Hot end fuel and lubricating oil pipeline structure of turbine engine

A turbine engine, oil-fueling technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to reduce oil coking, inability to reduce bearing cooling effect, inability to improve engine thermal efficiency, inability to reduce oil temperature, etc. Achieve the effect of good atomization and combustion, reduce the injection temperature of the lubricating oil, and reduce the probability of oil coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

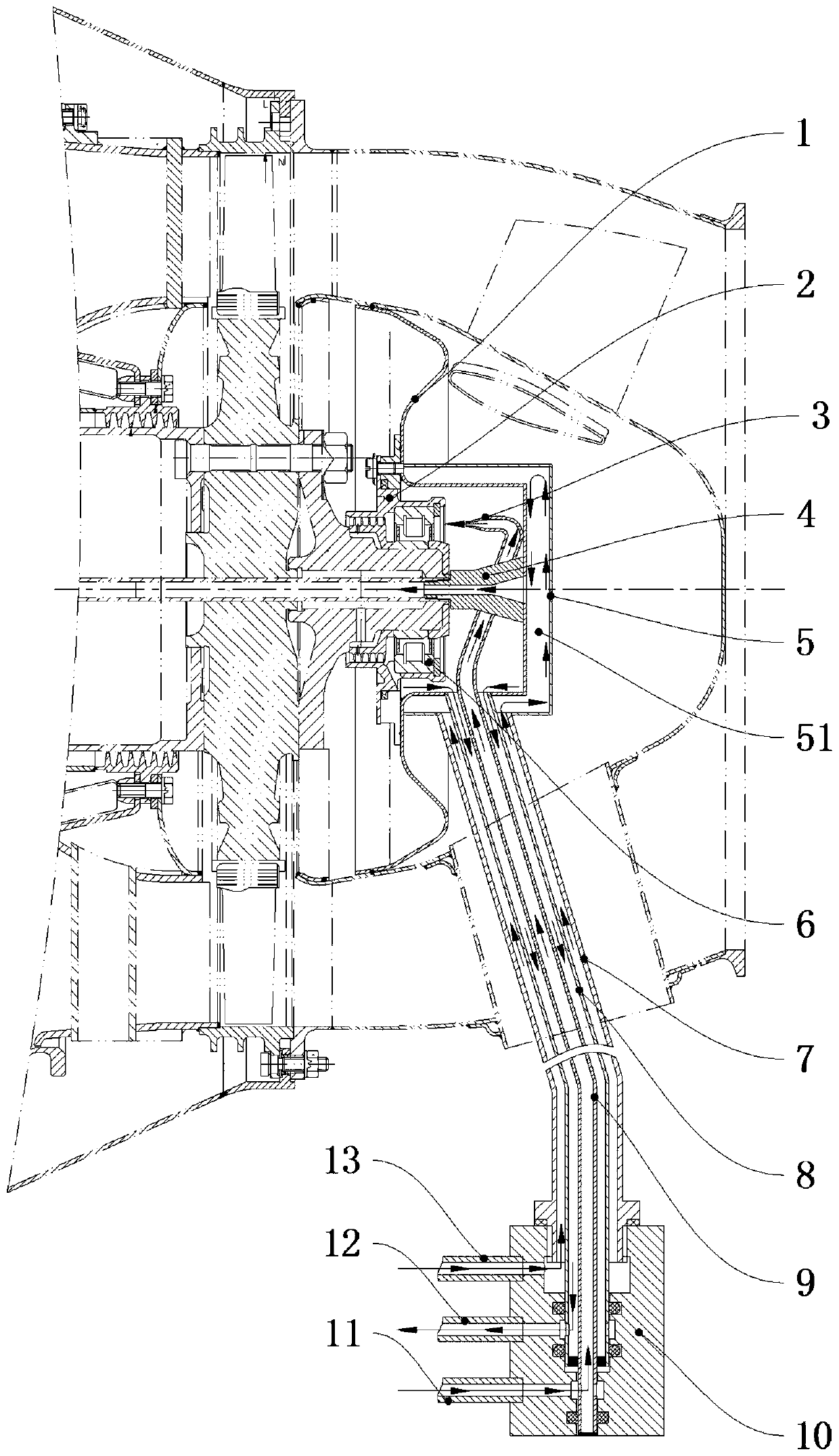

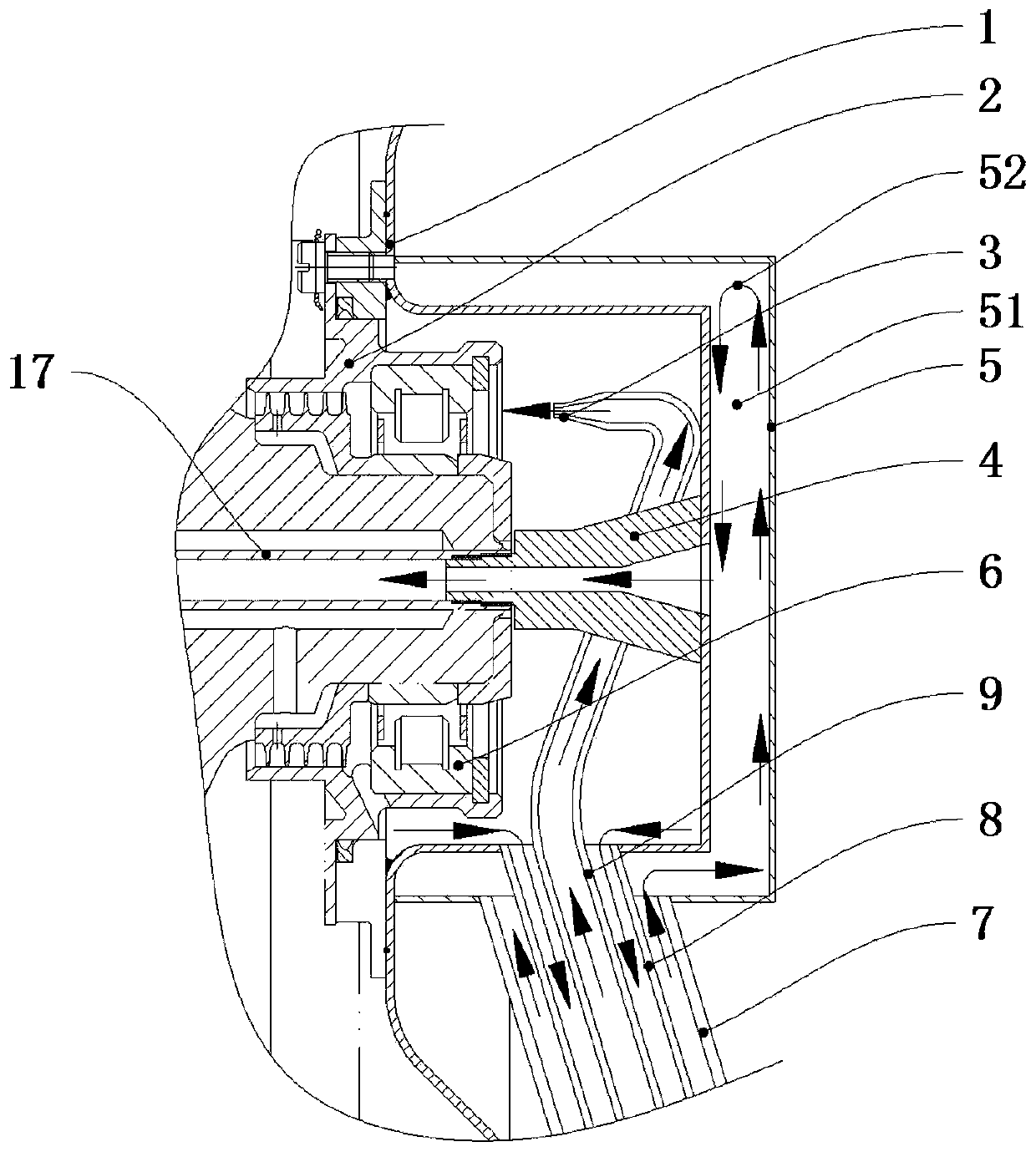

[0031]Such as Figure 1-5 As shown, a turbine engine hot end combustion oil pipeline structure includes a bearing 6, a bearing seat 2 is installed on the bearing 6, a lubricating oil return chamber housing 1 is installed on the bearing housing 2, and the lubricating oil return chamber housing 1 is wrapped with a fuel preheating chamber casing 5, and a fuel preheating chamber 51 is formed between the fuel preheating chamber casing 5 and the lubricating oil return chamber casing 1; it also includes nesting from the outside to the inside and leaving a gap between them One end of the fuel inlet pipe 7 communicates with the fuel preheating chamber 51, the fuel preheating chamber 51 communicates with the oil supply pipe 17, and the lubricating oil return pipe 8 One end communicates with the inside of the lubricating oil return chamber housing 1 , and one end of the lubricating oil inlet pipe 9 is located inside the lubricating oil return chamber housing 1 and opposite to the upper p...

