A kind of lithium battery packaging method

A packaging method and technology for lithium batteries, which are applied to lithium batteries, battery pack components, battery boxes/coats, etc., can solve the problems of low production efficiency, complicated lithium battery packaging process, and high packaging costs, and achieve high production efficiency and improved Market competitive advantage and the effect of reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

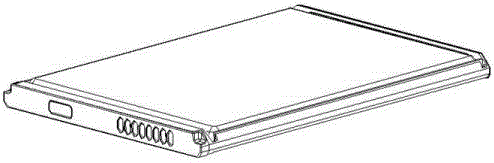

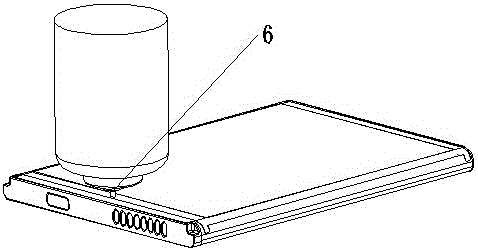

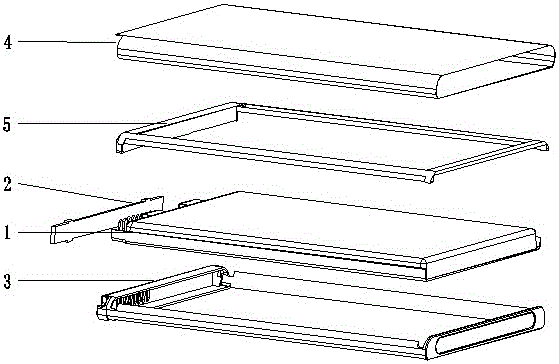

Image

Examples

Embodiment Construction

[0017] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0018] A lithium battery packaging method is characterized in that comprising the following steps:

[0019] The first step is to weld the battery cell 1 and the protective plate 2; the battery cell can be a single-segment or multi-series battery pack, the positive and negative nickel sheets of the battery pack, soft board (FPC), wire Spot welding or soldering with the protection plate, the cell group is multi-series parallel, the cells need to be connected in series and parallel welding first, and then welded with the protection plate after the series and parallel welding of the cells, the cell and the protection plate The sequence of welding needs to be welded in the order from low voltage to high voltage;

[0020] The second step is to put the welded bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com