Motor winding component and injection molding motor with winding component

A technology of motor windings and components, applied in the field of injection molding motors, which can solve the problems of enameled wire leakage, limited structural strength of stator windings, enameled wire breakage, etc., to reduce injection pressure and injection temperature, high long-term operation reliability, and low injection temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

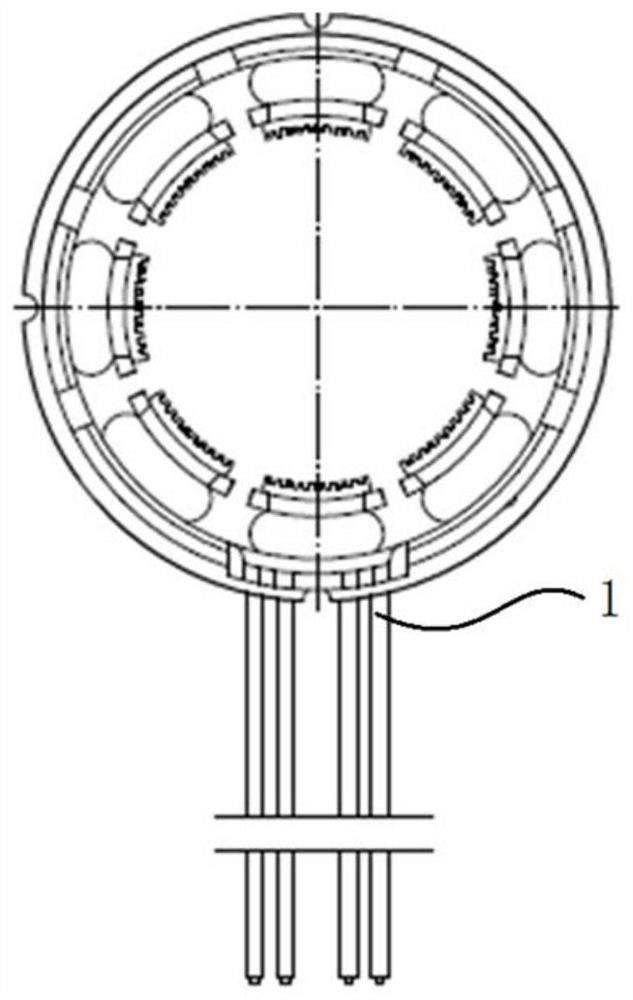

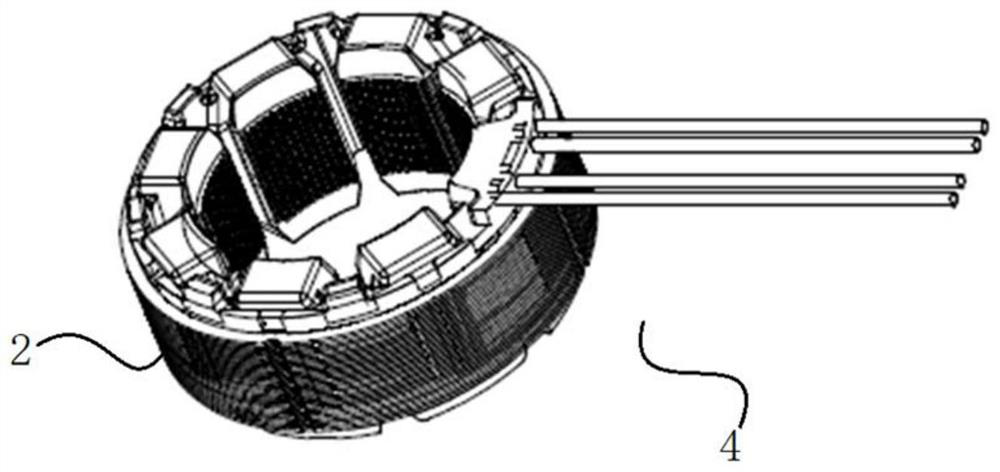

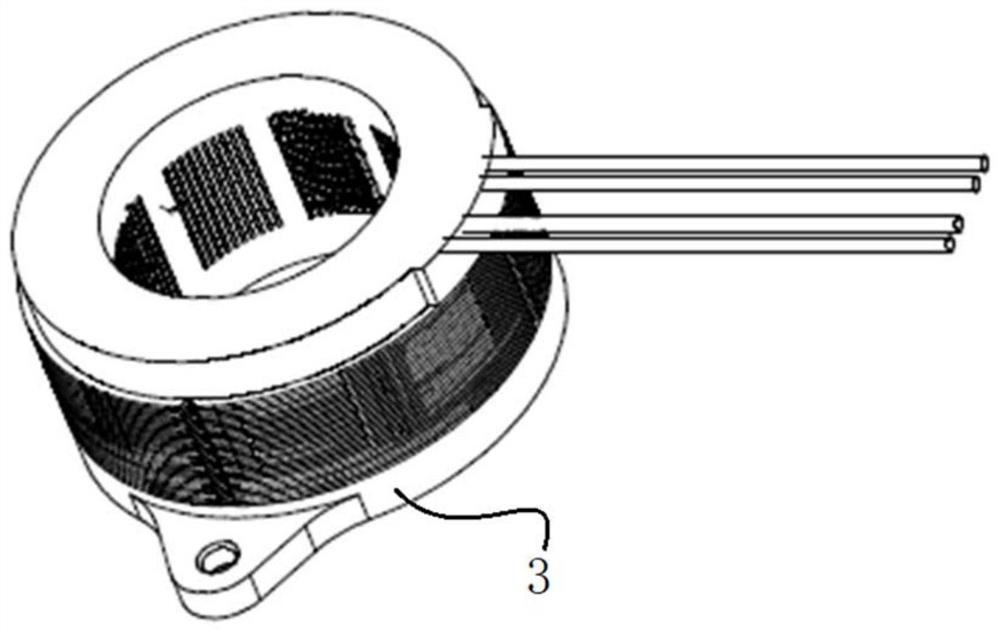

[0031] Such as Figure 1-3 As shown, a motor winding component, which is a winding component that is overmolded twice, the winding component includes a winding part 1, a low-pressure injection molding part 2 and a high-pressure injection molding part 3, and the low-pressure injection molding part 2 first wraps the winding The wire part 1 is overmolded to form a low-pressure injection molded preformed component 4 , and the low-pressure injection molded preformed component 4 is overmolded by the high-pressure injection molded part 3 .

[0032] The present invention proposes a secondary injection molding solution for motor winding components, i.e. motor winding components such as figure 1 As shown, two overmolding is used for forming, including the winding parts of the motor, the stator parts are preformed by low-pressure injection molding process to protect the winding parts, and high-pressure injection molding is performed after the parts are cooled to achieve Design final for...

Embodiment 2

[0036] The motor winding part is a rotor assembly, and the others are the same as in Embodiment 1.

Embodiment 3

[0038] An injection molding motor with a winding part, the motor includes the motor winding part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com