A modified resin and its application, as well as a two-color injection molded part and its preparation method

A modified resin and two-color injection molding technology, applied in the field of injection molding, can solve problems such as easy yellowing, expansion of unfavorable application range, and poor heat resistance of PC materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

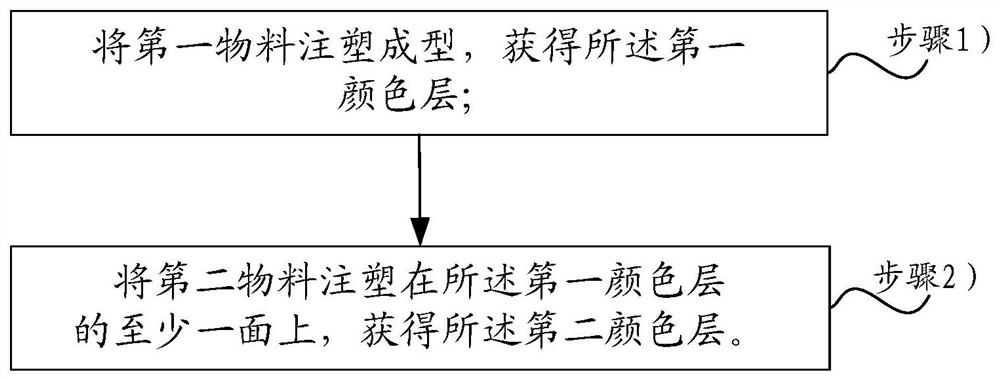

[0059] In the fourth aspect, an embodiment of the present invention provides a method for preparing a two-color injection molded part as described above, see figure 1 ,include:

[0060] Step 1) Injection molding the first material to obtain the first color layer;

[0061] Step 2) Injecting a second material onto at least one side of the first color layer to obtain the second color layer.

[0062] The embodiment of the present invention provides a method for preparing a two-color injection molded part. By using a modified resin as a two-shot material, since the modified resin uses acrylic resin / montmorillonite nanocomposite microspheres as a flow modifier, on the one hand , the acrylate resin itself has a low melting point and acts as a flow modifier; on the other hand, the acrylic resin / montmorillonite nanocomposite microspheres can be better dispersed in the In the resin matrix, rolling friction is formed between the resin matrix, which greatly reduces the friction between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com