and high bending strength, and can be widely used in the fields of electronic water pump rotors, automobile motor rotors, high-end home appliance motor rotors, induction magnetic rings, etc.; the magnetic powder fluidity in the preparation process Good, low injection temperature, low energy consumption, low requirements for molds, good product appearance, and low production costs.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Degradable material for anoscope and preparation method

The present invention provides a degradable material for an anoscope and a preparation method thereof. The degradable anoscope is composed of an outer cylinder and an inner core. The outer cylinder and the inner core are both composed of a degradable polymer ingredient of a degradable substrate, an enhancer and a lubricant. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section is of 155-165 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 165-175 DEG C; the mold temperature is 20-35 DEG C; the injection pressure is 50-80 Mpa; the injection molding time is 36-39 seconds; the dwell time is 0 seconds; and the screw speed is 180 r / min. The degradable anoscope can completely replace the disposable anoscope made of polystyrene, modified polystyrene and other plastics. The waste anoscope cannot pollute the environment by burning, and can completely degrade in the natural environment by landfill to achieve purposes of low-carbon, environmental protection, and energy saving.

Owner:江苏奥博金医药科技有限公司

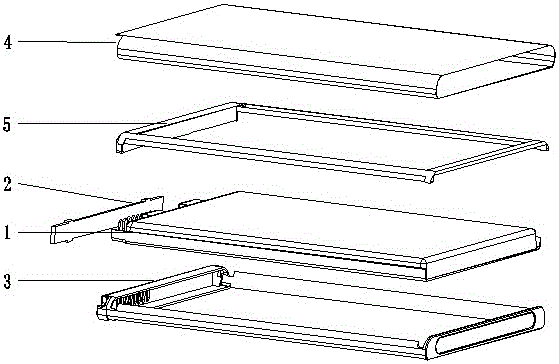

A kind of lithium battery packaging method

ActiveCN104241555BHigh temperature resistantWith vibration reductionSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsHot runnerLow voltage

The invention provides a lithium battery encapsulating method. The lithium battery encapsulating method is characterized by comprising the following steps: step I, welding a cell with a protective plate according to a welding sequence of low voltage to high voltage; step II, installing the well-welded cell and protective plate into a battery rubber frame, firstly positioning and assembling the protective plate and the battery rubber frame, and then horizontally placing the cell into the battery rubber frame without fixation; step III, filling all gaps inside the entire battery pack in an injection molding manner at low pressure and low temperature by adopting a hot runner for the well-placed cell, protective plate and battery rubber frame. The hot runner technology is applied to the battery encapsulation process, the encapsulated battery has the effects of high temperature resistance, shock absorption, moisture resistance, water resistance, chemical corrosion resistance and the like, no waste material such as runner and water gap is produced in the injection molding process, the waste material produced in the production process can be effectively reduced, the encapsulation cost of the battery is effectively reduced, the encapsulation process is simple, the production efficiency is high, and the market competitive advantage can be improved.

Owner:HUIZHOU DESAY BATTERY

Degradable material for otoscope and preparation method thereof

The present invention provides a degradable material for otoscope and a preparation method thereof. The degradable otoscope is composed of a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section is of 155-165 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 165-175 DEG C; the mold temperature is 20-35 DEG C; the injection pressure is of 50-80 MPa; the injection time is 36-39 seconds; the dwell time is 0 sec; and the screw speed is 180 r / min. The degradable otoscope is up to the requirements of clinical use in performances, and can completely replace ABS plastic disposable otoscope. The waste otoscope cannot pollute the environment by burning, and can completely degrade in the natural environment by landfill to achieve purposes of low-carbon, environmental protection, and energy saving.

Owner:江苏奥博金医药科技有限公司

Degradable titanium clamping seat and preparation method

InactiveCN103028151ALower injection temperatureReduce power consumptionSurgeryInjection pressureTitanium

The present invention provides a degradable titanium clamping seat and a preparation method. The degradable titanium clamping seat is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section is of 155-170 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 160-175 DEG C, the mold temperature is 20-40 DEG C, the injection pressure is 45-90 Mpa, the injection time is 40-50 seconds, the dwell time is 0 sec, and the screw speed is 180 r / min. The obtained degradable titanium clamping seat after being used can completely degrade by landfill in the natural environment to achieve the purposes of low carbon, energy saving, and environmental protection.