Embodiment 2

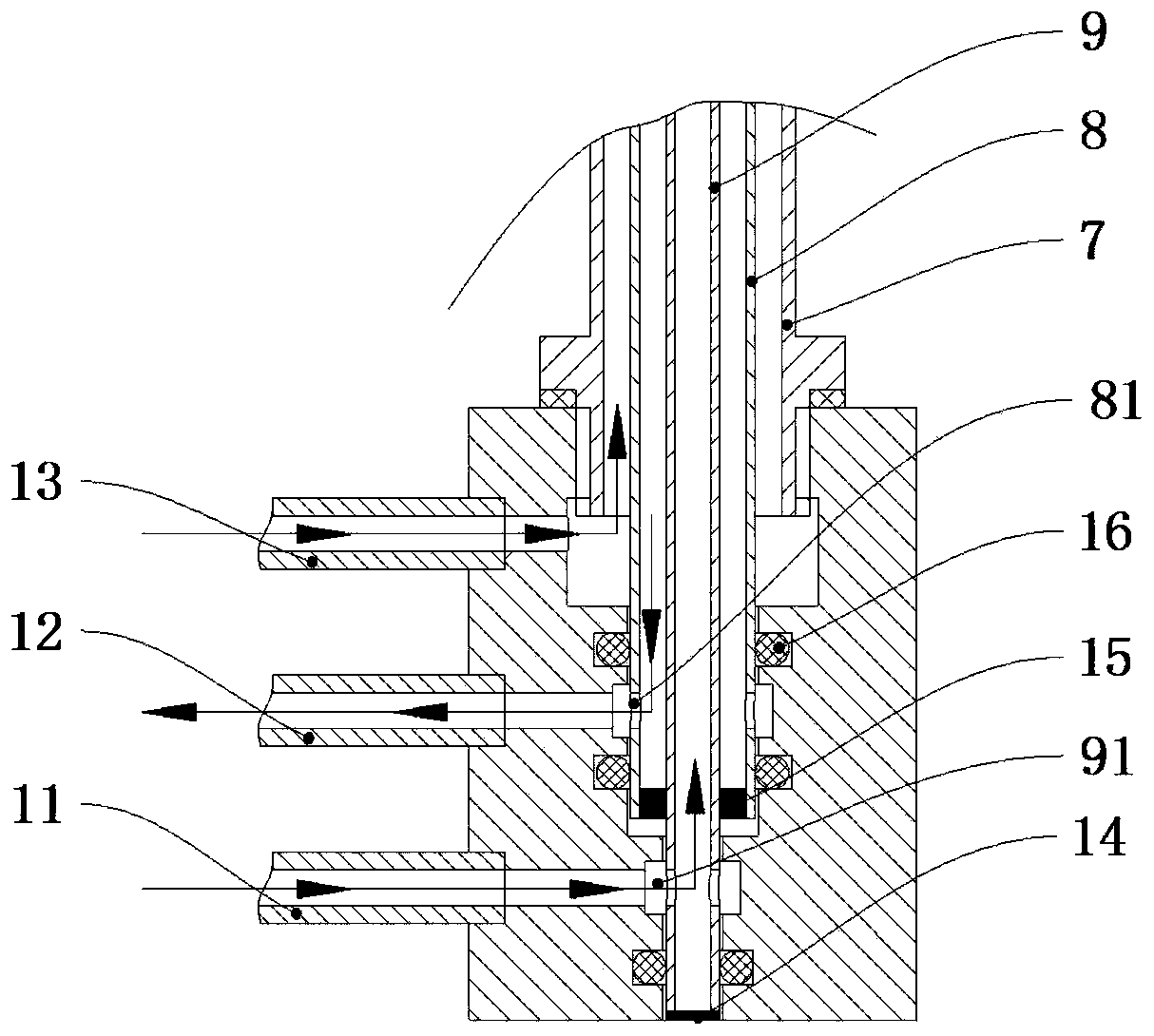

[0035] Such as Figure 1-5 As shown, on the basis of the above embodiments, this embodiment provides a preferred mechanism for connecting the fuel oil inlet pipe, the lubricating oil return pipe and the other end of the lubricating oil inlet pipe. That is, the other ends of the fuel inlet pipe 7, the lubricating oil return pipe 8 and the lubricating oil inlet pipe 9 are connected to the same pipe adapter 10, and the pipe adapter 10 is sequentially installed with a fuel oil inlet joint 13 and a lubricating oil outlet joint 12 , oil inlet joint 11, fuel oil inlet joint 13, oil outlet joint 12, oil inlet joint 11 are communicated with fuel oil inlet pipe 7, oil return pipe 8 and oil inlet pipe 9 successively.

[0036] Preferably, the middle part of the pipeline adapter 10 is sequentially provided with a fuel pipe connection hole 107, a lubricating oil return pipe connection hole 108 and a lubricating oil inlet pipe connection hole 109 from top to bottom, the fuel oil inlet pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com