Polylactic acid-polypropylene composite material, and preparation method and application thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid-polypropylene composite material and its preparation, can solve the problems of high injection molding temperature, large dimensional change, low tensile strength value, etc., and achieve high tensile strength and stable size , Low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

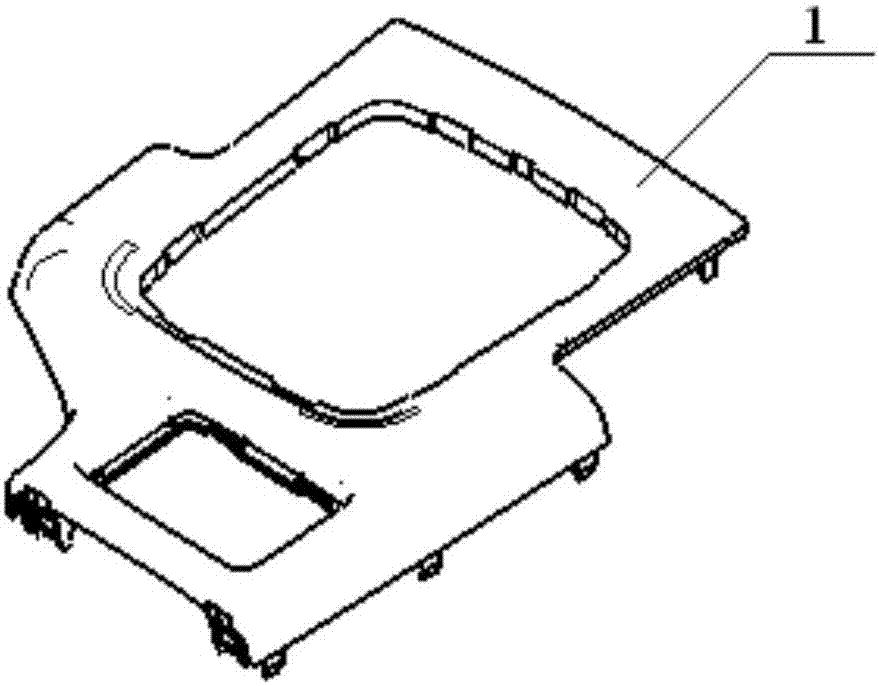

Image

Examples

Embodiment 1

[0035] 1. Polylactic acid-polypropylene composite material

[0036] The polylactic acid-polypropylene composite material of the present embodiment consists of the following components by weight:

[0037] Polylactic acid (weight average molecular weight: 300,000): 35 parts;

[0038] Polypropylene (weight average molecular weight: 800,000): 60 parts;

[0039] Maleic anhydride: 5 parts.

[0040] 2. Automobile shift cover

[0041] The preparation method of the automobile shift cover plate of the present embodiment is specifically as follows:

[0042] 1. mix

[0043] After each component in the polylactic acid-polypropylene composite material is prepared according to their respective parts by weight, they are uniformly mixed to obtain a mixed material.

[0044] 2. Dry

[0045] The above mixed material was dried at 90° C. for 30 min to obtain a dry raw material.

[0046] 3. Injection molding

[0047] Put the above-mentioned dry raw materials into the cylinder of the injectio...

Embodiment 2

[0050] 1. Polylactic acid-polypropylene composite material

[0051] The polylactic acid-polypropylene composite material of the present embodiment consists of the following components by weight:

[0052] Polylactic acid (weight average molecular weight: 500,000): 25 parts;

[0053] Polypropylene (weight average molecular weight: 600,000): 65 parts;

[0054] Maleic anhydride: 10 parts.

[0055] 2. Automobile shift cover

[0056] The preparation method of the automobile shift cover plate of the present embodiment is specifically as follows:

[0057] 1. mix

[0058] After each component in the polylactic acid-polypropylene composite material is prepared according to their respective parts by weight, they are uniformly mixed to obtain a mixed material.

[0059] 2. Dry

[0060] The above mixed material was dried at 100° C. for 25 min to obtain a dry raw material.

[0061] 3. Injection molding

[0062] The above-mentioned dry raw materials were put into the barrel of an inje...

Embodiment 3

[0065] 1. Polylactic acid-polypropylene composite material

[0066] The polylactic acid-polypropylene composite material of the present embodiment consists of the following components by weight:

[0067] Polylactic acid (weight average molecular weight: 400,000): 25 parts;

[0068] Polypropylene (weight-average molecular weight: 700,000): 70 parts;

[0069] Maleic anhydride: 5 parts.

[0070] 2. Automobile shift cover

[0071] The preparation method of the automobile shift cover plate of the present embodiment is specifically as follows:

[0072] 1. mix

[0073] After each component in the polylactic acid-polypropylene composite material is prepared according to their respective parts by weight, they are uniformly mixed to obtain a mixed material.

[0074] 2. Dry

[0075] The above mixed material was dried at 110° C. for 15 min to obtain a dry raw material.

[0076] 3. Injection molding

[0077] The above dry raw materials were put into the cylinder of an injection moldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com