Degradable material for otoscope and preparation method thereof

A technology for degrading materials and otoscopes is applied in the field of degradable disposable medical devices to achieve the effects of saving input costs, saving materials, saving energy, and saving electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

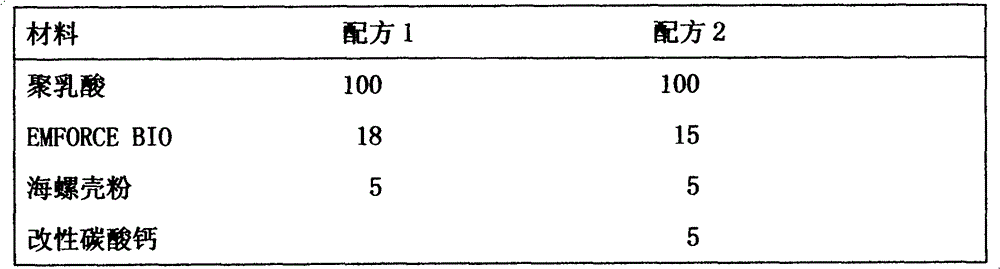

Embodiment 1

[0029] The injection molding method of embodiment 1 degradable otoscope:

[0030] The first step, vacuum drying: vacuum-dry the degradable substrate pellets of Formula 1 or Formula 2 at 50°C for 4 hours, and set aside;

[0031] The second step, injection molding: add the dried degradable substrate pellets of formula 1 or formula 2 to an injection molding machine for injection molding.

[0032] The barrel temperature is set as follows: feed inlet 150°C, compression section 155°C, metering section 165°C, nozzle 170°C;

[0033] Mold temperature: 30°C;

[0034] The injection pressure is: the first section is 75pa, the second section is 80Mpa, and the third section is 50Mpa;

[0035] Injection time: 38 seconds;

[0036] The holding time is: 0 seconds;

[0037] The screw speed is: 180 rpm.

[0038] The degradable otoscope adopting the degradable substrate of formula 1 or formula 2 was obtained.

[0039] The above-mentioned embodiment has described the biodegradable otoscope in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com