Carbon fiber reinforced polycarbonate composite material and product thereof

A technology of polycarbonate and composite materials, applied in the field of polymer materials, can solve the problems of few applications of high-end ultra-thin products, PET film and ink are not resistant to high temperature, etc., achieve beautiful appearance, reduce injection molding temperature, and ensure flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

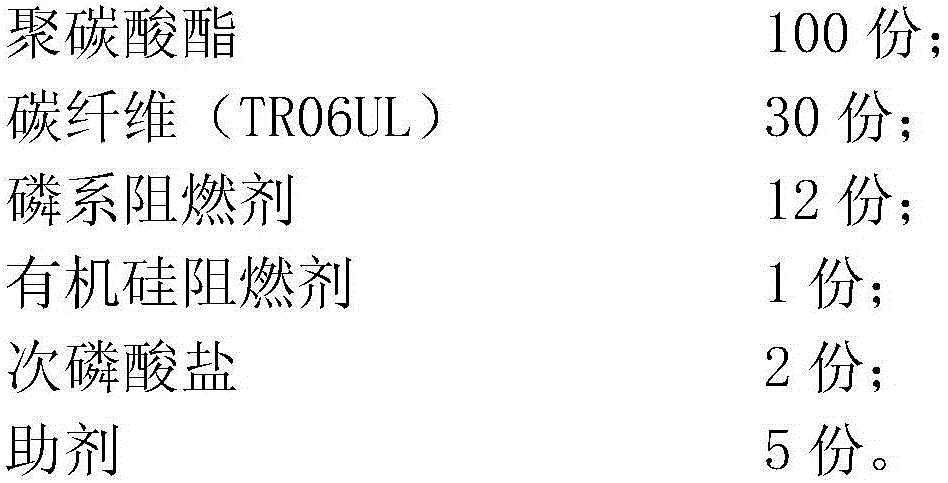

Embodiment 3

[0028] The carbon fiber used in embodiment 3 is the carbon fiber that the model that TR company produces is TR06UL;

[0029] The additives used in Examples 1, 2, 3 and Comparative Example 1 are the mixture of antioxidant, lubricant, anti-dripping agent and coloring agent.

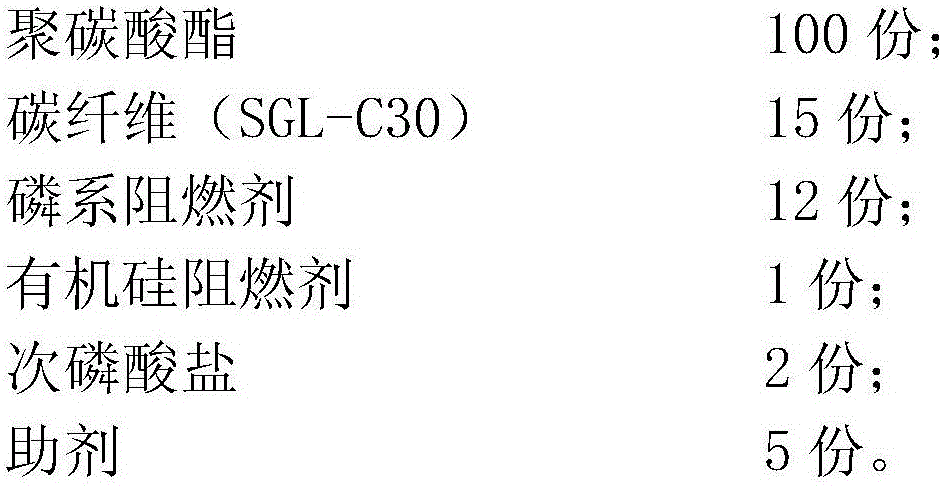

Embodiment 1

[0031]

[0032] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

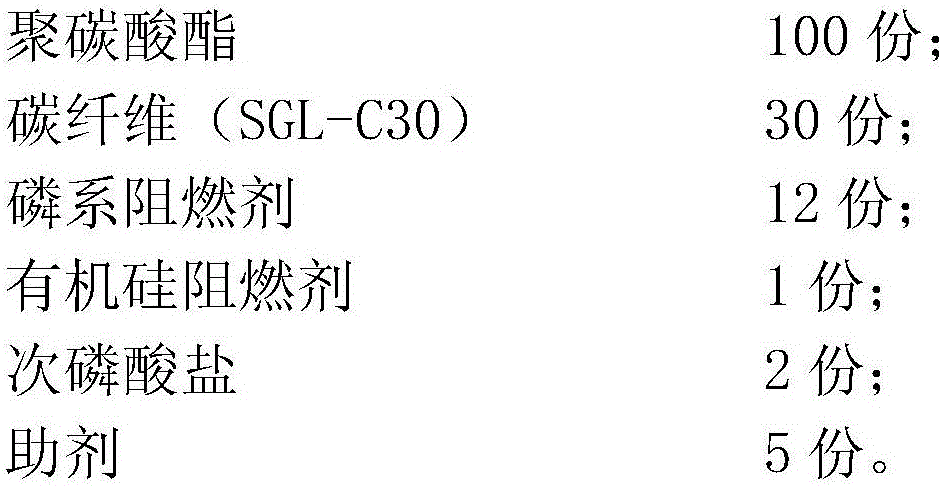

Embodiment 2

[0034]

[0035] Each component was weighed with corresponding weight; then, each component was stirred for 10 minutes with a single-shaft mixing barrel; the above-mentioned mixture was respectively added into a twin-screw extruder to melt, extrude and granulate.

[0036] Example 3

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com