Owner:SHANGHAI LINJING MEDICAL EQUIP

A modified resin and its application, as well as a two-color injection molded part and its preparation method

Owner:NINGBO BULL ELECTRIC CO LTD

Degradable material used for disposable umbilical cord clamp and preparation method

InactiveCN102727941ALower injection temperatureReduce power consumptionSurgeryEnvironmental resistanceHuman health

The invention provides a degradable material used for a disposable umbilical cord clamp and a preparation method. The disposable umbilical cord clamp is prepared from a degradable high polymer main material and a reinforcing agent. An injection molding process adopted in the invention comprises that: a feed inlet is at a temperature of 150-165DEG C, a compression section is at a temperature of 155-165DEG C, a metering section is at a temperature of 160-170DEG C, and a nozzle is at a temperature of 165-175DEG C; a mold is at a temperature of 20-45DEG C; the injection pressure is 70Mpa at the first level, 80Mpa at the second level, and 55Mpa at the third level; the injection molding period is 41sec; the pressure-holding time is 0sec; and the screw rotation speed is 180 rpm / min. The obtained degradable disposable umbilical cord clamp has all performances in full compliance with the requirements of clinical use, needs no burning after use and is completely biodegradable in the natural environment by landfill, thus reaching the purposes of low carbon, energy saving, environmental protection and human health protection.

Owner:SHANGHAI LINJING MEDICAL EQUIP

Degradable material for otoscope and preparation method thereof

The present invention provides a degradable material for otoscope and a preparation method thereof. The degradable otoscope is composed of a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section is of 155-165 DEG C, a metering section is of 160-175 DEG C, a nozzle is of 165-175 DEG C; the mold temperature is 20-35 DEG C; the injection pressure is of 50-80 MPa; the injection time is 36-39 seconds; the dwell time is 0 sec; and the screw speed is 180 r / min. The degradable otoscope is up to the requirements of clinical use in performances, and can completely replace ABS plastic disposable otoscope. The waste otoscope cannot pollute the environment by burning, and can completely degrade in the natural environment by landfill to achieve purposes of low-carbon, environmental protection, and energy saving.

Owner:江苏奥博金医药科技有限公司

Degradable disposable tongue depressor and preparation method

ActiveCN103030942ALower injection temperatureReduce power consumptionInjection pressureInjection moulding

The present invention provides a degradable disposable tongue depressor and a preparation method. The degradable disposable tongue depressor is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-160 DEG C, a compression section is of 155-165 DEG C, a metering section is of 155-170 DEG, a nozzle is of 155-175 DEG C, the mold temperature is 20-45 DEG C, the injection pressure is 50-100 MPa, the injection time is 38-44 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The used degradable disposable tongue depressor can completely degrade in the natural environment by landfill without burning and environmental pollution to achieve low-carbon, energy-saving and environmental protective purposes.

