Low-cost low-odor degradable natural-fiber-reinforced polycarbonate reclaimed material capable of achieving light weight and preparation method thereof

A natural fiber and polycarbonate technology, applied in the field of natural fiber reinforced degradable polycarbonate regenerated material and its preparation, can solve the problem of limited odor effect of polycarbonate regenerated material, inability to achieve lightweight polycarbonate, limited adsorption effect, etc. It can solve the problem of odor and emission, easy to mass produce, and the preparation method is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

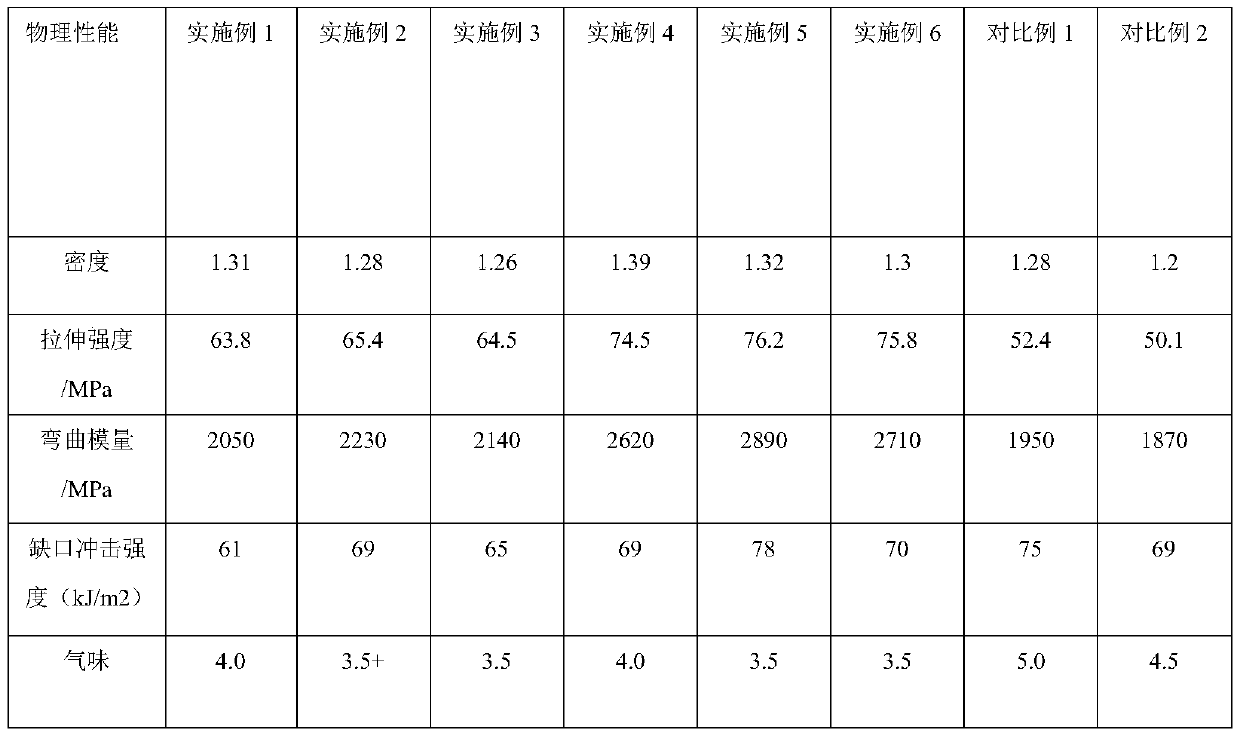

Examples

Embodiment 1

[0037] First weigh 20wt% acidified carbon nanotubes, sodium bicarbonate: 30wt%, sodium citrate: 15wt%, and other additives: 1wt% according to the following weight percentages; put them into a high-speed mixer and mix for 15-30min. After being mixed evenly, the polyethylene of mixture and 34wt% is placed in the main feeding bin of intermeshing co-rotating single-screw extruder, joins in the machine barrel of extruder through feeding screw rod, and extruder screw rod diameter is 30mm, length-to-diameter ratio L / D is 25, the temperature of each section of the main barrel from the feeding port to the nozzle outlet is set as: 70°C, 90°C, 100°C, 100°C, the main engine speed is 40 rpm, after melting Extrude, cool, and granulate to obtain foaming agent masterbatch.

[0038] Weigh 89wt% of PC regenerated material and 0.5wt% of antioxidant according to the following weight percentages, mix uniformly to obtain mixed raw materials, then weigh 0.5wt% of foaming agent masterbatch and mix wi...

Embodiment 2

[0044] First weigh 20wt% acidified carbon nanotubes, sodium bicarbonate: 30wt%, sodium citrate: 15wt%, and other additives: 1wt% according to the following weight percentages; put them into a high-speed mixer and mix for 15-30min. After being mixed evenly, the polyethylene of mixture and 34wt% is placed in the main feeding bin of intermeshing co-rotating single-screw extruder, joins in the machine barrel of extruder through feeding screw rod, and extruder screw rod diameter is 30mm, length-to-diameter ratio L / D is 25, the temperature of each section of the main barrel from the feeding port to the nozzle outlet is set as: 70°C, 90°C, 100°C, 100°C, the main engine speed is 40 rpm, after melting Extrude, cool, and granulate to obtain foaming agent masterbatch.

[0045] Take by weighing 88.5wt% of PC regenerated material and 0.5wt% of antioxidant according to the following weight percentages, mix uniformly to obtain mixed raw materials, then weigh 1.0wt% of foaming agent masterbat...

Embodiment 3

[0051] First weigh 20wt% acidified carbon nanotubes, sodium bicarbonate: 30wt%, sodium citrate: 15wt%, and other additives: 1wt% according to the following weight percentages; put them into a high-speed mixer and mix for 15-30min. After being mixed evenly, the polyethylene of mixture and 34wt% is placed in the main feeding bin of intermeshing co-rotating single-screw extruder, joins in the machine barrel of extruder through feeding screw rod, and extruder screw rod diameter is 30mm, length-to-diameter ratio L / D is 25, the temperature of each section of the main barrel from the feeding port to the nozzle outlet is set as: 70°C, 90°C, 100°C, 100°C, the main engine speed is 40 rpm, after melting Extrude, cool, and granulate to obtain foaming agent masterbatch.

[0052] Weigh 87.5wt% of PC regenerated material and 0.5wt% of antioxidant according to the following weight percentages, mix uniformly to obtain mixed raw materials, then weigh the following weight percentages of foaming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com