Owner:江苏奥博金医药科技有限公司

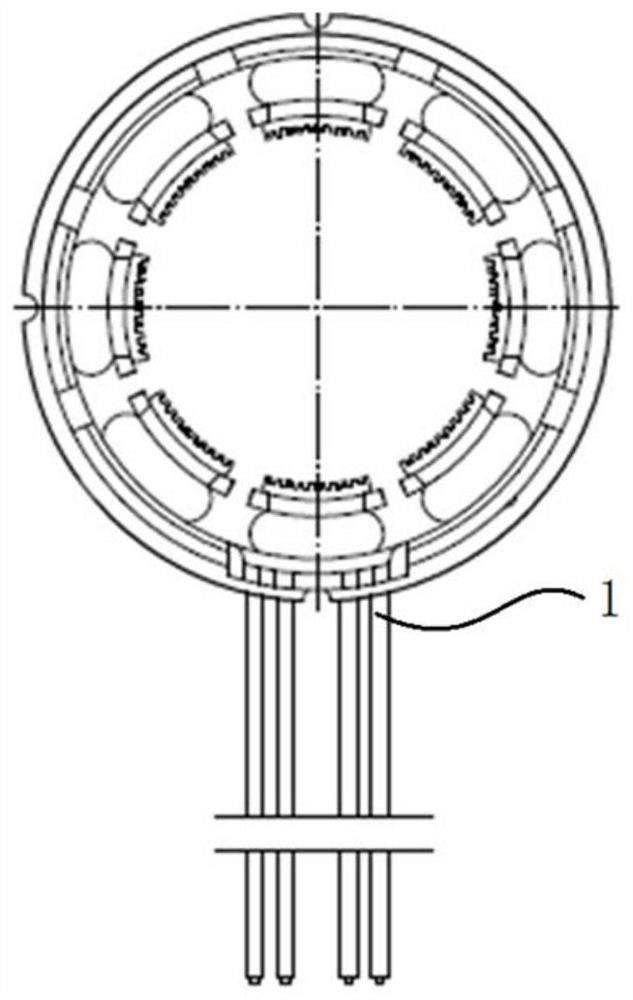

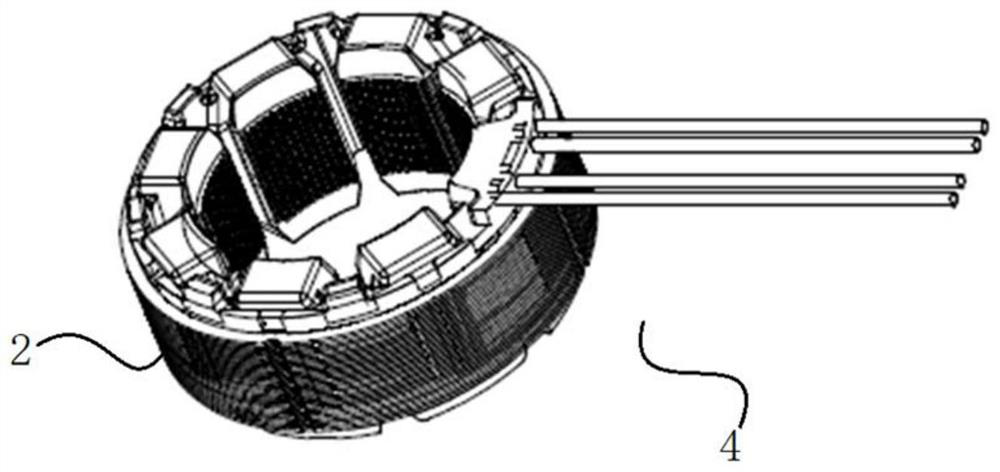

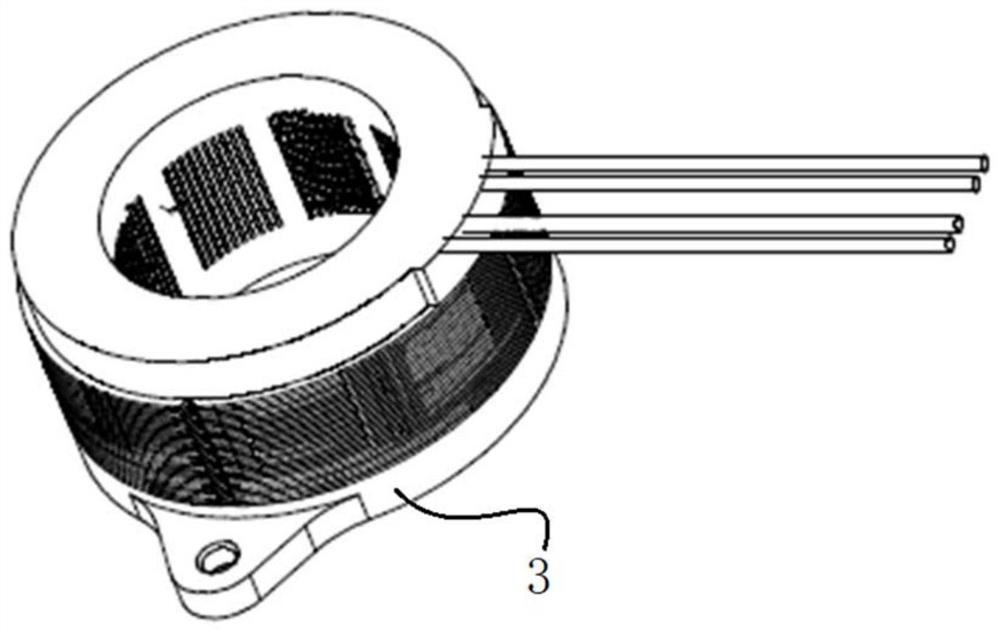

Motor winding component and injection molding motor with winding component

PendingCN113922547ALower requirementEffective protectionWindings insulation shape/form/constructionManufacturing stator/rotor bodiesElectric machineMechanical engineering

The invention relates to a motor winding component and an injection molding motor with the winding component. The component is a winding component formed by two times of plastic coating, and the winding component comprises a winding part, a low-pressure injection molding part and a high-pressure injection molding part; and the low-pressure injection molding part firstly carries out plastic coating molding on the winding part to form a low-pressure injection molding pre-forming assembly, and the low-pressure injection molding pre-forming assembly is subjected to plastic coating molding through the high-pressure injection molding part. Compared with the prior art, the invention has the advantages of being suitable for complex working conditions, high in product percent of pass, high in finished product reliability and the like.

Owner:SHANGHAI MOONS ELECTRICAL APPLIANCE

Degradable disposable injection needle blade and preparation method

ActiveCN103030941BLower injection temperatureSave electricity consumption in productionInjection pressureEngineering

The present invention provides a degradable disposable injection needle blade and a preparation method. The degradable disposable injection needle blade is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 145-165 DEG C, a compression section is of 150-165 DEG C, a metering section is of 155-170 DEG C, a nozzle is of 150-170 DEG C, the mold temperature is 20-45 DEG C, the injection pressure is 50-100 Mpa, the injection time is 39-45 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The degradable disposable injection needle blade can completely degrade by landfill in the natural environment after being used without burning to achieve low-carbon, energy-saving, and environmental protection purposes.

Owner:江苏奥博金医药科技有限公司

High-fluidity polyformaldehyde-based binder for metal injection formation and preparation method of fed material for metal injection formation

InactiveCN111014641AImprove rheologyImprove uniformityTransportation and packagingMetal-working apparatusPolyoxymethyleneKneader reactor

The invention relates to the technical field of powder metallurgy and particularly discloses a polyformaldehyde-based binder for metal injection formation and a preparation method of a fed material for metal injection formation. The binder comprises the following raw materials by weight percent: 75-90% of polyformaldehyde, 5-15% of polyethylene and 1-10% of a flow promoting agent. The preparationmethod of the fed material comprises the steps that metal powder and the binder are added into a kneading machine according to a certain proportion for mixing, extrusion for granulation is performed according to a single-screw extruder, and thus the granular fed material is obtained. The binder is low in viscosity and good in fluidity and has good mold filling capacity during injection formation,the defect of a green compact is reduced, and the yield is effectively increased.

Owner:CENT SOUTH UNIV +1

Environmentally-friendly, high fire-resistant and high seawater-resistant polypropylene

Owner:杭州金州高分子科技有限公司

A turbine engine hot end combustion lubricating oil pipeline structure

ActiveCN110821581BReduce temperature riseImprove cooling effectMachines/enginesEngine componentsCooling effectFuel oil

The invention relates to the technical field of turbine engines, in particular to a fuel oil pipeline structure at the hot end of a turbine engine, which is used to solve the problems in the prior art that the engine thermal efficiency cannot be improved and the bearing cannot be cooled better. The invention includes a lubricating oil return cavity shell, a fuel oil preheating cavity shell and a fuel oil preheating cavity, and also includes a fuel oil inlet pipe, a lubricating oil return pipe and a lubricating oil inlet pipe which are nested in sequence from the outside to the inside and leave a gap with each other. Oil pipe, one end of the fuel oil inlet pipe is communicated with the fuel preheating chamber and the fuel supply pipe in turn, one end of the lubricating oil return pipe is communicated with the interior of the lubricating oil return chamber shell, and one end of the lubricating oil inlet pipe is located at The lubricating oil returns to the inside of the oil chamber housing and is opposite to the upper part of the bearing. In the present invention, the fuel oil inlet pipe, the lubricating oil return pipe and the lubricating oil inlet pipe are nested in sequence from the outside to the inside, and the temperature of the fluid in the three pipes decreases sequentially from the outside to the inside, so the cooling effect on the bearing can be improved and the thermal efficiency of the engine can be improved.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Degradable uterine curette and preparation method thereof

The present invention provides a degradable uterine curette and a preparation method. The degradable uterine curette is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-165 DEG C, a compression section is of 155-165 DEG C, a metering section is of 160-170 DEG C, a nozzle is of 165-175 DEG C, the mold temperature is 15-30 DEG C, the injection pressure is 70 Mpa for a first level, 80 Mpa for a second level and 55 Mpa for a third level, the molding cycle is 44-48 seconds, the dwell time is 0 seconds, and the screw rotation speed is 180 rpm. The performances of the degradable uterine curette are in line with requirements of the national industry standard YY0090-1992 uterine curette. The degradable uterine curette has clinically practical value. The used uterine curette does not need incineration and does not pollute the environment, can completely degrade by landfill in the natural environment, and achieves the purposes of low carbon, environmental protection, and energy saving.

Owner:江苏奥博金医药科技有限公司

Degradable material and manufacturing method for three-way valve/dosing device of infusion set

ActiveCN103030952BLower injection temperatureSave electricity consumption in productionInfusion devicesInjection pressureAdditive ingredient

The present invention provides a degradable material for an infusion apparatus three-way valve / doser and a manufacturing method. The degradable infusion apparatus three-way valve / doser is prepared by a degradable polymer ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 155-165 DEG C, a compression segment is of 160-170 DEG C, a metering segment is of 160-175 DEG C, a nozzle is of 155-170 DEG C, the mold temperature is 20-30 DEG C, the injection pressure is 55-90 Mpa, the injection time is 40-45 seconds, the dwell time is 0-4 seconds, and the screw speed is 180 r / min. So the degradable infusion apparatus three-way valve / doser is obtained. The used degradable infusion apparatus three-way valve / doser does not need burning, and can completely biodegrade by landfill in the natural environment to achieve low-carbon, energy-saving and environmental-protection purposes.

Owner:江苏奥博金医药科技有限公司

Degradable disposable tongue depressor and preparation method thereof

The present invention provides a degradable disposable tongue depressor and a preparation method. The degradable disposable tongue depressor is prepared by a degradable polymer main ingredient of a degradable substrate and an enhancer. The injection molding process includes that: a feed inlet is of 150-160 DEG C, a compression section is of 155-165 DEG C, a metering section is of 155-170 DEG, a nozzle is of 155-175 DEG C, the mold temperature is 20-45 DEG C, the injection pressure is 50-100 MPa, the injection time is 38-44 seconds, the dwell time is 0 sec, and the screw speed is 180 rpm. The used degradable disposable tongue depressor can completely degrade in the natural environment by landfill without burning and environmental pollution to achieve low-carbon, energy-saving and environmental protective purposes.

Owner:江苏奥博金医药科技有限公司

Environment-friendly, energy-saving and degradable disposable infusion needle and its preparation method

The invention provides an environment-friendly and energy-saving biodegradable type disposable infusion device thrusting needle and a preparation method thereof. The environment-friendly and energy-saving biodegradable type disposable infusion device thrusting needle is formed by proportioning biodegradable macromolecular main ingredients and enhancers of biodegradable base materials. The injection molding process includes that the temperature of a feed inlet is 145-160 DEG C, the temperature of a compression section is 155-165 DEG C, the temperature of a metering section is 160-175 DEG C, and the temperature of a nozzle is 165-175 DEG C; the temperature of a mould is 10-20 DEG C; the injection pressure is 50-80 Mpa; the injection period is 41-52 seconds; the dwell time is 0 second; and the screw speed is 180 turns per minute. Thus, the environment-friendly and energy-saving biodegradable type disposable infusion device thrusting needle can be manufactured, the thrusting needle does not need to be incinerated after being discarded and can be absolutely biodegraded in the natural environment through landfill, and therefore the purposes of saving energy and protecting environment and human health are achieved.

Owner:江苏奥博金医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com